Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still dealing with inconsistent product quality, rejected shipments, and customer complaints about produce that "dies on the shelf."

The frustration is immense. You’ve optimized every link in the chain, yet the problems persist. This leads to credit claims, strained supplier relationships, and a constant battle to maintain your reputation for quality. You’re losing money on a system that should be saving it.

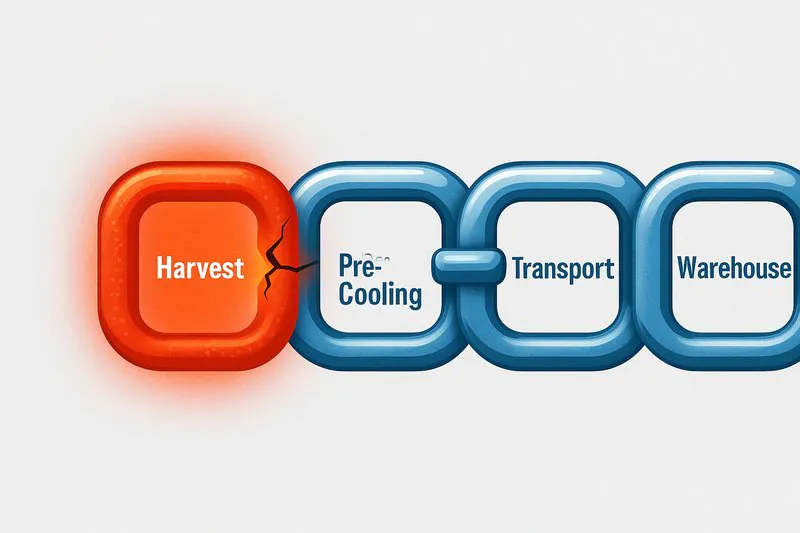

Yes, it often is. A cold chain is only as strong as its first link. If field heat is not removed with extreme speed before the produce is loaded for transport, the entire downstream system is forced to play catch-up, leading to uneven cooling, accelerated decay, and significant financial losses.

As someone who designs cooling solutions for large-scale logistics, I can tell you that the most common point of failure is not in the truck or the warehouse; it’s in the first three hours after harvest. Vacuum cooling isn’t just another piece of equipment; it’s the technology that forges the first, most crucial link of the cold chain in unbreakable steel.

Why Can’t a Refrigerated Truck Remove Field Heat Effectively?

A common and costly misconception is that a refrigerated truck (a "reefer") is designed to cool down warm produce. You load a pallet of lettuce harvested at 30°C (86°F) into a truck set to 2°C (36°F) and expect it to arrive cold. This is a recipe for disaster.

This practice leads to pallets arriving with warm cores and wet, slimy outer layers. The result is a rejected load, a costly return trip, and a panicked call to find a replacement product. It’s an expensive operational headache that is entirely preventable.

A refrigerated truck is designed only to maintain a cold temperature, not to remove the massive thermal load of field heat. The truck’s refrigeration unit lacks the power and airflow to cool a dense pallet uniformly, creating a "hot core" effect that fuels rapid decay during transit.

The Physics of In-Transit Cooling Failure

For a logistics professional like Norman, understanding this is key to setting effective supplier requirements. For a packing center owner like Carlos, it’s fundamental to guaranteeing the quality of every shipment he sends.

Power vs. Maintenance

Let’s talk in terms of energy. A single pallet of warm lettuce can hold a massive amount of thermal energy1. Removing this "field heat" requires a tremendous amount of cooling power concentrated over a short period. A vacuum cooler2 is a specialized, high-horsepower machine designed for exactly this task. It can extract that energy in under 30 minutes. A truck’s refrigeration unit, on the other hand, is a low-horsepower system designed for maintenance. Its job is to combat the small amount of heat that leaks through the trailer’s insulated walls. It has neither the BTUs of cooling power nor the airflow mechanism to penetrate a tightly packed pallet.

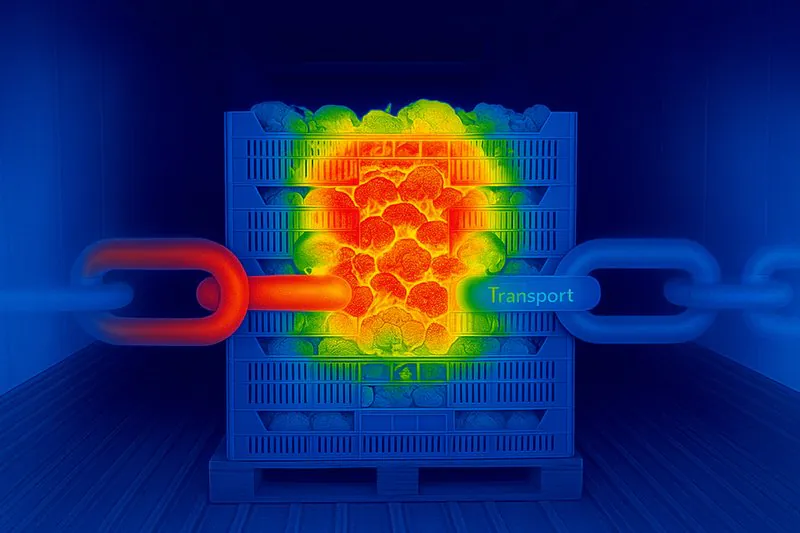

The Pallet Becomes an Insulator

When you stack boxes of produce onto a pallet and wrap it in plastic, you are creating a very effective insulator. The cold air from the reefer unit blows over the outside of the pallet, chilling the outer boxes. But deep inside, the produce continues to respire, generating its own heat. The pallet wrap and surrounding boxes trap this heat, creating a warm, humid micro-environment in the core. This is the perfect breeding ground for mold and bacteria. When Norman’s team inspects the delivery, they stick a probe into the center of the pallet. If that probe reads 10°C (50°F) instead of the required 2°C (36°F), the entire load is rejected. No excuses.

| Cooling Method | Primary Function | Power Level | Time to Cool Pallet Core | Result |

|---|---|---|---|---|

| Vacuum Cooler | Heat Removal (Pre-Cooling) | Very High | < 30 minutes | Uniformly cold, stable product for shipping |

| Refrigerated Truck | Temperature Maintenance | Low | 24-48+ hours (if ever) | Hot core, surface condensation, spoilage |

By insisting that his suppliers use vacuum cooling, Norman isn’t adding a cost; he’s eliminating the single biggest cause of load rejections3 and ensuring his multi-million dollar logistics network can actually do its job.

How Does Vacuum Cooling Maximize Warehouse Efficiency and Shelf Space?

Your distribution center is a high-stakes, high-turnover environment. Every square foot of refrigerated space costs money, and every pallet that sits there for too long is a drain on profitability. The goal is "First In, First Out" (FIFO), but that only works if the "In" product has a predictable life.

When you receive shipments of produce with inconsistent core temperatures, you can’t trust them. You’re forced to allocate extra space for quality control inspections, create "quarantine" zones for questionable pallets, and deal with the chaos of unpredictable spoilage, which disrupts your entire inventory flow.

Vacuum cooling delivers pallets that are uniformly cooled to the core, creating a product with a predictable and significantly extended shelf life. This allows warehouses to reduce inspection overhead, implement true FIFO systems, maximize space utilization, and drastically reduce costly write-offs.

From Chaotic Inventory to a Smooth Supply Chain

For a detail-oriented manager like Sophia, who runs a central kitchen for a fast-food chain, predictability is everything. She needs to know that the lettuce delivered on Monday will still be perfect for making sandwiches on Thursday. This starts with how it’s managed in the distribution center.

The Power of Predictability

When a pallet arrives at the warehouse pre-cooled by a vacuum cooler, it has a "Known Good" status. The receiving staff knows it’s at a stable 2°C throughout. It can be immediately logged into the inventory system with a predictable "Best By" date and moved directly into its designated slot. Contrast this with a truck-cooled pallet. It arrives with a temperature variance. The warehouse is now forced to break the pallet down, take multiple temperature readings, and make a judgment call. Does it need to be shipped out immediately? Can it wait a day? This guesswork leads to chaos. Some product is shipped prematurely, while other product sits and spoils. Vacuum cooling eliminates this guesswork. It turns produce from a variable into a constant, which is the foundation of all modern logistics.

Maximizing Cube and Minimizing Waste

A distribution center’s profitability is measured in cubic feet. The more product you can move through a given space, the more profitable you are. Unpredictable spoilage is the enemy of this model. When you have to write off 5-10% of your produce inventory because it spoiled in the warehouse, that’s a direct hit to your bottom line. It’s lost revenue and the lost cost of the space it occupied. By extending the reliable shelf life from, say, 3 days to 10 days, vacuum cooling4 gives the warehouse an enormous operational buffer5. It allows for more flexible dispatching, reduces the pressure for emergency sales, and dramatically cuts the percentage of product that must be discarded. This reduction in waste often pays for the incremental cost of properly pre-cooled produce many times over.

Can Pre-Cooling Reduce Overall Energy Consumption in the Cold Chain?

It seems counterintuitive. You’re adding a large, powerful machine at the start of the process. Surely that must increase the total energy bill for getting produce from the farm to the store, right?

This is a common concern for vertically integrated companies that own the farms, the packing houses, and the logistics network. They look at the total cost of energy per pallet and question the addition of another energy-consuming step.

Yes, it can. While a vacuum cooler is powerful, it is also incredibly efficient at its specific task of heat removal. By performing this function rapidly at the source, it prevents the inefficient, long-term energy waste of refrigerated trucks and warehouses trying (and failing) to do a job they weren’t designed for.

A Holistic View of Energy Logistics

An owner like Carlos, who is responsible for his packing center’s P&L, is highly sensitive to energy costs6. Showing him how an investment in pre-cooling reduces total chain-wide energy consumption is a powerful argument.

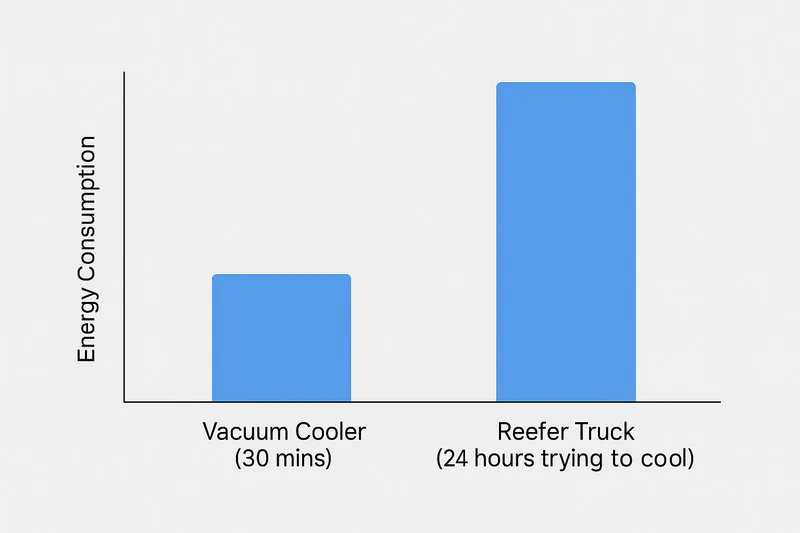

The Right Tool for the Job

Think of it like boiling water. You could leave a pot of water in a warm oven for five hours and it might eventually get hot, consuming a massive amount of energy inefficiently. Or, you could put it on a gas stove burner for five minutes. The burner uses intense energy for a short period, but the total energy consumed is far, far less. A vacuum cooler7 is the gas stove; a refrigerated truck is the oven. The vacuum cooler’s large pumps and refrigeration system are optimized for one thing: bulk heat removal. They do it in minutes. The truck’s system, running for 24, 48, or even 72 hours of a long haul, is constantly fighting a losing battle against the heat radiating from the pallet’s core. This sustained, inefficient effort consumes a staggering amount of diesel fuel over the journey.

The Cumulative Effect

The energy savings don’t stop at the truck. When warm pallets enter a warehouse, they radiate heat, forcing the warehouse’s own massive refrigeration systems to work harder to maintain the ambient temperature. It’s like leaving the door of your home refrigerator open. The compressor has to run constantly to compensate. By ensuring every pallet that enters the warehouse is already at a stable cold temperature, you significantly reduce the thermal load8 on the building’s cooling system. This leads to lower electricity bills for the distribution center. When you look at the energy consumption of the entire cold chain9 holistically, the short, intense, and highly efficient work done by the vacuum cooler at the beginning prevents a much larger, more sustained, and inefficient energy drain all the way down the line.

| Process Step | Energy Profile without Pre-Cooling | Energy Profile with Vacuum Pre-Cooling | Overall Energy Impact |

|---|---|---|---|

| Pre-Cooling | N/A | Intense, targeted energy use (~30 mins) | Added initial energy |

| Transport | Sustained, high energy use for 24-72 hrs | Low, maintenance-level energy use | Massive Savings |

| Warehouse | Higher ambient load, more compressor runtime | Lower ambient load, less compressor runtime | Significant Savings |

Conclusion

A modern cold chain is a system of precision. Investing in vacuum cooling at the source is the ultimate act of system optimization. It ensures the chain starts with a perfectly prepared product, allowing every subsequent link—from truck to warehouse to retailer—to function at peak efficiency, minimizing waste and maximizing profit.

-

Learn about thermal energy’s role in logistics to better grasp how it affects product quality and shipping efficiency. ↩

-

Explore this link to understand how vacuum coolers efficiently remove heat, ensuring product quality during transport. ↩

-

Understanding load rejections can help you improve shipping practices and reduce losses in your logistics operations. ↩

-

Explore how vacuum cooling can enhance your supply chain efficiency and reduce spoilage. ↩

-

Understand the concept of operational buffers and their critical role in enhancing supply chain performance. ↩

-

Understanding energy costs is crucial for optimizing logistics and reducing expenses. ↩

-

Explore how vacuum coolers enhance efficiency and reduce energy consumption in logistics. ↩

-

Learn about thermal load to better manage energy efficiency in warehouses and distribution centers. ↩

-

Discover the significance of cold chains in maintaining product quality and reducing energy waste. ↩

Mila

You May Also Like

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer

How Do You Customize a Vacuum Cooling Cycle for Different Vegetables?

You’ve invested in a powerful vacuum cooler, expecting it to be a simple "set it and forget it" solution. But