Why Do Your Mushrooms Spoil Before They Even Reach the Store?

You harvest beautiful, white mushrooms, but by the next day, they’re already turning brown. This lightning-fast spoilage shrinks your profits and puts your business under constant pressure.

Mushrooms spoil quickly due to an extremely high respiration rate that generates heat and activates browning enzymes. Vacuum cooling chills them in 15-25 minutes, instantly halting this process, preserving color and texture, and extending their marketable life.

As a factory owner specializing in cooling solutions, I see the financial pain this causes growers. They produce a high-value crop that loses its value by the hour. It’s a problem of biology, but the solution is engineering. The right technology can stop this spoilage in its tracks and protect your hard work. Let’s dig into exactly how to solve it.

What Makes Mushrooms So Perishable?

You’ve seen it happen: a perfect mushroom starts to brown and soften almost overnight. This isn’t just bad luck; it’s a powerful biological process that is actively working against your business.

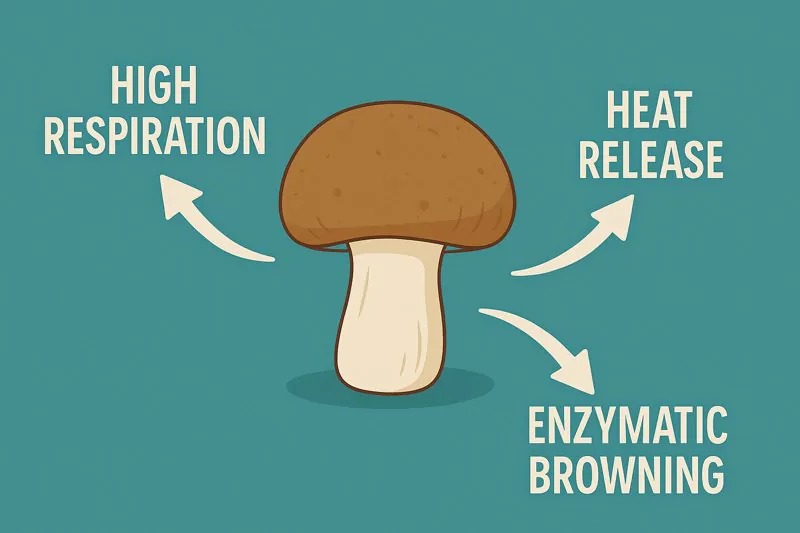

Mushrooms are highly perishable because they are fungi with an intense metabolic rate after harvest. They rapidly consume their own stored sugars, release heat, and trigger enzymes that cause browning, quickly destroying their commercial value.

The Biology of Rapid Decay

Understanding why mushrooms spoil so fast is the first step to preventing it. Unlike plants, mushrooms are fungi with an incredibly high metabolism. After they are harvested, they are still very much alive and they start to "breathe" at an accelerated rate. This process, called respiration1, rapidly consumes the mushroom’s stored sugars and generates a significant amount of internal heat. In essence, the mushrooms start cooking themselves from the inside out. This heat also triggers enzymes, particularly one called tyrosinase2, which is the primary culprit behind the rapid browning that makes them look old and unappealing to customers. It’s a chain reaction of self-destruction.

For a grower like Carlos or a buyer like Norman, this is a huge problem. Traditional cooling methods are simply too slow to fight this process. When you place pallets of mushrooms into a standard cold room, you create a new problem. The cardboard punnets and boxes are great insulators, trapping the heat that the mushrooms are generating. The cold air can take 12 to 24 hours to penetrate to the center of the pallet. By then, the browning process is well underway, the mushrooms have lost water weight, and their texture has started to soften. You’ve lost a significant portion of your shelf life before the product has even left your facility.

| Spoilage Factor | In Ambient Air | In a Cold Room |

|---|---|---|

| Respiration Rate | Very High | High, then slowly declining |

| Enzymatic Browning | Very Fast | Occurs for 12+ hours during cooling |

| Texture Loss | Rapid (softening) | Continues until core is cooled |

| Commercial Value | Degrades in hours | Significantly reduced |

How Can You Stop Mushrooms From Turning Brown?

The frustration of watching your perfectly white mushrooms turn brown is costly. You’ve tried to be careful, but the browning seems unstoppable, ruining your product’s appeal and your price point.

Vacuum cooling stops browning by rapidly chilling the mushrooms to their core. This instantaneous temperature drop halts the enzymatic activity and high respiration rate responsible for discoloration, preserving the mushroom’s pristine white color.

Halting Decay with Physics

The solution isn’t to cool mushrooms slowly; it’s to cool them almost instantly. This is where vacuum cooling technology3 becomes so powerful. We place the pallets of freshly harvested mushrooms into a sealed chamber and pull a deep vacuum. As the air pressure drops, the boiling point of water falls dramatically. A tiny amount of moisture on the surface of each mushroom begins to evaporate at a very low temperature. This evaporation requires energy, and it draws that energy—heat—directly from the mushroom itself. This process, called evaporative cooling4, pulls heat out of the product with incredible speed.

This isn’t like a cold room, which slowly cools from the outside in. Vacuum cooling happens to every mushroom in every box at the same time, from the surface to the core. The entire load reaches its target temperature, for example 3°C, in a cooling cycle of just 15-25 minutes. This rapid drop acts like an "off switch" for the mushroom’s biology. The high respiration rate stops. The tyrosinase enzyme that causes browning is instantly inactivated. The mushroom is put into a state of metabolic hibernation. We are not just making the mushroom cold; we are pausing the aging process itself, locking in that just-harvested white color and firm texture that customers demand.

| Cooling Method | Cooling Time | Enzyme Activity | Color Preservation |

|---|---|---|---|

| Cold Room | 12 – 24 hours | Continues for hours | Poor |

| ALLCOLD Vacuum Cooling | 15 – 25 minutes | Halted instantly | Excellent |

How Does Vacuum Cooling Extend Mushroom Shelf Life?

You lose sales because your mushrooms don’t last long enough for distant markets or retail shelves. This limited shelf life puts a hard ceiling on your farm’s growth and profitability.

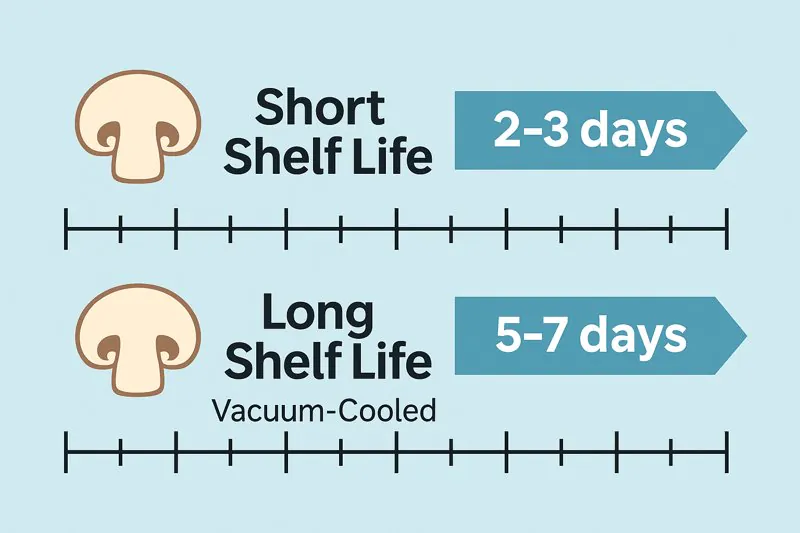

By instantly halting decay, vacuum cooling can extend mushroom shelf life from 2-3 days to 5-7 days or more. This allows growers to access more distant markets, reduces retail waste, and commands higher prices for a consistently premium product.

Unlocking New Markets and Higher Profits

The ability to reliably extend shelf life changes everything for a mushroom grower. Instead of a frantic race to sell a highly perishable product within 48 hours, you have a stable product with a sales window of a week or more. This has a massive impact on your entire business model. For a farm owner like Carlos, this means he is no longer limited to selling locally. He can now confidently ship his mushrooms to distribution centers in other cities or even other countries, knowing they will arrive in perfect condition. This opens up more lucrative markets that pay a premium for high-quality, consistent produce.

For a professional buyer like Norman, this reliability is priceless. His biggest pain point is receiving inconsistent products that spoil quickly on the retail shelf. It leads to waste, lost sales, and unhappy customers. When he sources vacuum-cooled mushrooms5, he gets a product he can trust. The extended shelf life6 means less waste for the supermarket and a better, fresher mushroom for the end consumer. This reliability is also critical for logistics. Loading hot mushrooms into a refrigerated truck is a recipe for disaster. The truck’s reefer unit is designed to maintain a cold temperature, not remove the huge amount of heat from a fresh harvest. By pre-cooling mushrooms with a vacuum cooler, you load a product that is already cold and stable, making the entire cold chain more efficient and effective.

| Supply Chain Stage | Without Pre-Cooling | With ALLCOLD Vacuum Cooling |

|---|---|---|

| At the Farm | Race against time, spoilage begins | Aging process is paused, quality locked in |

| Transportation | High risk of spoilage, limited range | Safe for long-distance shipping, wider market access |

| At the Retailer | Short shelf life, high waste | Longer shelf life, less waste, happier customers |

What Machine Features Are Critical for Mushroom Cooling?

You are considering a vacuum cooler, but you worry about reliability and ease of use. A complex or unreliable machine could create more problems than it solves for your busy farming operation.

A critical feature is user-friendly control, like a touch screen, to simply and reliably manage the fast cooling cycle. The system must also be built with top-brand components like Bitzer compressors and be backed by lifelong technical support.

Engineering for Reliability and Simplicity

Investing in capital equipment is a big decision, and it needs to deliver value without causing headaches. That’s why we focus on making our machines both powerful and easy to use. A complicated machine is a source of errors, especially in a fast-paced environment. Our systems feature simple touch screen operation, which allows any operator to run a perfect, repeatable cooling cycle every time. We also build in a troubleshooting assistance system to help diagnose any issues quickly. Many of our models are delivered plug-in ready, which means they are easy to install and integrate into your workflow.

Ultimately, a machine is only as good as its components and the support behind it. Reliability is not an accident; it’s a result of good engineering. That is why we use top-brand components from world-class suppliers like Bitzer for our compressors. These are the critical parts that ensure a long, productive life for the equipment. We stand behind this quality with a 12-month guarantee on all our systems. But our commitment doesn’t end there. We know that support is crucial for your peace of mind. Things can happen, and when they do, you need answers fast. That’s why we provide our customers with full technical support after installation and 7*24 hour phone assistance for the life of the machine. It’s a partnership to ensure your investment continues to pay dividends for years to come.

| Key Feature | Benefit for Mushroom Growers |

|---|---|

| Touch Screen Operation7 | Simple, consistent, and repeatable cooling cycles for any operator. |

| Top Brand Components8 | High reliability, long service life, and efficient operation. |

| 15-25 Minute Cycle Time | Prevents bottlenecks and allows cooling to match harvest speed. |

| *724 Lifelong Technical Support** | Provides peace of mind and minimizes potential downtime. |

| 12-Month Guarantee | Protects your investment and ensures quality from day one. |

Conclusion

Vacuum cooling transforms mushroom farming by stopping spoilage cold. It is a direct investment in quality, shelf life, and market access that delivers a clear return by protecting your valuable harvest.

-

Exploring respiration’s impact on mushrooms can provide insights into effective storage and preservation techniques. ↩

-

Understanding tyrosinase’s role can help you find ways to slow down mushroom spoilage and maintain freshness. ↩

-

Explore this link to understand the innovative vacuum cooling technology that preserves freshness and quality in harvested mushrooms. ↩

-

Learn about evaporative cooling and its role in food preservation, ensuring optimal quality and longevity of perishable products. ↩

-

This link will provide insights into the advantages of vacuum cooling, enhancing your understanding of its impact on freshness. ↩

-

Exploring this resource will reveal how extended shelf life can transform your business and reduce waste. ↩

-

Explore how touch screen operation enhances user experience and efficiency in machinery, making it easier for operators. ↩

-

Learn why using top brand components is crucial for reliability and longevity in machinery, ensuring optimal performance. ↩

Mila

You May Also Like

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But