How Do You Choose the Right Vacuum Cooler Capacity and Performance for Your Bakery?

You are ready to invest in a vacuum cooler, but now you are looking at technical specification sheets. You see terms like "cycle capacity," "pumping speed," and "compressor HP." These numbers can be confusing, and you are worried about making a very expensive mistake.

Choosing the wrong machine is a serious risk. If it’s too small, you’ve just bought a new bottleneck that can’t keep up with your ovens. If it’s too big, you’ve wasted a huge amount of capital and valuable floor space. You need to get this decision right.

To choose the right vacuum cooler, you must first calculate your bakery’s peak hourly production weight to determine the required "Cycle Capacity." Then, you must ensure the machine’s performance—driven by the vacuum pump and refrigeration system—can achieve a "Cycle Time" that matches your production rhythm.

As an engineer and manufacturer, my goal is to make this process clear for you. I want to help you read a spec sheet like a pro and choose a machine that fits your bakery perfectly. We will walk through the key specifications together, focusing on what really matters for your daily operation: capacity, performance, and build quality.

How Do You Calculate the Right Machine Capacity?

You’re looking at different models and see them listed as "Model ACT-100" or "ACT-200." These numbers refer to the capacity in kilograms, but what does that mean in the real world? How does that translate to your trolleys of bread or buns?

Choosing the wrong capacity is the number one mistake I see people make. They either underestimate their peak production needs, leading to a machine that can’t keep up, or they overestimate, leading to wasted money on a machine that sits idle half the time.

You calculate the right capacity by determining your "Peak Hourly Throughput" in kilograms. You then select a machine with a "Cycle Capacity" that can process that weight within the hour, based on its average cycle time. This ensures the cooler will always keep pace with your ovens.

A Step-by-Step Guide to Sizing Your Machine

This calculation is the most critical step in the entire process. Let’s walk through it with a practical example. Imagine you are a bakery owner like Carlos, who runs a fast-growing operation and needs to ensure his new equipment can handle his maximum output.

Step 1: Calculate Your Peak Production Throughput1

First, ignore your daily average. You need to size the machine for your busiest hour.

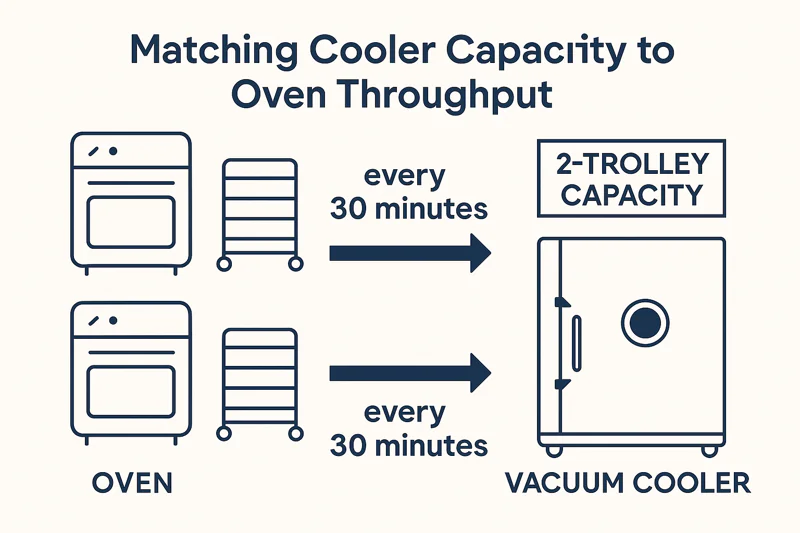

- How many ovens will feed the cooler? Let’s say Carlos has two main ovens.

- How many trolleys does each oven produce per hour? Each of his ovens bakes one trolley of bread every 30 minutes, so that’s two trolleys per hour, per oven.

- Total Trolleys Per Hour: 2 ovens x 2 trolleys/hour = 4 trolleys per hour at peak.

- What is the weight of the product on each trolley? His trolleys hold 80 kg of bread.

- Calculate Peak Hourly Throughput: 4 trolleys/hour x 80 kg/trolley = 320 kg/hour.

This number, 320 kg/hour, is the target the vacuum cooler must be able to handle.

Step 2: Understand "Cycle Capacity2" and "Cycle Time3"

Now we can look at machine models.

- Cycle Capacity is the maximum weight the machine can cool in one batch (one cycle). Common sizes are 100 kg (1 trolley), 200 kg (2 trolleys), 300 kg (3 trolleys), etc.

- Cycle Time is the time it takes to complete one cooling cycle, which is typically about 15 minutes from loading to unloading for planning purposes (even if the cooling itself is 5 minutes). This means you can run about four cycles per hour.

For Carlos, who needs to cool 320 kg per hour, a 100 kg machine is the perfect choice. He can run one cycle with one 80kg trolley every 15 minutes (4 cycles x 80 kg = 320 kg/hour). A 200 kg machine would also work, running a cycle with two trolleys (160 kg) every 30 minutes, which perfectly matches his ovens’ rhythm. The choice between them would depend on his preferred workflow.

| Your Bakery’s Scale | Example Peak Throughput | Recommended Cycle Capacity | Logical Machine Configuration |

|---|---|---|---|

| Small Craft Bakery | 1 trolley (60kg) per hour | 100 kg | 1-Trolley Machine4 |

| Medium Commercial | 2 trolleys (160kg) per hour | 100 kg | 1-Trolley Machine (running 2 cycles/hr) |

| Large Industrial | 4 trolleys (320kg) per hour | 200 kg | 2-Trolley Machine (running 2 cycles/hr) |

| High-Volume Plant | 8 trolleys (640kg) per hour | 400 kg | 4-Trolley Machine (running 2 cycles/hr) |

What Performance Specs Actually Affect Cooling Speed?

You’ve determined you need a 200 kg machine. But you see two different suppliers offering a 200 kg machine, and their prices are very different. The reason is almost always the performance specifications—the "engine" of the machine.

It’s tempting to go for the cheaper option, but if its performance components are weak, your cooling cycle could take 15 minutes instead of 5. This would completely fail to keep up with your ovens and would destroy the "Continuous Flow" benefit you’re trying to achieve.

Cooling speed, or "Cycle Time," is determined by the power of two core components: the vacuum pump, which creates the vacuum, and the refrigeration system, which removes the heat. A larger, higher-quality pump and compressor will always result in a faster and more reliable cooling cycle.

Understanding the Machine’s "Engine"

For a professional buyer like Norman, these component details are critical. He knows that brand names and specifications in this area are a direct indicator of the machine’s quality, reliability, and long-term performance.

The Vacuum Pump: Creating the Conditions for Cooling

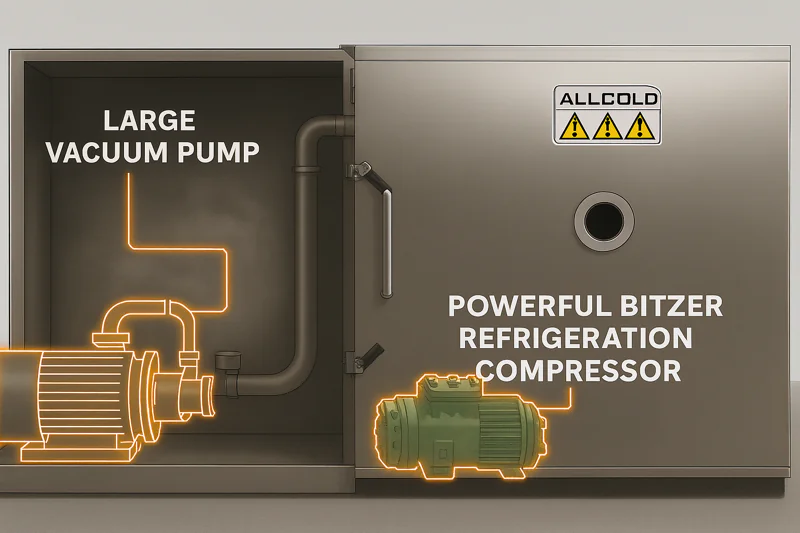

The vacuum pump’s only job is to remove air from the sealed chamber to lower the atmospheric pressure. When the pressure gets low enough, the water inside your hot bread will begin to boil at a very low temperature (around 30°C / 86°F). This rapid boiling, or evaporation, is what creates the cooling effect.

- Key Specification: Pumping Speed5, measured in cubic meters per hour (m³/h).

- What it means: A higher m³/h rating means the pump can remove air faster. This gets you to the "boiling point" sooner and shaves minutes off the total cycle time.

- What to look for: For a 200 kg machine cooling bread, you should be looking for a pump from a world-class brand like Busch6 (German) or Leybold (German). This is a sign of a high-quality machine. A cheaper, no-name pump is often a red flag.

The Refrigeration System: Removing the Heat

Once the water turns into hot vapor, you have to remove that heat from the chamber. This is the job of the refrigeration system. It has a very cold surface inside the chamber (called an evaporator or a "cold trap") that the hot vapor is drawn to. The vapor hits the cold surface and instantly turns back into ice, releasing its heat energy. The compressor is the heart of this system, working to keep that surface cold.

- Key Specification: Compressor Power7, measured in Horsepower (HP) or Kilowatts (kW).

- What it means: A more powerful compressor can remove heat faster. If your compressor is undersized, the cold trap will quickly get overwhelmed with heat, and the cooling process will slow down or stop completely.

- What to look for: This is arguably the most important component. We insist on using globally recognized brands like Bitzer (German) or Copeland (American). When a buyer like Norman sees "Bitzer8 Compressor" on our spec sheet, he knows we have not cut corners on quality.

| Performance Component | Key Specification | Its Function in Cooling | What We Recommend (Allcold Standard) |

|---|---|---|---|

| Vacuum Pump | Pumping Speed (m³/h) | Lowers chamber pressure to start evaporation. | A world-class brand like Busch or equivalent. |

| Refrigeration | Compressor Power (HP/kW) | Removes heat from the water vapor. | A globally-trusted brand like Bitzer or Copeland. |

| Control System9 | PLC and Touch Screen | Automates and optimizes the cooling cycle. | A reliable PLC like Siemens10 with a user-friendly interface. |

How Do Chamber Dimensions and Material Affect the Machine?

You’ve sized your machine’s capacity and confirmed it has a powerful engine. The final piece of the puzzle is the chamber itself—the part that actually touches your product trolleys. Will your specific trolleys fit? And what should it be made of?

These details can seem minor, but they have a huge impact on daily usability and long-term food safety. A standard machine might not fit your custom racks, wasting valuable space in every cycle. And using the wrong material can create a hygiene nightmare.

The internal chamber dimensions must be customized to your specific trolley size to ensure a snug fit and maximum efficiency. The chamber must be constructed from 100% SUS304 food-grade stainless steel to guarantee food safety, ease of cleaning, and long-term durability.

Customization and Quality You Can See

This is where working directly with a factory like ours makes a huge difference. For a central kitchen manager like Sophia, who operates under strict HACCP hygiene protocols11, these physical characteristics are just as important as the performance specs.

Customization is Not a Luxury, It’s a Necessity

We never assume a "one-size-fits-all" approach. Before we build a machine, we ask for the exact dimensions of your trolleys: width, depth, and height. We then design the internal chamber to fit them perfectly, leaving just enough clearance for easy loading and unloading. Why is this so important? Because any extra, empty space in the chamber is wasted volume that your vacuum pump has to empty of air in every cycle. A custom-fit chamber12 means a faster, more energy-efficient cycle. For example, many of our American clients use wider trolleys than our European clients. A standard European machine would be inefficient for them. By customizing, we provide a solution that is perfectly optimized for their workflow.

The Non-Negotiable Standard: SUS304 Stainless Steel

For any food application, there is only one right material for the chamber: SUS304 stainless steel13.

- Food Safe: It is non-porous and non-reactive, meaning it won’t harbor bacteria or transfer any taste or odor to your products.

- Corrosion Resistant: It will not rust, even in a humid bakery environment.

- Easy to Clean: Its smooth surface can be easily washed and sanitized to the highest hygiene standards, which is essential for a manager like Sophia.

- Durable: It can easily withstand the constant pressure and temperature changes of the vacuum cooling process for decades.

Some low-cost manufacturers may use cheaper materials like painted carbon steel to save money. This is unacceptable for food equipment and will lead to rust and hygiene problems. It’s a critical point of quality to check.

| Specification | Low-Cost Option | Allcold’s Quality Standard | Why It Matters for Your Bakery |

|---|---|---|---|

| Internal Dimensions | Standard, fixed sizes only. | Fully customized to your exact trolley dimensions. | Ensures maximum efficiency and a perfect workflow. |

| Chamber Material | Painted Carbon Steel or low-grade SS. | 100% SUS304 Food-Grade Stainless Steel. | Guarantees food safe14ty, hygiene, and long machine life. |

| Door Configuration | Single Door only. | Single Door or Double Door (Pass-Through). | A pass-through design15 is perfect for separating raw and cooked areas. |

| Build Quality | Thin steel, basic welds. | Reinforced structure, clean welds, robust hinges. | Ensures long-term reliability and low maintenance. |

Conclusion

Choosing the right vacuum cooler is a process of matching the machine’s specifications to your bakery’s unique needs. By calculating your capacity, demanding high-performance components, and insisting on quality construction, you can invest with confidence and secure the future of your bakery’s efficiency.

-

Understanding peak production throughput is essential for optimizing equipment and ensuring efficiency in your bakery. ↩

-

Learn about cycle capacity to choose the right cooling machine for your production needs and improve workflow. ↩

-

Explore how cycle time impacts production efficiency and helps in planning your bakery operations effectively. ↩

-

Discover the benefits of trolley machines in bakery cooling processes and how they can enhance your production. ↩

-

Understanding Pumping Speed helps in selecting the right vacuum pump for efficient cooling. ↩

-

Explore why Busch is synonymous with quality in vacuum pump technology. ↩

-

Learn how Compressor Power impacts cooling efficiency and system performance. ↩

-

Discover the reliability and performance that Bitzer compressors bring to cooling systems. ↩

-

Find out how advanced Control Systems enhance automation and efficiency in cooling. ↩

-

Learn how Siemens PLCs improve control and efficiency in various industrial processes. ↩

-

Understanding HACCP protocols is crucial for maintaining food safety and quality in any food-related business. ↩

-

Discover how a custom-fit chamber can enhance your workflow and energy efficiency in food processing. ↩

-

Learn about the benefits of SUS304 stainless steel for food safety and durability in kitchen equipment. ↩

-

Find out what defines food-safe materials and why they are essential for health and safety in food preparation. ↩

-

Understand how a pass-through design can optimize workflow and enhance safety in food handling. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy