How to Properly Maintain and Troubleshoot Your Vacuum Cooling Equipment?

Has your vacuum cooler ever suddenly failed during peak season? Ignoring regular maintenance is probably the root cause.

Properly maintaining your vacuum cooling equipment involves daily, weekly, monthly, and quarterly checks. Consistent maintenance ensures peak performance, prevents costly breakdowns, and extends equipment life.

Understanding and following structured maintenance routines are essential. Let’s explore each maintenance level together.

Why is Daily Maintenance of Vacuum Coolers Essential?

Do small daily maintenance tasks feel unnecessary? Skipping them could quickly escalate minor issues into expensive problems.

Daily maintenance checks, such as inspecting door seals, cleaning surfaces, and verifying pump noises, ensure your vacuum cooler operates efficiently and prevents small issues from becoming major disruptions.

Dive Deeper into Daily Maintenance Procedures

Routine daily checks are simple yet vital. I always remind my team of the importance of daily inspections. Here’s the daily maintenance routine that works best for us:

Essential Daily Maintenance Checklist

| Task | Importance | Time Required |

|---|---|---|

| Inspect door seals1 | Prevent vacuum leaks | 3 minutes |

| Clean door seal | Avoid contamination | 2 minutes |

| Check pump operation sound2 | Early detection of issues | 2 minutes |

Door seals directly impact vacuum efficiency. Even slight damage or dirt buildup can dramatically affect performance. One morning, we discovered a small tear during a daily check, and timely action saved a potential equipment failure. Listening carefully to the pump’s sound each day can help identify issues like lubrication problems or loose components before they worsen. These simple checks, taking less than 10 minutes, keep our vacuum cooler running smoothly.

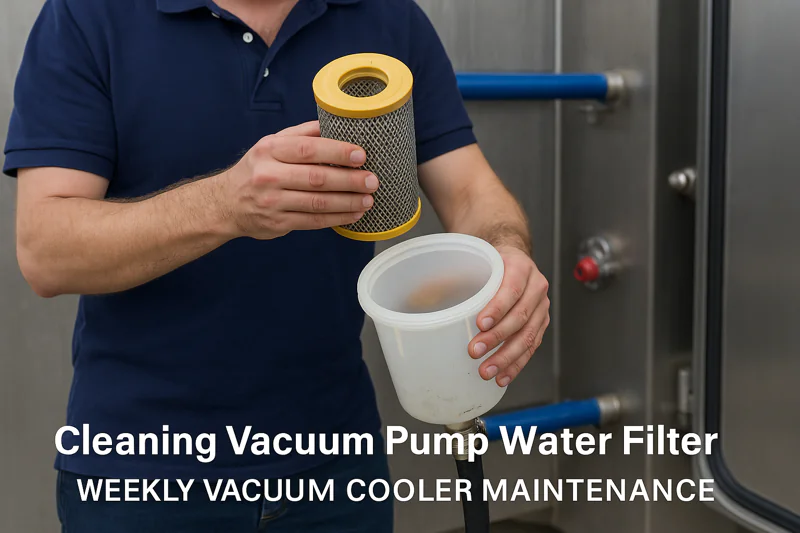

What Critical Weekly Checks Should You Perform on Your Vacuum Cooler?

Are you overlooking weekly maintenance tasks? Skipping these checks can gradually degrade your equipment’s performance.

Weekly maintenance involves cleaning water filters, verifying water flow, and ensuring temperature sensors operate accurately. Regular weekly inspections catch potential issues early and keep your cooling performance consistent.

Dive Deeper into Weekly Maintenance Essentials

Weekly checks need a bit more attention. I schedule these tasks consistently each week. Here is my recommended weekly checklist:

Weekly Maintenance Checklist

| Task | Why it Matters | Steps to Follow |

|---|---|---|

| Clean water filters3 | Ensures smooth water flow | Remove filters, clean thoroughly |

| Check water circulation | Maintains cooling efficiency | Inspect hoses and connections |

| Calibrate temperature sensors4 | Accurate temperature control | Compare sensor reading to thermometer |

A clean water filter ensures optimal water circulation, which directly impacts cooling speed. Recently, a client faced reduced cooling efficiency due to clogged water filters overlooked during weekly checks. Verifying sensor accuracy is also crucial; inaccurate sensors lead to improper cooling and quality issues with products. These weekly tasks help prevent common yet avoidable equipment problems.

How Can Monthly Maintenance Prevent Major Failures?

Does monthly maintenance seem excessive to you? Neglecting it might result in unexpected, expensive downtime.

Monthly maintenance covers deeper checks, including changing pump oil, inspecting door locks, and checking electrical components. These proactive inspections prevent unexpected equipment failures.

Dive Deeper into Monthly Maintenance Steps

Monthly checks are crucial for preventing major failures. I follow a strict monthly maintenance routine that significantly reduces unexpected breakdowns:

Monthly Maintenance Checklist

| Task | Benefit | Method |

|---|---|---|

| Replace vacuum pump oil5 | Ensures proper lubrication | Drain old oil; refill with fresh oil |

| Inspect door locks and seals | Maintains vacuum integrity | Examine locks and replace seals if damaged |

| Check electrical connections6 | Prevents sudden electrical issues | Tighten loose connections and inspect wiring |

Changing the vacuum pump oil5 regularly extends the pump’s life and prevents overheating. One month, we detected minor oil contamination early and avoided serious pump damage. Checking door locks and seals monthly ensures that vacuum integrity is always maintained. Inspecting electrical components monthly identifies minor faults before they become major failures, safeguarding against sudden operational shutdowns.

Why is Quarterly Maintenance Crucial for Long-Term Equipment Reliability?

Do you think quarterly maintenance is unnecessary? Overlooking these checks jeopardizes your equipment’s reliability.

Quarterly maintenance involves comprehensive valve inspections, checking electrical wiring thoroughly, and servicing air filters. These checks significantly contribute to long-term equipment health.

Dive Deeper into Quarterly Maintenance Practices

Quarterly inspections address wear and tear comprehensively. I follow these quarterly tasks carefully to ensure long-term reliability:

Quarterly Maintenance Checklist

| Task | Objective | How to Perform |

|---|---|---|

| Inspect all valves | Detect and repair leaks | Perform leak tests and replace valves as needed |

| Check electrical wiring | Ensure safety and continuity | Inspect for damage and repair immediately |

| Replace air filters | Maintain optimal airflow | Remove dirty filters; install clean ones |

Valve leaks directly impact vacuum efficiency and cooling speed. I once discovered a minor leak during a quarterly check, fixing it immediately prevented a bigger issue during harvest season. Electrical wiring inspections prevent unexpected downtime, protecting your operation during crucial business periods. Maintaining clean air filters ensures efficient airflow, crucial for optimal performance.

How Can You Quickly Troubleshoot Common Vacuum Cooler Issues?

Feeling unsure how to react when your vacuum cooler suddenly faces an issue? Rapid troubleshooting minimizes downtime.

Quick troubleshooting involves systematically checking door seals, verifying pump functionality, and examining cooling performance. Addressing these common problems quickly helps prevent prolonged downtime.

Dive Deeper into Quick Troubleshooting Techniques

I use a simple troubleshooting framework to quickly identify and fix common issues:

Quick Troubleshooting Guide

| Issue | Likely Cause | Quick Solution |

|---|---|---|

| Poor vacuum levels7 | Damaged door seal | Inspect and replace seal if needed |

| Reduced cooling8 | Blocked water lines | Clean filters and unblock pipes |

| Unusual pump noise | Low pump lubrication | Check and replace pump oil |

Minor vacuum leaks typically stem from worn or dirty door seals. Quick inspection and replacement easily resolve this issue. Reduced cooling8 effectiveness often comes from blocked water lines or dirty filters; clearing these blockages restores performance. If your pump produces strange noises, inadequate lubrication might be the issue. Quickly checking and replacing pump oil typically resolves this.

Conclusion

Consistent maintenance and quick troubleshooting protect your vacuum cooler from costly downtime, ensuring reliable performance when your business needs it most.

-

Understanding door seal maintenance is crucial for optimal vacuum efficiency and preventing costly repairs. ↩

-

Learning to interpret pump sounds can help you catch problems early, ensuring your vacuum system runs efficiently. ↩

-

Understanding the significance of clean water filters can enhance your maintenance routine and prevent costly equipment issues. ↩

-

Learning the calibration process ensures precise temperature control, crucial for maintaining product quality and operational efficiency. ↩

-

Explore this link to understand how regular oil changes can extend your vacuum pump’s life and prevent costly repairs. ↩ ↩

-

This resource provides insights on maintaining electrical connections to avoid sudden failures and ensure smooth operations. ↩

-

Understanding the causes of poor vacuum levels can help you troubleshoot and maintain your appliances effectively. ↩

-

Exploring solutions for reduced cooling can enhance your system’s efficiency and prolong its lifespan. ↩ ↩

Mila

You May Also Like

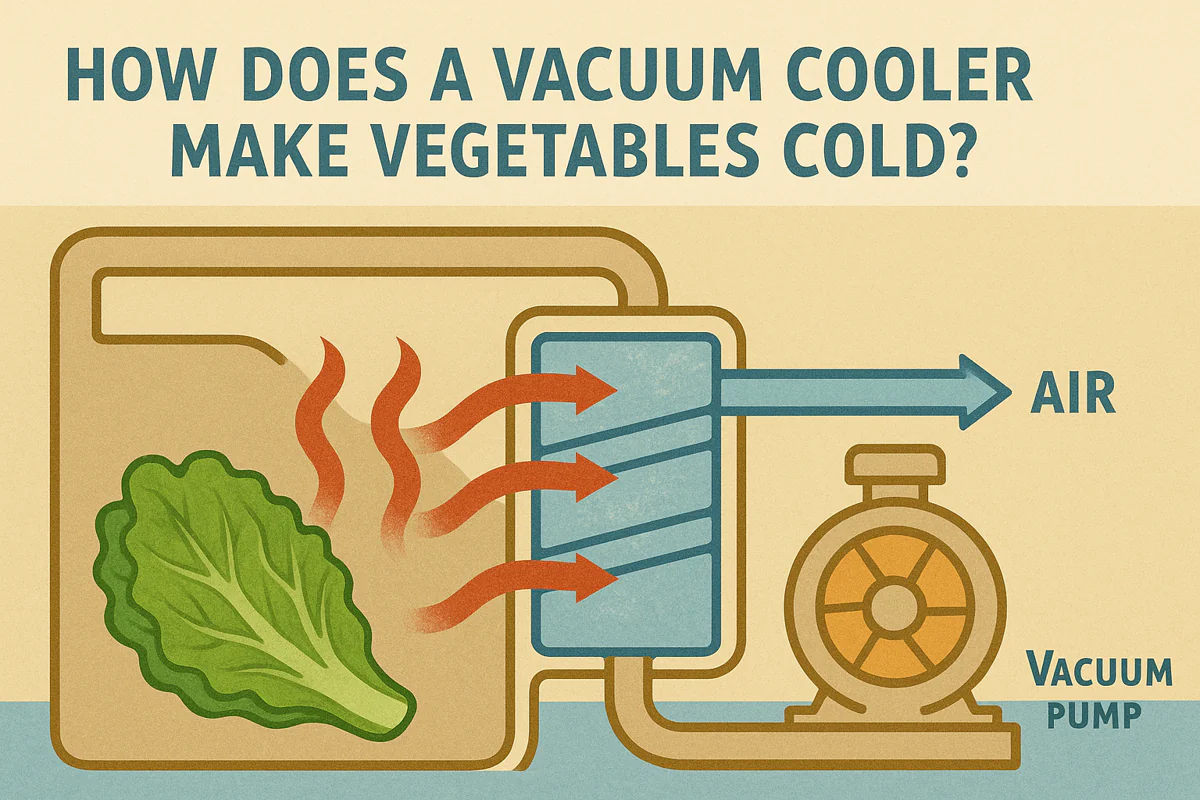

How Does a Vacuum Cooler Make Vegetables Cold?

It seems almost magical: you place warm vegetables in a steel chamber, and just 20-30 minutes later, they emerge perfectly

How Does Vacuum Cooling Forge the Strongest Link in Your Vegetable Cold Chain?

You work tirelessly to grow perfect, healthy vegetables. Yet, you know that from the moment of harvest, an invisible clock

Small-Scale vs. Large-Scale Vacuum Cooler: How Do You Choose the Right Fit?

You’re convinced that vacuum cooling is the key to elevating your product quality, but now you face a critical decision.

How Can You Master Vacuum Cooling for Leafy Greens to Maximize Quality and Profit?

You grow beautiful, vibrant leafy greens, but you know the invisible enemy is time. From the moment of harvest, the

Which Vegetables Benefit Most from Vacuum Cooling Technology?

You see the promise of rapid cooling, extended shelf life, and superior quality, but you’re unsure if this technology is

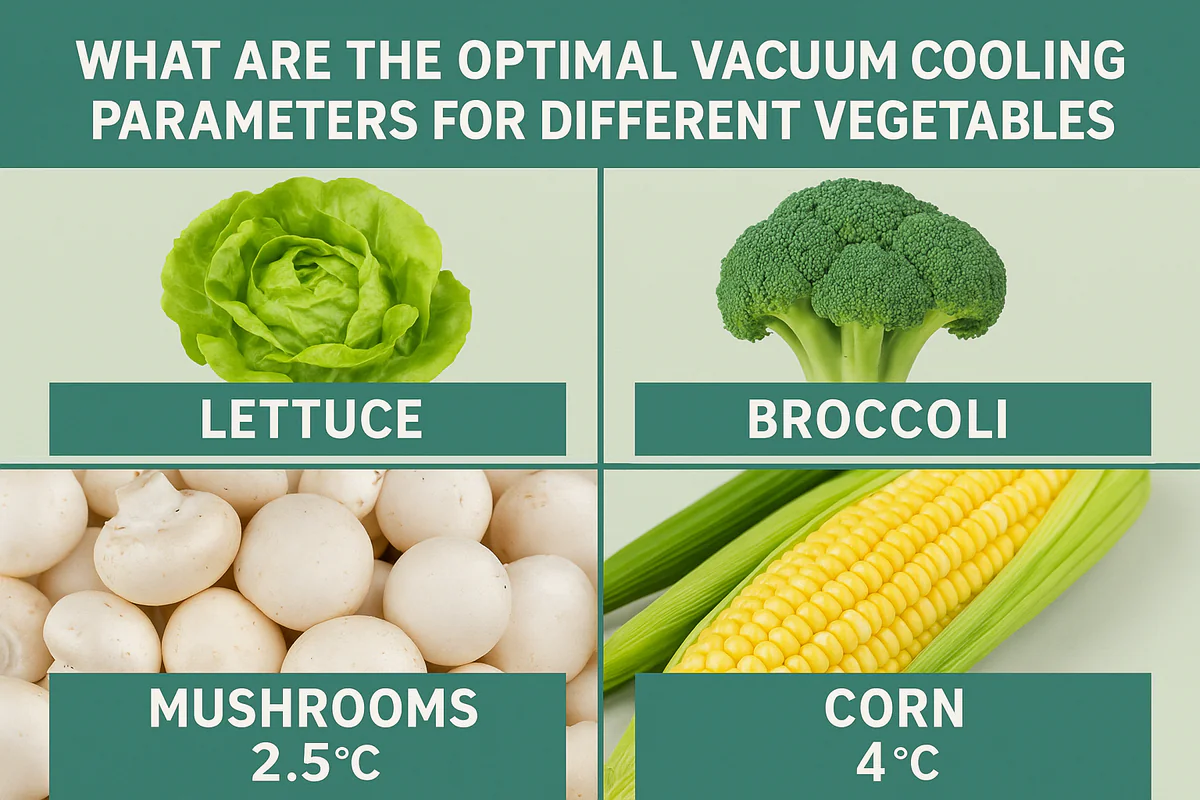

What Are the Optimal Vacuum Cooling Parameters for Different Vegetables?

You’ve harvested beautiful produce, from crisp lettuce to delicate mushrooms. But using a "one-size-fits-all" setting on your vacuum cooler feels

How Can You Reduce the Energy Costs of Your Vacuum Cooler?

Your vacuum cooler is a powerhouse of productivity, but your monthly electricity bill is climbing. You’re starting to wonder if

How Can You Keep Your Vacuum Cooler Running Flawlessly?

Your vacuum cooler is a vital asset, but you’re worried about unexpected breakdowns during peak season. Neglecting maintenance feels like

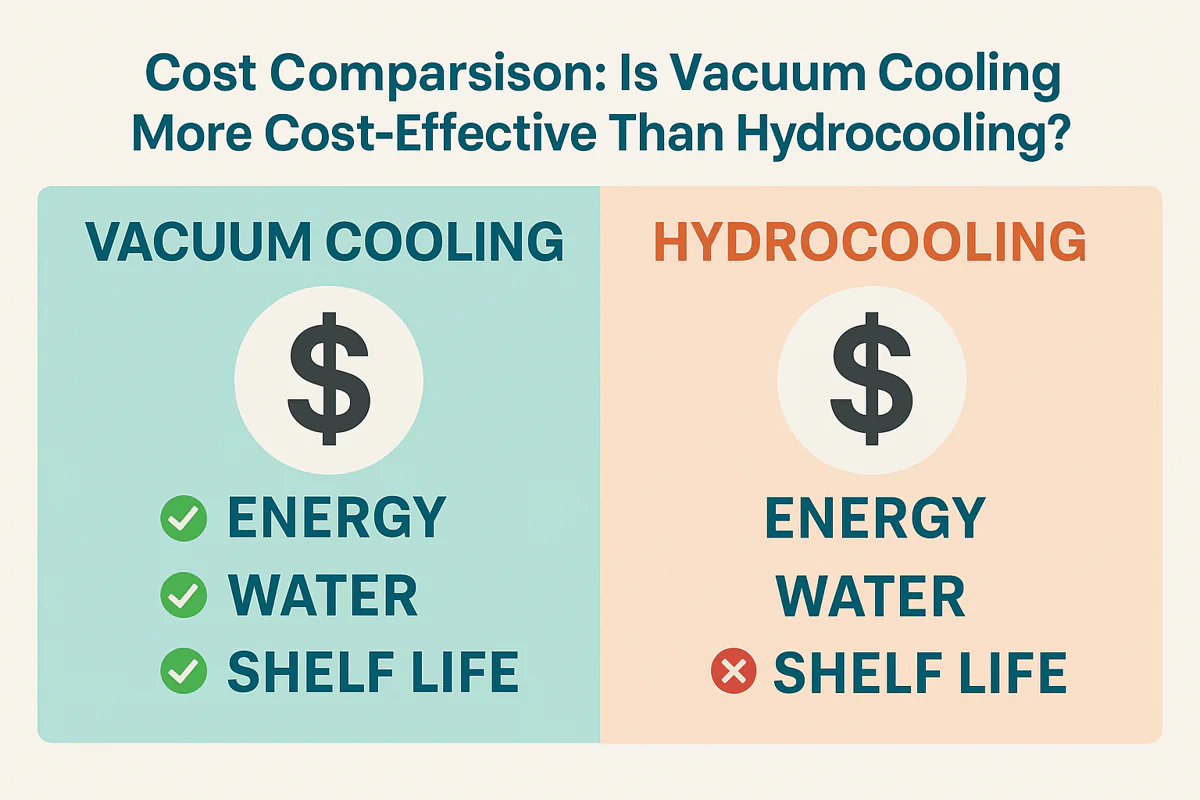

Cost Comparison: Is Vacuum Cooling More Cost-Effective Than Hydrocooling?

Choosing between cooling technologies feels like a high-stakes gamble. You need to lower your operational costs, but the wrong decision

Who Are the Top Vacuum Cooler Manufacturers for Vegetables?

Searching for a list of top vacuum cooler brands can be overwhelming. You’re not just buying a machine; you’re investing