Bakery Vacuum Cooling vs. Traditional Cooling: Which Is Truly Better?

You’ve perfected your baking process, but your entire operation grinds to a halt at the final step: cooling. Your bakery floor is a maze of hot racks, you’re waiting hours to slice and package, and you are losing time and money with every minute that ticks by.

This production bottleneck is infuriating. It feels inefficient and outdated, forcing your entire schedule to revolve around this slow, passive process. You worry about the space it wastes and the quality you lose as your perfect crusts slowly turn soft and soggy.

For any serious commercial bakery, vacuum cooling is overwhelmingly better than traditional methods across every key metric: speed, product quality, space efficiency, and long-term profitability. Traditional rack cooling is only "better" for hobbyists or very small-scale operations where the low initial cost is the only factor.

As an engineer and manufacturer, I talk to bakers every day who are struggling with the limits of traditional cooling. They know there has to be a better way. My goal is not just to tell you that vacuum cooling is superior, but to show you why. Let’s break down this comparison across the four areas that truly matter to your business: speed, quality, space, and cost.

Which Method Is Faster and More Efficient?

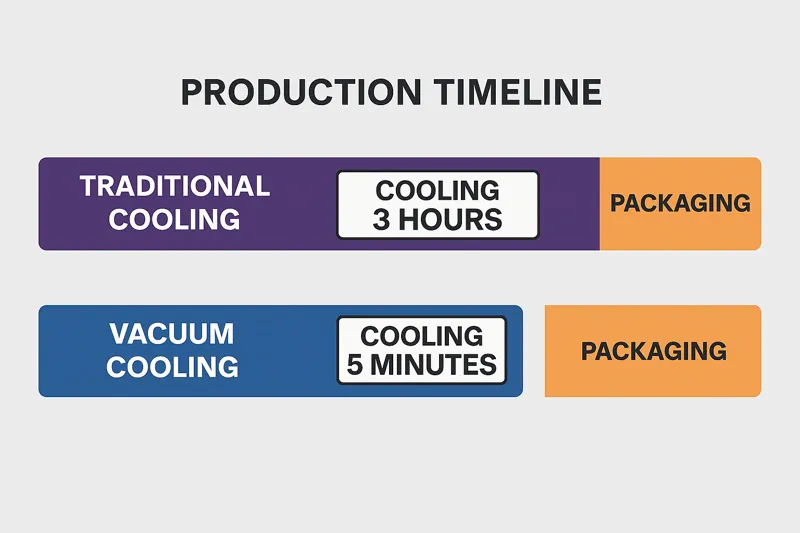

The most painful part of traditional cooling is the waiting. You can bake bread in 20 minutes, but then it sits for two or three hours. This isn’t just a minor delay; it’s a fundamental barrier that dictates your entire production capacity and workflow.

You are constantly playing a waiting game. Your ovens can produce more, but you have nowhere to put the finished product. Your staff is waiting, your slicer is sitting idle, and your delivery schedules are constrained, all because of this one slow, inefficient step.

There is no comparison in speed. Vacuum cooling is over 90% faster, cooling bread in 3-6 minutes versus the 2-3 hours required for traditional rack cooling. This transforms your bakery from a "batch-and-wait" operation into a continuous, streamlined flow.

The Impact of a Continuous Workflow

The difference between 3 minutes and 3 hours is so profound that it changes the entire philosophy of your production floor. A technical owner like Carlos immediately sees that this isn’t just a small improvement; it’s a complete revolution.

The End of Bottlenecks

With traditional cooling, your oven is the fastest part of your process. This should never be the case. You are forced to stop production or find massive amounts of space to hold hours’ worth of baked goods. With a vacuum cooler1, the cooling step is finally faster than the baking step. This means as soon as one trolley of bread comes out of the oven, it can be cooled and moved to packaging, clearing the way for the next one. The bottleneck simply disappears. This allows you to maximize the output of your most valuable asset—your ovens—and significantly increase your daily production capacity2 without adding a single new oven.

A New Level of Responsiveness

Imagine a client like Sophia, a manager for a fast-food chain, calls you with a last-minute emergency order for 2,000 burger buns needed in three hours. With traditional cooling, you’d have to say no. The cooling time alone makes it impossible. With vacuum cooling, you can confidently say "yes." You can bake, cool, and package the entire order in a continuous flow3 and meet her deadline. This ability to be flexible and responsive is a massive competitive advantage and allows you to become a more valuable partner to your key clients.

| Metric | Traditional Rack Cooling | Allcold Vacuum Cooling | Impact on Bakery Operations |

|---|---|---|---|

| Average Cooling Time | 2 – 3 Hours | 3 – 6 Minutes | Transforms production into a continuous flow. |

| Production Model | Batch-and-Wait | Continuous Flow | Maximizes oven output and daily capacity. |

| Labor Workflow | Stop-and-go, inefficient | Smooth, predictable, and efficient. | Reduces staff downtime and improves morale. |

| Order Flexibility | Very Low (long lead times) | Very High (can accept rush orders) | Creates a major competitive advantage. |

Which Method Produces Higher Quality Bread?

You’ve invested in the best ingredients and perfected your baking process to create a delicious loaf with a beautiful, crispy crust. But then, during the long cooling process, you watch that quality degrade. Moisture from the inside migrates out, making your perfect crust soft and leathery.

It’s disheartening to lose quality at the very last stage. Furthermore, as the bread sits for over an hour in the temperature "danger zone," it creates a breeding ground for mold and bacteria, forcing you to use preservatives or accept a shorter shelf life for your products.

Vacuum cooling produces a significantly higher quality product. It locks in a crispy crust, creates a more stable crumb structure for better slicing, and naturally extends shelf life by 3 to 7 days by virtually eliminating time spent in the microbial growth danger zone.

The Science of a Superior Loaf

The quality improvement is not a matter of opinion; it is the direct result of the physics behind the cooling method. A procurement manager like Sophia, who must adhere to strict HACCP standards4, and a professional buyer like Norman, who is sensitive to quality, will immediately recognize these benefits.

Locking in Texture

The dreaded "soggy crust5" is a direct result of slow, passive cooling. As the bread sits, the temperature difference between the hot, moist interior and the cooler exterior causes that moisture to migrate outwards, ruining the crust. Vacuum cooling is an active process. It physically pulls water vapor out of the entire loaf, including the surface. This rapidly sets the crust and prevents moisture migration. The result is a audibly crispy crust that lasts. At the same time, the rapid "gelatinization stop" locks the bread’s internal starch structure, leading to a more stable crumb that doesn’t collapse and stands up perfectly to automatic slicers.

A Natural Extension of Shelf Life

This is perhaps the most powerful quality benefit. The temperature range between 60°C and 10°C (140°F – 50°F) is where mold spores and bacteria thrive. A loaf of bread on a cooling rack will spend over an hour in this zone. A vacuum cooler takes the bread through this entire danger zone in less than 5 minutes. By preventing this initial microbial bloom from ever starting, you are not killing microbes—you are preventing them from ever getting a foothold. This allows you to extend the natural, preservative-free shelf life of your packaged bread by days. For a business looking to expand its distribution area or reduce waste from stale returns, this is a game-changer.

| Quality Attribute | Traditional Rack Cooling | Allcold Vacuum Cooling | Reason for Difference |

|---|---|---|---|

| Crust Texture | Becomes soft, soggy, and leathery. | Stays audibly crispy and stable for longer. | Vacuum actively removes surface moisture. |

| Crumb Structure | Can be prone to collapsing or tearing. | Stronger, more stable, perfect for slicing. | Rapid "gelatinization stop" locks the internal structure. |

| Natural Shelf Life | Standard (e.g., 3-4 days). | Extended by 3-7 days (e.g., 7-10 days). | Passes through microbial "danger zone" in <5 minutes. |

| Need for Preservatives | Often required to achieve longer shelf life. | Often eliminated, allowing for a "clean label." | Shelf life is extended naturally through hygiene. |

Which Method Saves More Space and Reduces Costs?

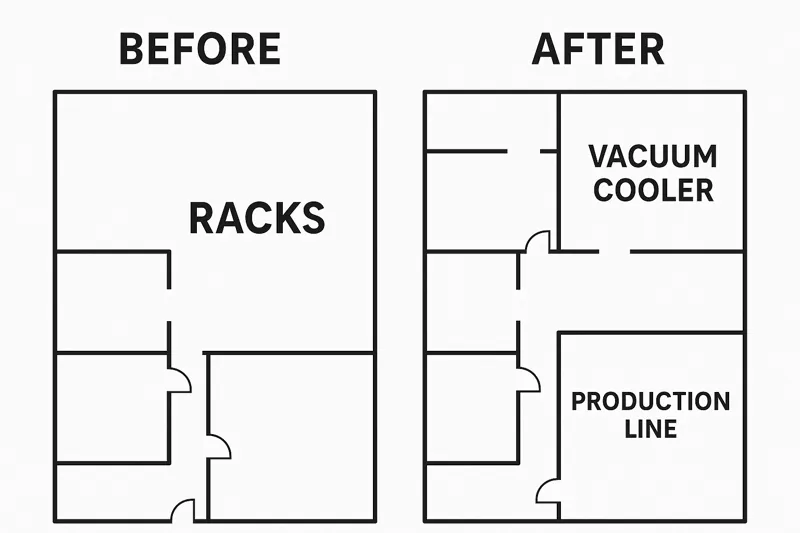

Walk onto any large bakery floor, and you’ll see it: a sea of metal cooling racks. They occupy a massive footprint, clog up walkways, cause damage to walls, and create a chaotic, inefficient working environment. This isn’t just clutter; it’s a huge operational cost.

You are paying for every square foot of your facility. Dedicating a huge portion of that valuable space to the passive, unproductive task of storing hot bread is a massive hidden expense. You are paying for space that you could be using to generate more revenue.

A vacuum cooler offers monumental space savings and reduces operational costs. A single machine can replace the need for 30, 40, or even more cooling racks, freeing up hundreds of square feet of valuable production space and cutting down on labor and maintenance costs.

The Tangible Value of Space

For a bakery owner, space is money6. Freeing up a large area of your floor opens up possibilities that have a direct impact on your bottom line. You can use that newly available space to add another oven, install a new packaging line, or simply de-clutter your operation to improve workflow and safety.

Calculating Your Space ROI7

Let’s do some simple math. A standard cooling rack holds about 15-20 trays and takes up about 1 square meter of space. To hold 3 hours of production from a medium-sized oven, you might need 30-40 of these racks, consuming 30-40 square meters (or around 300-400 sq. ft.) of your floor. A vacuum cooler that can handle that same capacity might only take up 5-6 square meters. You have instantly reclaimed a massive, valuable area of your factory. If you are leasing your facility, you can calculate the monthly cost of that wasted space and see it as a direct saving.

The Hidden Costs of Racks8

The cost of traditional cooling goes beyond just the space. There are ongoing operational costs that many people overlook.

- Labor: Your staff spends time moving these heavy, cumbersome racks around—from the oven to the cooling area, then from the cooling area to the slicer. This is unproductive labor.

- Maintenance: Racks get damaged. Their wheels break, they get bent, and they need to be replaced. They also cause damage when they are inevitably bumped into walls and other expensive equipment.

- Energy: All of those hot trolleys of bread are radiating heat directly into your facility for hours. This places a significant extra load on your air conditioning system, driving up your energy bills, especially in warmer climates. A vacuum cooler contains all the heat and expels it efficiently through its refrigeration system.

| Cost Factor | Traditional Rack Cooling | Allcold Vacuum Cooling9 | Financial Impact |

|---|---|---|---|

| Floor Space Required | Very High (e.g., 30-40 m²) | Very Low (e.g., 5-6 m²) | Frees up valuable space for revenue-generating activities. |

| Labor Costs10 | High (staff needed to move and manage racks). | Minimal (load and press a button). | Reduces unproductive labor hours. |

| Energy Costs11 | Increases air conditioning load significantly. | Self-contained; no significant impact on room temp. | Lowers overall factory energy consumption. |

| Maintenance & Damage | Racks need frequent repair/replacement; damage walls. | Contained system with low maintenance needs. | Reduces repair budgets and equipment damage. |

What About the Initial Investment and Return?

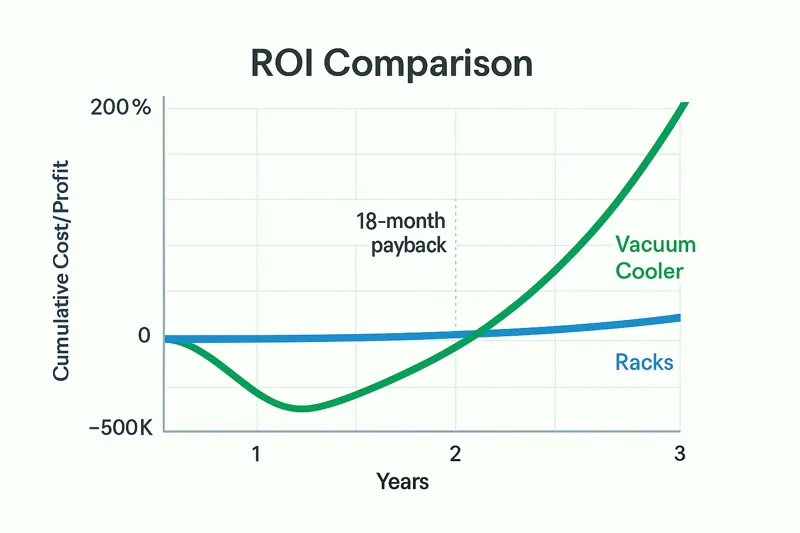

This is the most direct and important question for any business owner. Cooling racks are cheap, costing a few hundred dollars each. A bakery vacuum cooler is a serious piece of industrial machinery and represents a significant capital investment.

You see the price tag for a vacuum cooler and you hesitate. It’s a big number, and it’s easy to get sticker shock. You wonder if you can truly justify the expense, and how long it would take to get your money back. This is the final hurdle for most people.

While traditional cooling has a very low initial cost, vacuum cooling offers a rapid and compelling return on investment (ROI), typically within 12 to 24 months. The upfront cost is an investment in efficiency that pays for itself through increased output, labor savings, and higher-quality products.

Thinking Like an Investor

An informed buyer like Norman knows that the initial price is only one part of the equation. The true measure of a purchase is its total value and return. We need to be honest: if you are a tiny neighborhood bakery making 100 loaves a day, the investment is likely not for you. But for a commercial or industrial bakery, the math is clear and powerful.

How to Calculate Your Payback

The ROI comes from multiple streams. You can calculate your potential payback period with a simple formula:

Payback Period = (Upfront Machine Cost) / (Monthly Savings + Monthly New Profit)

Let’s break down the savings and profit drivers:

- Increased Output: If you can produce and sell 20% more bread every day because the cooling bottleneck is gone, that is new, direct revenue.

- Labor Savings: Calculate the hours your staff currently waste waiting for bread to cool or moving racks. Re-deploying them to more productive tasks is a direct cost saving.

- Reduced Waste: If extending your shelf life reduces returned or stale products by even 1-2%, that is pure profit added back to your bottom line.

- Energy Savings: Lower air conditioning bills contribute to the monthly savings.

For most medium to large bakeries, these combined savings and new profits quickly add up to thousands of dollars per month, leading to that fast payback period.

Investment vs. Expense

This is the key mindset shift. Racks are a simple expense. You buy them, they do a poor job, and they cost you money in hidden ways every day. A vacuum cooler is a capital investment. It is a productive asset that actively makes you more money and saves you more money than it costs. It is a tool that generates its own return.

| Financial Metric | Traditional Rack Cooling | Allcold Vacuum Cooling | The Bottom Line |

|---|---|---|---|

| Upfront Cost | Low | High (Significant Capital Investment) | Racks are an expense; a vacuum cooler is an investment. |

| Return on Investment | None (It’s a cost center) | High (Typically pays for itself in 12-24 months) | The machine becomes a profit-generating asset. |

| Key ROI Drivers | N/A | Increased throughput, labor savings, reduced waste. | Multiple streams contribute to a rapid payback. |

| Long-Term Value | Depreciating, low-value assets. | A core asset that drives business growth and quality. | Enhances the overall value and capability of your company. |

Conclusion

For commercial bakeries, the choice is clear. Traditional cooling is a costly bottleneck, while vacuum cooling is an investment in speed, quality, and efficiency that provides a rapid and substantial return. It is the superior method in every meaningful way.

-

Explore how vacuum coolers can revolutionize your baking process and enhance efficiency. ↩

-

Discover effective strategies to boost your bakery’s production capacity without major investments. ↩

-

Learn about the advantages of continuous flow production and how it can maximize your output. ↩

-

Understand the importance of HACCP standards in food safety and how they impact bread production. ↩

-

Learn effective techniques to avoid soggy crusts and achieve a perfect texture in your baked goods. ↩

-

Understanding the financial implications of space can help bakery owners optimize their operations. ↩

-

Learn effective methods to calculate ROI on space to maximize profitability in your bakery. ↩

-

Discover the often-overlooked expenses associated with traditional cooling methods in bakeries. ↩

-

Find out how Allcold Vacuum Cooling can save space, reduce costs, and improve efficiency. ↩

-

Explore how labor costs can affect your bakery’s efficiency and profitability. ↩

-

Understanding energy costs can help bakeries make informed decisions about cooling systems. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy