Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as you research, you run into confusing terms: "commercial" and "industrial." They seem similar, but choosing the wrong one can be a disaster.

A machine that is too small for your harvest will create a bottleneck, leaving produce to wilt while you wait. A machine that is too large wastes capital, space, and electricity on every cycle. How do you find the machine that is perfectly sized for your operation, right now and for the future?

The choice between a commercial and an industrial vacuum cooler is determined by your daily processing volume, not the size of your business. Industrial coolers are built for high-throughput, continuous operation (over 4 pallets per cycle), while commercial coolers are best for smaller, more varied batches (1-3 pallets per cycle).

I’ve spoken with hundreds of growers, and this is one of the most common points of confusion. I’ve seen a large farm try to save money with a "commercial" unit, only to find they can’t cool their harvest fast enough and end up with unacceptable product losses. I’ve also seen smaller, specialized farms overspend on an "industrial" giant they can’t fill. This guide will break down the key differences so you can choose with confidence.

What’s the Real Difference in Capacity and Throughput?

The most obvious difference between the two types is size. But it’s not just about the machine’s footprint; it’s about the "throughput"—the amount of product you can cool in an hour or a day. This is the single most important factor in your decision.

Thinking your 2-pallet machine can handle a 4-pallet harvest is a recipe for failure. During peak season, your produce can’t wait. A delay of even a few hours can lead to lost shelf life and rejected shipments. You need a machine that can keep up with your busiest day.

Industrial vacuum coolers are designed for high throughput, typically processing 4 to 12 pallets at a time. This allows for cooling over 4 tons of produce an hour. Commercial coolers are smaller, handling 1 to 3 pallets, ideal for lower-volume operations or specialized products.

Calculating Your Needs

Let’s talk in practical terms. A large-scale broccoli grower like Carlos in Mexico needs to supply major supermarket chains. During harvest, he might pull 50 tons of broccoli from the fields in a single day. He needs to cool it all down to 2-3°C within hours of picking. A 2-pallet commercial machine, cooling about 2 tons per hour, would take over 24 hours of non-stop work to process that volume. It’s simply not feasible. Carlos needs an industrial machine1, likely an 8 or 10-pallet model that can process 8-10 tons per hour, clearing his entire day’s harvest in one shift.

On the other hand, a smaller organic farm might harvest 5 tons of mixed leafy greens a day. For them, an industrial machine1 would be overkill. They wouldn’t have enough product to fill it for a single cycle, which is incredibly inefficient. A 2-pallet commercial machine that they can run three or four times throughout the day is a much better fit. It gives them the flexibility to cool different types of vegetables in separate batches. To make the right choice, you must calculate your peak daily harvest volume in tons and work backward.

| Feature | Commercial Vacuum Cooler | Industrial Vacuum Cooler |

|---|---|---|

| Pallet Capacity | 1 – 3 Pallets | 4 – 12+ Pallets |

| Typical Throughput | 1 – 3 Tons per Hour | 4 – 12+ Tons per Hour |

| Ideal User | Small to medium farms, packing centers, central kitchens | Large farms, major packing houses, food processing plants |

| Operational Use | Intermittent (a few cycles per day) | Continuous (12-20 hours per day during season) |

How Do Build Quality and Design Requirements Differ?

At first glance, both machines look like steel boxes. But how they are built is fundamentally different, because they are designed for vastly different workloads. An industrial machine is engineered for the marathon; a commercial machine for the sprint.

Imagine running a family car like a race car, 24 hours a day. It would break down in a week. The same principle applies here. Using a commercial-grade machine for an industrial-level workload will lead to premature failure, metal fatigue, and critical-season downtime.

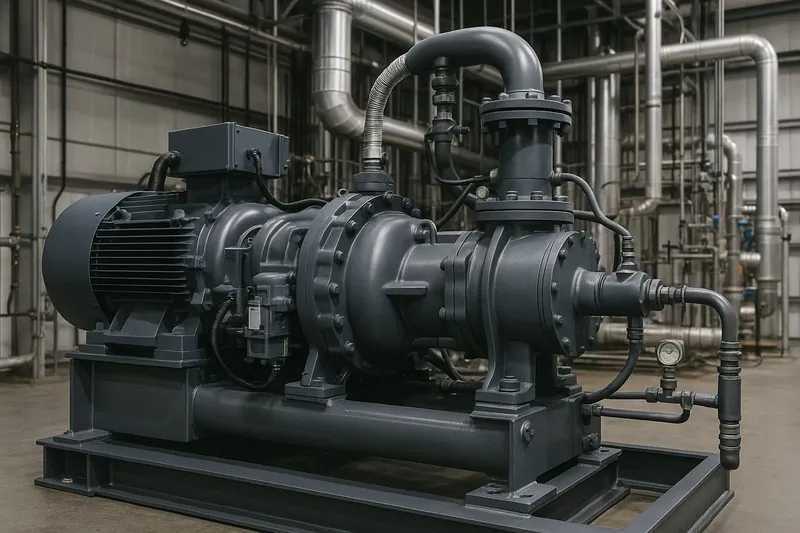

Industrial coolers are built with heavier-duty construction—thicker steel, reinforced chamber walls, and robust components to withstand the stress of 20+ cycles per day. Commercial units are well-built but are engineered for the lower stress of fewer daily cycles, making them more cost-effective for smaller operations.

The Engineering of Endurance

Every time a vacuum cooler runs, the immense force of atmospheric pressure puts stress on the chamber walls and door. An industrial machine operating during a harvest season might go through this high-pressure cycle over 3,000 times. A commercial machine might only see 500 cycles in the same period. This massive difference in workload demands a different level of engineering. For our industrial models at ALLCOLD, we use 10mm or even 12mm thick steel with extra reinforcement rings around the vessel, because we know it has to endure that stress for over a decade. The doors are heavy and automated with powerful hydraulic systems because no worker can be expected to manually open a 1-ton door 30 times a day.

For a professional buyer like Norman, this industrial-level reliability2 is a key sourcing point. He can’t afford to have a machine go down. Even if his tonnage is on the borderline, he might choose a smaller "industrial-built" machine over a larger "commercial-built" one because he is buying for long-term reliability. Commercial machines are still very robust. They are perfect for their intended use. But their steel might be 8mm thick, and the door might be a manual or electric sliding design, which is perfectly fine for 5-10 cycles a day. The key is to match the build quality to your operational intensity.

| Feature | Commercial Build | Industrial Build |

|---|---|---|

| Chamber Steel | 8mm Thick | 10mm+ Thick with Reinforcements |

| Door System | Manual or Electric Sliding | Fully Automated Hydraulic Door |

| Component Duty Cycle | Rated for Intermittent Use | Rated for Continuous, Heavy-Duty Use3 |

| Expected Lifespan | 10-15 years under intended use | 15-20+ years under heavy use |

| Best For | Lower frequency, high-flexibility needs | High frequency, maximum reliability needs |

Do They Use Different Cooling Systems and Technologies?

The "engine" inside the machine—the refrigeration and vacuum systems—is also scaled differently. It’s not just about putting a bigger compressor on a bigger box. The entire technology philosophy changes to match the intended use.

Using the wrong type of cooling system is like putting a small car engine in a massive truck. It might move, but it will be incredibly slow, inefficient, and will strain itself to the breaking point. The energy costs alone could be staggering.

Industrial systems prioritize efficiency at high capacity, often using powerful screw compressors and multi-pump vacuum arrays for the fastest pulldown on large volumes. Commercial systems use cost-effective and reliable scroll or reciprocating compressors, which are perfectly efficient for smaller, intermittent loads.

The Technology of Scale

For a technically-minded owner like Carlos or a procurement manager like Sophia, the technology inside matters for performance and operating cost. The workhorse of the industrial world is the screw compressor4. These units are at their most energy-efficient5 when they are running near 100% capacity for long, continuous periods. This perfectly matches the workflow of a large processing plant that runs the cooler all day long. In contrast, a scroll compressor, typically found in commercial units, is very reliable and efficient across a wide range of loads, including starting and stopping frequently. It’s a perfect match for a business that only runs a few cycles per day.

The vacuum system6 is another key difference. To pull down the pressure in a massive 10-pallet chamber quickly, an industrial machine often uses a combination system: a powerful rotary vane pump working in tandem with a roots pump. This two-stage system can remove the huge volume of air much faster and more efficiently than a single pump could. A commercial unit, with a much smaller chamber, can achieve its target pressure quickly and efficiently with a single, high-quality rotary vane pump7 like those from Leybold or Busch. You are paying for speed and efficiency at scale. An industrial system is a finely-tuned engine for high-volume production, while a commercial system is a reliable and flexible motor for smaller-batch work.

| Technology | Commercial System | Industrial System |

|---|---|---|

| Compressor Type | Scroll or Reciprocating | Screw Compressor |

| Vacuum Pump System | Single Rotary Vane Pump | Roots Pump + Rotary Vane Pump Combination |

| Best Efficiency | During intermittent, varied loads | During continuous, high-capacity operation |

| Energy Consumption | Excellent for start/stop cycles | Lowest kWh/ton on long runs |

| Control System | Often simpler controls for ease of use | Advanced PLC for process integration & data logging |

How Do Price and ROI Factor Into the Decision?

The upfront price tag on an industrial vacuum cooler can be intimidating. This often makes the lower cost of a commercial model seem like a much safer, more logical choice. But this sticker-price thinking can be a deeply flawed way to make an investment decision.

Basing your purchase on the initial price alone can lead to a disastrously high total cost of ownership. A machine that is too small for your needs has a hidden cost in lost product value, while a machine that is too big has a hidden cost in wasted energy and capital.

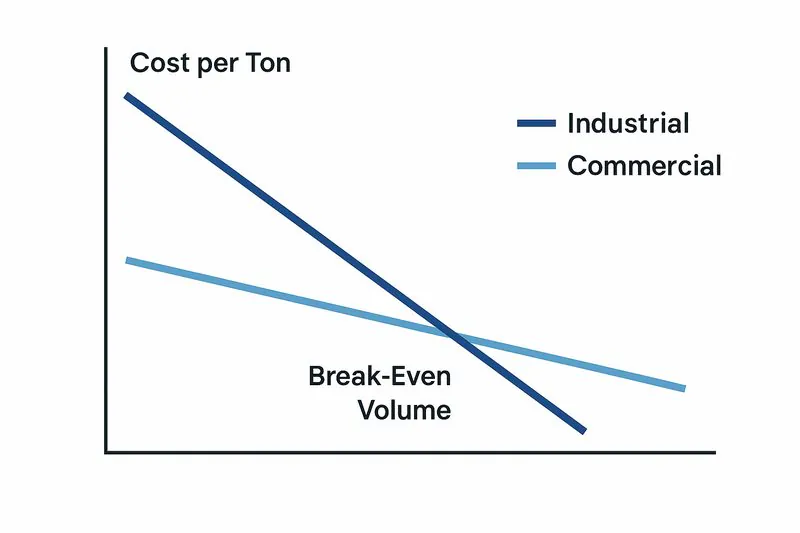

An industrial machine has a higher initial price but delivers a lower cost-per-ton and a faster ROI at high volumes due to superior efficiency and throughput. A commercial machine provides a lower entry cost, making it the financially smarter choice for smaller operations where volume doesn’t justify the larger investment.

The Total Cost of Ownership

The true financial measure isn’t the price you pay today, but the Total Cost of Ownership8 (TCO) over the machine’s life. This includes the purchase price, installation, energy costs, maintenance, and labor. Crucially, it also includes the return you get from preventing product loss and increasing shelf life. For Carlos, the calculation is simple. An 8-pallet industrial machine costs significantly more upfront than four separate 2-pallet commercial machines. However, its screw compressor system is vastly more energy-efficient9 per ton of broccoli cooled. Its automated door reduces labor. Most importantly, by cooling 50 tons in 6 hours instead of 24, he can reduce his post-harvest losses by 5%. For a harvest of that size, preventing that loss can be worth hundreds of thousands of dollars per season, meaning the industrial machine can pay for itself in less than two years.

For a central kitchen manager like Sophia, who needs to cool cooked food, a smaller 1-pallet stainless steel commercial unit is a far better investment. Her volume is lower, and she needs to run specific batches hygiene-critically. The lower initial cost fits her department’s budget, and the ROI comes from meeting HACCP requirements10, improving food safety, and creating a more efficient kitchen workflow. The massive throughput of an industrial machine would be wasted, making it a poor financial choice for her. You must analyze your own operation: calculate the value of the product you could save and the premium you can charge for higher quality. This will reveal the true ROI.

| Financial Factor | Commercial Vacuum Cooler | Industrial Vacuum Cooler |

|---|---|---|

| Initial Purchase Price | Lower | Higher |

| Cost per Ton (Energy) | Efficient for small batches, high for large volume | Higher for small batches, very low for high volume |

| Return on Investment | Driven by enabling new quality standards | Driven by massive reduction in product loss at scale |

| TCO at Low Volume | Lower | Higher |

| TCO at High Volume | Prohibitively High | Lower |

Conclusion

The choice is not about which type is "better"—an industrial cooler is not inherently better than a commercial one. It is about which tool is right for the job. By honestly assessing your peak daily tonnage, your operational intensity, and your future growth plans, you can confidently select the machine that will be a profitable and reliable asset for your business for years to come.

-

Explore this link to understand how industrial machines can efficiently cool large harvests, ensuring quality and freshness. ↩ ↩

-

Understanding industrial-level reliability can help you choose machines that last longer and perform better under stress. ↩

-

Exploring this concept will provide insights into the durability and performance expectations for industrial machines. ↩

-

Explore the advantages of screw compressors for energy efficiency and performance in industrial settings. ↩

-

Find out how to enhance energy efficiency in industrial operations, saving costs and resources. ↩

-

Discover the importance of vacuum systems in industrial applications and their role in efficiency. ↩

-

Learn about rotary vane pumps, their operation, and why they are essential in various industrial processes. ↩

-

Understanding TCO helps businesses make informed financial decisions, ensuring long-term savings and efficiency. ↩

-

Exploring energy efficiency can lead to significant cost savings and environmental benefits for your operations. ↩

-

Understanding HACCP is essential for ensuring food safety and compliance in food production and handling. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf

How Do You Troubleshoot Common Vacuum Cooler Problems?

Your harvest is ready, the pallets are stacking up, but your vacuum cooler suddenly stops. A red light is flashing,