How Can Bakery Vacuum Cooling Machines Double Your Production Capacity?

You have a problem that most business owners dream of: you have too many orders. Your ovens are running hot, your staff is working overtime, but you still cannot produce enough bread to satisfy your customers. You think the only solution is to build a bigger factory or buy more ovens.

A vacuum cooling machine is the fastest way to increase production capacity without expanding your building. By reducing cooling times from hours to minutes, it clears bottlenecks, frees up floor space for more production equipment, and allows your existing ovens to run more cycles per shift.

When I talk to clients like Carlos, who runs a massive operation in Mexico, he often tells me, "Mila, I need to knock down a wall to fit another oven." I tell him to wait. I tell him that his problem is not his ovens. His problem is the traffic jam happening after the ovens. If you cannot cool the bread fast enough, you cannot bake more bread. It is that simple. Today, I want to explain how a vacuum cooler is not just a cooling machine—it is a capacity multiplier.

Is Your Cooling Room the Real Bottleneck in Your Production Line?

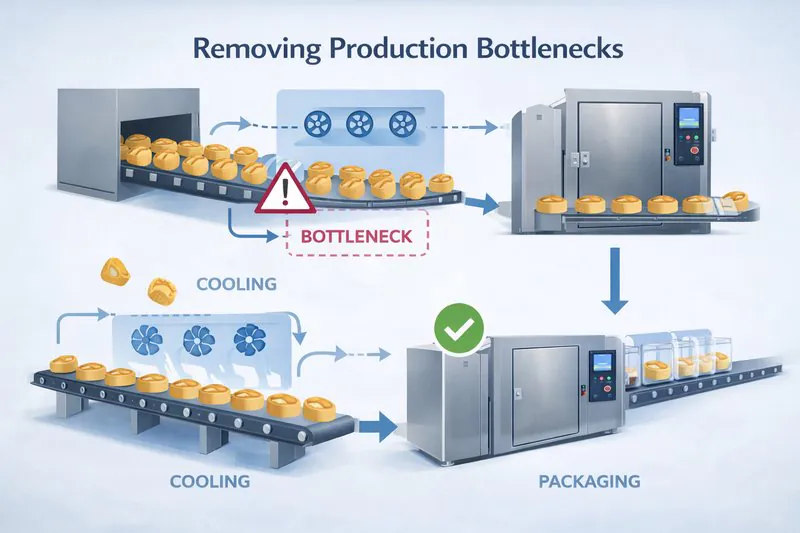

Your ovens are fast. Your mixers are fast. But once the bread is baked, everything stops. The bread sits on racks for two hours. This "waiting room" blocks your entire production flow and dictates how many batches you can bake in a day.

Vacuum cooling removes this blockage instantly. By cooling bread in 5 to 8 minutes instead of 120 minutes, you create a continuous flow. This allows your ovens to keep baking until the very end of the shift, significantly increasing your daily output.

The Mathematics of Oven Utilization

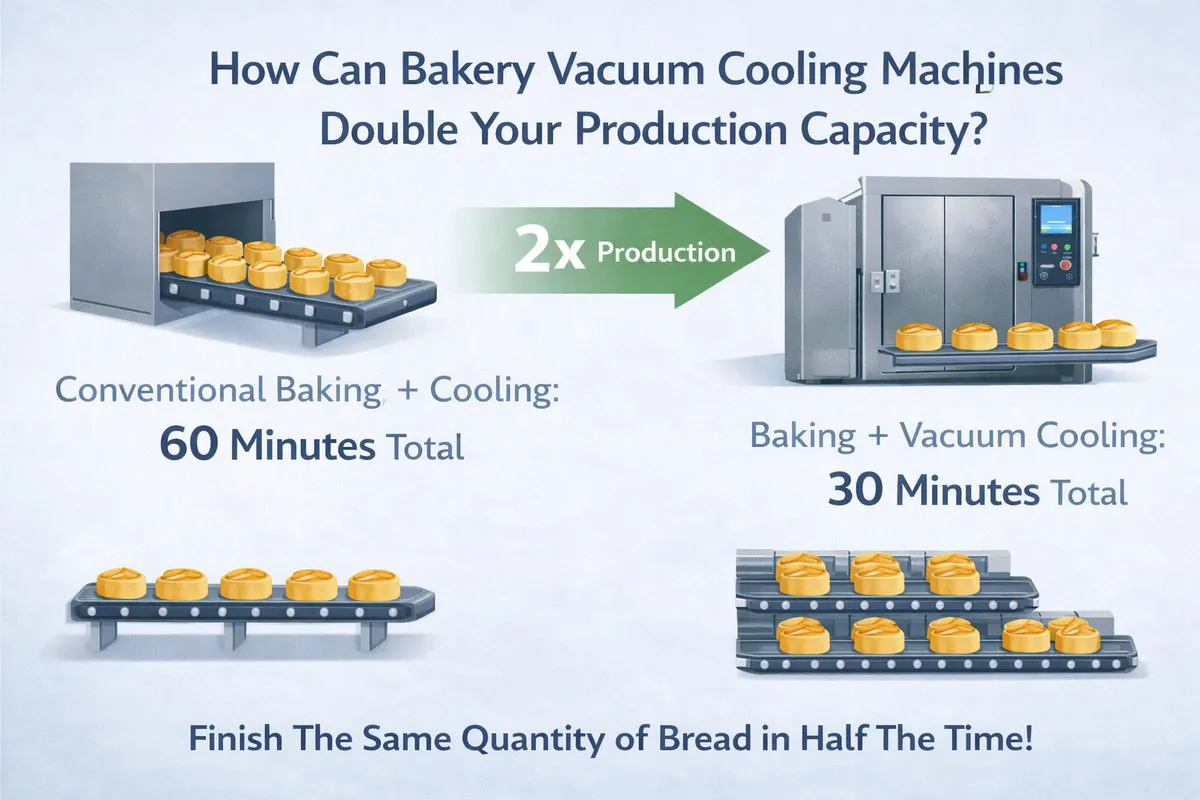

Let’s look at this with a critical eye. Many bakery owners, like Norman from the USA, focus strictly on "Baking Time." They think if they can bake faster, they produce more. But they forget about "Total Process Time1."

In a traditional bakery, the cooling process dictates the schedule.

Imagine you have an 8-hour shift.

- The Old Way: Your bread takes 2 hours to cool naturally. This means you must stop baking 2 hours before the packing shift ends, or 2 hours before the delivery trucks leave. If the trucks leave at 5:00 PM, your ovens must stop at 3:00 PM. Your expensive ovens sit idle for 25% of the workday. That is lost capacity.

- The Allcold Way: Our vacuum cooler brings the temperature down in roughly 5 minutes. You can keep baking until 4:45 PM. The bread will be cool, sliced, and packed by 5:00 PM.

By simply switching the cooling method, you have gained nearly 2 extra hours of baking time every single day. You did not buy a new oven. You did not hire more bakers. You simply reclaimed the time you were previously wasting on waiting.

Furthermore, consider the "Rack Traffic Jam." In a traditional system, if you run out of empty racks because they are all holding cooling bread, you have to stop the ovens. You literally cannot unload the next batch. Vacuum cooling cycles the racks so fast that they are emptied and returned to the production line almost immediately. You never have to stop the oven because you ran out of trolleys.

| Efficiency Metric | Traditional Air Cooling | Allcold Vacuum Cooling2 |

|---|---|---|

| Cooling Time | 90 – 120 Minutes | 3 – 8 Minutes |

| Oven Stop Time | 2 Hours before shift end | 15 Minutes before shift end |

| Rack Turnover | 1 cycle per 3 hours | 1 cycle per 20 minutes |

| Oven Utilization | ~75% | ~98% |

| Daily Capacity | Limited by cooling space | Limited only by oven speed |

Can You Increase Capacity Without Building a New Factory?

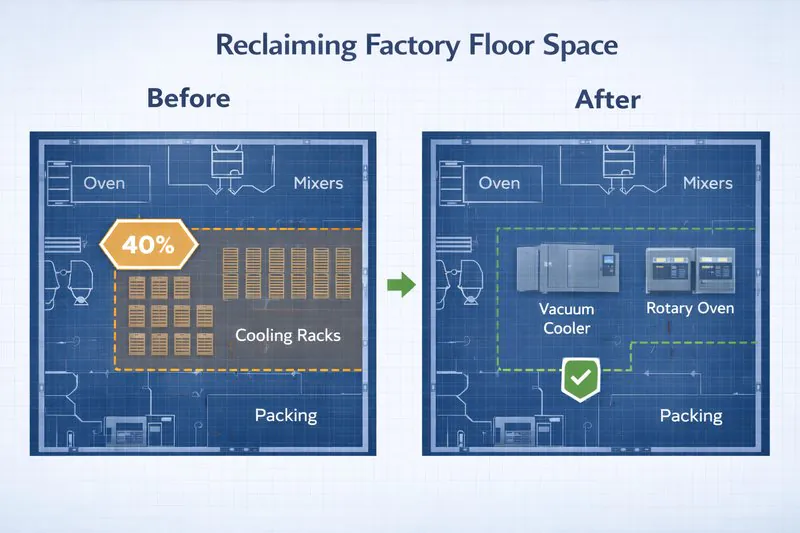

Real estate costs are rising everywhere. Whether you are in Singapore like Sophia or in a growing industrial zone in China, space is expensive. You might feel you have "maxed out" your current square footage, but you are likely just using it poorly.

Vacuum cooling machines have a tiny footprint compared to cooling rooms. By replacing 50 racks of cooling bread with one compact machine, you reclaim up to 80% of your floor space. You can fill this space with more production equipment to double your volume.

The "Phantom Factory3" Within Your Walls

I call this the concept of the "Phantom Factory." You already have the space for a bigger factory; it is just hiding underneath your cooling racks.

Let’s analyze the space requirements for a medium-to-large bakery producing 1,000 loaves per hour.

- The Space Trap: To cool 1,000 loaves naturally, you need them to sit for 2 hours. That means at any given moment, you have 2,000 loaves sitting on the floor. That requires about 20 to 30 trolleys. You need space for the trolleys, space between them for airflow, and walking paths for the bakers. This can easily consume 50 to 80 square meters of high-hygiene, climate-controlled floor space4.

- The Space Solution: An Allcold vacuum cooler5 that handles 4 racks per cycle (cooling 1,000 loaves roughly every 15-20 minutes) takes up about 10 to 12 square meters.

What can you do with an extra 40 to 60 square meters?

- Add More Ovens: You can install two additional rotary rack ovens in that reclaimed space. This instantly increases your baking capacity6 by 100% or more, without renting a new building.

- Expand Prep Areas: You can add another dough make-up line or more mixers.

- Improve Logistics: You can create a proper staging area for packing, reducing errors and speeding up dispatch.

For Sophia in Singapore, this was the deciding factor. She literally could not rent a bigger space. Her kitchen was in a dense urban center. By installing our machine, she doubled her output in the exact same room. She converted low-value "storage space" (cooling) into high-value "production space" (baking).

| Resource Factor | Traditional Cooling Room | Vacuum Cooling System |

|---|---|---|

| Space Required | 50 – 100 sq. meters | 8 – 15 sq. meters |

| Space Usage | Passive Storage (Low Value) | Active Processing (High Value) |

| Expansion Potential | Low (Must move buildings) | High (Add equipment in saved space) |

| Cost of Space | High monthly rent for "air" | One-time equipment purchase |

Does Faster Turnover Mean You Need Fewer Racks and Trays?

It is a headache to manage hundreds of trolleys and thousands of baking trays. They get damaged, they need washing, and they cost a lot of money to buy. You might think increasing capacity means buying more of them.

Actually, you need fewer. Because vacuum cooling recycles your racks back to the start of the line 10 times faster, you can produce double the volume with half the number of trolleys. This saves capital and reduces maintenance labor.

The Velocity of Equipment

Capacity is not just about space and ovens; it is about the "velocity" of your assets. How fast does a dollar invested in a stainless steel trolley return to you?

In a traditional bakery, a trolley has a slow life.

- It is loaded with dough.

- It goes into the oven.

- It sits in a cooling room for 2 hours7.

- It is unloaded at packaging.

- It goes to washing.

- It returns to the dough station.

That 2-hour wait is "dead time" for your equipment. To keep production moving while those trolleys are stuck in the "waiting room," you have to buy more trolleys to feed the ovens. You end up with a massive inventory of metal on wheels.

With vacuum cooling, the cycle changes.

- It is loaded.

- It goes into the oven.

- It is cooled in 5 minutes8.

- It is unloaded.

- It is washed and ready for dough again in 15 minutes.

This increased velocity allows for two strategies:

- The "Lean" Strategy: You can run a high-capacity bakery with a very small fleet of trolleys. This drastically lowers your startup costs and your replacement costs.

- The "Volume" Strategy: If you already have a lot of trolleys, you can push them through the system much harder. You never encounter the problem of "we are waiting for clean racks." The racks are always available.

For a buyer like Norman, who watches his budget carefully, this is a key insight. He realizes that the cost of the vacuum cooler is partially offset by the money he saves not buying 50 extra stainless steel trolleys and 500 extra baking trays. He is buying speed, and speed saves money on hardware.

| Equipment Metric | Slow Rotation (Air Cool) | Fast Rotation (Vacuum Cool) |

|---|---|---|

| Cycle Time per Rack | ~3 – 4 Hours | ~1 Hour |

| Racks Needed | High Inventory (e.g., 100) | Low Inventory (e.g., 30) |

| Wear and Tear | High (more handling/storage) | Low (controlled movement) |

| Washing Logic | Large batches, large space | Continuous flow, small space |

| Capital Tied Up | High investment in metal | Investment shifts to technology |

Conclusion

Increasing your production capacity does not always mean building a bigger factory. It means removing the barriers that slow you down. By replacing the slow, passive process of air cooling with the active, rapid speed of vacuum cooling, you unlock the true potential of the ovens and floor space you already own.

-

Understanding Total Process Time can help bakery owners optimize their operations and increase productivity. ↩

-

Exploring Vacuum Cooling can reveal innovative methods to enhance baking efficiency and reduce idle time. ↩

-

Explore this concept to understand how to maximize your bakery’s space and efficiency. ↩

-

Understand the critical role of hygiene and climate control in ensuring product quality and safety. ↩

-

Learn how this innovative cooling solution can significantly enhance your production capacity. ↩

-

Discover strategies to boost your bakery’s output effectively without the need for more space. ↩

-

Understanding cooling time can help optimize bakery operations and reduce costs. ↩

-

Explore how vacuum cooling technology can significantly enhance production efficiency. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy