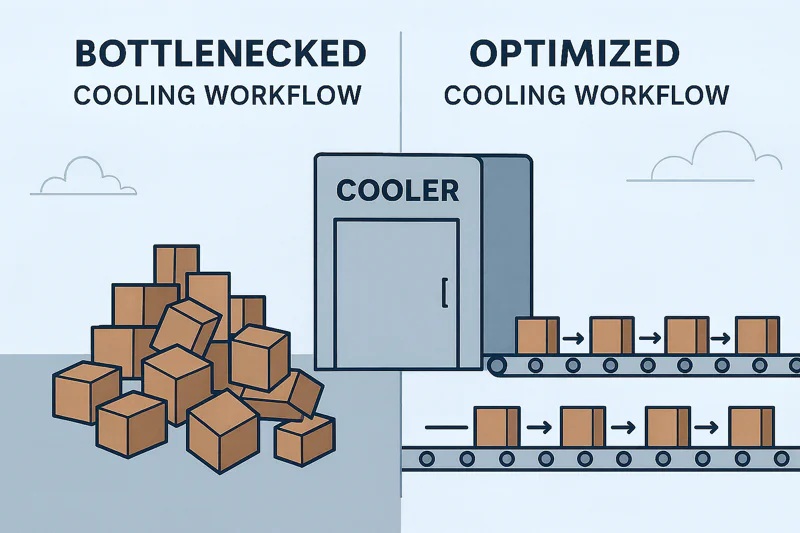

Is Your Cooling Process Creating a Bottleneck in Your Production Line?

Your production line constantly stops, waiting for your cooling process to catch up. This bottleneck wastes time, increases labor costs, and disrupts your entire workflow, costing you money.

To avoid bottlenecks, your vacuum cooler must be integrated with automated conveyor systems. Optimizing the pre-cooling and post-cooling workflow ensures a continuous flow, matches the cooler’s cycle time to your line’s speed, and eliminates costly delays.

As a factory owner, I often see customers buy powerful equipment but fail to think about how it fits into their day-to-day operations. A vacuum cooler is incredibly fast, but if you spend 15 minutes manually loading it and another 15 unloading it, you’ve lost a huge chunk of your efficiency. The goal is to make the machine a seamless part of your flow, not an island that disrupts it. Planning the workflow is just as important as choosing the machine itself.

Where Should a Vacuum Cooler Go in Your Production Line?

You’ve invested in a new cooler, but where does it fit? Placing it wrong can disrupt your entire process, creating more problems than it solves and causing logistical nightmares.

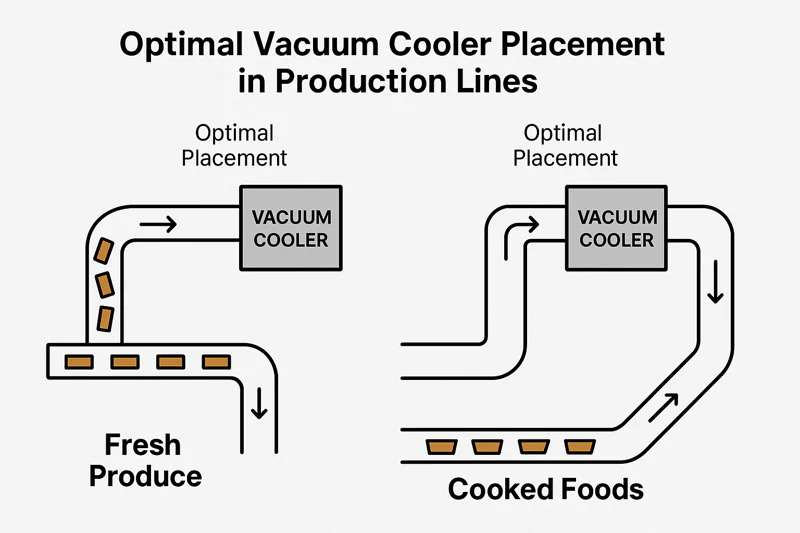

For fresh produce, the cooler goes immediately after harvest/packing (pre-cooling). For cooked foods, it goes right after the oven (post-cooling). The goal is to remove heat at the earliest possible moment to maximize quality and safety.

Strategic Placement: Pre-Cooling vs. Post-Cooling

The correct placement of your vacuum cooler is the foundation of an efficient workflow. The decision depends entirely on your product. The guiding rule is always: cool it fast and cool it early.

For a farm owner like Carlos who grows fresh vegetables, the process is called pre-cooling1. The enemy is "field heat." Every minute his lettuce or mushrooms sit after harvest, they are losing water weight, burning sugars, and starting to spoil. The vacuum cooler must be placed directly in the post-harvest workflow. The ideal sequence is: Harvest -> Clean/Pack -> Vacuum Cool -> Move to Cold Storage or Refrigerated Truck. Placing the cooler here stops degradation in its tracks, locking in freshness and weight before the product enters the cold chain. Putting it anywhere else means you are shipping a product that has already begun to spoil.

For a central kitchen manager like Sophia, who deals with cooked foods, the process is called post-cooling2. Her main concern is food safety, specifically the HACCP "danger zone" (5°C to 60°C) where bacteria multiply rapidly. The vacuum cooler must be placed immediately after the cooking stage. The workflow is: Cook (in an oven, steamer, or kettle) -> Vacuum Cool -> Package or Move to Final Chiller. By cooling a large batch of rice or cooked chicken from 90°C to below 5°C in under 30 minutes, she moves the product through the danger zone so quickly that bacteria have no time to grow. This ensures a safe, high-quality product and is critical for passing food safety audits.

| Workflow Scenario | Placement of Vacuum Cooler | Primary Goal | Example Products |

|---|---|---|---|

| Pre-Cooling | Immediately after packing | Halt respiration & preserve freshness | Vegetables, mushrooms, herbs, flowers |

| Post-Cooling | Immediately after cooking | Pass through HACCP danger zone quickly | Cooked rice, pasta, meat, sauces, bread |

How Can You Automate Your Cooler’s Loading and Unloading?

Your team spends too much time manually moving pallets in and out of the cooler with a forklift. This slow, labor-intensive process is a weak link, creating delays and safety risks.

Automate loading by integrating powered conveyor systems. These systems automatically move pallets into the chamber and then onward to the next station, minimizing labor, eliminating delays, and creating a truly continuous production flow.

From Manual Labor to Continuous Flow

The real secret to maximizing the speed of a vacuum cooler3 lies in how you feed it. Manually handling pallets with a forklift is the most common method, but it’s also the slowest and most prone to creating bottlenecks. For a high-volume operation, this manual step completely negates the speed benefits of the 20-minute cooling cycle. The solution is to automate the material handling.

I recently worked with a large bakery that needed to cool thousands of loaves of bread per hour. Their oven was continuous, but their old cooling racks were creating a massive pile-up. We designed a system where a conveyor belt brought the hot bread directly from the oven to an accumulation table. Once enough bread for a full load was ready, it was automatically pushed onto a conveyor that led into the vacuum cooler. The door closed, the cycle ran, and when the door opened, the cooled bread was pushed out onto another conveyor that took it directly to the slicing and bagging machines. The entire process requires only one operator to supervise, not a team of people with pallet jacks. This is the key to true workflow optimization4.

We offer several levels of automation to match a client’s needs:

- Manual System: The operator uses a forklift or pallet jack to load and unload. Best for lower volume or varied product sizes.

- Semi-Automated System: We install powered rollers or a chain conveyor just at the cooler’s door. The operator places the pallet on the conveyor, and the machine handles the rest.

- Fully Automated System: The cooler is one part of a fully integrated conveyor line, as described with the bakery. This is the ultimate solution for maximizing throughput.

| System Type | Labor Requirement | Throughput Speed | Best For… |

|---|---|---|---|

| Manual (Forklift) | High (1-2 operators) | Low | Small farms, varied pallet sizes |

| Semi-Automated (Door Conveyor) | Medium (1 operator) | Medium | Medium-sized producers, dedicated lines |

| Fully Automated (Integrated Line) | Very Low (Supervisory) | High / Continuous | Large factories, central kitchens (like Sophia’s) |

How Do You Synchronize Cooling Cycles with Your Production Rate?

Sometimes your production line outpaces your cooler, creating a pile-up. Other times, the cooler sits empty. This mismatch creates constant bottlenecks and makes your workflow unpredictable.

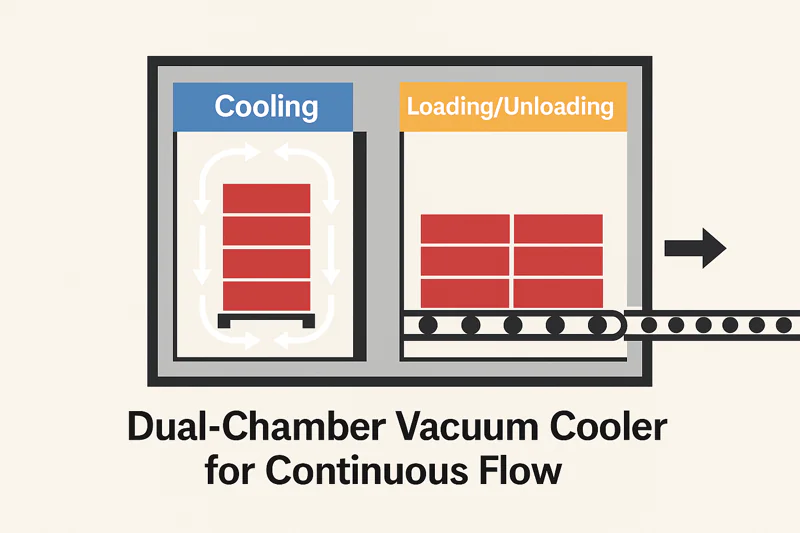

You synchronize them by calculating your hourly throughput and choosing a cooler with the right capacity. For a truly continuous flow, a dual-chamber system allows one chamber to cool while the other is loaded, eliminating all waiting time.

Matching the Heartbeat of Your Production

Your production line5 has a certain rhythm, or "heartbeat"—the number of units or pallets it produces per hour. Your cooling system must match this rhythm perfectly. If your cooler is too slow, product piles up. If it’s too fast (or too large), it sits idle, wasting energy and capital. Synchronization is about doing the math before you buy.

The calculation is straightforward. Let’s say Carlos’s team can harvest and pack 6 pallets of lettuce per hour. A standard vacuum cooling cycle6 for lettuce is about 20 minutes. This means a single cooler can run 3 cycles per hour. To match his production, he needs a vacuum cooler that can hold at least 2 pallets per cycle (2 pallets/cycle * 3 cycles/hour = 6 pallets/hour). By choosing a 2-pallet machine, his cooling process7 is perfectly synchronized with his harvesting team. There are no delays and no wasted capacity. We always work with our clients to do this simple but critical calculation.

For the most demanding, high-speed production lines, like a large-scale food processing plant, even a perfectly sized single-chamber cooler can create a small delay during the loading/unloading phase. The ultimate solution here is a dual-chamber vacuum cooler8. This is essentially two coolers built together with a shared vacuum system. While Chamber A is in its 20-minute cooling cycle, the operator is unloading and reloading Chamber B. As soon as Chamber A is finished, the vacuum system switches to Chamber B, and the cycle continues. The main production line never, ever has to stop. It creates a truly seamless and continuous flow of cooled product.

| Feature | Single Chamber Cooler | Dual Chamber Cooler |

|---|---|---|

| Workflow | Batch (Cool -> Unload -> Load -> Cool) | Continuous (Cooling overlaps with loading) |

| Production Line Stoppage | Yes, during loading/unloading | No, the line can run continuously |

| Ideal Throughput | Medium to High | Very High / Non-Stop |

| Best For | Most farms and kitchens (Carlos) | Large industrial food plants (Sophia) |

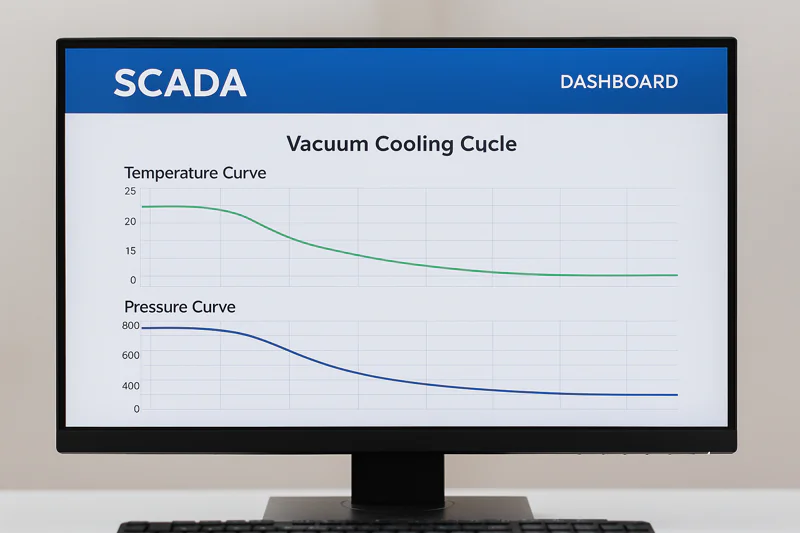

How Can You Integrate Cooling Data into Your Factory’s Management System?

Your cooler is a ‘black box.’ You don’t know the exact cooling times or final temperatures for each batch, making it impossible to guarantee quality control or provide compliance data.

Modern vacuum coolers can output all cycle data, including temperatures and times, via ethernet. This data is logged into your central factory system (SCADA) for quality assurance, traceability, and process optimization.

Turning Your Cooler into a Smart Device

In modern manufacturing and food production, data is king. You cannot manage what you do not measure. A buyer like Norman wants proof of a stable cold chain. A manager like Sophia needs to provide HACCP audit trails. A simple "on/off" cooler doesn’t provide this. Our coolers are designed to be smart devices that integrate into your factory’s data ecosystem.

The brain of our machine is a PLC (Programmable Logic Controller) that monitors everything. We install multiple temperature probes, including wireless probes that you place directly into the core of the product on the pallet. During the cycle, the PLC records a continuous stream of data: the vacuum pressure curve, the time, and the real-time temperature of the product. Once the cycle is complete, this data package, tied to a specific batch ID, can be automatically exported. This allows you to build a complete quality record for everything you produce.

For Sophia, this is a game-changer. If an auditor asks for proof that Batch #742 of cooked chicken was cooled safely, she can pull up the exact report showing it went from 85°C to 4°C in 22 minutes. She has indisputable proof of compliance. For Carlos, this data helps him optimize. He might notice that a certain variety of spinach cools 3 minutes faster, allowing him to shorten the cycle time and increase his throughput. This integration transforms the cooler from a dumb appliance into an intelligent data node in a smart factory.

| Data Point | Why It’s Important | Example Use Case |

|---|---|---|

| Batch ID | Connects data to a specific product batch. | Traceability for a product recall. |

| Start/End Temperature | Verifies the cooling was effective. | Proof of reaching a safe temperature for HACCP. |

| Cycle Duration | Used for process efficiency and scheduling. | Optimizing cycle times to increase daily throughput. |

| Temp/Pressure Curves | Provides a detailed "fingerprint" of the cycle. | Diagnosing issues or validating the process for new products. |

Conclusion

Proper workflow integration makes your cooler the heart of your production line. It transforms a standalone machine into a seamless asset that boosts your speed, quality, and overall efficiency.

-

Understanding pre-cooling can help you optimize freshness and quality in your produce. ↩

-

Exploring post-cooling techniques is essential for ensuring food safety and quality in cooked products. ↩

-

Understanding vacuum coolers can enhance your knowledge of efficient cooling systems in food production. ↩

-

Explore effective strategies for workflow optimization to improve efficiency in your operations. ↩

-

Discover why synchronizing production lines is crucial for maximizing efficiency and minimizing waste. ↩

-

Learn about the vacuum cooling cycle and its importance in maintaining product quality and efficiency. ↩

-

Understand the key factors that influence the cooling process and how to optimize it for better results. ↩

-

Explore the advantages of dual-chamber vacuum coolers for continuous production flow in high-speed environments. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf