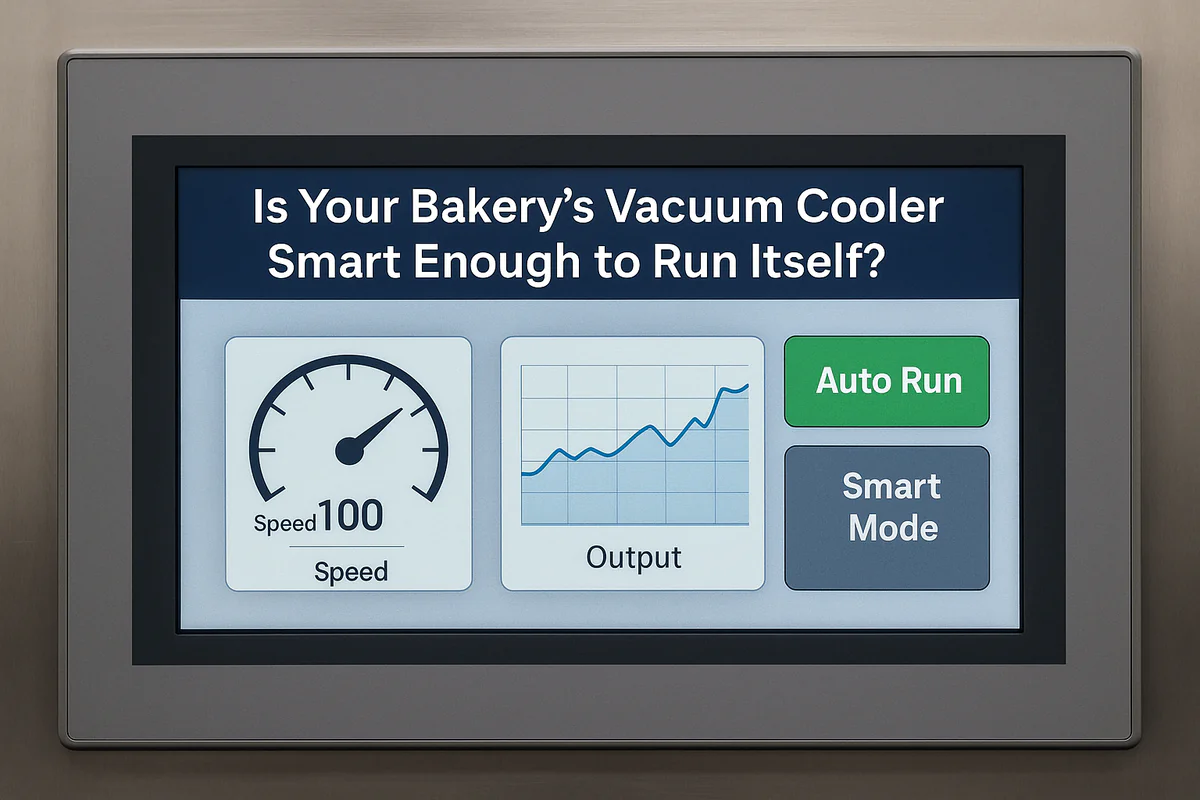

Is Your Bakery's Vacuum Cooler Smart Enough to Run Itself?

You have invested in the best ovens, the finest ingredients, and skilled bakers. But when it comes to cooling, are you still relying on guesswork?

In the past, cooling was a manual game. You watched the clock, checked the core temperature with a handheld probe, and hoped for the best. Today, that is not enough. Modern bakeries demand consistency, speed, and data. This is where the brain of the machine—the Automated Control System—changes everything.

Modern vacuum cooling equipment is driven by sophisticated PLC (Programmable Logic Controller) systems, typically from Siemens. These systems integrate touch screen HMIs, precise vacuum sensors, and automated cycle management to deliver consistent cooling from 90°C to 30°C in minutes, without constant human supervision.

As a manufacturer, I see the relief on my clients’ faces when they realize they don’t need a PhD in engineering to operate our machines. Let’s look at what makes these "smart" systems the backbone of a modern bakery.

What Are the Key Components of the Control System?

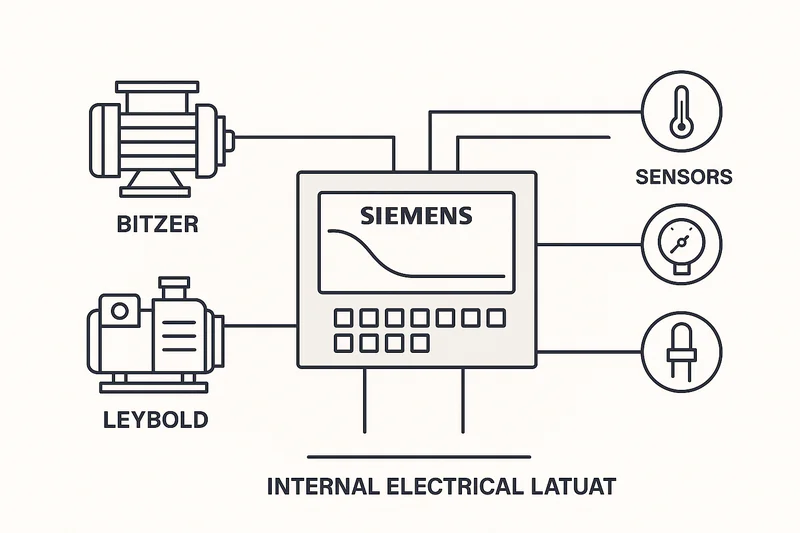

The "brain" of a vacuum cooler isn’t just one part; it is a network of high-quality components working together. If you buy a cheap machine with generic controls, you are buying a headache. We use top-tier brands because, in a bakery, downtime is not an option.

Our standard control architecture relies on a Siemens PLC and Touch Screen, supported by Schneider Electric contactors and Carlo Gavazzi phase protection. This combination ensures that the vacuum pump and compressor operate in perfect harmony, protecting your investment from electrical faults.

The Hardware Behind the Intelligence

For a technical decision-maker like Carlos, knowing the brand names matters. It speaks to reliability and ease of finding replacement parts.

1. The Core Processor (PLC)

We use Siemens1 PLCs. This is the industrial standard. It processes data from temperature probes and pressure sensors millisecond by millisecond. It decides when to open the vacuum valve, when to start the Bitzer2 compressor, and when to stop the cycle.

2. The Human Machine Interface (HMI)

The Siemens Touch Screen is your window into the process. It replaces old-fashioned buttons and dials.

- Visual Feedback: You can see the vacuum level (mbar) and product temperature (°C) in real-time.

- Simple Operation: Operators just press "Start." The system handles the complex sequencing of valves and motors.

3. Safety and Protection

Behind the scenes, components like Schneider thermal relays and Carlo Gavazzi phase protection stand guard.

- Why it matters: If your factory’s voltage spikes or a phase is lost, these components cut the power instantly to save the expensive vacuum pump and compressor motors.

| Component | Brand Used | Function | Why it matters? |

|---|---|---|---|

| PLC | Siemens | Central Processing | Reliable logic control, global support. |

| Touch Screen | Siemens | Operator Interface | Easy to use, visual data display. |

| Contactors | Schneider | Power Switching | High durability for frequent cycling. |

| Phase Protection | Carlo Gavazzi | Safety Monitoring | Prevents motor burnout from bad power. |

How Does Automation Guarantee Product Consistency?

Consistency is the holy grail of baking. You want every loaf of bread to have the same crust, the same moisture, and the same shelf life. Manual cooling cannot guarantee this.

An automated system removes the "human error" factor. It doesn’t get tired, and it doesn’t forget to check the probe.

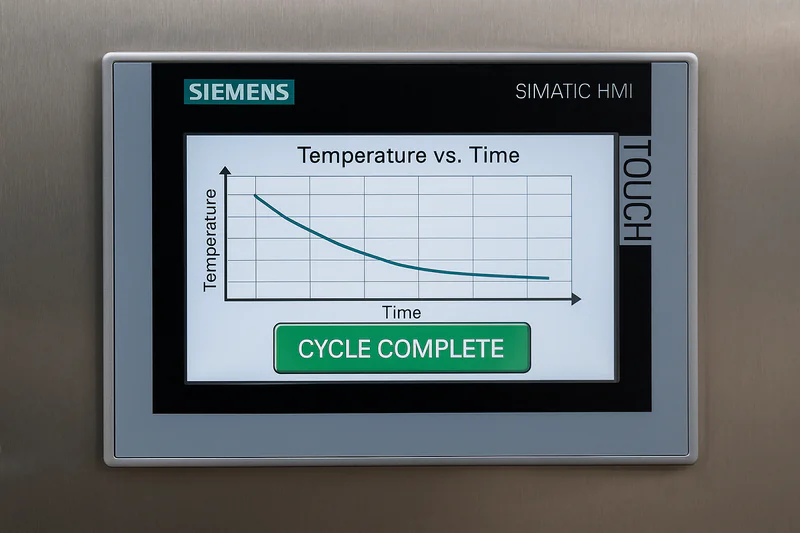

The control system offers "Recipe Management" and "Target Temperature" modes. You can set the machine to cool to exactly 30°C or 3°C. The system monitors the core temperature probe and automatically stops the vacuum cycle the precise moment the target is reached.

Modes of Operation

For a QA manager like Sophia, these modes are critical for HACCP compliance.

Temperature-Based Control3

This is the most accurate method. You insert a probe into the bread.

- Process: You set the target (e.g., 30°C).

- Action: The PLC runs the vacuum pump. As the pressure drops, water evaporates, and the bread cools.

- Precision: When the probe reads 30°C, the machine automatically repressurizes. No over-cooling, no under-cooling.

Time-Based Control

Useful for standard batches where the parameters are well-known.

- Process: Set the timer for 15 minutes.

- Action: The machine runs a fixed cycle.

- Benefit: Good for high-speed throughput where inserting probes might slow down the workflow.

Vacuum Delay Facility4

This is a smart feature for special products.

- The Problem: Some products (like delicate sponges) might explode if the vacuum pulls too fast.

- The Solution: The "Vacuum Delay" allows the pressure to drop in steps or holds it at a certain level to let the structure stabilize before deep cooling. This ensures uniform cooling for the whole product load.

Can the System Save Energy and Reduce Maintenance?

A "dumb" machine runs at full power until you turn it off. A "smart" machine knows when to rest. This intelligent management is key to lowering your operational costs.

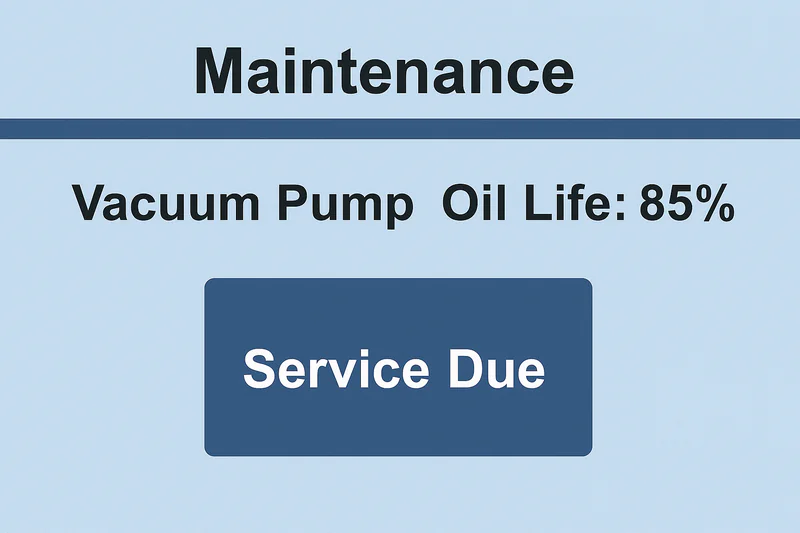

Automated systems feature "Auto-Shutdown" and "Eco-Modes." If the machine has not been used for a set period, it automatically shuts down to save electricity. Furthermore, the HMI tracks run-hours to remind you of maintenance intervals, preventing costly breakdowns.

Intelligent Efficiency & Diagnostics

For an owner like Norman, this translates directly to the bottom line.

Energy Saving Logic5

Our systems are programmed to minimize waste.

- Standby Mode: When the vacuum cooler has not been operated for a period of time, the machine will automatically shut down to save electricity usage. You don’t pay for an idling machine.

- Zero Load Protection: After work is finished, the system suggests keeping the vacuum pump running for 40 minutes under zero load to evaporate moisture from the oil. This automated suggestion extends the life of your expensive pump oil.

Predictive Maintenance6

The PLC acts as a mechanic on board.

- Oil Change Reminders: It tracks the running hours of the compressor and vacuum pump. It reminds you to change the compressor oil every 2 years or check the pump oil monthly.

- Fault Diagnostics: If the machine stops, the screen doesn’t just say "Error." It tells you "Thermal Overload" or "Phase Error." This allows for remote commissioning support, which is perfect for clients in places like Singapore who need quick answers.

Conclusion

The automated control system is not just a fancy screen; it is your guarantee of quality. With Siemens components, precise temperature control, and energy-saving logic, modern vacuum coolers transform a complex industrial process into a simple "push-button" operation.

When you choose a vacuum cooler, look beyond the steel. Look at the brain. A smart machine works harder, so you don’t have to.

-

Explore this link to understand why Siemens PLCs are considered the industrial standard for reliability and performance. ↩

-

Discover the benefits of Bitzer compressors and why they are essential for efficient cooling and refrigeration systems. ↩

-

Understanding Temperature-Based Control is essential for ensuring food safety and quality in HACCP compliance. ↩

-

Exploring the Vacuum Delay Facility can enhance your knowledge of advanced cooling techniques for delicate products. ↩

-

Explore how Energy Saving Logic can significantly reduce operational costs and enhance efficiency in your systems. ↩

-

Learn how Predictive Maintenance can prevent costly downtimes and extend the lifespan of your machinery. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy