How Can You Add Days of Vase Life to Your Cut Flowers?

Your beautiful roses look perfect at harvest, but wilt before they even reach the florist. This lost inventory kills your profit and reputation, turning a beautiful product into a frustrating loss.

Vacuum cooling adds days to vase life by rapidly removing field heat in 15-25 minutes. This process stops respiration, reduces water loss, and prevents wilting, ensuring flowers arrive at market in peak condition and stay fresh longer for the end customer.

I’ve had the pleasure of visiting flower farms in places like Colombia and the Netherlands. The dedication to growing a perfect bloom is incredible. But I’ve also seen the panic that sets in after harvest. The race against time begins, and it’s a race that biology and heat are designed to win. Our technology is designed to press the "pause" button on that race, giving growers the control they need to turn their beautiful harvest into a profitable one.

Why Do Cut Flowers Wilt So Quickly After Harvest?

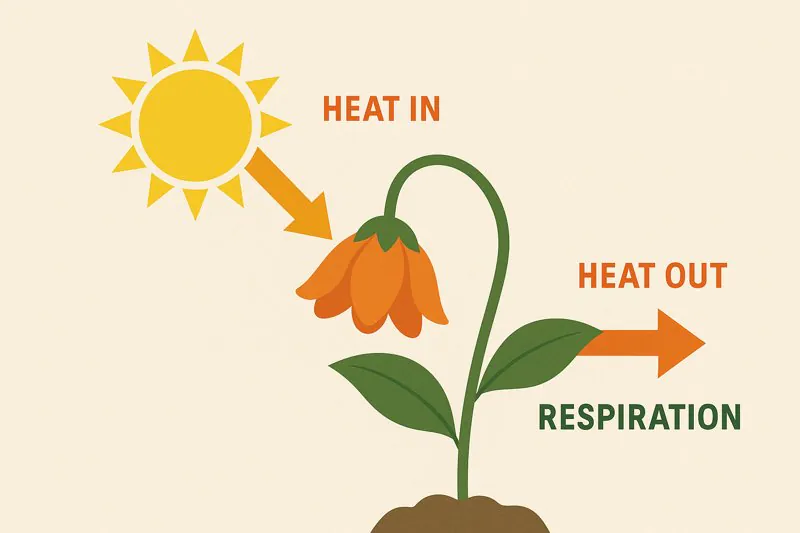

Cut flowers look alive, but they are fighting a losing battle. Their own metabolic processes produce heat that causes them to wilt, open too early, and decay from the inside out.

Flowers wilt quickly due to high respiration rates and water loss (transpiration), which accelerate after cutting. Trapped field heat from the sun dramatically speeds up these processes, causing petals to lose turgidity, droop, and decay before they can be sold.

The Twin Enemies: Respiration and Transpiration

When you cut a flower, you separate it from its life source of water and nutrients. However, the flower is still very much alive. It continues to perform two key processes. First is respiration1: the flower consumes its own stored sugars to stay alive, and this process generates internal heat. Second is transpiration2: it loses water vapor through tiny pores on its leaves and petals, especially when it’s warm. The "field heat" it holds from the sun acts as an accelerator for both of these destructive processes. Together, they create a vicious cycle: heat causes water loss, and respiratory heat adds to the problem, causing even faster water loss. This leads to a loss of "turgor," which is the internal water pressure that keeps petals firm and stems upright. The result is a wilted, drooping flower with a drastically shortened vase life.

A large-scale farm owner like Carlos knows this all too well. He can have a perfect field of carnations, but if they sit for even a few hours before cooling, their quality plummets. Simply placing boxes of flowers into a large cold room isn’t an effective solution. The cardboard boxes are excellent insulators, and the dense flowers continue to generate their own heat. It can take 12 to 24 hours for the flowers in the center of the pallet to cool down, by which time significant damage has already been done.

| Cooling Method | Cooling Time (Center of Pallet) | Respiration Rate During Cooling | Vase Life Impact |

|---|---|---|---|

| No Cooling | Never cools | Extremely High | Very Negative |

| Standard Cold Room | 12 – 24 hours | High, then slowly drops | Negative |

| ALLCOLD Vacuum Cooling | 15 – 25 minutes | Halted almost instantly | Very Positive |

How Does Vacuum Cooling "Pause" the Aging Process in Flowers?

You can’t stop time, but you can dramatically slow it down for your flowers. Traditional cooling is too slow, letting them age rapidly before they are even shipped, reducing their final value.

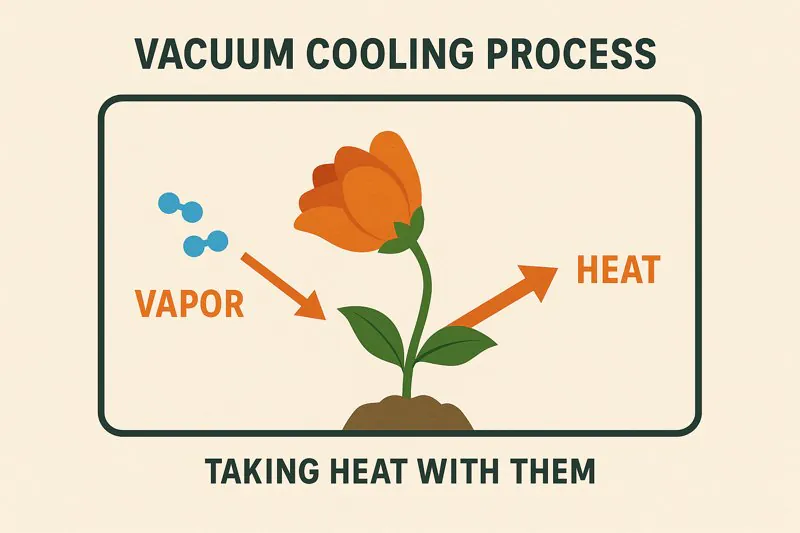

Vacuum cooling "pauses" aging by using a deep vacuum to force water to evaporate from the petals at a low temperature. This rapid evaporative cooling drops the flower’s core temperature instantly, halting respiration and metabolism almost completely.

From Field Heat to Hibernation in Minutes

The principle behind vacuum cooling3 is elegant physics. We place the boxes of harvested flowers into our sealed chamber and start the vacuum pump. As the air pressure drops, the boiling point of water also drops. At a very deep vacuum, water will boil at just 2-3°C (35-37°F). This doesn’t mean the flowers are being cooked; they are being cooled. The moisture on the surface of the countless petals begins to evaporate, or "flash off." This phase change from liquid to gas requires a huge amount of energy, and it draws this energy in the form of heat directly from the flower itself.

Because this happens to every flower in every box at the same time, the entire pallet load is cooled with incredible speed and uniformity. The process essentially puts the flower into a state of metabolic hibernation4. The respiration rate drops to almost zero. Transpiration stops. The biological clock that was ticking down rapidly is paused. By achieving this state in 20 minutes instead of 20 hours, we preserve the flower’s stored energy and moisture. This gives the flower a much larger reserve of life to draw upon later, which directly translates to a longer vase life for the final consumer. It turns a highly perishable product into a stable and manageable one.

| Metric | Slow Cooling in a Cold Room | ALLCOLD Vacuum Cooling |

|---|---|---|

| Physiological State | Active aging, slow decline | Hibernation / Metabolic stasis |

| Stored Sugar/Energy | Consumed rapidly during cooling | Preserved for later vase life |

| Cooling Principle | Slow heat transfer (conduction) | Rapid evaporative cooling |

| Result | A flower that is cold but "older" | A flower that is cold and "paused" |

Can Rapid Cooling Prevent Petal Damage and Preserve Color?

Shipping can be rough on delicate flowers, causing bruised petals and faded colors. Slow cooling makes them even more fragile, leading to significant damage and financial losses during transit and handling.

Yes, rapid cooling preserves quality by locking in turgidity, making petals firmer and more resistant to physical damage during packing and shipping. By halting decay processes, it also prevents color fading and keeps flowers looking vibrant.

More Than Just Cool: Stronger Petals and Brighter Colors

A professional buyer like Norman, who sources flowers for major retailers, is extremely sensitive to quality. He can’t accept shipments with bruised petals, faded colors, or the beginnings of mold. The physical condition of the flower upon arrival is critical. When flowers lose turgor pressure due to slow cooling and water loss, their cells become flaccid. This makes the petals soft, weak, and extremely susceptible to bruising and tearing during the bumps and jostles of transportation.

Vacuum cooling5 directly addresses this by maintaining maximum turgor. The rapid cooling locks in the water, keeping the cell walls fully inflated and rigid. A vacuum-cooled flower is physically stronger and more resilient than a slow-cooled one. Furthermore, the slow cooling process in a damp cold room creates the perfect breeding ground for Botrytis6, or gray mold, a devastating fungal disease. Vacuum cooling, being a fast and relatively dry process, creates an environment hostile to mold growth. It also preserves color. The vibrant colors of a rose or lily are pigments that degrade as the flower ages. By putting the flower into hibernation, vacuum cooling effectively stops this degradation, ensuring the colors remain bright and vivid all the way to the retail vase. It delivers a visually superior product that commands a premium price.

| Quality Factor | Slow Cooling | ALLCOLD Vacuum Cooling |

|---|---|---|

| Petal Firmness (Turgor) | Low (soft, fragile petals) | High (firm, resilient petals) |

| Risk of Botrytis (Mold) | High | Very Low |

| Color Vibrancy | Prone to fading | Preserved, remains bright |

| Physical Damage Resistance | Low | High |

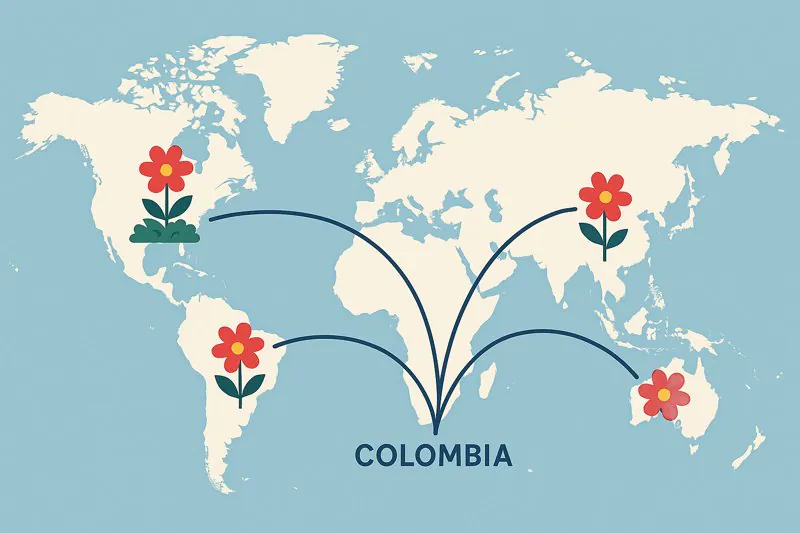

How Does Pre-Cooling Revolutionize Flower Logistics and Market Access?

Your farm’s location limits your reach. You can only sell to customers you can reach quickly before your flowers wilt. You dream of supplying more lucrative markets in distant cities or other countries, but the transport time is just too long.

Pre-cooling revolutionizes logistics by ensuring flowers are loaded onto trucks or planes already at their ideal cold-chain temperature. This dramatically reduces spoilage during transit and allows growers to confidently ship to more distant and profitable international markets.

Breaking Down Geographic Barriers

The success of the global flower trade depends entirely on mastering the cold chain. The cold chain starts on the farm. Loading pallets of warm flowers into a refrigerated truck is the most common and costly mistake in the industry. The truck’s reefer unit is designed only to maintain a temperature, not to remove the massive amount of field heat from an entire load. The reefer will run constantly, burn excess fuel, and still fail to cool the flowers in the center of the load. This leads to massive spoilage and rejected shipments.

Vacuum cooling7 is the tool that perfects the first, most critical link of the cold chain8. By pre-cooling the flowers to a stable 2-3°C before they are loaded, you are putting a "hibernating," stable product onto the truck. The reefer unit can now easily and efficiently maintain the temperature. This reliability is everything. It means a grower like Carlos in Mexico or Colombia can now compete on the global stage. He can confidently ship his flowers to buyers like Norman in the United States or Sophia in Singapore, knowing they will arrive in the same pristine condition they were in at harvest. It transforms a local farm into a global exporter. This technology breaks down the barriers of distance, opening up new, more profitable markets that were previously unreachable.

Conclusion

For the floriculture industry, vacuum cooling is a transformative technology. It extends vase life, protects quality, and unlocks global markets, turning perishable beauty into a stable, highly profitable, and globally competitive business.

-

Understanding respiration in plants is crucial for maintaining their health and longevity, especially in cut flowers. ↩

-

Exploring transpiration helps you grasp its role in plant health and how to manage it for better flower preservation. ↩

-

Explore this link to understand the science behind vacuum cooling and its benefits for preserving flowers. ↩

-

Learn about metabolic hibernation and how it helps extend the life of flowers, ensuring freshness for consumers. ↩

-

Explore how vacuum cooling enhances flower quality, ensuring stronger petals and vibrant colors for a premium product. ↩

-

Learn effective strategies to combat Botrytis, ensuring your flowers arrive in pristine condition without mold. ↩

-

Exploring vacuum cooling can provide insights into innovative techniques that enhance flower preservation and reduce spoilage. ↩

-

Understanding the cold chain is crucial for anyone involved in the flower trade, as it directly impacts product quality and profitability. ↩

Mila

You May Also Like

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But