How Does Vacuum Cooling Truly Revolutionize Bakery Production Efficiency?

Your ovens are running, producing perfect bread, but your production line is constantly stopping and starting. A massive traffic jam of hot cooling racks clogs your factory floor, and everything grinds to a halt for hours. You can’t bake more until you have space.

This constant bottleneck is incredibly frustrating. It feels like your entire operation is being held hostage by the slowest, most inefficient step in the process. You are wasting space, labor, and your ovens’ capacity, all while losing product quality. This inefficiency is costing you money every single day.

Vacuum cooling revolutionizes bakery production by transforming the manufacturing model from an inefficient "Batch and Wait" system into a highly efficient "Continuous Flow." This single change eliminates the primary bottleneck, unlocking massive gains in speed, space utilization, and labor efficiency that were previously impossible.

As an engineer who designs these systems, I’ve seen this transformation firsthand. Bakeries go from being constrained and chaotic to being streamlined and highly responsive. This isn’t just about cooling bread faster; it’s about fundamentally re-engineering your entire workflow for maximum profitability. Let’s explore exactly how this revolution unfolds in your facility.

How Does It Eliminate the Main Production Bottleneck?

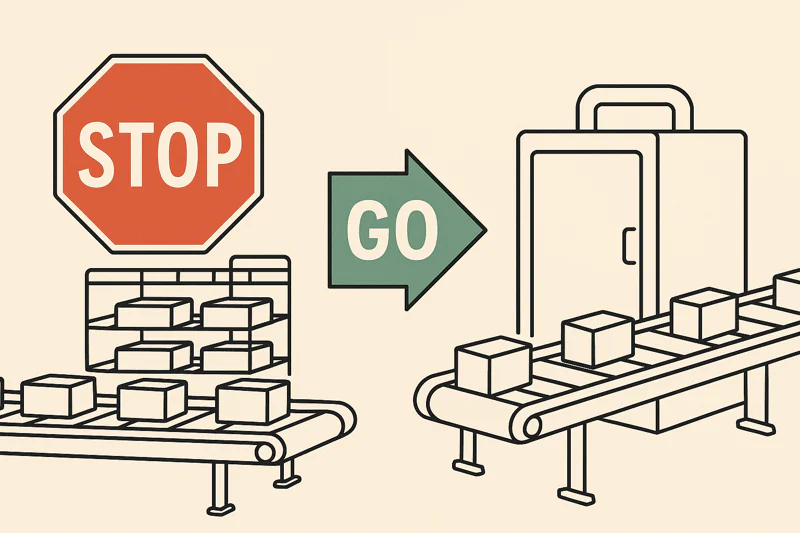

The biggest problem in almost every commercial bakery is the cooling process. It forces you to operate in a "batch" mentality. You bake a batch, then you have to stop and wait for hours while it cools, because you have nowhere to put the next one.

This "Batch and Wait" model is the root cause of all your inefficiency. Your most expensive assets—your ovens and your skilled staff—are sitting idle for significant parts of the day. You feel like you’re constantly fighting against time and space limitations.

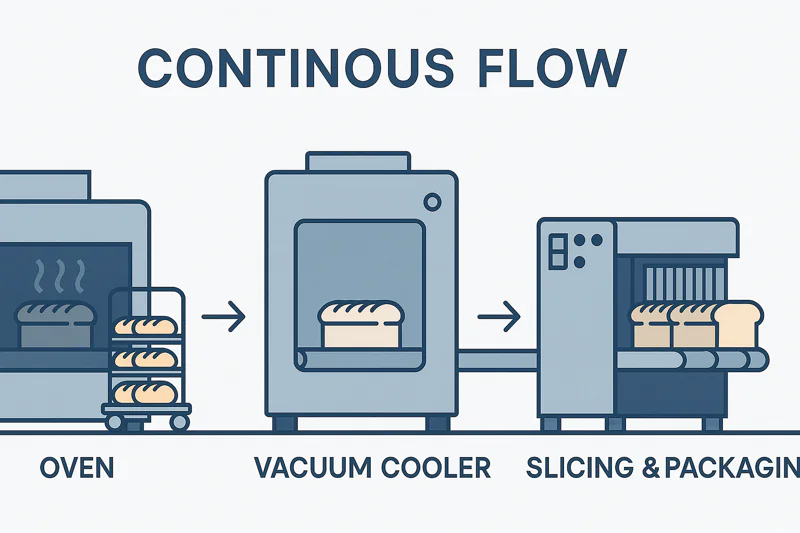

By cooling products in 3-6 minutes instead of 2-3 hours, a vacuum cooler completely eliminates the waiting period. This allows you to adopt a "Continuous Flow" production model where bread moves seamlessly from the oven to the cooler to packaging without any delay, maximizing your oven’s uptime and daily output.

From "Batch and Wait1" to "Continuous Flow2"

This shift in production philosophy3 is the core of the revolution. For a hands-on owner like Carlos, who manages a large-scale operation, understanding this change is key to unlocking new levels of output.

The Old Model: "Batch and Wait"

In this traditional model, your entire operation is defined by starts and stops. Let’s say your oven can bake a trolley of bread every 30 minutes. After you bake 4-5 trolleys, your cooling area is completely full. You now have to wait for at least two hours for the first trolley to be cool enough to move to packaging. During this time, your ovens might sit empty. Your slicer is idle. Your packaging line is waiting. You are paying for equipment and staff that are not producing. This is the definition of inefficiency.

The New Model: "Continuous Flow"

A vacuum cooler4 makes the cooling step faster than the baking step. Now, as soon as a trolley comes out of the oven, it goes directly into the vacuum cooler. Six minutes later, it comes out cool and is moved to the slicer. The vacuum cooler is now empty and ready for the next trolley, which is just coming out of the oven. There is no waiting. There is no accumulation of hot racks. Your ovens can run continuously all shift long, your packaging line is always fed, and your entire operation becomes a smooth, predictable, and highly productive system. You are maximizing the output of every piece of equipment in your facility.

| Production Model | Oven Usage | Production Pace & Rhythm | Result |

|---|---|---|---|

| Batch and Wait | Intermittent (forced downtime). | Stop-and-go, chaotic, unpredictable. | Massive inefficiency, wasted capacity. |

| Continuous Flow | Continuous (maximized uptime). | Smooth, predictable, streamlined. | Dramatically increased output with the same assets. |

How Can It Radically Reduce Your Factory’s Footprint?

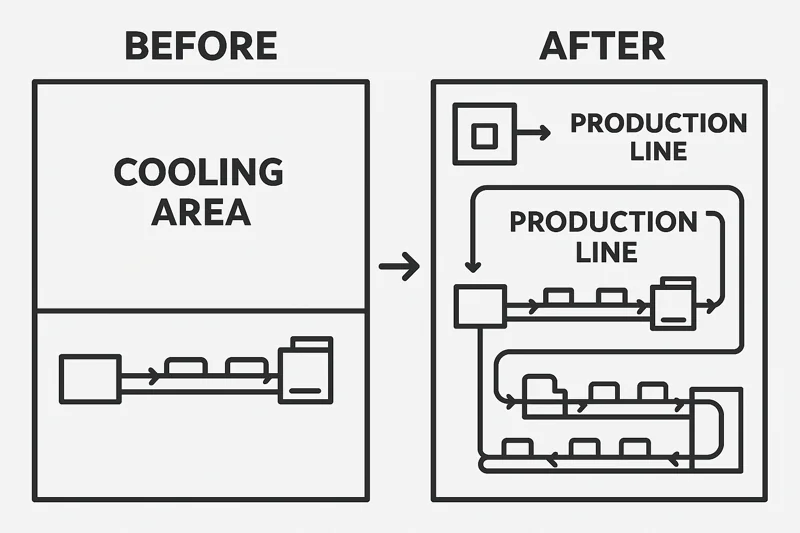

Step onto the floor of a large traditional bakery. What’s the first thing you notice? A massive, sprawling area dedicated to nothing but cooling racks. This "rack city" can take up hundreds, sometimes thousands, of square feet of your most valuable real estate.

This is more than just clutter; it’s a huge financial drain. You are paying rent or mortgage on production space that is being used for a passive, non-value-added activity. It’s like paying for a huge parking lot in the middle of your factory floor.

A single bakery vacuum cooler can do the work of 30, 40, or even more traditional cooling racks, liberating an enormous amount of floor space. This allows you to reclaim valuable square footage for revenue-generating activities like adding new production lines or storage.

Turning Wasted Space into Profit

The efficiency of vacuum cooling5 has a direct, physical impact on your factory layout. For a professional buyer like Norman, who analyzes costs from every angle, this space saving6 translates into a tangible financial benefit and a clear return on investment.

Quantifying the Space Savings

Let’s use a real-world example. A standard bakery rack might hold 100 loaves and take up about 1 square meter (~10 sq. ft.). If your production is 2,000 loaves per hour and cooling takes 2 hours, you need to store 4,000 loaves at any given time. That requires 40 racks, consuming 40 square meters (~400 sq. ft.) of floor space, not including the wide aisles needed to move them. A single large vacuum cooler that handles this capacity might only have a footprint of 8 square meters (~86 sq. ft.). You have instantly reclaimed over 30 square meters of prime production space.

What Can You Do With That Reclaimed Space?

This is where the revolution gets exciting. That newly available space is not just an empty spot on the floor; it’s an opportunity for growth.

- Add a New Production Line: You could install a new oven and a new line for pastries or cakes, diversifying your product offerings.

- Expand Packaging Capacity: You can add a second slicing and bagging machine to keep up with your new, higher throughput.

- Increase Storage: You can add more raw material or finished goods storage, allowing you to buy ingredients in greater bulk at better prices.

- Improve Workflow and Safety: You can simply use the space to create wider, safer aisles, making your entire operation less congested and more efficient.

| Metric | Traditional Racks (4,000 loaves) | Allcold Vacuum Cooler | Value Unlocked |

|---|---|---|---|

| Footprint Required | ~40 m² / 400 sq. ft. | ~8 m² / 86 sq. ft. | Reclaim ~32 m² for revenue-generating activities. |

| Workflow | Cluttered, congested, high traffic. | Open, streamlined, safe. | Improved safety and operational flow. |

| Flexibility | Fixed, inflexible use of space. | Opens up space for growth. | Enables business expansion without moving facilities. |

What Is the Impact on Labor and Daily Workflow?

In a traditional bakery, a significant portion of your staff’s time is spent on low-value, physically demanding tasks. They are constantly pushing and pulling heavy, hot racks, navigating a cluttered floor, and then waiting around for the next stage of production to begin.

This is an inefficient use of your most valuable resource: your people. Their time is being wasted on logistics instead of on tasks that add real value to your product, like quality control, sanitation, or mastering the baking process. It can also lead to a more chaotic and less safe work environment.

Vacuum cooling dramatically improves labor efficiency by replacing hours of manual rack handling with a simple, automated 5-minute cycle. This frees up your staff to focus on high-value tasks, reduces physical strain, and creates a safer, more organized workflow.

Re-tasking Labor for Value

For a manager like Sophia, who is responsible for a team’s productivity and safety in a fast-paced environment, the impact on labor is a primary concern. The goal is to make her team more effective, not just work harder.

From Logistics to Quality Control

Think about the daily tasks of a bakery worker. In a traditional setup, they might spend 20% of their day just moving racks. This is unproductive time. With a vacuum cooler7, the task becomes: "Roll a trolley from the oven into the machine, press start." That’s it. The same employee who was previously a "rack mover" can now be retrained and re-tasked. They can spend their time performing quality checks8 on finished products, ensuring proper sanitation of equipment, or preparing the next batch for the ovens. You are transforming a low-skill logistical job into a high-value quality assurance or production role.

Creating a Safer and More Predictable Environment

The "rack city" is not just inefficient; it’s often dangerous. The constant movement of hot, heavy, and bulky racks leads to collisions, damaged walls, and potential injuries. The workflow is unpredictable and reactive. A vacuum cooling system creates a fixed, predictable process. The path from the oven to the cooler is always the same. The floor is open and clear. This reduces the risk of accidents and creates a calmer, more organized, and professional working environment, which can improve staff morale and retention.

| Labor Aspect | Traditional Rack Workflow | Vacuum Cooling Workflow | Impact on Staff and Operations |

|---|---|---|---|

| Primary Task | Moving, managing, and storing dozens of racks. | Loading a trolley and pushing a button. | Drastically reduces physical strain and repetitive tasks. |

| Time Allocation | High % of time on non-value-added logistics. | High % of time on value-added tasks (QC, etc.). | Boosts overall team productivity and product quality. |

| Work Environment | Cluttered, chaotic, higher risk of accidents. | Organized, open, predictable, and safer. | Improves safety, reduces damage, and boosts morale. |

| Skill Level Required | Low-skill, manual labor focus. | Opportunity for up-skilling9 to operator/QC. | Develops a more skilled and valuable workforce. |

How Does This Efficiency Create New Business Opportunities?

You are currently limited by your production capacity. You have to be careful about which orders you accept. A huge, last-minute contract from a major supermarket or food service client might be impossible to fulfill, forcing you to say "no" to your most profitable opportunities.

This inability to scale quickly means your business growth is capped. You can’t expand your distribution to more distant regions because your product’s standard shelf life is too short. You are stuck serving your existing market, unable to seize new, larger opportunities.

The massive efficiency gains from vacuum cooling directly translate into new business opportunities. You can now confidently accept large, high-volume contracts, expand into new geographic markets, and develop new product lines that were previously impractical.

Turning Operational Efficiency into Market Growth

This is the ultimate goal of the revolution. The efficiency you gain inside your factory allows you to become a more powerful and competitive player in the market.

Winning Large Contracts

Let’s return to the scenario with a procurement manager like Sophia. Her fast-food chain needs 50,000 buns delivered daily, with tight delivery windows. With traditional cooling, the sheer space and time required would make this impossible for many bakeries. With a continuous flow vacuum cooling system, this type of high-volume, just-in-time production becomes your specialty. You can build your business around serving these large, stable, and profitable anchor clients. You are no longer just a bakery; you are a reliable manufacturing partner.

Expanding Your Sales Territory

One of the most significant benefits of vacuum cooling is the natural extension of shelf life by 3-7 days. For a business that distributes its packaged products, this is a revolutionary advantage. A product that was previously limited to a 100-mile delivery radius can now be shipped 300 or 500 miles away and still arrive with plenty of fresh life left. This allows you to enter new cities and regions without needing to build a new bakery. A buyer like Norman will see this as a huge advantage, as he can now use a single, high-quality supplier to serve a much larger portion of his distribution network.

| Business Capability | Limited by Traditional Cooling | Enabled by Vacuum Cooling Efficiency | Strategic Advantage |

|---|---|---|---|

| Order Size | Limited to smaller, manageable batches. | Can accept massive, high-volume contracts. | Ability to serve large supermarket and food service chains. |

| Responsiveness | Long lead times required, cannot handle emergencies. | Can fulfill large, last-minute orders. | Become a go-to supplier for urgent needs. |

| Market Reach | Limited by product shelf life (e.g., local/regional). | Can expand to new cities and national markets. | Massive growth in potential customer base and revenue. |

| Product Development | Difficult to handle delicate or sticky items. | Can easily cool cakes, pastries, and gluten-free items. | Diversify product lines and capture new market segments. |

Conclusion

Vacuum cooling does more than just make your bakery faster. It revolutionizes your entire production model, freeing up space, optimizing labor, and unlocking growth opportunities that are simply out of reach with traditional methods. It’s an investment in pure efficiency.

-

Understanding the drawbacks of Batch and Wait can help you identify areas for improvement in your production process. ↩

-

Explore the advantages of Continuous Flow production to enhance efficiency and output in your operations. ↩

-

Discover various production philosophies to find the best approach for optimizing your manufacturing operations. ↩

-

Learn how vacuum coolers can revolutionize your cooling process and boost productivity in food manufacturing. ↩

-

Explore the advantages of vacuum cooling to enhance efficiency and profitability in your production processes. ↩

-

Learn how optimizing space can lead to significant financial benefits and improved workflow in manufacturing. ↩

-

Explore how vacuum coolers can enhance efficiency and safety in bakery operations. ↩

-

Learn best practices for quality checks to ensure product safety and quality. ↩

-

Find out how up-skilling can transform your workforce and improve operational efficiency. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy