How Can You Maximize Your Cooler's Daily Throughput?

Your new vacuum cooler is a beast, cooling pallets in under 30 minutes. But between cycles, it sits idle while your team scrambles to load and unload, creating a bottleneck that caps your daily output.

You maximize throughput not by running the cooling cycle faster, but by optimizing the entire workflow around it. This involves strategic palletizing, smart batching, and streamlined loading systems to slash the machine’s downtime between batches.

The 25-minute cooling cycle is only one part of the equation. If it takes 20 minutes to unload the cold pallet and load the next warm one, your machine is only working half the time. That’s a huge loss of potential. Let’s dive into the practical strategies that will turn your vacuum cooler into a non-stop engine of productivity.

How Does Pallet Stacking Affect Cooling Time?

You want to get as much product into each cycle as possible, so you pack the pallets tightly. But then you find frustrating "hot spots" in the middle of the load, forcing you to run the cycle again.

Tight stacking blocks the vacuum’s path. Air and water vapor must flow freely through the boxes for uniform cooling. Leaving strategic air gaps is more important than packing a few extra boxes in.

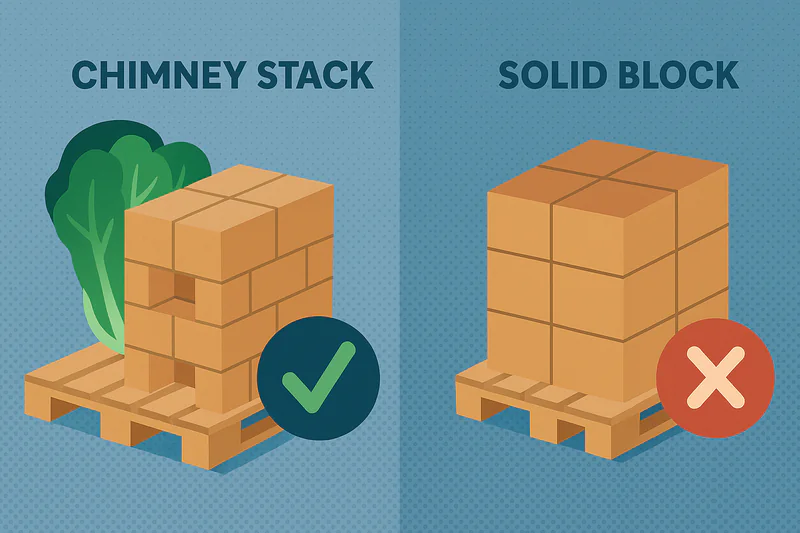

Think of the vacuum process as a powerful force that needs to reach every single vegetable. If you create a solid, dense wall of boxes, that force can only touch the outside. The vegetables in the center will be shielded, their field heat remaining trapped. I visited a client in California last year who was struggling with this exact issue. Their outer boxes were perfectly chilled to 2°C, but the inner boxes were still at 15°C. The problem wasn’t the machine; it was the stacking. Vacuum cooling works by making water evaporate, and that water vapor needs a path to escape. By arranging your boxes in a "chimney stack" pattern or simply leaving a few inches of space between columns, you create channels for this vapor to flow out freely. This allows the vacuum to pull heat evenly from the entire load. This means a faster, more reliable cycle and eliminates the risk of a partially cooled pallet—a huge red flag for a professional buyer like Norman, who expects absolute consistency. Failing a batch due to poor stacking doesn’t just cost electricity; it costs labor to unstack, re-cool, and disrupts your entire day’s shipping schedule.

Good Stacking vs. Bad Stacking

| Stacking Method | Airflow & Vacuum Path | Cooling Speed & Uniformity | Spoilage Risk | Key Action |

|---|---|---|---|---|

| Bad: Solid Block | Blocked, inefficient. | Slow. Poor uniformity (hot core). | High. | AVOID |

| Good: Chimney Stack1 | Excellent flow. | Fast. Excellent uniformity. | Low. | RECOMMENDED |

| Good: Columnar w/ Gaps2 | Very good flow. | Fast. Excellent uniformity. | Low. | RECOMMENDED |

Should You Mix Different Vegetables in the Same Batch?

You have half a load of spinach and half a load of broccoli ready to go. Running them together seems like the most efficient use of the machine’s capacity. But is it a good idea?

As a general rule, you should never mix vegetables with different structures in the same batch. Each requires a specific pressure and cycle time. Mixing them guarantees that one product will be improperly cooled or damaged.

This is one of the most common—and costly—mistakes I see new operators make. It goes beyond just density; it’s about the "moisture release rate." Leafy spinach has a massive surface area and releases its moisture almost instantly. It needs a gentle cycle with a final pressure around 7.0 mbar to prevent being frozen or damaged. Dense broccoli, however, holds heat and moisture deep in its stalk and requires a much stronger, longer cycle at around 5.0 mbar to be cooled properly. You physically cannot achieve both conditions in the same cycle. If you run the batch on the powerful "broccoli" setting, you’ll destroy the spinach. If you use the gentle "spinach" setting, the broccoli will be warm inside and fail quality control. You’ve tried to be efficient but have ended up compromising the quality and value of the entire load. For a large-scale farmer like Carlos, who harvests multiple crops daily, the best practice is to create separate staging areas: one for "delicates" and one for "denses." This simple organizational step prevents costly mixing mistakes and ensures every batch is perfect for demanding clients like a HACCP-certified kitchen manager Sophia.

The Compatibility Matrix

| Vegetable Combination | Compatibility | Reason | Who This Affects |

|---|---|---|---|

| Iceberg + Romaine Lettuce3 | Good | Similar structure, density, and moisture release rate. | Any user |

| Broccoli + Cauliflower4 | Good | Both are dense florets and require a strong, deep cool. | Carlos (farmer) |

| Spinach + Broccoli | Bad | Conflicting needs: delicate/fast vs. dense/slow cooling. | Sophia (kitchen) |

| Mushrooms + Cabbage | Bad | Conflicting needs: extremely fragile vs. sturdy and dense. | Norman (buyer) |

What’s the Fastest Way to Load and Unload?

The cooling cycle itself is incredibly fast. But the biggest time-waster is often the downtime between cycles, as forklifts carefully maneuver pallets in and out of the chamber, one at a time.

The absolute fastest method is a drive-through or conveyor system. This allows your team to stage the next batch while the current one is cooling, reducing the changeover time from 15 minutes to under 2.

A standard single-door cooler creates a stop-and-go workflow. The forklift loads, the door closes, the cycle runs, the door opens, the forklift unloads. That unload/load process can easily consume 10-15 minutes of machine downtime. But even if you can’t install a full drive-through system, you can still dramatically improve. The first step is creating a "pre-staging" area. Have the next pallet fully prepared and waiting on a pallet jack right at the cooler door. As soon as the cold pallet is removed, the warm one goes in. This simple step can cut changeover time by half. For high-volume operations like Carlos’s farm, upgrading to a two-door drive-through system with rails is a true game-changer. While Batch A is cooling, Batch B is on the rails, ready to go. The moment Batch A is pulled out, Batch B is pushed in. The entire exchange takes less than two minutes. Let’s quantify that: if you run 20 cycles a day and save 10 minutes per cycle, you gain 200 minutes—over 3 hours—of productive time. That’s like getting another 6-8 cooling cycles for free, boosting your daily capacity by 30-40% without buying a second machine.

Comparing Loading Systems

| Metric | Manual Forklift (1 Door) | Staged Pallet Jack (1 Door) | Drive-Through Rail System (2 Doors) |

|---|---|---|---|

| Unload/Load Time5 | 10-15 minutes | 5-7 minutes | < 2 minutes |

| Machine Downtime | High | Medium | Minimal |

| Typical Cycles/Hour | 1.5 – 2 | ~2 | 2.5+ |

| Operational Flow6 | Stop-and-Go | Improved Flow | Continuous Flow |

Should You Wait for a Full Load or Run Smaller Batches?

It’s the end of a long harvesting day. You have two pallets of high-value organic lettuce ready, but your vacuum cooler can hold eight. Do you wait for more, or run the machine half-empty?

You should run the smaller batch immediately. In post-harvest, we live by the "Golden Hour." The financial cost of produce deteriorating from field heat far exceeds the small energy cost of running a partial load.

The "Golden Hour" refers to that critical period right after harvesting where prompt removal of field heat has the maximum impact on final quality and shelf life. The damage from heat isn’t linear; it’s cumulative and gets worse the longer it sits. A head of lettuce at 25°C is respiring rapidly, burning through its stored sugars and moisture. This leads to wilting, weight loss, and a shortened shelf life. Let’s do the simple math. The electricity to run one cycle might cost a few dollars. Two pallets of premium organic lettuce could be worth over $1,000. If you let that lettuce sit warm for an extra hour just to wait for more product, you could easily lose 5-10% of its value due to quality degradation. That’s a $50-$100 loss to save $2 in electricity. It’s a terrible trade. A discerning buyer like Norman can spot the difference immediately. His quality control team will notice dullness or slight wilting, which can lead to price negotiations or even rejection of the shipment. Running a partial load feels inefficient, but it is always the correct business decision. Your vacuum cooler is an investment in quality preservation; use it to protect that quality immediately.

The Decision Checklist

| Question | Run Partial Load? | Why? |

|---|---|---|

| Is produce in the "Golden Hour7"? | Yes | Maximum impact on shelf life and value preservation. |

| Is the produce high-value8? | Yes | The risk of financial loss from quality decay is too high. |

| Is it the end of the day? | Yes | Letting produce sit warm overnight is a recipe for disaster. |

| Is the produce low-value & very sturdy? | Wait (with caution) | Only if you are confident it can handle the delay without loss. |

Conclusion

Maximizing your throughput is about smart workflow, not just raw power. By optimizing how you stack, batch, and load, you can transform your vacuum cooler into the fast and efficient heart of your operation.

-

Explore the advantages of Chimney Stacks for efficient airflow and cooling in food storage. ↩

-

Learn how Columnar stacking with gaps enhances cooling efficiency and reduces spoilage risk. ↩

-

Discover the advantages of this combination for salads and nutrition. ↩

-

Learn about the benefits of pairing these two nutrient-rich vegetables. ↩

-

Understanding Unload/Load Time can help optimize logistics and improve efficiency in operations. ↩

-

Exploring Operational Flow can reveal strategies to enhance productivity and streamline processes in your warehouse. ↩

-

Understanding the Golden Hour can significantly enhance your produce’s shelf life and quality. ↩

-

Exploring the significance of high-value produce can help you minimize financial losses and optimize your operations. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not