Can Reducing Cooling Time by 90% Revolutionize Your Bakery's Productivity?

Watching fresh bread cool naturally is like watching paint dry. It stalls your packaging line, wastes staff hours, and keeps your delivery trucks waiting longer than necessary. You are losing momentum every minute the bread sits on the rack.

Vacuum cooling reduces cooling cycles from hours to minutes. This 90% time reduction instantly accelerates your "oven-to-shelf" velocity, allowing you to fulfill late orders, reduce labor overtime, and maximize the output of your existing workforce.

At Allcold, I often tell my clients that time is their most expensive ingredient. When I visit factories, I see bakers working hard, but then I see the bread sitting idle for two hours. It creates a "stop-and-go" traffic jam in your production line. By implementing vacuum cooling, we delete that waiting time. We turn a slow, disjointed process into a high-speed continuous line. This isn’t just about cooling; it is about radically changing your production schedule.

Does Faster Cooling Mean Your Staff Can Go Home Earlier?

Your bakers finish their shift early, but your packaging team has to wait around for hours until the bread is cool enough to handle. You are paying for idle time, and that hurts your profit margins every single day.

Yes. By syncing the cooling speed with the baking speed, you eliminate the "dead time" between production and packaging. Your staff can pack immediately, reducing overtime costs and streamlining your shift management.

Closing the "Shift Gap1"

Let’s analyze the labor inefficiency in a standard bakery. I call this the "Shift Gap."

In a traditional bakery, there is a massive disconnect between the Baking Team and the Packaging Team.

Imagine your Baking Team starts at 4:00 AM.

The first batch of bread comes out of the oven at 4:30 AM.

However, that bread cannot be sliced until it cools down to roughly 30°C. In a standard room, this takes 2 hours.

So, your Packaging Team cannot start working until 6:30 AM.

This creates two problems:

- Morning Waste: If you bring the packers in at 4:00 AM, they have nothing to do for 2.5 hours. You pay them to stand around.

- Evening Overtime: Because they started late, they have to stay late. If the bakers finish at 12:00 PM, the packers are still stuck there until 2:30 PM waiting for the last batch to cool.

Now, look at the Allcold vacuum cooling2 scenario.

The Baking Team starts at 4:00 AM.

The bread comes out at 4:30 AM.

It goes into the vacuum cooler for 5 minutes.

The bread is ready to slice at 4:40 AM.

The "Shift Gap" shrinks from 2 hours to 10 minutes.

This allows you to align your teams perfectly. They start together, and they leave together. For a business owner like Carlos in Mexico, who employs a large staff, cutting 2 hours of "waiting time" per person per day is a massive financial saving. You are no longer paying for the bread to sit on a rack; you are only paying for active work.

| Shift Phase | Traditional Cooling Schedule | Vacuum Cooling Schedule |

|---|---|---|

| Bake Finish | 10:00 AM | 10:00 AM |

| Cooling Time | 2 Hours (Passive wait) | 10 Minutes (Active cool) |

| Ready to Slice | 12:00 PM | 10:15 AM |

| Packing Finish | 1:00 PM | 11:15 AM |

| Total Time | 3 Hours | 1 Hour 15 Minutes |

Can You Accept Last-Minute Orders Without Panicking?

A major supermarket calls at 2 PM needing 500 extra loaves by 5 PM. Usually, you have to say no because the bread won’t be cool enough to slice in time. You lose the sale and disappoint the customer.

With vacuum cooling, you can say yes. Because the cooling process is almost instant, you can bake fresh product late in the day and have it sliced and loaded within 15 minutes, making your bakery incredibly agile.

Moving from "Plan-Driven" to "Demand-Driven"

Most bakeries operate on a rigid "Plan-Driven" model. You guess what you need to bake the day before. Once the production run starts, you cannot easily change it because the cooling time acts as a concrete barrier. The physics of cooling prevents you from reacting to the market.

For my client Norman in the USA, flexibility is everything. He deals with fluctuating orders from restaurant chains. If a chain suddenly gets busy and needs more burger buns, Norman used to be helpless.

With traditional cooling, the "Lead Time3" (the time from starting the mixer to loading the truck) is about 4 to 5 hours. If a customer calls at 2:00 PM, the bread won’t be ready until 7:00 PM. That is often too late for delivery.

With vacuum cooling4, you slash the Lead Time down to roughly 2 to 2.5 hours.

This shift allows you to become "Demand-Driven."

- The Late Add-On: You can keep one oven on standby. If an urgent order comes in, you mix, bake, vacuum cool, and pack immediately.

- Freshness Guarantee: You don’t have to bake bread 12 hours in advance to ensure it is cool for the morning trucks. You can bake it closer to the delivery time. This means your customer receives bread that is 2 hours old, not 14 hours old.

This agility is a competitive weapon. When your competitors say "No, it is too late," you say "Yes." You capture the revenue they leave on the table. You solve your customer’s pain points. This builds loyalty that price alone cannot buy. Vacuum cooling turns your production line into a sports car—fast, responsive, and ready to turn corners instantly.

| Responsiveness Factor | Standard Bakery | Vacuum Cooled Bakery |

|---|---|---|

| Lead Time | 4 – 5 Hours | 2 – 2.5 Hours |

| Reaction Window | Closes early in the day | Open until late afternoon |

| Product Freshness | Baked hours in advance | Baked "Just in Time" |

| Emergency Orders | Impossible to fulfill | Easy to accommodate |

Does Speed Actually Improve Your Slicing Yield and Waste?

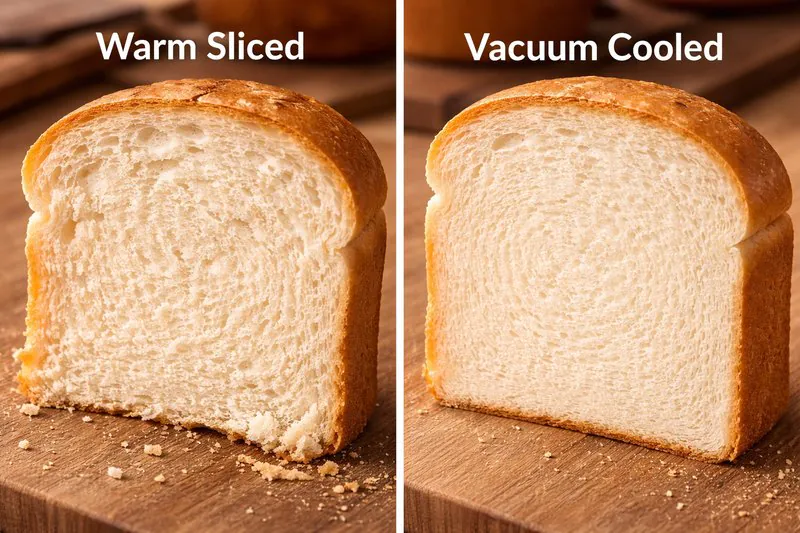

Rushing to slice warm bread destroys the loaf. You end up with crushed shapes and wasted crumbs, forcing you to re-bake and lose valuable production time. It is a classic case of "haste makes waste."

Vacuum cooling stabilizes the bread’s structure instantly. This creates a firm, dry, and easy-to-slice crumb that reduces waste at the slicer to almost zero, ensuring every loaf you bake is sellable and perfectly shaped.

The Hidden Productivity Killer—Slicer Jams

Productivity is not just about how fast you bake; it is about how much saleable product ends up in the bag.

I see this problem constantly with clients like Sophia in Singapore who produce sandwich bread.

The Slicing Station5 is often the bottleneck.

Why? Because slicing warm or moist bread is a nightmare.

- gumming up the blades: If the bread is even slightly too warm in the center (which happens often with air cooling), the crumb is sticky. It builds up on the slicer blades.

- The Crush Effect: The slicer blades crush the soft loaf instead of cutting it. You get "waisted" loaves that look like hourglasses. These cannot be sold to premium customers.

- Downtime: Your staff has to stop the machine every 20 minutes to scrape the sticky dough off the blades. This stops the whole line.

Vacuum cooling6 acts as a "structure lock."

When we flash-cool the bread, we gelatinize the starches instantly and uniformly. The crust becomes crispy, but more importantly, the crumb becomes stable and resilient.

The temperature is uniform. There is no "hot core."

When this bread hits the slicer:

- It cuts cleanly.

- It produces very few crumbs.

- It does not stick to the blades.

This means your slicer can run at full speed without stopping. You don’t lose 5% of your bread to damage.

If you bake 1,000 loaves and damage 50 of them at the slicer, you have wasted the ingredients, the energy, and the labor for those 50 loaves. That is negative productivity7. By fixing the structure with vacuum cooling, you ensure that 1,000 baked loaves equal 1,000 sold loaves.

| Productivity Metric | Warm/Air Cooled Slicing | Vacuum Cooled Slicing |

|---|---|---|

| Blade Condition | Sticky, needs frequent cleaning | Clean, runs continuously |

| Loaf Structure | Soft, prone to collapsing | Set, resilient to pressure |

| Rejection Rate | High (due to misshaping) | Near Zero |

| Machine Speed | Slow (to prevent damage) | Maximum Rated Speed |

Conclusion

Productivity is about flow. Traditional cooling is a dam that stops your flow. Vacuum cooling breaks that dam. By reducing cooling time by 90%, you align your staff, you empower your sales team to say yes, and you ensure every loaf is sliced perfectly.

-

Understanding the Shift Gap can help optimize bakery operations and reduce labor costs significantly. ↩

-

Exploring vacuum cooling technology can reveal innovative solutions to enhance efficiency and reduce waste in bakeries. ↩

-

Understanding Lead Time is crucial for bakeries to optimize their production and meet customer demands effectively. ↩

-

Exploring vacuum cooling can reveal innovative methods to enhance efficiency and responsiveness in bakery operations. ↩

-

Understanding the Slicing Station’s impact can help optimize your bread production process. ↩

-

Explore how vacuum cooling can enhance your bread’s texture and reduce waste. ↩

-

Learn about the factors contributing to negative productivity and how to address them. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy