How Does Vacuum Cooling Perfectly Preserve Vegetable Freshness and Quality?

Your vegetables lose freshness with every minute they sit in a slow cooler. This lost time translates directly into lost quality and lost profit.

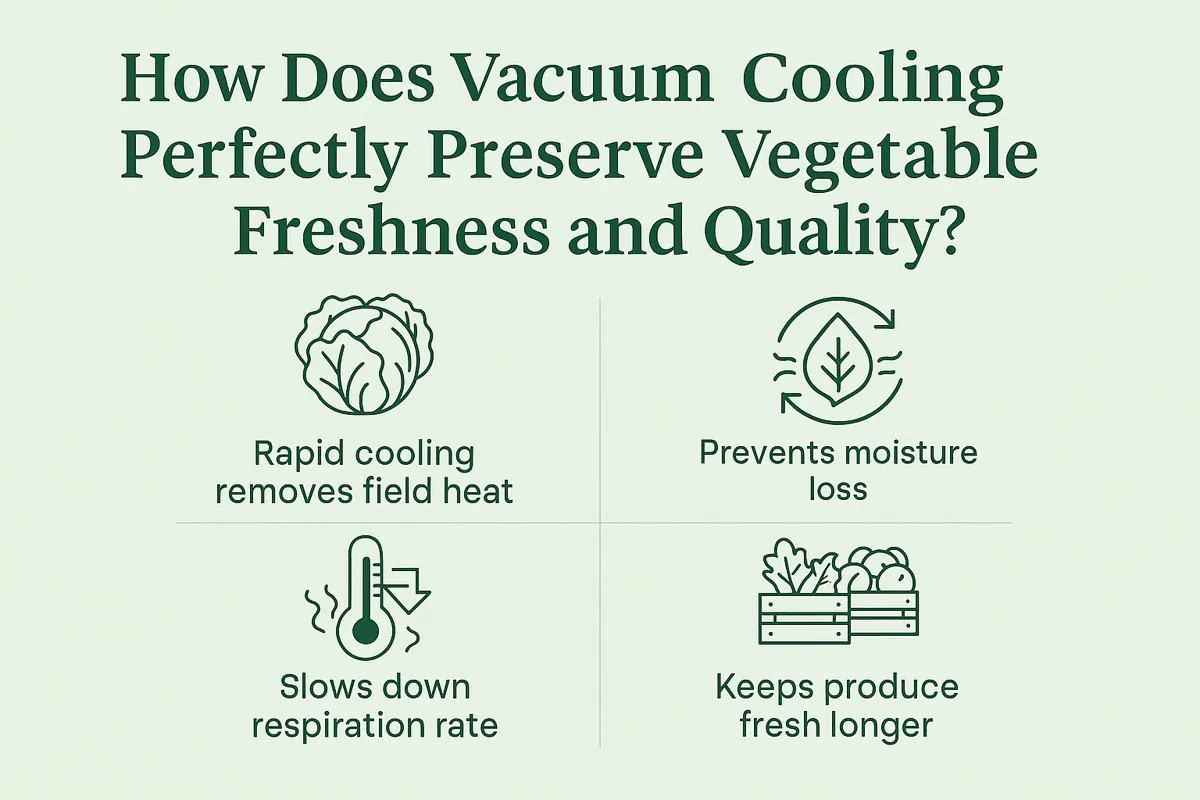

Vacuum cooling preserves produce by rapidly lowering its core temperature in just 15-25 minutes. This speed halts respiration and moisture loss almost instantly, locking in freshness in a way traditional methods cannot.

I’ve talked to many farm owners who are frustrated with how much quality their produce loses before it even ships. They work hard in the field, only to see their profits diminish in a slow cold room. Let’s break down exactly how this technology works to protect your hard work.

Why is cooling speed the most critical factor?

The "field heat" in your freshly harvested vegetables is a ticking clock. The longer it takes to remove, the more your product quality degrades.

Vacuum cooling wins on speed, completing a full cycle in just 15-25 minutes. This stops the natural decay process immediately, preserving the vegetable’s weight, crispness, and nutritional value right from the start.

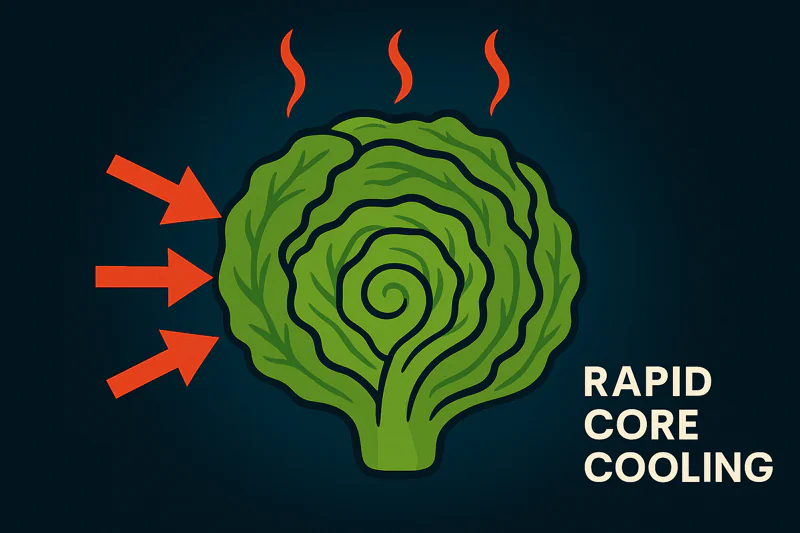

The Science of Stopping the Clock

The science is simple but powerful. After harvest, a vegetable is still a living thing. It breathes (respires), consuming its own sugars and releasing heat. It also loses water through its surface. The goal of cooling is to slow down these processes as quickly as possible. Traditional cooling methods are slow because they only cool the surface. The heat has to travel slowly from the inside of the vegetable to the outside. This can take hours. During that time, significant damage is done. A vacuum cooler works differently. By lowering the air pressure inside a sealed chamber, it makes water boil at a very low temperature, around 3°C. This process, called evaporative cooling1, pulls heat directly from the core of the vegetable at the same time as the surface. The speed is remarkable. For one of my clients in Hungary, we designed a machine to cool baked bread from 92°C down to 30°C in less than 5 minutes. For vegetables, bringing the temperature down in 15-25 minutes means you are capturing the peak freshness from the field and stopping quality loss in its tracks. It’s the single most important step in extending shelf life.

| Feature Comparison | Vacuum Cooling2 | Traditional Cooling |

|---|---|---|

| Primary Mechanism | Evaporation from the core | Convection on the surface |

| Time to Cool | 15-25 minutes | Many hours |

| Decay Process | Halted almost instantly | Continues for hours during cooling |

| Result on Freshness | Peak freshness is locked in | Freshness degrades significantly |

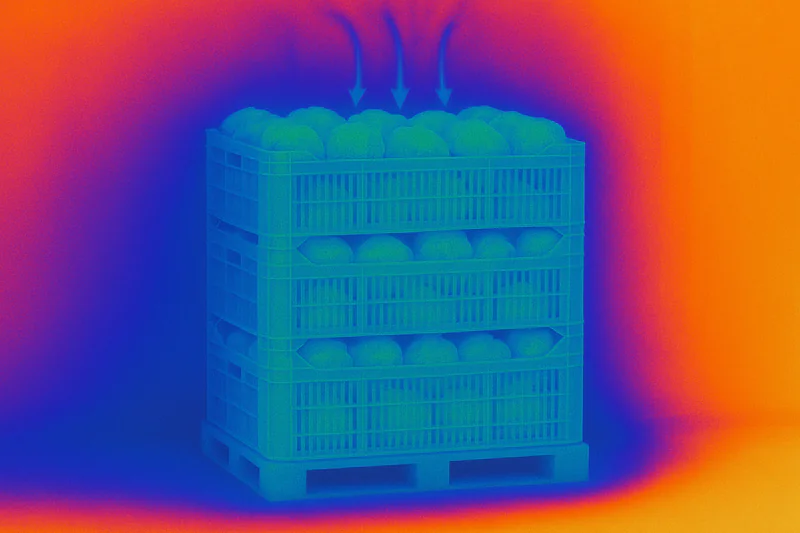

How does vacuum cooling ensure uniform temperature?

What good is fast cooling if it is uneven? A cold exterior with a warm core is a recipe for spoilage and inconsistent quality.

Our systems use a special "vacuum delay facility". This feature ensures that even produce with high water resistance is cooled uniformly throughout the entire load, from the outside in.

Consistency is Key to Quality

Having a consistent temperature throughout the entire pallet of produce is just as important as the speed of cooling. In traditional cold rooms, the vegetables on the outside of the pallet get cold air blasted at them, while the ones in the middle stay warm for much longer. This temperature difference causes major problems. The warm vegetables in the center continue to respire and degrade, while the outer ones might suffer from chilling injury. This leads to an inconsistent product and a shorter overall shelf life3. This is a common pain point for producers like Carlos, who supplies to large supermarket chains and cannot afford rejected shipments. To solve this, we’ve engineered a specific solution. Our vacuum coolers4 can be supplied with a "vacuum delay facility". This function is used for produce that doesn’t release its water easily, what we call higher water yield resistance. It automatically adjusts the cycle to make sure that the cooling process happens evenly, pulling heat from the core of every single item, whether it’s on the edge of the pallet or tucked deep inside. The result is a perfectly uniform final temperature across the entire load, which is critical for maintaining quality and guaranteeing a long, predictable shelf life for your customers.

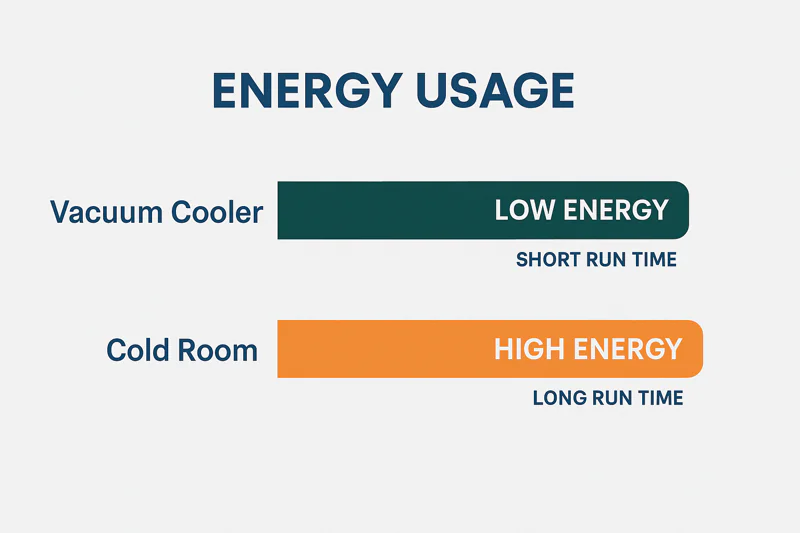

Does better preservation mean higher running costs?

You see a powerful, fast machine and naturally assume it must be expensive to operate. High electricity bills can eat into your profits.

Not at all. Our vacuum coolers are designed for high efficiency. They use smart features like automatic shutdown and premium components to minimize electricity usage and lower your long-term operational costs.

Smart Design for Lower Costs

It’s a common misconception that speed and power must equal high energy consumption. In reality, the efficiency of a vacuum cooler makes it very cost-effective. The main reason is the short cycle time. The large motors for the compressor and vacuum pump only need to run for 15-25 minutes to cool an entire load. Compare this to a conventional cold room, where the refrigeration system has to run continuously for many hours to do the same job. The total energy used per pallet is significantly lower. We also build our machines with energy-saving components5 right from the start. We use high-efficiency evaporators and air-cooled condensers, which are specifically chosen to minimize the power rating (KW) of the compressors. Beyond the hardware, we’ve built in smart software6. For example, if the machine is left idle for a period of time, it will automatically shut down all systems to save electricity. To start it again, you just press the cycle start button. This prevents wasted energy between cooling cycles, which is a feature my more detail-oriented clients like Sophia really appreciate. This intelligent design means you get superior preservation quality without the penalty of high running costs.

Can you rely on this technology for the long term?

Investing in new technology can feel risky. You need a machine that is not only effective but also dependable for many seasons to come.

Absolutely. We build our machines with world-class components from brands like Bitzer and Siemens for maximum reliability. This is backed by a full warranty and 24/7 technical support.

Built for Trust and Uptime

Reliability is at the core of our design philosophy. We know that downtime during harvest season is not an option. That’s why we source our key components from the best manufacturers in the world. When a professional buyer like Norman asks about quality, I show him the parts list. The heart of the refrigeration system7, the compressor, is from Bitzer in Germany. The vacuum pump8 is from another German leader, Leybold. The entire control system, including the touch screen, is built with Siemens technology. We also use parts from Schneider, Danfoss, and Frascold. Using these premium brands ensures a long service life and consistent performance. Maintenance is also straightforward. On a monthly basis, you just need to do a simple check to see if the vacuum pump oil looks milky, which would mean it needs to be changed. We also recommend a general hygiene cleaning every two seasons. While major services like changing the compressor oil should be done by a professional every couple of years, the day-to-day operation is simple. For your complete peace of mind, every machine comes with a 12-month guarantee and access to our technical team via phone 24 hours a day, 7 days a week. We build machines you can trust.

Conclusion

Vacuum cooling isn’t just a faster method; it’s a better one. It locks in freshness, ensures uniform quality, and does so efficiently, protecting your investment from the field to the market.

-

Learn about evaporative cooling’s advantages in food preservation and how it enhances quality and longevity. ↩

-

Explore this link to understand how Vacuum Cooling preserves freshness and extends shelf life effectively. ↩

-

Learn about the impact of temperature on shelf life to ensure your produce remains fresh and marketable. ↩

-

Explore this link to understand how vacuum coolers can enhance produce quality and shelf life. ↩

-

Explore this link to understand how energy-saving components enhance efficiency and reduce costs in vacuum coolers. ↩

-

Discover how smart software optimizes performance and energy use in vacuum coolers, leading to significant cost savings. ↩

-

Explore this link to discover top-rated refrigeration systems that ensure reliability and uptime, crucial for your operations. ↩

-

Learn about vacuum pumps in refrigeration systems to understand their importance in maintaining efficiency and performance. ↩

Mila

You May Also Like

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But