How Can You Master Vacuum Cooling for Leafy Greens to Maximize Quality and Profit?

You grow beautiful, vibrant leafy greens, but you know the invisible enemy is time. From the moment of harvest, the cold chain clock is ticking, and every hour of field heat causes your profits to wilt away through spoilage and reduced shelf life.

The key to mastering vacuum cooling for leafy greens is a three-part process: proper pre-cooling preparation, optimized cycle settings for different green varieties, and leveraging the results to streamline your entire logistics chain. This lets you get from 30°C to 2°C in under 25 minutes.

This is where theory meets reality. I’ve visited dozens of farms and packing houses, and the story is often the same. I remember speaking with a large-scale grower in Salinas, California. He had invested in a competitor’s vacuum cooler but was getting inconsistent results. Some pallets were perfect, while others had "hot spots" deep inside. He was frustrated. We walked his line, and I saw the issue wasn’t the machine itself, but the process around it. His team was harvesting in the afternoon heat and packing the pallets too tightly. They were asking the machine to do all the work. It’s like trying to run a marathon without stretching first. True mastery isn’t about just owning the equipment; it’s about building a finely-tuned system around it. By implementing a few key best practices, we transformed his operation, demonstrating that the right process is just as important as the right machine.

What Are the Critical Steps Before Pressing ‘Start’?

You might think the cooling process begins when you close the chamber door. But you worry that mistakes made earlier in the chain could be sabotaging your results, leading to uneven cooling and lost quality before the machine even starts its work.

Your success is determined before the cycle begins. Best practices demand harvesting in the cool early morning, ensuring pallets are packed uniformly, and most importantly, pre-wetting the product to enable efficient and even heat removal.

Preparation is 90% of the Success

I can’t stress this enough to my clients, especially hands-on farm owners like Carlos in Mexico. The vacuum cooler1 is incredibly powerful, but it’s not a magic box. It works by amplifying the principles of physics, and you can help it work more efficiently. Think of it as preparing a patient for surgery; the preparation is as critical as the procedure itself. We need to give the machine the best possible starting conditions to deliver the best possible results. Every degree of field heat2 you remove naturally is a degree your machine doesn’t have to work to remove, saving you time, energy, and money.

Harvest Timing and Handling

The sun is your enemy. Field heat is the biggest variable we fight against. A head of lettuce harvested at 30°C in the afternoon requires significantly more energy to cool than one harvested at 18°C in the early morning. I always advise my clients to adjust their harvest schedules to bring in crops during the coolest parts of the day. Furthermore, how the product is handled and packed is crucial. Pallets should be stacked uniformly, without being packed too tightly. You want to allow pathways for the water vapor to escape from the center of the pallet. Overly dense packing creates a barrier and can lead to the very "hot spots" my client in California was experiencing. This level of detail in process control is something a quality-focused buyer like Norman looks for in his suppliers.

The Game-Changer: Pre-Wetting (Hydro-Vac)3

This is the most important single best practice. Some growers are afraid to add water, thinking it will promote rot. The opposite is true. Pre-wetting involves misting the pallet with a small amount of clean, cool water just before it enters the chamber. This added water acts as "sacrificial" moisture. When the vacuum is applied, this free water on the surface evaporates first, providing a powerful initial cooling effect and protecting the vegetable’s own internal moisture. It ensures the cooling starts evenly across the entire surface of every leaf.

| Practice | Why It’s Critical | Bad Practice Example |

|---|---|---|

| Early Harvest | Reduces initial field heat, saving energy and time. | Harvesting at 2 PM when field heat is 30°C+. |

| Uniform Packing | Ensures even airflow and vapor escape from the pallet core. | Jamming produce tightly into boxes, creating dense spots. |

| Pre-Wetting | Provides "sacrificial" water for rapid, uniform cooling. | Putting a dry-harvested pallet directly into the cooler. |

| Minimize Wait Time | Reduces pre-cooling respiration and quality loss. | Leaving harvested pallets sitting on the dock for hours. |

How Do You Optimize the Cooling Cycle for Different Greens?

You produce a variety of leafy greens, from dense heads of iceberg to delicate baby spinach. You press the same button for all of them, but you suspect this "one-size-fits-all" approach is damaging your delicate products and not cooling your dense ones fast enough.

You must customize the cycle. Dense products like iceberg lettuce can handle a rapid pressure drop, while delicate greens like baby leaf spinach require a slower, more controlled pressure ramp ("soft-venting") to prevent cellular bruising and damage.

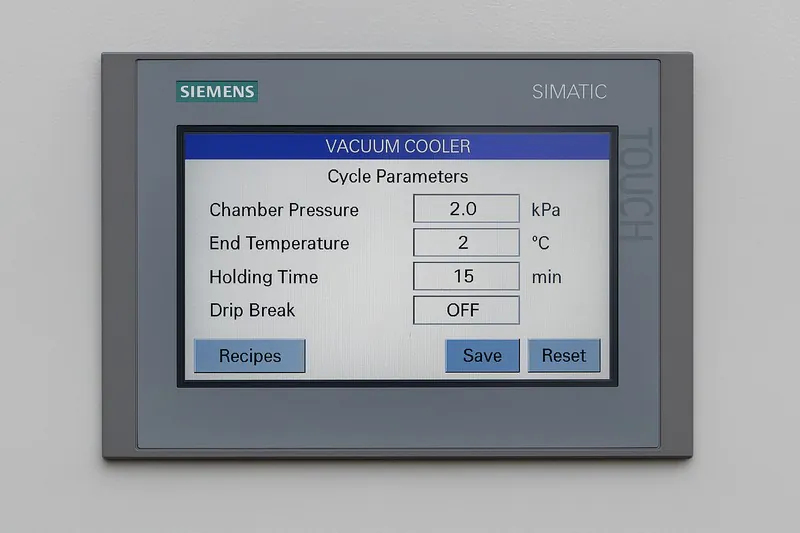

It’s All in the Controls

This is where a high-quality machine really differentiates itself. A basic vacuum cooler might only have an on/off switch for the pump. It’s a brute-force approach. But a modern, German-engineered system from a company like ours uses a sophisticated Siemens PLC4 and high-precision sensors. This gives you complete control over the cooling curve. For a technical manager like Sophia, who is responsible for a variety of sensitive food products, this level of control is non-negotiable. It allows her to create and save specific recipes for each product, ensuring consistent, repeatable results that meet her strict HACCP protocols5. It’s the difference between a blunt instrument and a surgical tool.

Matching the Cycle to the Product

The key variables you can control are the final pressure point (which determines the final temperature) and the speed at which you reach that pressure.

- For Dense Greens (Iceberg Lettuce): Iceberg is hardy and dense. Its structure can withstand a rapid drop in pressure. For these products, we can use an aggressive cycle, opening the vacuum valve fully to pull the pressure down as fast as possible. This minimizes the cycle time, maximizing throughput.

- For Moderate Greens (Romaine Lettuce): Romaine is less dense than iceberg but more robust than baby greens. It benefits from a slightly more moderate pressure ramp6. We might program the cycle to reach the target pressure over a few minutes, rather than all at once.

- For Delicate Greens (Baby Spinach, Arugula, Spring Mix): This is where finesse is required. If you pull a vacuum too quickly on these fragile leaves, you can cause them to freeze, bruise, or get physically damaged. For these, we use a "soft-venting7" or "ramp control" program. The PLC slowly opens the valve, gradually lowering the pressure over a longer period (e.g., 5-8 minutes) before the main cooling phase. This allows the vapor to escape gently, cooling the product without shocking it.

This level of customization ensures you get the fastest possible cooling for each product without sacrificing quality.

| Leafy Green Type | Key Characteristic | Recommended Cycle Strategy | Potential Risk w/ Wrong Cycle |

|---|---|---|---|

| Iceberg Lettuce | High density, robust structure | Rapid, aggressive pressure drop for maximum speed. | Minimal. |

| Romaine/Butter Lettuce | Medium density, leafy but structured | A moderate pressure ramp, balancing speed and care. | Minor bruising, potential for outer leaf damage. |

| Baby Spinach/Spring Mix | Very low density, highly fragile | Slow, gentle "soft-venting" to avoid cell damage. | Severe bruising, freezing, and product loss. |

| Cabbage (Green/Red) | Extremely high density | Requires hydro-vac and a long, powerful cycle. | Very poor core cooling, high-temperature differential. |

What Are the Measurable Results You Can Actually Expect?

You’ve heard the impressive claims: longer shelf life, better quality, less waste. But as a business owner, you need concrete numbers and data. You want to know what tangible, measurable results you will see in your own operation that justify the investment.

You can expect truly transformative results. This includes a 7-10 day extension in shelf life, holding product weight loss to under 2.5%, a dramatic reduction in bacterial load, and visibly superior color, crispness, and overall appearance.

The Data Doesn’t Lie

When I talk to bottom-line-focused clients like Carlos or quality-obsessed buyers like Norman, I move away from abstract benefits and focus on the hard data. The results of proper vacuum cooling are not subtle; they are dramatic and easily quantifiable. We are talking about changes that fundamentally impact your profitability, market access, and brand reputation. Let’s break down the comparison between vacuum cooling8 a pallet of lettuce in 25 minutes versus letting it sit in a traditional cold room for 10 hours.

Shelf Life and Financial Return9

This is the number one metric. By stopping respiration and enzymatic breakdown almost instantly, you aren’t just adding a day or two to the shelf life; you’re often doubling it. An extra 7-10 days of viability is a paradigm shift. It means less waste at the distribution center, less spoilage on the supermarket shelf, and a better experience for the end consumer. For Carlos, this meant he could start shipping his produce to more distant, higher-paying markets that were previously out of reach. That additional shelf life translated directly into a higher price per head of lettuce and access to entirely new revenue streams.

Quality, Safety, and Appearance10

For a procurement manager like Sophia, food safety is paramount. The temperature "danger zone" (4°C to 60°C) is where bacteria multiply fastest. A cold room brings produce through this zone over several hours. A vacuum cooler blasts through it in minutes. This immediate halt to bacterial growth11 is a critical control point for any HACCP plan. Furthermore, the minimal, controlled water loss (1% for every 5-6°C of cooling) results in what we call "nature’s shrink-wrap." It makes the outer leaves slightly more pliable and resistant to damage during packing, while the core remains crisp. The color stays vibrant, and the texture remains firm. A slow-cooled product, by contrast, loses more weight through uncontrolled respiration, leading to a wilted, less appealing appearance.

| Metric | Vacuum Cooling (25 Minutes) | Forced-Air Cold Room (10 Hours) |

|---|---|---|

| Time to Reach 2°C Core Temp | Less than 25 minutes | 8 – 12 hours |

| Temperature Uniformity | Excellent (Core and surface are nearly identical) | Poor (Core remains warm for hours) |

| Shelf Life Extension | +7 to 10 days | Baseline |

| Typical Weight Loss | 1.5% – 2.5% (Controlled) | 3% – 8% (Uncontrolled Respiration) |

| Bacterial Growth During Cooling | Negligible | Significant |

| Visual Appearance After 5 Days | Crisp, vibrant green, firm | Noticeable wilting, browning edges |

Conclusion

Mastering vacuum cooling for leafy greens is about creating a total system. It starts with smart harvesting and packing, moves to precise machine control, and results in numbers that transform your business’s logistics, quality, and profitability.

-

Understanding vacuum coolers can enhance your cooling efficiency and save resources in your operations. ↩

-

Learn about field heat’s impact on crop quality and cooling strategies to optimize your harvest. ↩

-

Discover how Pre-Wetting can revolutionize your cooling process and improve produce quality. ↩

-

Explore how Siemens PLC technology enhances precision and control in industrial applications. ↩

-

Learn about HACCP protocols to understand their critical role in ensuring food safety and quality. ↩

-

Understand the significance of pressure ramp techniques in optimizing cooling processes for various food types. ↩

-

Discover the benefits of soft-venting in preserving the quality of delicate food products. ↩

-

Discover the science behind vacuum cooling and its advantages over traditional cooling methods. ↩

-

Explore how extending shelf life can significantly reduce waste and increase profitability in food distribution. ↩

-

Learn about the critical role of vacuum cooling in enhancing food safety and maintaining quality during storage. ↩

-

Understand how temperature control can prevent bacterial growth and ensure food safety. ↩

Mila

You May Also Like

How Does Vacuum Cooling Forge the Strongest Link in Your Vegetable Cold Chain?

You work tirelessly to grow perfect, healthy vegetables. Yet, you know that from the moment of harvest, an invisible clock

Small-Scale vs. Large-Scale Vacuum Cooler: How Do You Choose the Right Fit?

You’re convinced that vacuum cooling is the key to elevating your product quality, but now you face a critical decision.

Which Vegetables Benefit Most from Vacuum Cooling Technology?

You see the promise of rapid cooling, extended shelf life, and superior quality, but you’re unsure if this technology is

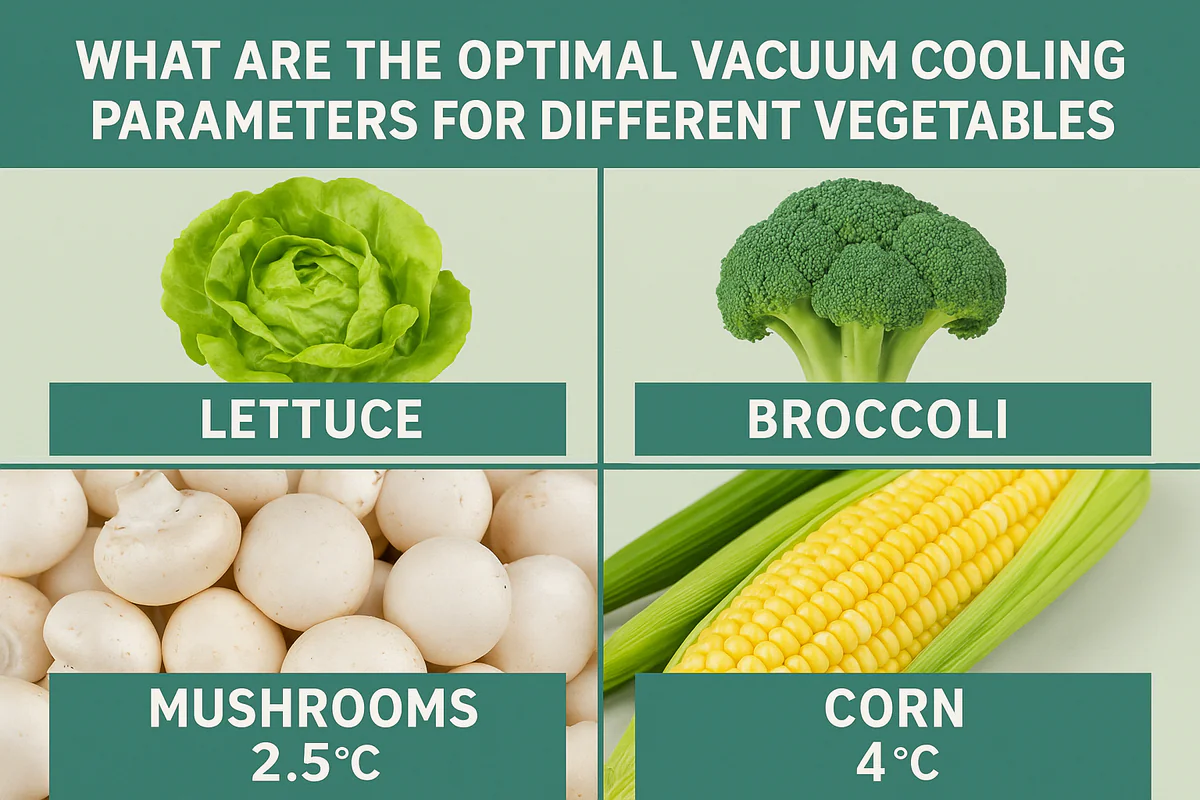

What Are the Optimal Vacuum Cooling Parameters for Different Vegetables?

You’ve harvested beautiful produce, from crisp lettuce to delicate mushrooms. But using a "one-size-fits-all" setting on your vacuum cooler feels

How Can You Reduce the Energy Costs of Your Vacuum Cooler?

Your vacuum cooler is a powerhouse of productivity, but your monthly electricity bill is climbing. You’re starting to wonder if

How Can You Keep Your Vacuum Cooler Running Flawlessly?

Your vacuum cooler is a vital asset, but you’re worried about unexpected breakdowns during peak season. Neglecting maintenance feels like

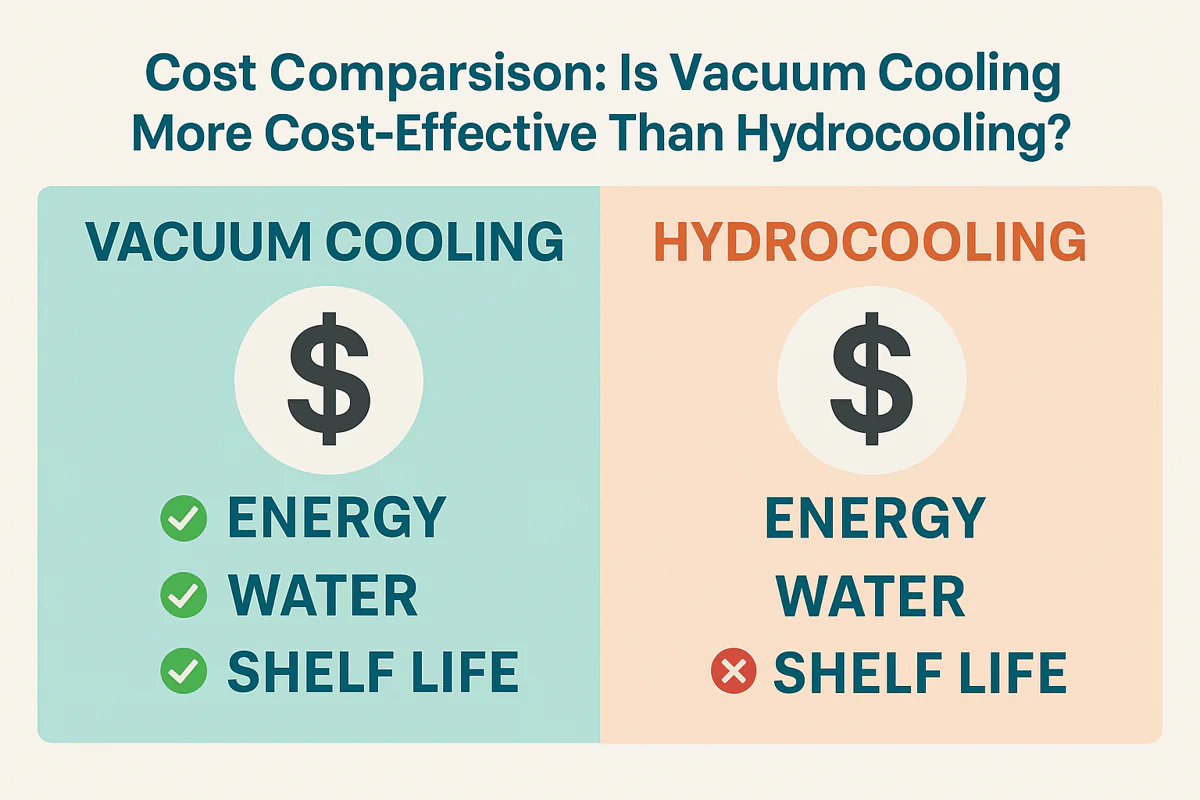

Cost Comparison: Is Vacuum Cooling More Cost-Effective Than Hydrocooling?

Choosing between cooling technologies feels like a high-stakes gamble. You need to lower your operational costs, but the wrong decision

Who Are the Top Vacuum Cooler Manufacturers for Vegetables?

Searching for a list of top vacuum cooler brands can be overwhelming. You’re not just buying a machine; you’re investing

ROI Analysis: Is a Vacuum Cooler Worth the Investment for Your Farm?

You see the high upfront cost of a vacuum cooler and hesitate. But slow cooling methods and post-harvest losses are

What Defines the Best Commercial Vacuum Cooler for Your Vegetable Processing Facility?

Choosing the right equipment is a huge decision. A slow or unreliable cooler can ruin your harvest’s quality, hurt your