ROI Analysis: Is a Vacuum Cooler Worth the Investment for Your Farm?

You see the high upfront cost of a vacuum cooler and hesitate. But slow cooling methods and post-harvest losses are already costing you money every day, silently eating into your farm’s profits.

Yes, a vacuum cooler is worth the investment. It delivers a strong Return on Investment (ROI) by dramatically increasing your daily throughput, which boosts revenue, while high-quality components and an efficient operational design lower your long-term costs.

I’ve walked through this exact cost-benefit analysis with countless farm owners. They start by looking at the price tag, but the real story is in the total value over time. An investment in the right equipment isn’t just an expense; it’s a strategic move that pays for itself. Let’s break down the real numbers and factors that contribute to a powerful ROI.

How does upfront cost compare to long-term value?

The initial price of a quality machine can seem high. But opting for a cheaper alternative often leads to expensive breakdowns and lost product, especially during your busiest harvest season.

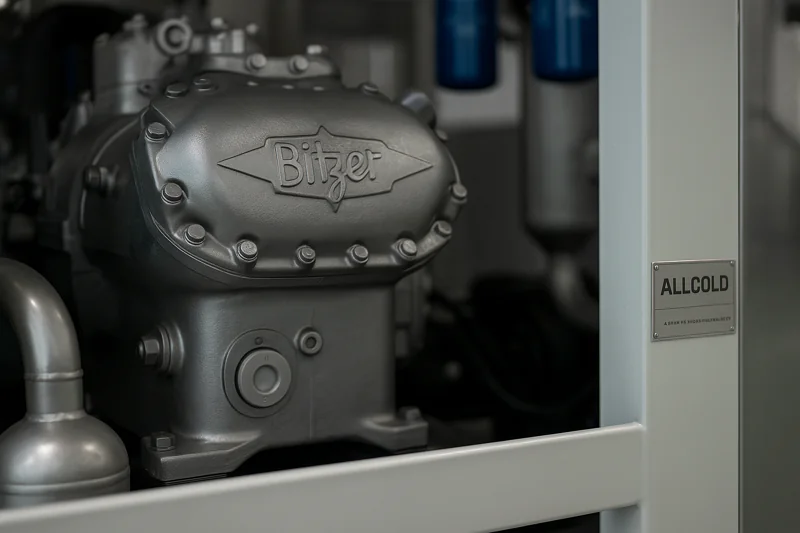

The incredible long-term value comes from using premium, world-class components. Machines built with brands like Bitzer from Germany for compressors ensures durability and reliability, leading to fewer repairs and a lower total cost of ownership.

Building for a Decade, Not a Season

This is a topic I discuss frequently with professional buyers. They understand that the initial invoice is only one part of the cost equation. The true cost of a machine reveals itself over five, ten, or even fifteen years of operation. That’s why we build our coolers as long-term assets, not disposable equipment. The foundation of this philosophy is our choice of components. The compressor, the heart of the system, is a German-made Bitzer1. The vacuum pump, which does the essential work of lowering the pressure, is from Leybold, another benchmark of German engineering.

We extend this quality-first approach to the entire machine. The control system uses a Siemens PLC2 for flawless, responsive operation, and the electricals are managed by reliable Schneider contactors. When you invest in a machine built with these parts, you are buying down your risk of future problems. A breakdown during peak season doesn’t just cost you a repair bill; it costs you lost revenue, damaged client relationships, and immense stress. The higher upfront cost of quality components is your insurance against these much larger, unpredictable expenses, making it a smarter financial decision in the long run.

| Component | Brand We Use | Why It Creates Long-Term Value |

|---|---|---|

| Compressor | Bitzer (Germany) | Industry leader in reliability, reducing downtime risk. |

| Vacuum Pump | Leybold (Germany) | Ensures fast, consistent cycles for years of service. |

| Control System | Siemens (Germany) | Provides stable, error-free automated operation. |

| Electricals | Schneider (Germany/France) | Guarantees safe and dependable power management. |

What are the direct financial gains from faster cooling?

Your current cooling process is likely a bottleneck. It’s slow and limits how much produce you can process and ship in a single day, putting a hard cap on your farm’s potential revenue.

Extremely fast and automated cooling cycles directly increase your farm’s daily product throughput. This allows you to process more harvests, fulfill larger orders, and significantly boost revenue without adding more labor shifts.

Turning Speed into Revenue

For farm owners who supply large supermarket chains, speed is money. Their contracts have strict delivery windows, and missing them is not an option. This is where a vacuum cooler completely changes the game. While traditional cold rooms can take many hours to cool a pallet of lettuce, a vacuum cooler achieves the same result in a fraction of the time. The entire process is automated. Your operator simply presses ‘Start’ on the touch screen to begin the cycle.

This speed isn’t just a small improvement; it’s a massive expansion of your farm’s capacity. Think about what this means for a full day’s work. In one 8-hour shift, a cold room might cool one batch. In that same shift, a vacuum cooler3 can run more than 15 automated cycles. You can now handle peak harvest volumes with ease, take on new, larger clients, and respond to urgent orders that your competitors have to turn down. This ability to say "yes" to more business is a direct path to increased revenue4. Furthermore, because the cycles are so fast and automated, you achieve this higher throughput with your existing team. You’re not paying more for labor; you’re simply making your entire operation more productive and profitable.

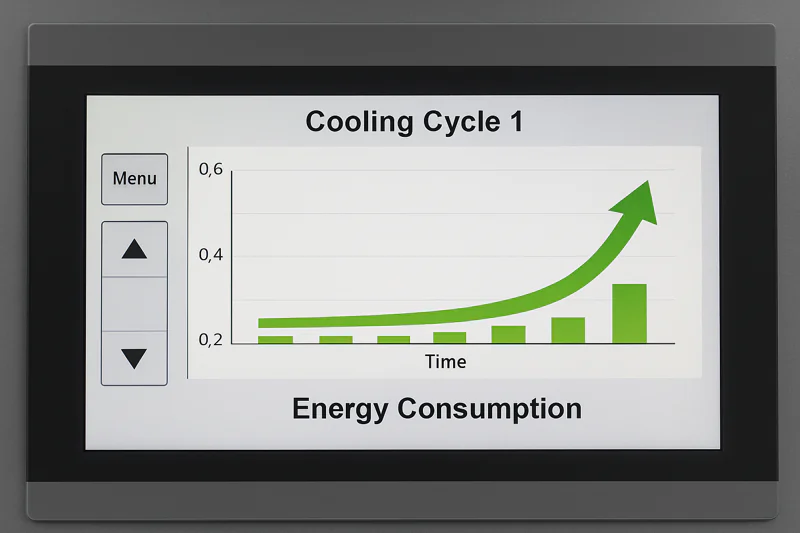

How do operational costs affect the overall ROI?

You’ve made the investment, but now you’re watching the electricity meter. A machine that is expensive to run day-to-day can quickly erode the financial benefits it provides.

A positive ROI depends on low operational costs. Our vacuum coolers are designed for efficiency, with automatic shutdown features and a straightforward maintenance schedule to minimize your daily expenses.

Efficiency That Protects Your Bottom Line

Operational costs are always on the mind of managers who have to balance budgets. A common misconception is that a fast, powerful machine must be an energy hog5. In reality, the opposite is true. Our system is designed with efficiency built-in. For example, once the product reaches the target temperature, the compressor and condenser fans stop automatically, preventing wasted energy. The machine also has a smart maintenance feature: after a cycle, the vacuum pumps keep running for a set time to remove water from the pump oil, protecting the equipment.

Maintenance costs are also predictable and low6. A monthly check of the vacuum pump oil is a simple visual task for your staff; you just look to see if it is emulsified. A major service, like changing the compressor oil, is only required every two years by a professional. Annually, the condenser should be washed to maintain efficiency. And we recommend a general hygiene cleaning every two seasons. This combination of low energy use and predictable, minimal maintenance ensures that the machine saves you money every single day, strengthening its ROI.

| Operational Factor | How We Minimize Cost | Financial Impact |

|---|---|---|

| Energy Use | Compressor & fans stop automatically | Lower monthly electricity bills. |

| Routine Maintenance | Simple monthly oil checks | Minimal labor cost, can be done in-house. |

| Major Service | Long intervals (2 years for compressor oil) | Predictable and infrequent major expenses. |

| Hygiene | Bi-seasonal cleaning recommendation | Prevents issues and maintains performance. |

How does reduced risk contribute to a positive ROI?

What is the cost to your farm if your primary cooler breaks down in the middle of harvest? The loss from spoiled produce, a broken contract, and a damaged reputation can be catastrophic.

Reduced risk is a critical part of ROI. Our comprehensive 12-month guarantee and accessible technical support line act as a safety net, ensuring any issue is resolved fast to protect your harvest and income.

Your Investment is Protected

For any business owner, managing risk is just as important as generating revenue. When you depend on a single piece of equipment to get your product to market, that machine’s reliability is everything. We understand this, which is why our relationship with you doesn’t end when the machine is delivered. We stand behind our equipment with a full 12-month guarantee7 that begins after the B/L date or installation is finished. This ensures your initial period of operation is completely protected.

Even more valuable is the ongoing support. Problems don’t always happen between 9 and 5. That is why we list our service line and email in the user manual so you can always reach us. If you have an issue, our engineering team is there to help you diagnose the problem immediately. This rapid response is invaluable. It can be the difference between a minor adjustment and a full day of costly downtime. This level of support minimizes your operational risk8 and protects the value of your harvest. It’s a fundamental part of the ROI, providing the peace of mind to know that your investment is, and will remain, a productive asset for your farm.

Conclusion

A vacuum cooler’s ROI becomes clear when you look beyond the price tag. It is a powerful tool that boosts revenue, lowers operational costs, and minimizes risk, making it a wise and profitable investment.

-

Explore the advantages of German-made Bitzer compressors for reliability and efficiency in your operations. ↩

-

Learn how Siemens PLCs enhance automation and operational stability in industrial applications. ↩

-

Explore how vacuum coolers can revolutionize your farming operations and boost efficiency. ↩

-

Learn strategies to enhance your farm’s profitability and maximize revenue potential. ↩

-

Understanding what constitutes an energy hog can help you make informed decisions about energy-efficient machinery. ↩

-

Exploring predictable and low maintenance costs can help you budget effectively and choose the right equipment for your needs. ↩

-

Explore this link to understand how a 12-month guarantee can protect your investment and ensure reliability. ↩

-

Discover strategies to minimize operational risk, ensuring your business runs smoothly and efficiently. ↩

Mila

You May Also Like

How Does Vacuum Cooling Forge the Strongest Link in Your Vegetable Cold Chain?

You work tirelessly to grow perfect, healthy vegetables. Yet, you know that from the moment of harvest, an invisible clock

Small-Scale vs. Large-Scale Vacuum Cooler: How Do You Choose the Right Fit?

You’re convinced that vacuum cooling is the key to elevating your product quality, but now you face a critical decision.

How Can You Master Vacuum Cooling for Leafy Greens to Maximize Quality and Profit?

You grow beautiful, vibrant leafy greens, but you know the invisible enemy is time. From the moment of harvest, the

Which Vegetables Benefit Most from Vacuum Cooling Technology?

You see the promise of rapid cooling, extended shelf life, and superior quality, but you’re unsure if this technology is

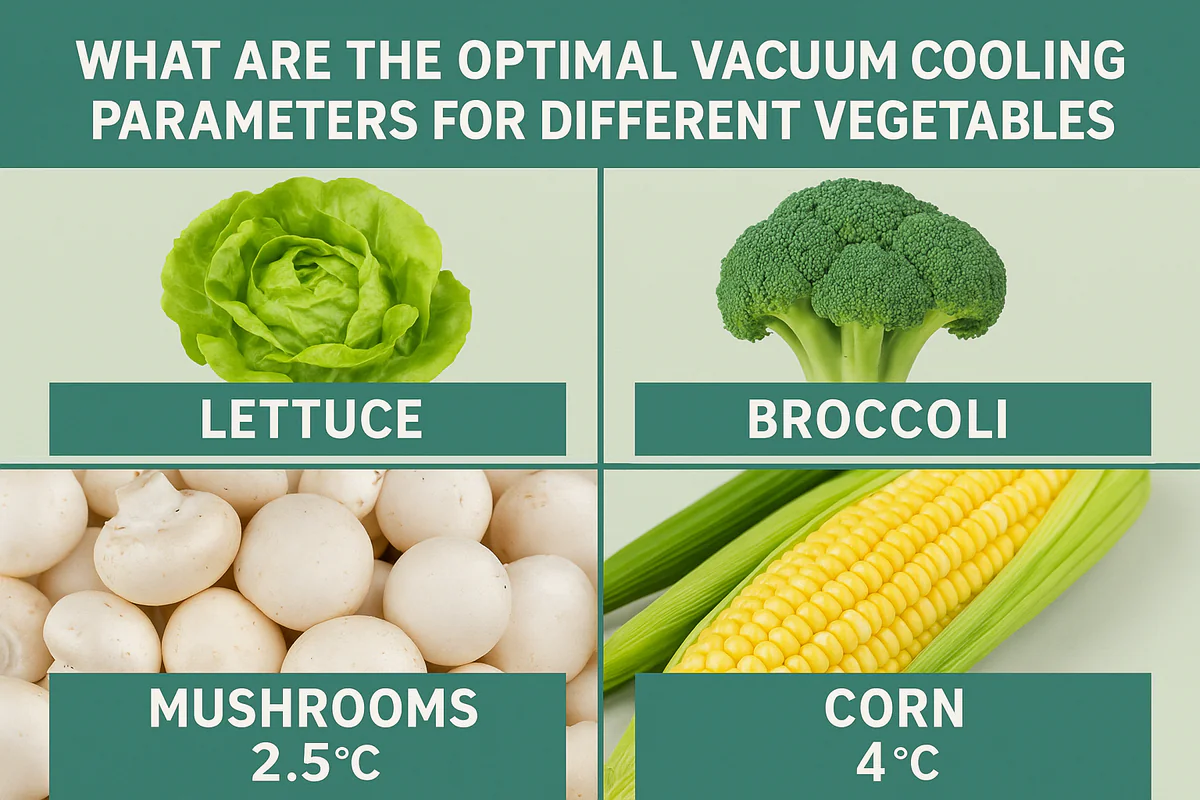

What Are the Optimal Vacuum Cooling Parameters for Different Vegetables?

You’ve harvested beautiful produce, from crisp lettuce to delicate mushrooms. But using a "one-size-fits-all" setting on your vacuum cooler feels

How Can You Reduce the Energy Costs of Your Vacuum Cooler?

Your vacuum cooler is a powerhouse of productivity, but your monthly electricity bill is climbing. You’re starting to wonder if

How Can You Keep Your Vacuum Cooler Running Flawlessly?

Your vacuum cooler is a vital asset, but you’re worried about unexpected breakdowns during peak season. Neglecting maintenance feels like

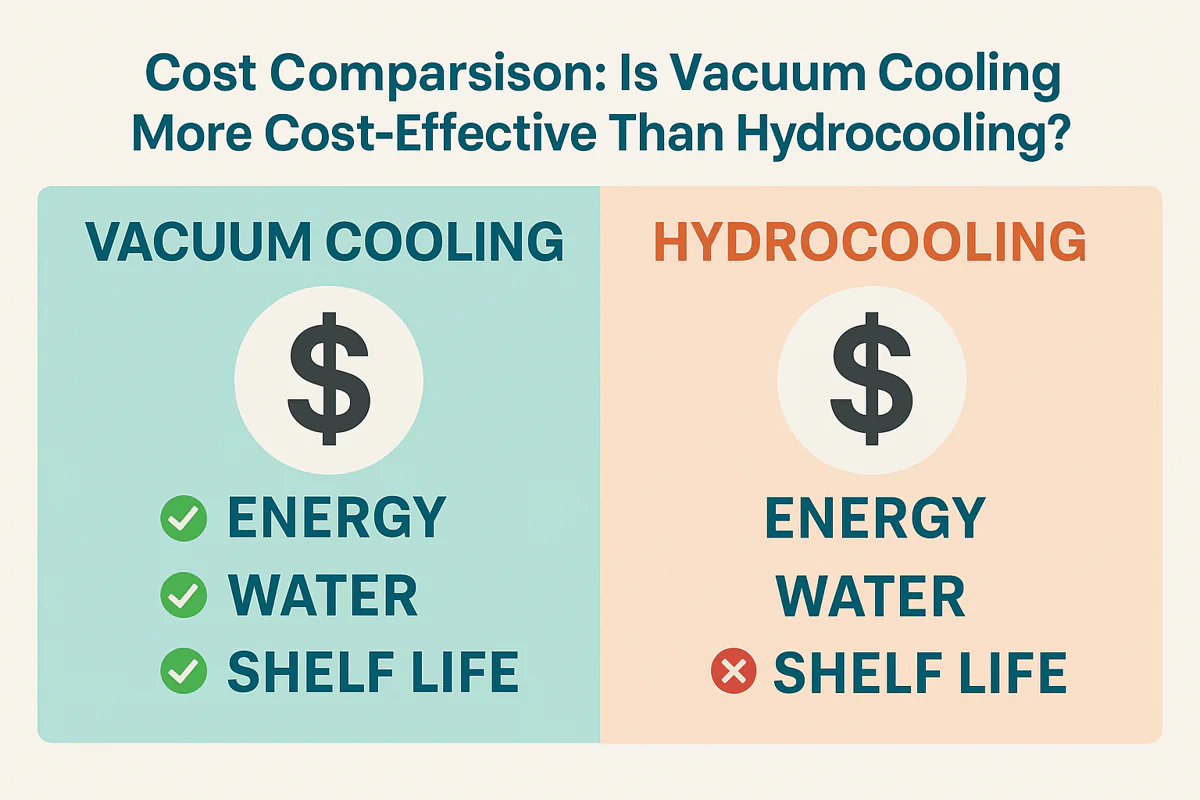

Cost Comparison: Is Vacuum Cooling More Cost-Effective Than Hydrocooling?

Choosing between cooling technologies feels like a high-stakes gamble. You need to lower your operational costs, but the wrong decision

Who Are the Top Vacuum Cooler Manufacturers for Vegetables?

Searching for a list of top vacuum cooler brands can be overwhelming. You’re not just buying a machine; you’re investing

What Defines the Best Commercial Vacuum Cooler for Your Vegetable Processing Facility?

Choosing the right equipment is a huge decision. A slow or unreliable cooler can ruin your harvest’s quality, hurt your