How Does Vacuum Cooling Forge the Strongest Link in Your Vegetable Cold Chain?

You work tirelessly to grow perfect, healthy vegetables. Yet, you know that from the moment of harvest, an invisible clock starts ticking. Every hour that produce sits in the field, its shelf life shortens and your profits diminish. The cold chain is your only defense, but you worry its first link is too slow and weak.

Vacuum cooling transforms the first link of the cold chain from the weakest to the strongest. By crashing the core temperature of vegetables from 30°C to 2°C in under 25 minutes, it immediately halts the degradation process, locking in freshness and quality right at the source.

The concept of the "cold chain" can feel a bit abstract, but for me, it’s very real. I once visited the facility of a large-scale broccoli grower, a man much like Carlos, who was losing a significant percentage of his harvest to spoilage before it even reached the port. He had refrigerated trucks and cold rooms, but there was a fatal gap: the hours between harvesting under the hot sun and finally getting the product’s core temperature down. We installed a 6-pallet vacuum cooler right at his packing house. The change was immediate and profound. He could now harvest a field, pack it, cool it to the core, and have it loaded onto a reefer truck in just over an hour. He wasn’t just selling broccoli anymore; he was selling certainty. This is what professional buyers like Norman are looking for. They’re not just buying a product; they are buying a guarantee of quality that can only come from a strong, unbroken cold chain.

Why is the "Golden Hour" of Post-Harvest Cooling so Critical?

You’ve successfully harvested your crop, and it looks perfect. But you have a nagging feeling that the time it takes to get it from the field to the cold room is causing invisible damage. You worry that slow cooling is costing you shelf life and money, but you aren’t sure just how fast the damage occurs.

The first hour after harvest—the "Golden Hour"—is the most critical period in the entire cold chain. During this time, field heat causes respiration to remain high, accelerating water loss, wilting, and bacterial growth. Slow cooling in this window is the primary cause of post-harvest losses.

The Race Against Respiration

This is a topic I’m passionate about because it’s where we can make the biggest impact for our clients. A freshly harvested vegetable is a living, breathing organism. It continues to respire, consuming its own stored sugars and moisture to survive. The rate of this respiration is directly tied to its temperature. A head of lettuce at 25°C can respire up to 25 times faster than one at 2°C. Think about that. For every hour it sits warm on the loading dock, it’s living a full day of its shelf life. This is the race you are in. When I explain this to farm owners like Carlos, they get it immediately. They work for months to cultivate a beautiful product; watching it lose quality by the minute is painful. Traditional cold rooms are simply too slow to win this race. They cool from the outside in, and it can take 10, 12, or even 24 hours for the core of a densely packed pallet to reach the target temperature. All that time, respiration is burning through your profits.

The Hidden Enemies: Water Loss and Bacteria

This rapid respiration process creates two devastating side effects.

- Water Loss: Vegetables are mostly water. Respiration releases this water as vapor. This loss of moisture is what causes wilting, a loss of crispness, and a direct loss of sellable weight. A product that loses 5% of its weight to respiration is 5% less product to sell.

- Bacterial Growth: The temperature range of 5°C to 60°C is known as the "food temperature danger zone1." This is where bacteria, like Pseudomonas, thrive and multiply. A slow-cooling process means your vegetables spend hours in this danger zone. This is a major concern for any buyer, but especially for detail-oriented managers like Sophia, who operate under strict HACCP plans. A product that arrives with a high bacterial load has a short shelf life and poses a potential safety risk.

Vacuum cooling2 offers a direct solution by forcing water to evaporate at low pressure, using this physical principle to pull heat out of the product from the core outwards in a matter of minutes. It bypasses the danger zone almost entirely.

| Cooling Method | Time to Cool Core to 2°C | Time in Temperature "Danger Zone" | Typical Water Loss3 | Impact on Shelf Life |

|---|---|---|---|---|

| Room Cooling | 24-48 hours | Very High (many hours) | >8% | Drastically Reduced |

| Forced-Air/Cold Room | 8-12 hours | High (several hours) | 3-5% | Moderately Reduced |

| Hydro-Cooling | 15-30 minutes | Low | <1% (can add weight) | Good, but adds moisture |

| Vacuum Cooling | 20-25 minutes | Very Low (minutes) | 1.5-2.5% (controlled) | Maximized |

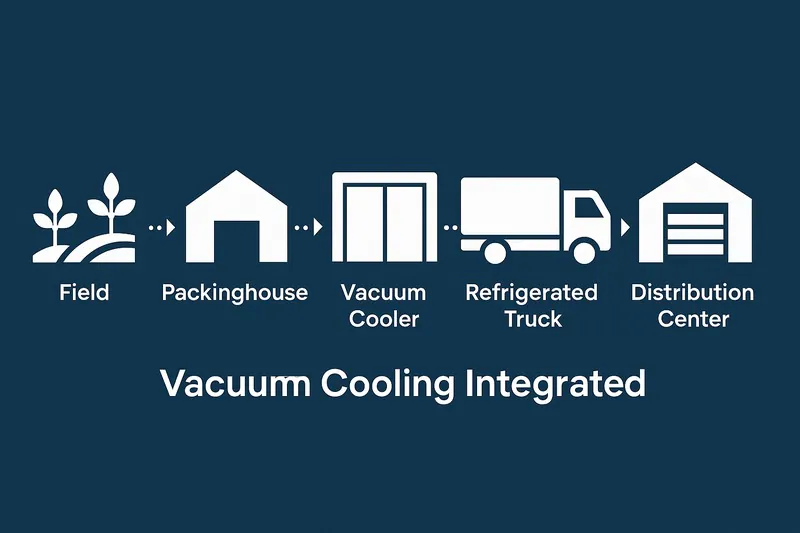

How Does Vacuum Cooling Integrate with the Rest of the Logistics Chain?

You understand the need for speed, but you look at your operation and see a complex dance of harvesting, packing, and shipping. You wonder how this powerful technology can fit into your existing workflow without causing chaos. You’re afraid of trading one bottleneck for another.

Vacuum cooling acts as a powerful bridge, not a barrier. By creating a predictable, rapid-cooling step, it allows you to synchronize your harvesting and transportation, turning your packing house into a highly efficient, continuous-flow operation.

vacuum cooler4, the process becomes like clockwork. Let’s imagine Carlos’s 6-pallet machine, which can cool a full load in about 30 minutes. He knows he can cool 12 pallets per hour, every hour. This allows him to schedule his harvest crews and his trucks with precision. The crew harvests for an hour, delivering 12 pallets to the packing house. Those 12 pallets are cooled and loaded directly onto a pre-cooled reefer truck. There is no pile-up. There is no guesswork. The packing house is no longer a storage facility; it’s a high-speed transfer station. This level of operational efficiency5 is a key selling point for a professional buyer like Norman. It shows a level of control that guarantees on-time shipments and consistent product flow.

vacuum cooler4, the process becomes like clockwork. Let’s imagine Carlos’s 6-pallet machine, which can cool a full load in about 30 minutes. He knows he can cool 12 pallets per hour, every hour. This allows him to schedule his harvest crews and his trucks with precision. The crew harvests for an hour, delivering 12 pallets to the packing house. Those 12 pallets are cooled and loaded directly onto a pre-cooled reefer truck. There is no pile-up. There is no guesswork. The packing house is no longer a storage facility; it’s a high-speed transfer station. This level of operational efficiency5 is a key selling point for a professional buyer like Norman. It shows a level of control that guarantees on-time shipments and consistent product flow.

Designing the System Around the Cooler

To achieve this, we design the layout with the cooler as the central hub.

- Infeed: Harvested pallets are brought to a designated "pre-wetting" station right next to the cooler’s door. Here, a light mist of water is applied to ensure even cooling, a practice some might refer to as hydro-vac cooling6.

- The Cooling Cycle: The pallet is moved into the chamber. The operator selects the correct cooling program from the touch screen designed for that specific vegetable—a faster cycle for sturdy iceberg lettuce, a gentler cycle for delicate herbs . The automated system does the rest.

- Outfeed: Once the cycle is complete (typically signaled by a light or alarm), the chamber door opens, and the pallet is moved directly to the refrigerated loading dock, where its temperature is verified before being loaded onto the truck. In very large operations, this entire process is automated with conveyor belts.

This system ensures the cold chain7 is established within minutes of packing and is never broken.

What is the Ultimate Impact on Market Access and Profitability?

Ultimately, this is a business. You invest in equipment to see a clear return. You need to know how extending shelf life and improving quality will translate into tangible dollars, new customers, and a stronger, more resilient business.

Proper vacuum cooling fundamentally changes your market access and profitability. The dramatic extension of shelf life (often 7-14 extra days) allows you to ship to more distant, higher-value markets by sea instead of air, drastically reducing waste and unlocking new revenue streams.

Unlocking the Global Market

This is the end game. This is what gets me really excited for my clients. I have seen companies that were previously limited to regional markets start exporting globally because of this technology. Let’s take the example of a lettuce grower in China who wants to sell to a market in the Middle East, like Dubai. Shipping by air freight is incredibly expensive and eats up most of the profit margin. Shipping by sea freight takes 20-25 days. Without vacuum cooling8, the lettuce would be a wilted mess upon arrival. But by vacuum cooling it at the source, the grower adds at least 10-14 days of high-quality shelf life. This makes the 25-day sea journey possible. They can now compete in a high-value market they could never have reached before. This is a complete business transformation. It’s moving from a local supplier to a global exporter.

The Financial Case: Reduced Waste and Premium Prices

The ROI is multifaceted and powerful.

- Reduced Spoilage: A conservative estimate is that proper pre-cooling can reduce post-harvest losses9 by 10-15%. For a large grower, this represents a massive amount of recovered revenue. If Carlos harvests 100 tons a day, saving 10% means he has 10 extra tons of product to sell, every single day.

- Higher Prices: Quality commands a premium. A buyer like Norman, who represents a major supermarket chain, is willing to pay more for produce that looks better, lasts longer on the shelf, and has a lower bacterial load. He knows this means less waste in his own distribution centers and happier end customers. His sourcing preference is always for quality, but at a competitive price, and vacuum cooling allows my clients to deliver both.

- Brand Reputation: Becoming known as a supplier of consistently high-quality produce builds a powerful brand. It leads to long-term contracts and makes you a preferred supplier, shielding your business from market volatility. You are no longer competing just on price; you are competing on the guarantee of quality.

Conclusion

Integrating vacuum cooling is the single most impactful step you can take to strengthen your cold chain. It immediately stops degradation, streamlines your logistics, reduces waste, and unlocks access to more profitable, distant markets.

-

Learn about the critical temperature range that affects food safety and how to avoid risks. ↩

-

Explore how vacuum cooling can significantly enhance the shelf life and quality of your produce. ↩

-

Understand the impact of water loss on your produce and ways to mitigate it for better sales. ↩

-

Explore how vacuum coolers enhance efficiency and product quality in agricultural operations. ↩

-

Learn strategies to boost operational efficiency, ensuring timely shipments and better resource management. ↩

-

Discover the innovative hydro-vac cooling technique and its impact on produce freshness. ↩

-

Understand the critical role of the cold chain in preserving food quality and safety during transport. ↩

-

Explore how vacuum cooling enhances produce quality and extends shelf life, crucial for global shipping. ↩

-

Learn effective strategies to minimize post-harvest losses, maximizing revenue for growers. ↩

Mila

You May Also Like

Small-Scale vs. Large-Scale Vacuum Cooler: How Do You Choose the Right Fit?

You’re convinced that vacuum cooling is the key to elevating your product quality, but now you face a critical decision.

How Can You Master Vacuum Cooling for Leafy Greens to Maximize Quality and Profit?

You grow beautiful, vibrant leafy greens, but you know the invisible enemy is time. From the moment of harvest, the

Which Vegetables Benefit Most from Vacuum Cooling Technology?

You see the promise of rapid cooling, extended shelf life, and superior quality, but you’re unsure if this technology is

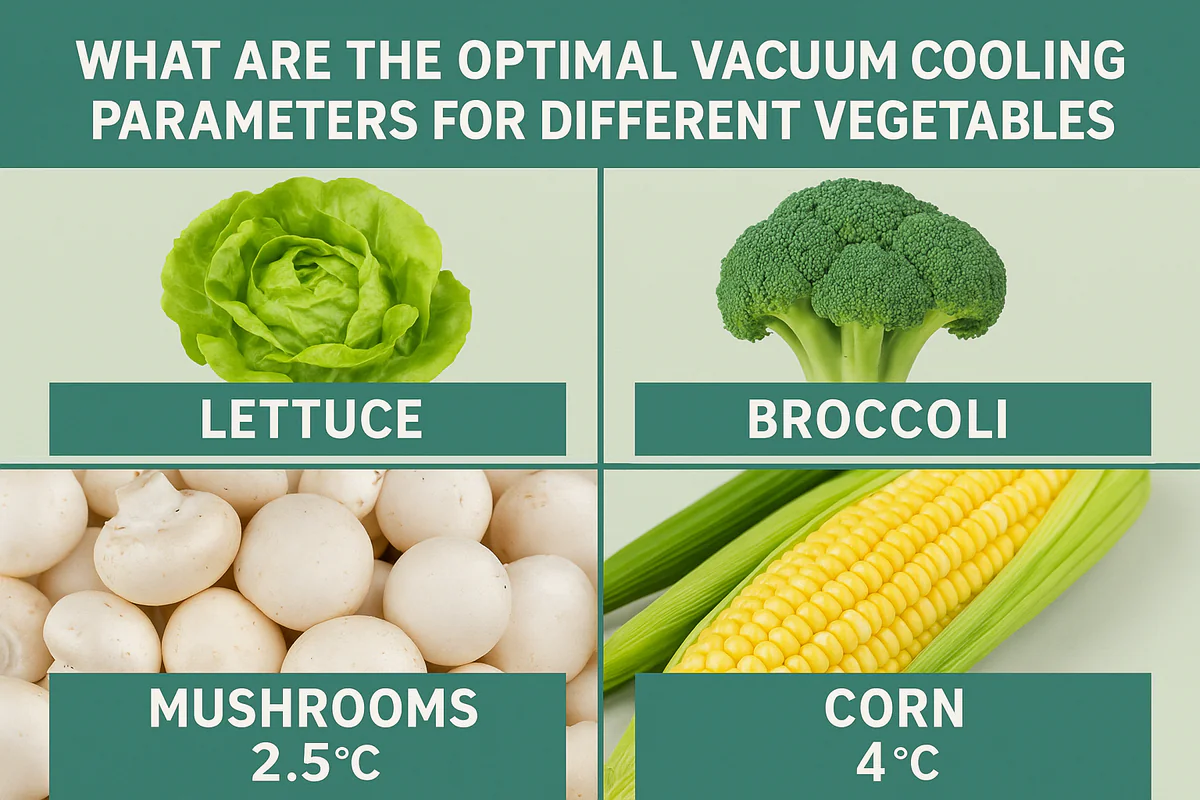

What Are the Optimal Vacuum Cooling Parameters for Different Vegetables?

You’ve harvested beautiful produce, from crisp lettuce to delicate mushrooms. But using a "one-size-fits-all" setting on your vacuum cooler feels

How Can You Reduce the Energy Costs of Your Vacuum Cooler?

Your vacuum cooler is a powerhouse of productivity, but your monthly electricity bill is climbing. You’re starting to wonder if

How Can You Keep Your Vacuum Cooler Running Flawlessly?

Your vacuum cooler is a vital asset, but you’re worried about unexpected breakdowns during peak season. Neglecting maintenance feels like

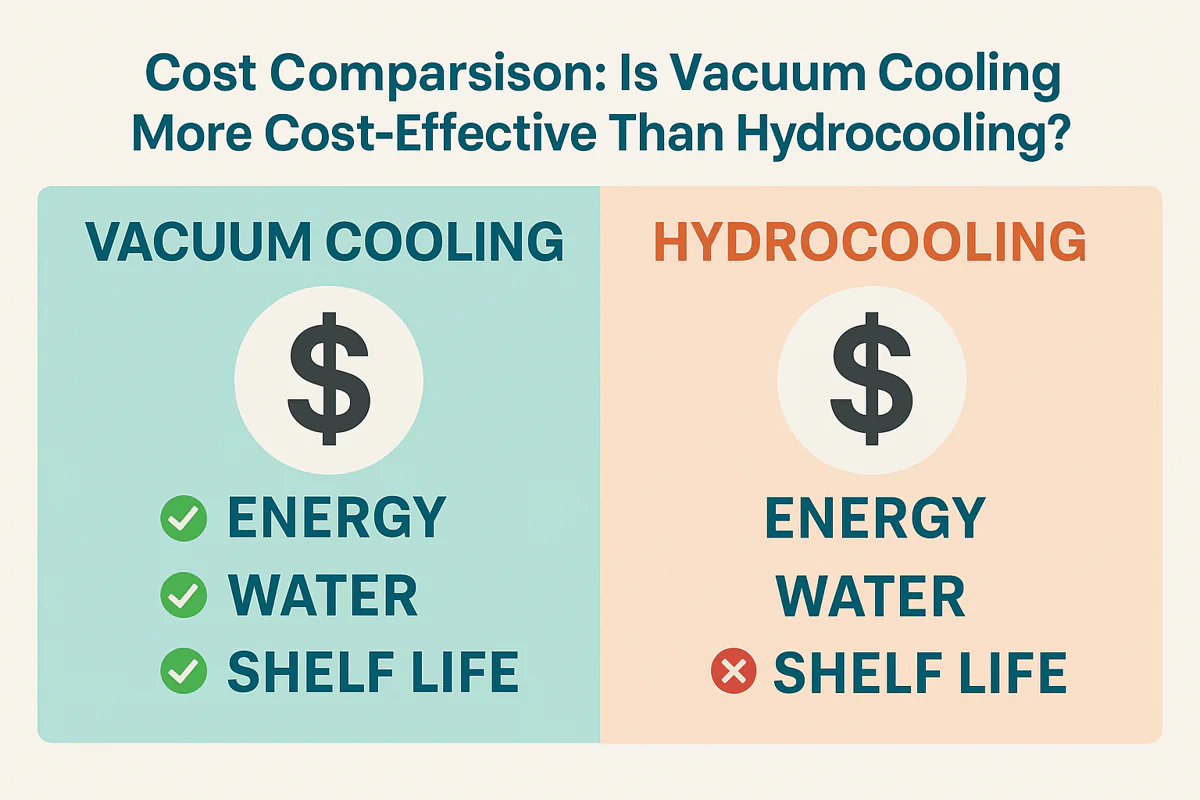

Cost Comparison: Is Vacuum Cooling More Cost-Effective Than Hydrocooling?

Choosing between cooling technologies feels like a high-stakes gamble. You need to lower your operational costs, but the wrong decision

Who Are the Top Vacuum Cooler Manufacturers for Vegetables?

Searching for a list of top vacuum cooler brands can be overwhelming. You’re not just buying a machine; you’re investing

ROI Analysis: Is a Vacuum Cooler Worth the Investment for Your Farm?

You see the high upfront cost of a vacuum cooler and hesitate. But slow cooling methods and post-harvest losses are

What Defines the Best Commercial Vacuum Cooler for Your Vegetable Processing Facility?

Choosing the right equipment is a huge decision. A slow or unreliable cooler can ruin your harvest’s quality, hurt your