Cost Comparison: Is Vacuum Cooling More Cost-Effective Than Hydrocooling?

Choosing between cooling technologies feels like a high-stakes gamble. You need to lower your operational costs, but the wrong decision could end up costing you more in the long run.

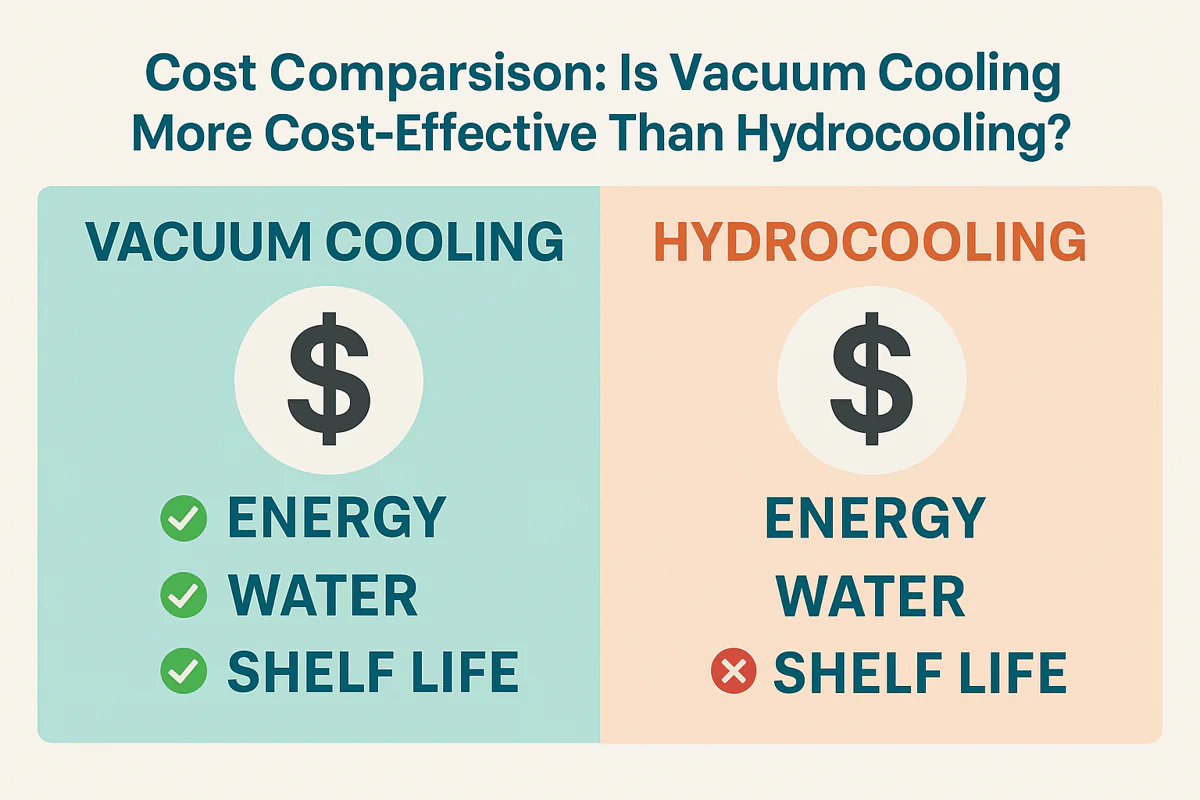

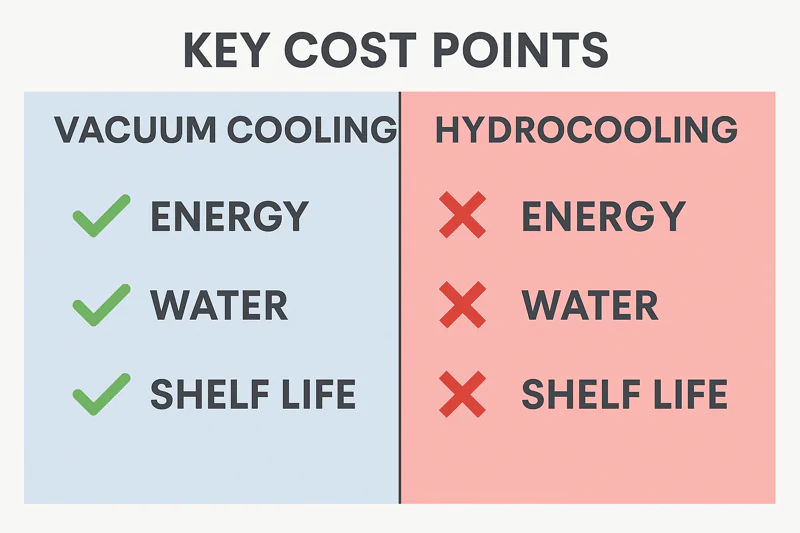

When comparing total costs, vacuum cooling is often more cost-effective than hydrocooling. This is due to its significantly lower operational expenses in energy and water, reduced maintenance needs, and its ability to increase revenue by extending the shelf life and quality of vegetables.

As someone who helps growers and producers make this choice, I’ve seen the analysis paralysis firsthand. People get stuck on the initial purchase price and forget to look at the bigger picture. The true cost of any machine isn’t what you pay today; it’s what you pay over its entire lifespan. Let’s break down the real costs—upfront, operational, maintenance, and even the hidden ones—to see which system truly offers the best return on investment.

How do upfront investment costs compare?

You see a lower sticker price on a hydrocooler and think it’s the cheaper option. But you’re worried about hidden installation costs and whether it’s the best long-term financial decision.

While the initial purchase price can vary, a vacuum cooler’s investment should be evaluated on its Total Cost of Ownership. Its advanced, durable components and efficient, "plug-in ready" design can lead to lower long-term expenses, offering a better return.

Looking Beyond the Sticker Price

When you buy a piece of major equipment, you’re not just buying a machine; you’re investing in a system. The initial price is only one part of the equation. Hydrocooling systems1 can sometimes appear cheaper upfront, but they often require extensive on-site construction, including large water tanks, filtration systems, and complex plumbing. These installation costs can quickly add up, narrowing any initial price advantage.

Vacuum cooler2s, on the other hand, are typically engineered as self-contained systems that are "plug-in ready and well piped". This simplifies installation significantly. More importantly, the value is built into the core of the machine. We invest in premium, world-renowned components to ensure longevity and reliability. For example, using a German-made Bitzer compressor and a Leybold vacuum pump means the machine is built to last. This focus on quality minimizes the risk of premature failure and costly replacements. So, while the initial quote for a vacuum cooler might be higher, its simpler installation and superior build quality often result in a lower total investment over the equipment’s lifespan.

| Cost Factor | Vacuum Cooler | Hydrocooler (General) |

|---|---|---|

| Initial Price | Moderate to High | Low to Moderate |

| Core Components | Premium, durable brands (e.g., Bitzer, Leybold) | Varies, can use lower-cost parts |

| Installation | Simpler, often plug-in-ready | Complex, requires plumbing and water systems |

| Long-Term Value | High, due to reliability and efficiency | Lower, potential for higher repair costs |

Which method has lower operational costs?

Your electricity and water bills are already a major concern. You can’t afford a cooling system that dramatically increases these monthly expenses and eats into your profit margins.

Vacuum cooling has significantly lower daily operational costs. Its efficient, automated cooling cycle consumes far less energy and virtually no process water compared to the high resource demands of hydrocooling.

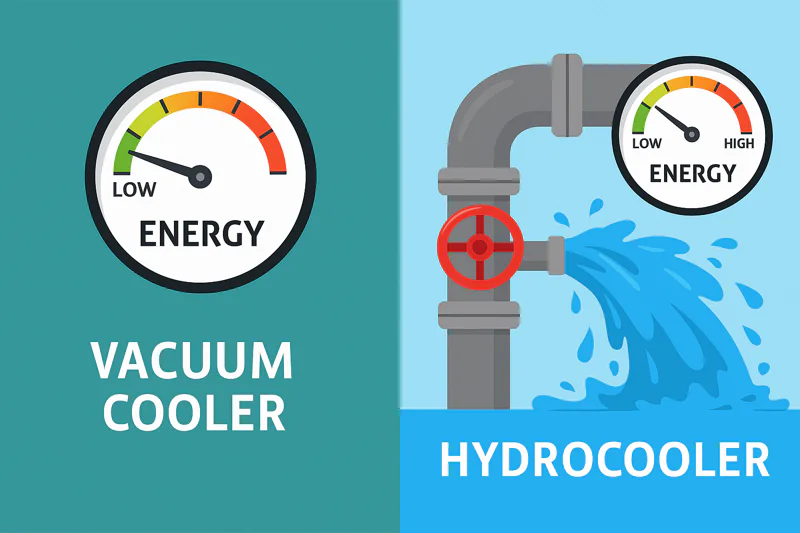

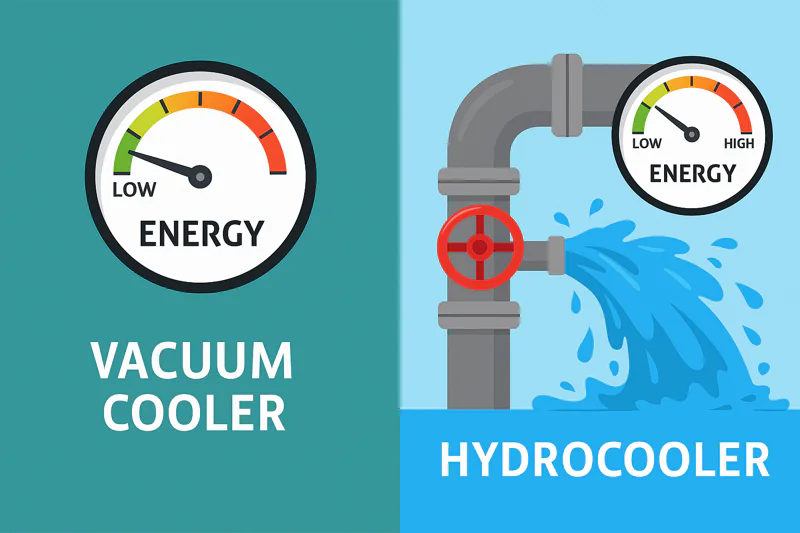

The Daily Drain on Your Profits

This is where the financial difference between the two technologies becomes crystal clear day after day. Hydrocooling3 is, by its very nature, a resource-intensive process. It requires massive volumes of water, which must be continuously chilled. Chilling that water is an energy-heavy process. You are essentially paying for electricity to cool water, and then paying for the water itself, plus any chemicals needed to keep it sanitary.

Vacuum cooling4 works on a completely different, far more efficient principle. It cools produce by causing its own moisture to evaporate under low pressure. The system is highly automated; you press ‘Start’, and the machine runs the vacuum pump and compressor until the target temperature is reached. Once the goal is met, the compressor and condenser fans stop automatically. This means the machine is only drawing maximum power during the active cooling cycle, not continuously. When you compare the high, constant energy and water consumption of a hydrocooler to the brief, efficient power usage of a vacuum cooler, the daily operational savings become a massive financial advantage.

What are the long-term maintenance and labor costs?

You’re worried about the hidden costs of upkeep. You need a machine that your team can manage easily without requiring constant professional service or complex daily sanitation procedures.

Vacuum coolers are designed for minimal and simple maintenance. This drastically reduces long-term service costs and labor compared to the daily sanitation and water quality management required for hydrocoolers.

The Cost of Complexity

Maintenance is a critical factor in the total cost of ownership. A machine that constantly needs attention is a drain on both time and money. Hydrocooling systems5 demand rigorous daily maintenance. This includes monitoring sanitizer levels, cleaning filters, and performing regular flushes to prevent bacterial buildup. This is a significant daily labor cost.

Vacuum coolers6 are engineered for simplicity, keeping your long-term costs low. The maintenance schedule is predictable and infrequent. For instance, a key routine task is a simple monthly visual check to see if the vacuum pump oil looks milky; if it does, it needs changing. More significant services are few and far between. Changing the compressor’s lubrication oil, a job for a professional, is only required every two years. We also recommend washing the condenser annually and performing an overall hygiene check every two seasons. This "low-touch" maintenance philosophy means less downtime and lower labor costs, making the vacuum cooler a far less costly machine to own over its lifetime.

How do indirect costs like product quality affect the bottom line?

You lose money every time produce spoils or loses weight before it can be sold. You need a cooling method that not only cools but also protects your product’s value and extends its selling window.

Vacuum cooling’s rapid and uniform chilling extends shelf life and minimizes moisture loss, directly increasing your marketable yield and revenue. This financial gain often outweighs any initial cost difference compared to hydrocooling.

The Hidden Costs of Spoilage

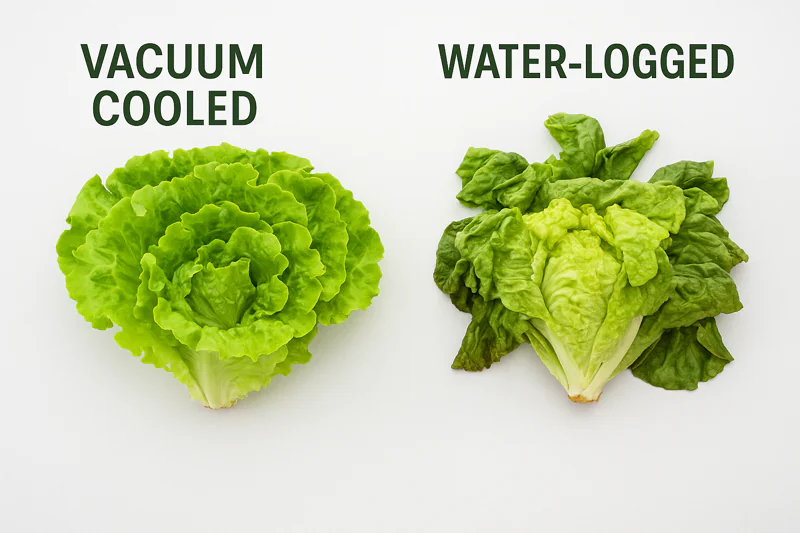

The most significant cost difference may not appear on any invoice. It’s the money you gain or lose based on the quality and shelf life of your final product. Hydrocooling submerges produce in water. While it cools the product, it can also lead to waterlogged vegetables, promote the spread of waterborne bacteria, and damage delicate leafy greens. This can shorten shelf life7 and lead to higher rates of spoilage—a direct hit to your revenue.

Vacuum cooling, however, enhances a product’s value. The process is incredibly fast, removing field heat in minutes. This rapid cooling immediately halts the degradation process, locking in freshness, crispness, and color. Because it cools the product from the inside out by evaporating a tiny amount of its own moisture, the cooling is perfectly uniform throughout the entire pallet. This extended freshness means a longer sales window, less waste, and the ability to command higher prices for premium-quality produce. These gains in product value are real profits that make vacuum cooling8 a powerful investment in your bottom line.

Conclusion

When you look beyond the initial price and consider operational costs, maintenance, and product quality, vacuum cooling consistently emerges as the more cost-effective, long-term solution for preserving the value of your vegetables.

-

Learn about hydrocooling systems and their installation costs to understand their long-term value versus alternatives. ↩

-

Explore the advantages of vacuum coolers, including efficiency and reliability, to make informed investment decisions. ↩

-

Understanding the costs of Hydrocooling can help you make informed decisions about your cooling technology. ↩

-

Exploring Vacuum cooling can reveal significant energy savings and operational efficiencies for your business. ↩

-

Explore this link to understand the maintenance needs of Hydrocooling systems and how they impact overall costs. ↩

-

Discover how Vacuum coolers simplify maintenance and lower long-term ownership costs, making them a smart investment. ↩

-

Understanding shelf life is crucial for maximizing profits and minimizing waste in your business. ↩

-

Explore how vacuum cooling can enhance freshness and profitability, making it a smart investment for your operations. ↩

Mila

You May Also Like

How Does Vacuum Cooling Forge the Strongest Link in Your Vegetable Cold Chain?

You work tirelessly to grow perfect, healthy vegetables. Yet, you know that from the moment of harvest, an invisible clock

Small-Scale vs. Large-Scale Vacuum Cooler: How Do You Choose the Right Fit?

You’re convinced that vacuum cooling is the key to elevating your product quality, but now you face a critical decision.

How Can You Master Vacuum Cooling for Leafy Greens to Maximize Quality and Profit?

You grow beautiful, vibrant leafy greens, but you know the invisible enemy is time. From the moment of harvest, the

Which Vegetables Benefit Most from Vacuum Cooling Technology?

You see the promise of rapid cooling, extended shelf life, and superior quality, but you’re unsure if this technology is

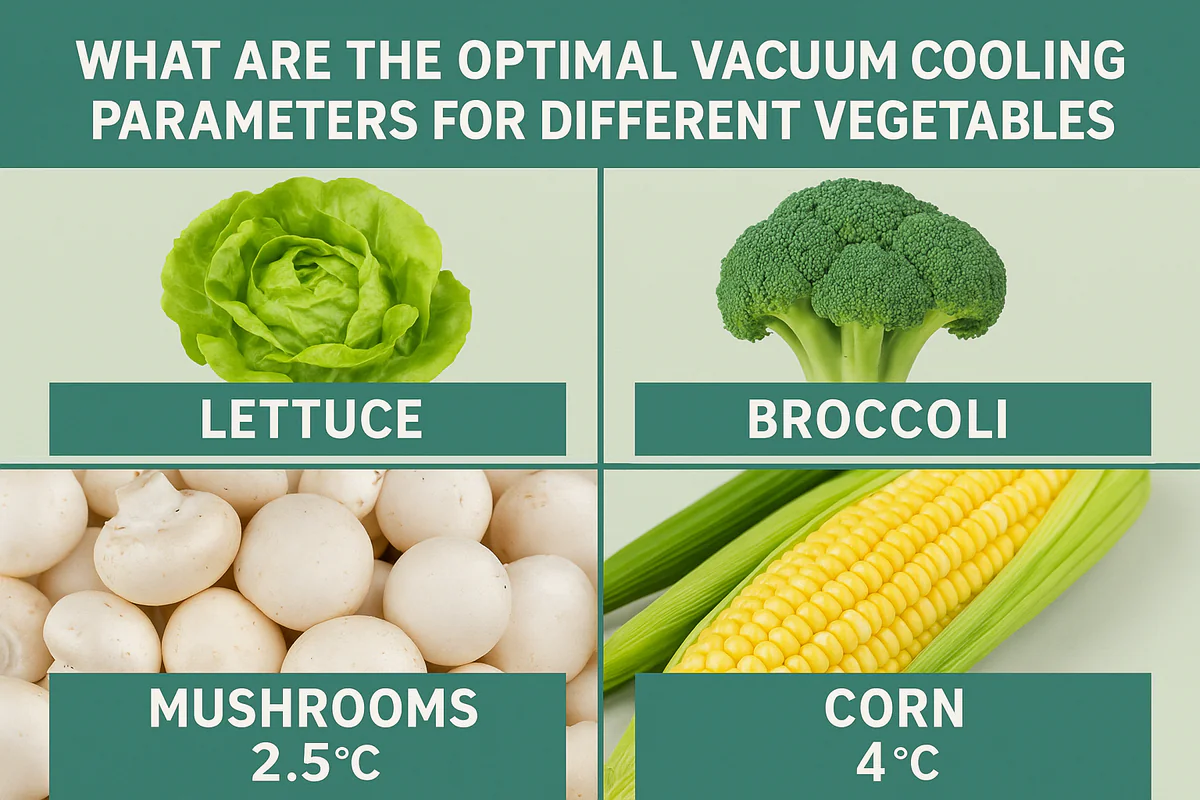

What Are the Optimal Vacuum Cooling Parameters for Different Vegetables?

You’ve harvested beautiful produce, from crisp lettuce to delicate mushrooms. But using a "one-size-fits-all" setting on your vacuum cooler feels

How Can You Reduce the Energy Costs of Your Vacuum Cooler?

Your vacuum cooler is a powerhouse of productivity, but your monthly electricity bill is climbing. You’re starting to wonder if

How Can You Keep Your Vacuum Cooler Running Flawlessly?

Your vacuum cooler is a vital asset, but you’re worried about unexpected breakdowns during peak season. Neglecting maintenance feels like

Who Are the Top Vacuum Cooler Manufacturers for Vegetables?

Searching for a list of top vacuum cooler brands can be overwhelming. You’re not just buying a machine; you’re investing

ROI Analysis: Is a Vacuum Cooler Worth the Investment for Your Farm?

You see the high upfront cost of a vacuum cooler and hesitate. But slow cooling methods and post-harvest losses are

What Defines the Best Commercial Vacuum Cooler for Your Vegetable Processing Facility?

Choosing the right equipment is a huge decision. A slow or unreliable cooler can ruin your harvest’s quality, hurt your