How Much Energy Can You Save with Bakery Vacuum Cooling Technology?

You dread opening your electricity bill every month. You see the numbers, and you know that a huge chunk of that profit is disappearing into your cooling rooms and air conditioning systems. You wonder if there is a way to stop this financial bleeding without compromising the quality of your bread.

Bakery vacuum cooling technology can cut your energy costs for cooling by up to 60%. By utilizing the physics of vacuum evaporation, you cool the bread from the inside out in just minutes, rather than spending hours trying to cool it with expensive air conditioning.

As a manufacturer at Allcold, I spend a lot of time talking about compressors and pumps. But what I am really talking about with my clients is their bottom line. When I speak to a customer like Norman in the USA, he always asks me about the "sticker price" of the machine. I always tell him to look at the "running cost." Traditional cooling is like driving an old truck that guzzles gas; it is cheap to buy but expensive to drive. Vacuum cooling is like an electric car; it is an investment that saves you money every single mile. Today, I want to show you exactly how this technology slashes your energy bills.

Why Is Traditional Air Cooling So Energy Inefficient?

You might think that putting hot bread in a cold room is simple. But from a physics perspective, it is one of the most wasteful ways to remove heat. You are fighting a losing battle against thermodynamics.

Air is a terrible conductor of heat. To cool a loaf of bread with air, you have to run large compressors for hours to overcome the heat resistance of the crust. This wastes massive amounts of electricity cooling the space, not just the product.

The Hidden "Heat Load" of Your Bakery

To understand why your energy bill1 is so high, you have to understand what your cooling system is actually doing. I often explain this to Carlos, my client in Mexico. He has a large facility, and his cooling rooms are running 24 hours a day.

When you push a rack of hot bread into a cooling room or a spiral cooler, you are introducing a massive "heat load2." Let’s say the bread is 95°C. The room is 20°C.

In a traditional system, you rely on convection3. Cold air blows over the bread. The problem is that the crust of the bread acts like a winter coat. It insulates the hot crumb inside. The heat is trapped. Your Air Conditioning (AC) system has to work incredibly hard to push cold through that barrier.

But here is the real waste: You are not just cooling the bread.

- You are cooling the steel racks: Hundreds of kilograms of stainless steel absorb heat from the bread and hold it. Your AC has to cool that metal down too.

- You are cooling the room: The walls, the floor, and the ceiling all absorb heat.

- You are cooling the infiltration air: Every time a baker opens the door to push a rack in, hot bakery air rushes in. Your system has to cool that down instantly.

This means that for every $100 you spend on electricity for that room, maybe only $40 is actually cooling the bread. The other $60 is wasted on cooling the environment and fighting inefficient physics. In my experience, large bakeries are often running 50HP or 100HP compressors4 for hours just to bring bread down to slicing temperature. It is a slow, brute-force method that burns energy.

| Energy Factor | Traditional Air Cooling | The Hidden Cost |

|---|---|---|

| Heat Transfer Method | Convection (Air to Surface) | Very slow, requires constant power input. |

| Target Area | The entire room volume | Wasted cooling on empty space and walls. |

| Equipment Runtime | Continuous (2-4 hours per batch) | Compressors run 100% of the time. |

| Insulation Barrier | The Bread Crust | Traps heat, forcing longer cooling times. |

How Does a 5-Minute Cycle Drastically Reduce kWh Usage?

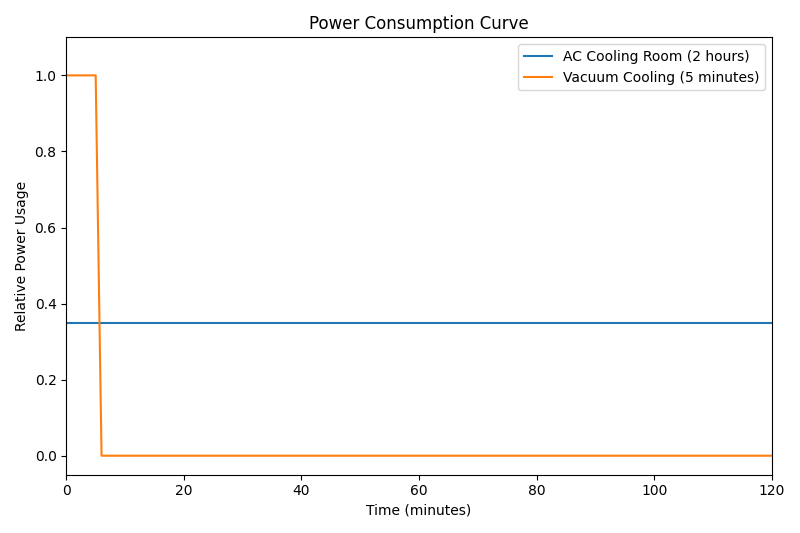

People see our vacuum coolers and see a large motor. They assume "Big Motor = Big Electricity Bill." This is a common misunderstanding. You must look at the total time the motor is running.

Vacuum cooling is a "sprint," not a "marathon." Although the pump is powerful, it only runs for 5 to 8 minutes per batch. This short duration results in a significantly lower total Kilowatt-Hour (kWh) consumption compared to running weaker AC compressors for hours.

The Physics of Flash Evaporation

This is where the magic happens. I want to explain why the 5-minute cycle is the hero of your energy bill5.

In vacuum cooling, we do not use cold air. We use pressure6.

We place the bread in the chamber and seal the door. The pump turns on. As the pressure drops, the boiling point of water drops. The moisture inside the bread starts to boil (evaporate) at a low temperature, say 30°C.

When water turns to steam, it sucks up a huge amount of heat energy. This is called the "Latent Heat of Vaporization7."

This process happens uniformly throughout the entire loaf. We are not trying to push cold in from the outside; we are extracting heat from the inside.

Because this is so efficient, the machine only needs to run for 5 minutes.

Let’s do the math for a typical scenario I see with customers like Sophia in Singapore:

- The Old Way: She uses a cooling tunnel with huge fans and compressors. The total system is rated at 40kW. It takes 90 minutes to cool a batch.

- Energy Used: 40kW × 1.5 hours = 60 kWh.

- The Allcold Way: Our vacuum cooler has a peak rating of 60kW (looks bigger, right?). But, it only runs for 6 minutes (0.1 hours).

- Energy Used: 60kW × 0.1 hours = 6 kWh.

Do you see the difference?

Even though the vacuum cooler is a "powerful" machine, it uses 90% less energy for that specific batch because it is so fast.

Additionally, our machines use Variable Frequency Drives (VFD)8. This is a smart computer that controls the motor speed. The motor does not run at 100% power the whole time. In the last few minutes of the cycle, when the vacuum is already established, the motor slows down, sipping even less electricity. This is a massive saving that accumulates every single hour of your production day.

| Comparison Point | Continuous Cooling Tunnel | Allcold Vacuum Cooler |

|---|---|---|

| Power Rating | 40 kW | 60 kW |

| Time to Cool | 90 Minutes | 6 Minutes |

| Energy per Batch | 60 kWh | 6 kWh |

| Cost @ $0.15/kWh | $9.00 | $0.90 |

| Savings per Batch | — | $8.10 |

Does Vacuum Cooling Reduce the Load on Your Freezers?

Many of you are not just selling fresh bread; you are freezing dough or par-baked bread for later distribution. The energy cost of freezing hot products is astronomical. This is a hidden energy killer in your factory.

Yes. By bringing the core temperature of the bread down to 20°C or even 10°C in minutes, you stop your freezer from working overtime. You eliminate the "thermal shock" to your freezer, saving roughly 30% of your refrigeration energy.

The "Chain of Cold" Efficiency

I have a client, let’s call him Mark, who runs a par-baked baguette factory. He used to take bread that was "cool enough" (maybe 35°C or 40°C) and throw it directly into his blast freezer.

He thought he was saving time. He was actually destroying his profits.

When you put a 40°C baguette into a -20°C freezer:

- The Freezer Spikes: The compressors have to ramp up to maximum power to fight the sudden influx of heat.

- Ice Formation: The steam coming off the warm bread hits the cold freezer coils and turns to ice instantly. This ice acts as an insulator on the coils, making the freezer less efficient.

- Defrost Cycles: Because of the ice build-up, the freezer has to run "defrost cycles" more often. A defrost cycle uses heat (electricity) to melt ice. So you are paying for electricity to heat up the machine you are paying electricity to keep cold. It is madness.

With Allcold vacuum cooling technology, we can bring that baguette down to 10°C or even 5°C before it enters the freezer.

The vacuum cooler handles the heavy lifting of heat removal. Vacuum cooling is much more energy-efficient at removing high heat (from 90°C to 10°C) than a mechanical freezer is.

By feeding your freezer with cold product:

- Your freezer runs at a steady, low-energy state.

- You have almost no ice build-up on the coils.

- You reduce defrost cycles by half.

This "Pre-Cooling" strategy is one of the smartest things a large-scale bakery can do. It protects the lifespan of your expensive freezers and slashes the electricity bill for your most power-hungry department.

Can You Save Money on Maintenance and HVAC Infrastructure?

Energy costs are not just about the machine running. They are also about the infrastructure you need to support that machine. Traditional cooling requires complex ducting, massive fans, and huge air conditioning units that break down.

Vacuum cooling is a self-contained system. It eliminates the need for complex HVAC ducting and reduces the strain on your facility’s general air conditioning, lowering your overall building maintenance and utility costs.

The Holistic Energy View

Let’s zoom out and look at your whole factory. This is something Norman and I discuss often because he hates unexpected repair bills.

1. The "heat spill9" effect:

In a standard bakery, the cooling area spills heat into the rest of the factory. If you have open racks of hot bread, that heat drifts into the packaging area. Now, you have to turn up the AC in the packaging room to keep your workers comfortable. You are paying twice: once to cool the bread, and once to cool the room heated by the bread.

A vacuum cooler10 is a sealed chamber. The heat is extracted and exhausted outside the building (or into a water loop). It does not heat up your factory. Your general building AC works less, saving you money on the facility’s total electric bill.

2. Maintenance energy11:

Think about the maintenance of a large cooling tunnel or a climate-controlled room. You have:

- Huge condenser fans on the roof.

- Evaporator fans inside.

- Miles of copper piping that can leak refrigerant.

- Filters that need changing constantly.

Every time a fan belt slips or a coil gets dirty, the efficiency drops and energy usage spikes. You might be paying 20% more for energy just because your AC unit is dirty.

An Allcold vacuum cooler is much simpler. It has a pump, a chamber, and a water circuit. It is easier to maintain. When a machine is easy to maintain, it stays efficient. You do not have the slow "efficiency drift12" that happens with complex HVAC systems.

For Carlos in Mexico, where summers are brutal, taking the heat load out of the building is a game-changer. His packaging staff is happier because the room isn’t hot, and he isn’t running the building AC at max power just to compensate for the cooling racks.

| Infrastructure Item | Traditional Cooling | Vacuum Cooling |

|---|---|---|

| Building AC Load | Increases (Heat spill) | Neutral (Heat exhausted) |

| Complexity | High (Ducts, multiple units) | Low (Plug and Play) |

| Efficiency Drift | High (Dirty coils = high cost) | Low (Sealed system) |

| Maintenance Cost | Frequent AC repair | Routine pump oil changes |

Conclusion

Energy is not a fixed cost; it is a controllable cost. By switching to vacuum cooling, you move from an inefficient, slow, passive process to a rapid, active, and precise method. You save money on the direct cooling cycle, you save money on freezing, and you save money on your facility’s total power load. It is the greenest choice for your wallet.

-

Explore strategies to lower your energy bills and improve your bakery’s profitability. ↩

-

Learn about heat load to better manage your bakery’s cooling efficiency and save on energy bills. ↩

-

Understanding convection can help you optimize your cooling system and reduce energy costs. ↩

-

Discover the different types of compressors to choose the best one for your bakery’s cooling needs. ↩

-

Discover effective strategies to lower your energy costs through advanced cooling solutions. ↩

-

Understanding pressure’s role in vacuum cooling can enhance your knowledge of energy-efficient technologies. ↩

-

Exploring this concept will deepen your understanding of energy transfer during phase changes. ↩

-

Learn how VFD technology optimizes energy use in machinery, leading to significant cost savings. ↩

-

Understanding the heat spill effect can help optimize energy efficiency in your facility. ↩

-

Discover the advantages of vacuum coolers for energy savings and improved working conditions. ↩

-

Learn how maintenance energy affects costs and efficiency, crucial for managing factory operations. ↩

-

Explore the factors leading to efficiency drift to enhance your HVAC system’s performance. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy