Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing the shelf life, and cutting into the potential profit of your vegetables. This post-harvest race against time is a major source of stress and financial loss.

Traditional cooling methods are too slow. They can take many hours, or even days, to remove the core heat from your produce. During this time, your vegetables are losing moisture, wilting, and becoming more susceptible to decay, resulting in a less valuable product for your customers.

Yes, if you grow produce with a high surface-area-to-mass ratio, it will excel with vacuum cooling. This technology is designed for leafy greens, certain "flower" vegetables like broccoli, and specific high-moisture items like mushrooms, delivering rapid, uniform cooling in minutes, not hours.

As a manufacturer, I’ve had the opportunity to test hundreds of different products in our vacuum coolers. The results can be truly transformative, but the technology is not a magic bullet for everything. Success comes from understanding the science. Let’s explore which vegetables are the superstars of vacuum cooling and why.

Are Leafy Greens the Perfect Match for Vacuum Cooling?

Leafy greens are one of the most perishable and delicate crops a farmer can grow. A head of lettuce or a bunch of spinach can lose its crispness and visual appeal within hours of being picked, especially on a hot day. This rapid quality loss is a constant challenge.

The structure of leafy greens—millions of tiny pores on the surface of thin leaves—makes them incredibly susceptible to wilting and decay. Slow cooling methods allow these delicate products to sit in the temperature "danger zone" for too long, leading to significant moisture loss and reduced marketability.

Absolutely. Leafy greens are the ideal candidates for vacuum cooling. Their high surface area allows for extremely rapid water evaporation, leading to cooling times of just 15-25 minutes. This locks in freshness, crispness, and vibrant color, dramatically extending shelf life.

The Science of Cooling Leafy Greens

For a large-scale grower like Carlos, the ability to cool thousands of heads of lettuce in under 30 minutes is a complete game-changer for his packing house logistics. This speed and the resulting quality are exactly what a professional buyer like Norman is looking for from his suppliers.

Vacuum cooling1 works by reducing the atmospheric pressure, which lowers the boiling point of water. The water on the surface of the leaves, and just below it, begins to evaporate (boil) at a very low temperature. This evaporation pulls heat energy from the vegetable, cooling it from the inside out. This is why a high surface area is so important.

| Vegetable | Surface-to-Mass Ratio2 | Typical Cycle Time (mins) | Final Temp (°C) | Expected Shelf-Life Increase |

|---|---|---|---|---|

| Iceberg Lettuce | Extremely High | 15 – 20 | 1 – 2°C | Doubles or Triples |

| Romaine Lettuce | Very High | 18 – 25 | 1 – 2°C | Up to 21 days |

| Baby Leaf Spinach | Extremely High | 15 – 20 | 2 – 3°C | Adds 5-7 days of peak quality |

| Cabbage | High (but dense) | 25 – 30 | 2 – 3°C | Significant increase |

| Celery | High | 20 – 25 | 2 – 3°C | Maintains crispness for weeks |

This rapid cooling immediately stops the respiration process, effectively putting the vegetable into hibernation. For every 1% of moisture loss during the cooling process, the product temperature drops by approximately 6°C (10°F). Our systems are precisely controlled to achieve the target temperature with minimal moisture loss, typically between 1.5% and 2.5%.

Can You Use a Vacuum Cooler for Broccoli and Cauliflower?

Broccoli and cauliflower, often called "flower" vegetables, are dense and have a lot of stored field heat. After harvest, they can quickly turn yellow or develop off-flavors if not cooled properly. Their unique structure presents a different challenge than leafy greens.

The dense heads and thick stalks of these vegetables make it difficult for traditional cooling methods to penetrate to the core. Forced-air cooling can take many hours, and during this time, the delicate florets are respiring rapidly, degrading the quality and value of the product.

Yes, broccoli and cauliflower respond exceptionally well to vacuum cooling, often after being misted with a small amount of clean water. The water provides the "fuel" for evaporative cooling, allowing the vacuum process to efficiently pull heat from the dense heads in around 20-30 minutes.

The Hydro-Vacuum Advantage

This technique, known as hydro-vacuum cooling3, is a perfect example of adapting the process to the product. For a technical owner like Carlos, understanding this method is key to maximizing the use of his machine. For a food service manager like Sophia, the resulting quality and consistency of the florets are paramount.

Because broccoli has a waxy cuticle and is denser than lettuce, it has less "free" water available to evaporate. By lightly misting the product before it enters the chamber, we provide the extra surface moisture needed for the process to work efficiently.

- The Misting Process: A fine spray of potable water is applied to the pallets just before loading. This adds the necessary moisture without making the product "wet."

- The Result: The vacuum pulls4 this surface water off first, which in turn rapidly pulls the heat out from the core of the broccoli or cauliflower head. This prevents the yellowing and aging that occurs during slow cooling.

| Vegetable | Pre-Cooling Step | Typical Cycle Time (mins) | Final Temp (°C) | Key Benefit for Quality |

|---|---|---|---|---|

| Broccoli | Light Misting5 | 20 – 25 | 1 – 3°C | Prevents yellowing of florets, extends green life |

| Cauliflower | Light Misting | 25 – 30 | 1 – 3°C | Prevents discoloration and maintains curd whiteness |

| Sweet Corn | Often misted | 20 – 30 | 2 – 4°C | Immediately stops sugar-to-starch conversion, keeps it sweet |

| Artichokes | No misting needed | 25 – 30 | 3 – 4°C | Slows down the opening of the bracts (leaves) |

The ability to stop the metabolic process so quickly is especially critical for sweet corn6. After picking, the sugars in sweet corn begin converting to starch, reducing its sweetness by the hour. Vacuum cooling can halt this process in its tracks, preserving that "just-picked" flavor that commands a premium price.

What Other Types of Produce Are Compatible?

Once a farm or packing house invests in a vacuum cooler, they often wonder what else they can use it for. It’s a significant piece of equipment, and maximizing its utility across different product lines is a smart business move. But not all produce is created equal.

Trying to vacuum cool a product that is not suitable can be ineffective at best and damaging at worst. Produce with a thick, waxy skin and a low surface-area-to-mass ratio simply does not have the right characteristics for the evaporative cooling process to work.

Beyond greens and flowers, vacuum cooling is highly effective for high-moisture, high-respiration products like mushrooms and bean sprouts. However, it is generally unsuitable for thick-skinned items like tomatoes, peppers, cucumbers, and most fruits.

The Compatibility Spectrum

Understanding the "why" behind compatibility is crucial. It saves time, prevents wasted energy, and protects product quality. Carlos needs to know which of his secondary crops can be cooled, while Sophia needs to be sure that the process is appropriate for the products she sources.

Excellent Candidates:

- Mushrooms: This is a star performer. Mushrooms have a very high respiration rate and a high moisture content. Vacuum cooling7 can take them from 20°C to 2°C in about 15-20 minutes, preventing browning and extending their delicate shelf life significantly.

- Bean Sprouts & Microgreens: Like leafy greens, these are extremely delicate and have a huge surface area. Vacuum cooling is the only practical way to cool them rapidly without causing physical damage.

Poor Candidates (And Why):

The common denominator for unsuitable products is a barrier to moisture evaporation.

- Thick Skins: Vegetables like tomatoes, bell peppers, eggplant, and cucumbers have a thick, waxy skin that prevents water from evaporating from the surface. The vacuum process will have little to no effect on their internal temperature.

- Low Surface Area / Dense Flesh: Root vegetables like potatoes, carrots, and onions have a very low surface-area-to-mass ratio and dense flesh. The heat is trapped deep inside, and there isn’t enough surface evaporation to cool the core effectively.

- Most Fruits: Fruits like apples, oranges, and berries generally have protective skins and are more susceptible to damage from the pressure change. Traditional cooling methods are better suited for these items.

| Produce Category | Compatibility | Scientific Reason | Best Cooling Method |

|---|---|---|---|

| Mushrooms | Excellent | High respiration, high moisture, porous structure | Vacuum Cooling |

| Leafy Greens | Excellent | Very high surface-area-to-mass ratio | Vacuum Cooling |

| Broccoli/Cauliflower | Very Good | Good surface area, benefits from hydro-cooling | Vacuum Cooling (Hydro) |

| Tomatoes/Peppers | Not Suitable | Thick, waxy skin prevents evaporation | Forced-Air or Hydro-Cooling |

| Potatoes/Carrots | Not Suitable | Low surface area, dense flesh traps heat | Forced-Air Cooling |

Conclusion

Choosing the right cooling technology is about matching it to your crop. Vacuum cooling offers a revolutionary advantage for high-surface-area vegetables, locking in freshness and maximizing shelf life in a way no other method can.

-

Understanding vacuum cooling can enhance your knowledge of efficient cooling methods for leafy greens. ↩

-

Exploring the significance of surface-to-mass ratio can improve your insights into vegetable storage and quality. ↩

-

Explore this link to understand the innovative hydro-vacuum cooling technique and its benefits for food preservation. ↩

-

Learn about the science behind vacuum pulls and their role in effective food cooling methods. ↩

-

Discover how Light Misting enhances the quality of vegetables, ensuring freshness and longevity. ↩

-

Find out why sweet corn is prized for its sweetness and how preservation techniques maintain its flavor. ↩

-

Explore this link to understand the science behind vacuum cooling and its benefits for preserving freshness. ↩

Mila

You May Also Like

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But

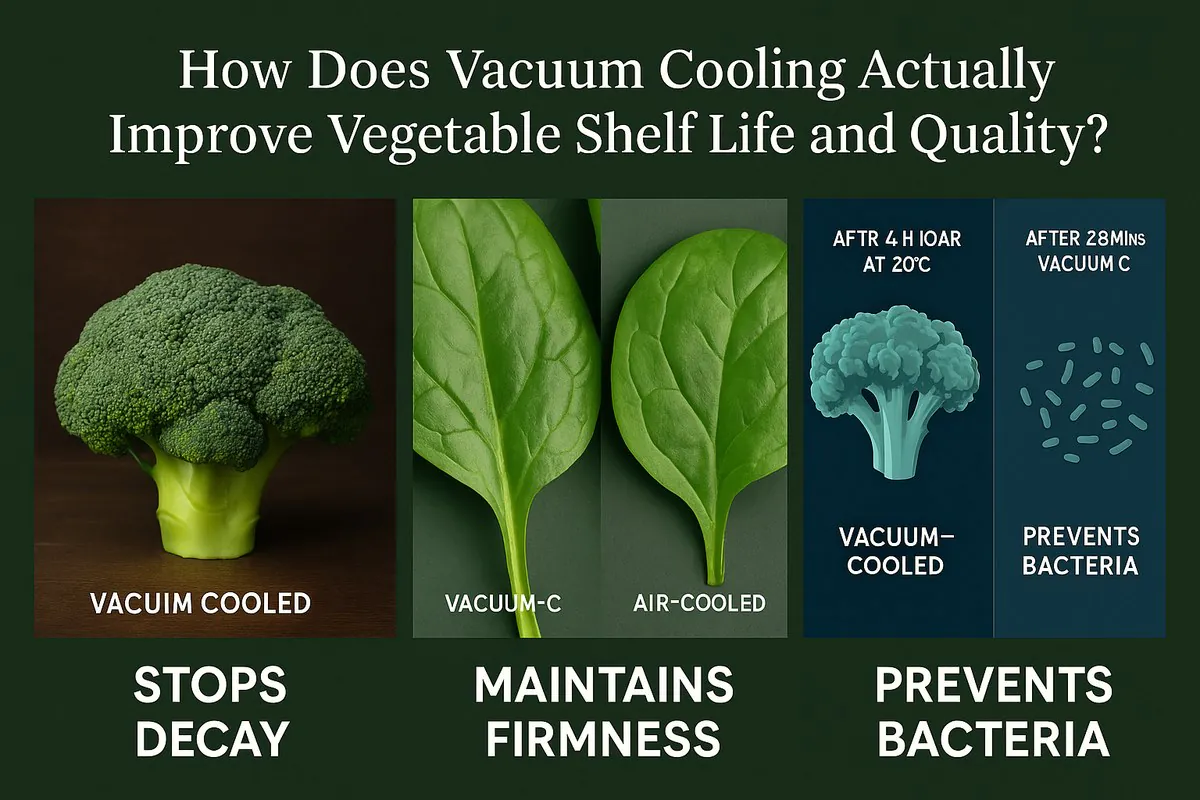

How Does Vacuum Cooling Actually Improve Vegetable Shelf Life and Quality?

You’ve done the hard work. Your harvest is in, and the vegetables look perfect—crisp, vibrant, and full of life. But