Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not just free of chemicals, but are also vibrant, nutritious, and bursting with natural vitality. But that "just-picked" perfection is incredibly fragile and starts to fade the moment of harvest.

This creates a serious dilemma. You can’t use conventional post-harvest treatments to fight decay, so you’re in a race against time, watching your premium product lose its value with every passing hour. This limits your market, increases your spoilage rate, and threatens the very quality that defines your brand.

Yes, it is essential. For organic producers, vacuum cooling is the most powerful non-chemical tool available to preserve the crop’s integrity. It locks in the visual appeal, nutrient value, and freshness that justify the organic premium, while naturally suppressing the decay process and dramatically extending shelf life.

The principles of organic farming are about working with nature, not against it. Vacuum cooling aligns perfectly with this ethos. It uses the natural properties of water to protect your harvest, ensuring the product that reaches your customers is a true reflection of the care you took to grow it. Let’s explore why this technology is not just an advantage, but a necessity for the modern organic farm.

How Does Rapid Cooling Protect Your Organic Price Premium?

The organic premium isn’t just for the certification; it’s for a visibly superior product. Customers are willing to pay more for lettuce that is crisper, spinach that is a deeper green, and broccoli that is firm and vibrant. When that visual quality degrades, your price justification vanishes.

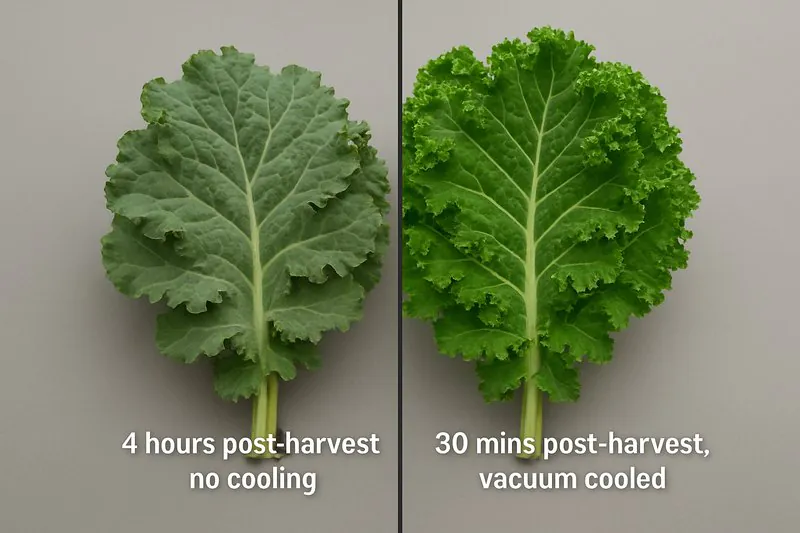

Slow cooling allows for the slow process of wilting and cellular breakdown to begin immediately. Even a few hours of field heat can cause a noticeable loss of turgor (crispness) and color. This forces you to either sell a product that doesn’t represent your brand or discount it, eroding your hard-earned margins.

Vacuum cooling acts as a "pause button" on the processes that degrade visual quality. By instantly halting respiration and locking in cellular moisture, it preserves the bright colors and crisp texture that customers equate with premium organic freshness, safeguarding your price point and brand reputation.

The Science of Perceived Value

For an organic grower like Anna, her product’s appearance is her brand. She knows that a discerning buyer like Norman can spot the difference in quality from across the warehouse. Protecting that quality is her number one priority.

Locking in Turgor and Chlorophyll

The value of organic produce is judged in seconds by the consumer. That judgment is based on two key physical properties: turgor pressure1 and chlorophyll content2. Turgor is the water pressure inside the plant’s cells that makes it feel crisp and firm. Chlorophyll is the pigment that gives it a vibrant, healthy green color. Field heat is the enemy of both. It accelerates respiration, which causes the cells to lose water, leading to limp, wilted leaves. It also activates enzymes that break down chlorophyll, leading to yellowing. Vacuum cooling’s sub-30-minute temperature drop effectively flash-freezes these degradation processes in their tracks. It stops the water loss, keeping the turgor high. It deactivates the enzymes, locking in the chlorophyll. The result is a product that doesn’t just last longer, but looks farm-fresh for days longer. This visible, tangible difference is what allows Anna to confidently charge a premium and what convinces Norman to choose her produce over a competitor’s.

A Measurable Difference in Quality

This isn’t just subjective. Studies have shown a quantifiable difference. For example, vacuum-cooled lettuce can retain up to 95% of its initial Vitamin C content after a week of storage, while slowly cooled lettuce might retain only 75-80%. While the average consumer might not have a lab, they can see and taste the difference. They perceive the crisper texture and brighter color as signs of higher nutrient content and freshness, reinforcing their belief in the value of organic and building loyalty to your farm’s brand.

| Quality Metric | Without Vacuum Cooling (after 24 hours) | With Vacuum Cooling (after 24 hours) | Impact on Organic Premium |

|---|---|---|---|

| Visual Crispness | Noticeably softer, slight wilting | "Just-picked" firmness | High – Justifies Price |

| Color | Begins to dull, hints of yellowing | Vibrant, deep green | High – Sign of Health |

| Moisture Loss | 2-4% weight loss | ~1.5% controlled loss | Moderate – Affects Profit |

| Nutrient Value | Degradation begins immediately | Largely preserved | High – Core Brand Promise |

Can Vacuum Cooling Replace the Need for Post-Harvest Treatments?

As an organic grower, your toolbox for fighting post-harvest decay is intentionally limited. You cannot use fungicides to control mold, bactericides to stop rot, or waxes to seal in moisture. You must rely on natural, physical processes.

This can feel like a competitive disadvantage when your produce is sitting next to conventionally grown items that have been treated to extend their shelf life. The pressure to maintain quality and safety without these tools is immense, as microbial growth can lead to rapid spoilage and waste.

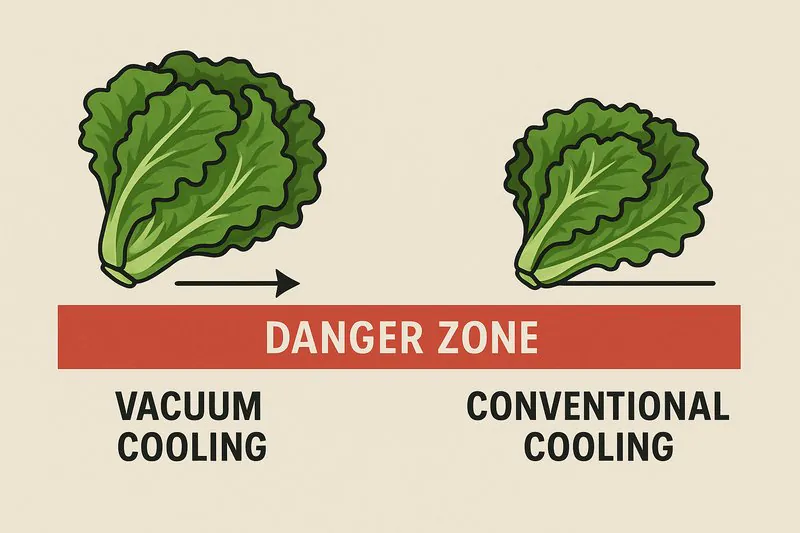

Absolutely. Vacuum cooling is a powerful physical intervention that acts as a microbial control point. By rapidly pulling the produce through the temperature "danger zone" (4-40°C or 40-100°F), it gives mold spores and bacteria no time to activate and multiply, offering a level of protection that rivals chemical treatments.

A Physical Solution Aligned with Organic Principles

For a supply chain manager like Sophia, who must adhere to strict HACCP and food safety standards, the low microbial load of vacuum-cooled organic produce3 is a major advantage. It makes Anna’s farm a preferred supplier.

Winning the Race Against Microbes

Every vegetable harvested is covered in a natural biofilm of microorganisms, including common spoilage agents like Botrytis (grey mold) and Erwinia (soft rot bacteria). At warm field temperatures, these organisms are primed for explosive growth. All they need is time. A traditional cold room, which can take 12-24 hours to cool the center of a pallet, provides the perfect incubation period. This is a risk organic growers cannot afford. Vacuum cooling removes the "time" variable from the equation. In under 30 minutes, the product is brought to a temperature where microbial activity4 is virtually dormant. It’s a purely physical process—no additives, no residues, just the power of thermodynamics. This aligns perfectly with the USDA National Organic Program (NOP) standards5, which emphasize physical and mechanical methods over synthetic inputs.

Ensuring Uniform Safety

One of the biggest risks in any cooling process is a lack of uniformity. With forced-air cooling6, the produce on the outside of the pallet gets cold, but the warm, humid center can become a breeding ground for bacteria. This leads to unpredictable shelf life and potential safety issues. Vacuum cooling is fundamentally different. The pressure drop occurs throughout the entire chamber at once, meaning every single leaf on every head of lettuce, from the corner of the pallet to the very core, cools at the same rate. This unprecedented uniformity eliminates "hot spots" and guarantees that the entire shipment has been brought to a safe temperature. For Anna, this means she can ship her products with absolute confidence, knowing there won’t be any unpleasant surprises when her customer opens the box. This reliability is priceless.

How Can This Technology Unlock New, More Profitable Organic Markets?

The market for premium organic produce is often not in your local town; it’s in the affluent urban centers, the high-end restaurant districts, and the dedicated organic supermarket chains hundreds of miles away. But without a long and reliable shelf life, reaching these markets is just a dream.

You’re stuck competing locally, often against other organic growers, which can drive down prices. You know that if you could just get your product to the city in perfect condition, you could command a much higher price and secure larger, more stable contracts.

Vacuum cooling is the key that unlocks these distant markets. By adding 7-14 days of viable shelf life, it transforms your fragile organic vegetables into a stable, shippable product. This allows you to confidently bypass local competition and build a profitable business supplying premium urban markets.

Building a Resilient, Scalable Organic Business

Expanding her market is Anna’s primary goal for long-term growth. She wants to move from selling by the crate at the farmers’ market to selling by the pallet to regional distributors.

Becoming a Distributor’s Dream Partner

Regional produce distributors who specialize in organics, the kind who would work with a buyer like Norman, operate on logistics. They need a reliable supply7 of high-quality products8 that can withstand a 2-3 day journey in a refrigerated truck and still offer a week of shelf life at the retail store. Without vacuum cooling9, this is nearly impossible for highly perishable items like leafy greens. With vacuum cooling, Anna can meet these requirements easily. She can guarantee that her lettuce will arrive crisp and her herbs will arrive fragrant. This makes her a low-risk, high-value partner for a distributor. It allows her to negotiate from a position of strength, securing contracts that provide a stable, predictable income stream for her farm.

Tapping into the Direct-to-Consumer and Restaurant Market

The rise of organic meal kits and direct-to-consumer10 (DTC) delivery boxes is a massive opportunity. These businesses require ingredients with a guaranteed shelf life to plan their menus and delivery schedules. Vacuum-cooled produce is a perfect fit. Similarly, high-end restaurants pride themselves on the quality of their ingredients. A chef who receives a box of Anna’s vacuum-cooled spinach will immediately notice that it lasts longer in their walk-in cooler and performs better in their dishes. This builds a reputation for excellence and allows Anna to become a direct, premium supplier to the culinary scene, often at the highest price points in the entire market. This technology doesn’t just let you ship farther; it allows you to aim higher.

| Business Model | Without Vacuum Cooling | With Vacuum Cooling | Growth Potential |

|---|---|---|---|

| Local Farmers’ Market | High competition, price sensitive, high daily waste | Product stays fresh all weekend, commands premium price | Low |

| Local Restaurants | Limited to daily delivery, small order sizes | Can deliver for several days at once, ensures consistency | Moderate |

| Regional Distributor | Essentially Impossible for fragile greens | Becomes Primary Business Model, stable pallet orders | High |

| Urban DTC/Meal Kits | Impossible – cannot guarantee shelf life | Ideal Supplier, meets quality and logistics requirements | Very High |

Conclusion

For organic producers, vacuum cooling isn’t just a piece of equipment; it’s a strategic partner. It protects the premium quality your customers demand, operates in perfect harmony with organic principles, and unlocks the profitable markets you need to build a sustainable business. It ensures your hard work in the field translates to full value at the market.

-

Understanding turgor pressure helps grasp how plants maintain their structure and quality, crucial for organic growers. ↩

-

Exploring chlorophyll’s role reveals why vibrant color is essential for perceived freshness and quality in organic farming. ↩

-

Discover how vacuum cooling enhances the safety and quality of organic produce, making it a game-changer for suppliers. ↩

-

Explore the science behind vacuum cooling and its impact on microbial activity, ensuring safer food for consumers. ↩

-

Learn about the USDA NOP standards to understand how they ensure organic integrity and consumer trust. ↩

-

Find out why forced-air cooling can be risky for produce safety and how alternatives like vacuum cooling can help. ↩

-

Understand the importance of a reliable supply chain in maintaining product quality and meeting market demands. ↩

-

Discover the key attributes of high-quality organic products that attract distributors and premium customers. ↩

-

Explore how vacuum cooling enhances produce quality and shelf life, making it essential for distributors and restaurants. ↩

-

Learn strategies for thriving in the DTC market, especially with organic meal kits and delivery services. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer