Vacuum Coolers for Cooked Food & Bakery

Quickly cool cooked meals and baked goods to enhance food safety, preserve texture, and improve shelf life. Our advanced vacuum cooling technology delivers fast and consistent performance for industrial kitchens and food production facilities.

Why Vacuum Cooling Benefits Your Food Business

Discover how our vacuum cooling systems give bakeries, restaurants, and food manufacturers a competitive edge—reducing cooling time, boosting productivity, and ensuring consistent product quality.

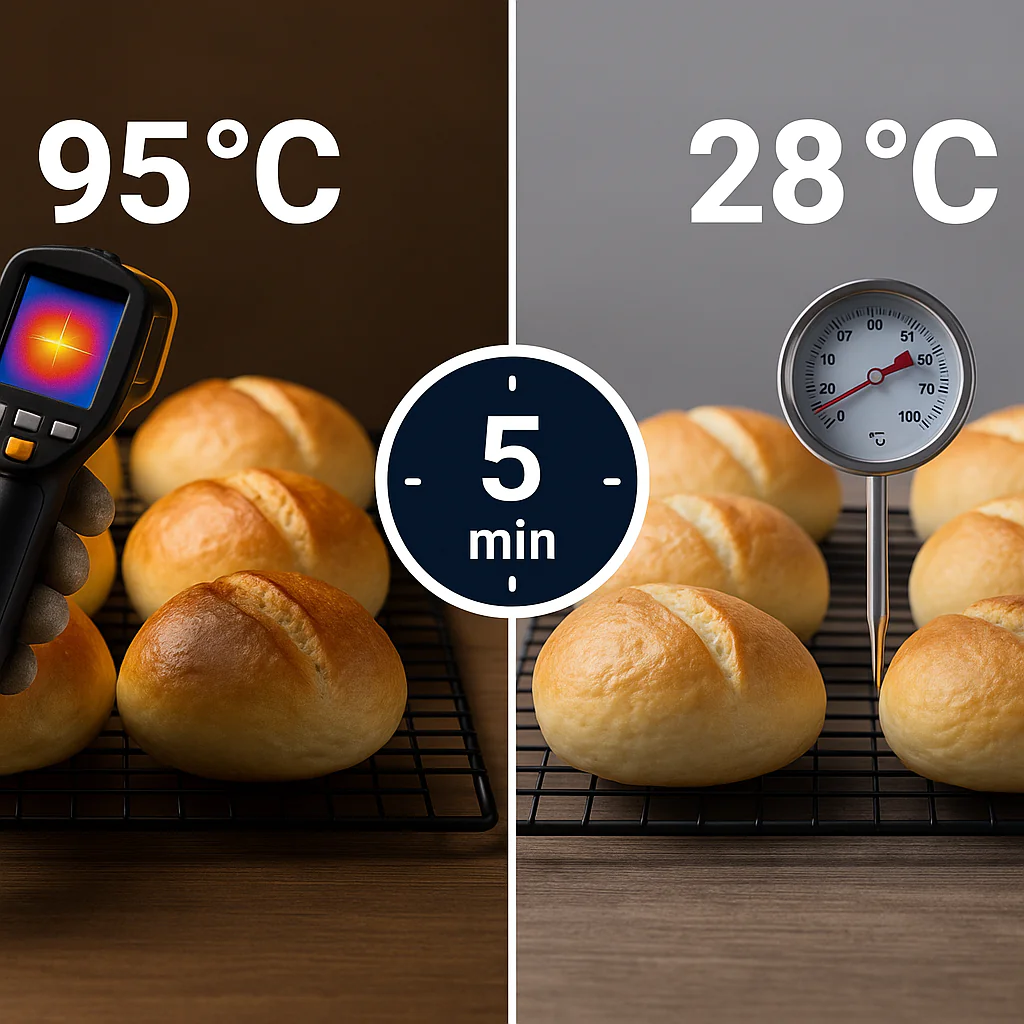

Rapid Cooling Process

Quickly cool cooked foods and baked goods from 98°C to 28°C in just 5 minutes, significantly reducing cooling time and boosting overall production efficiency

Enhanced Food Safety

Rapidly pass through the critical temperature zone (60°C to 10°C) to minimize bacterial growth. Meet HACCP food safety standards and reduce spoilage risks in cooked food processing.

Superior Product Quality

Preserve the original texture, flavor, and appearance of your cooked foods. Our vacuum cooling technology reduces moisture loss and extends shelf life by up to 50%, improving export value and customer satisfaction.

Increased Production Efficiency

Eliminate cooling delays and labor inefficiencies. Our automated vacuum cooling cycles streamline your workflow, cut costs, and keep your production line moving faster.

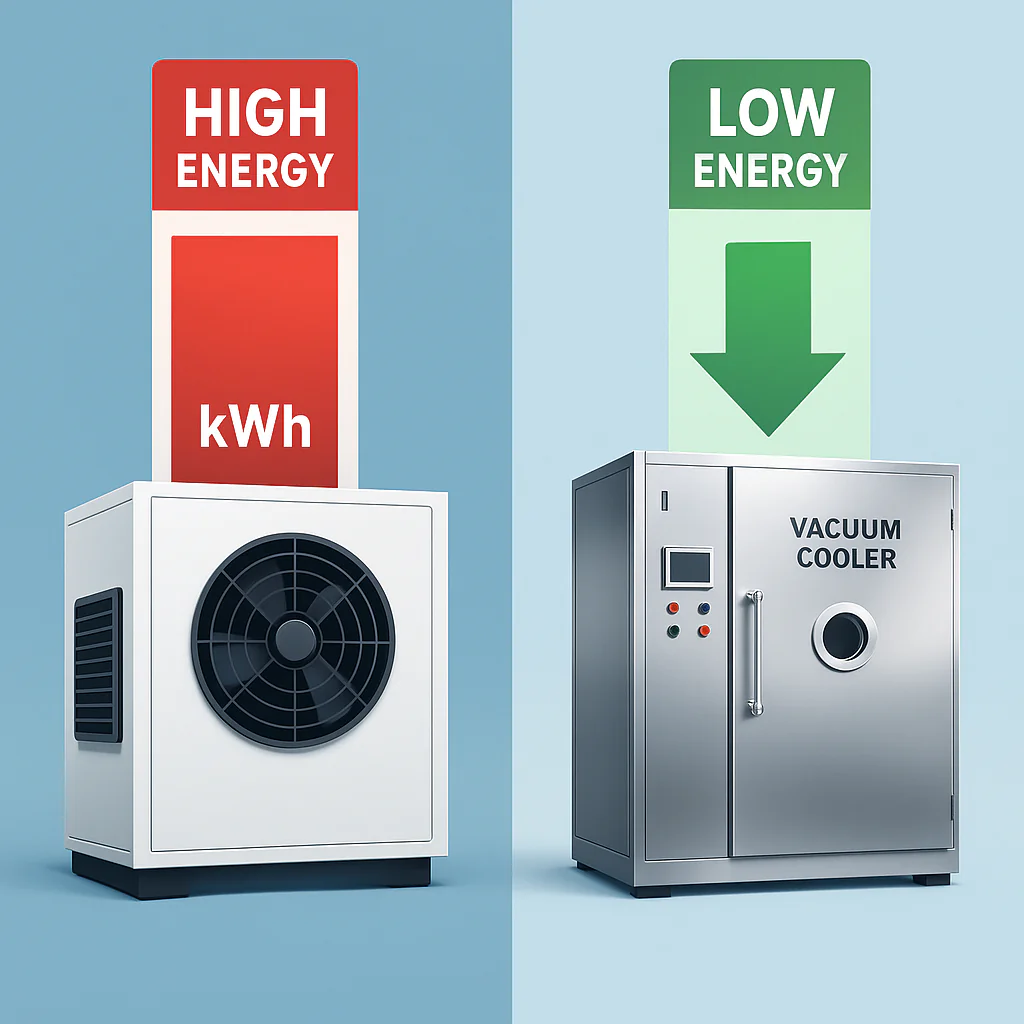

Energy Efficient

Use up to 40% less energy than traditional cooling systems. Our eco-friendly technology helps lower your carbon footprint while saving on utility bills.

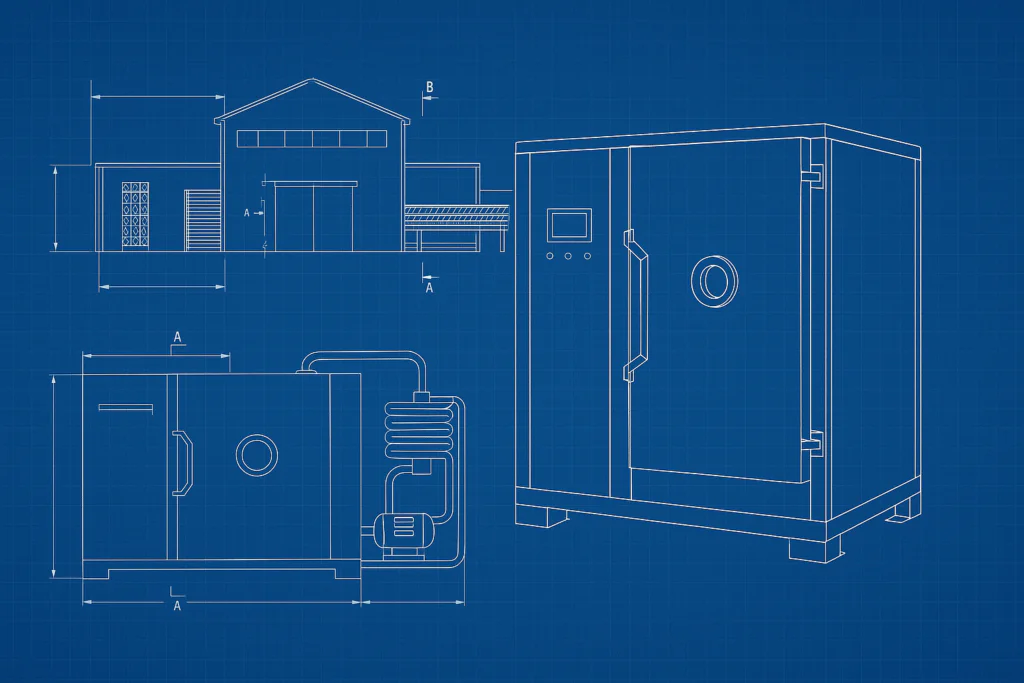

Customizable Solutions

Offered in multiple sizes and setups to fit your output needs, floor space, and specific cooked or baked product requirements. Tailored for seamless integration.

Ideal Applications

Bakery Products

Perfect for cooling bread, pastries, cakes, cookies, and other baked goods to maintain texture and prevent sogginess.

Ready Meals

Designed for pasta, rice dishes, pre-cooked meals, and portioned catering trays—ensuring quick cooling and safe storage.

Soups & Sauces

Effectively cool hot liquids like broths, gravies, and sauces without compromising flavor or consistency.

Prepared Foods

Suitable for cooked meats, vegetables, and processed meal components—improving shelf life and production throughput.

Ready to Upgrade Your Food Cooling Process?

Speak with our specialists today to explore how a tailored vacuum cooling solution can improve your product quality, safety, and efficiency.

Why Our Vacuum Cooling Systems Are Ideal for Cooked Food & Bakery

Unlock faster cooling, longer shelf life, and higher food safety with our advanced vacuum cooling technology—engineered specifically for cooked meals, baked goods, and food manufacturers seeking consistent performance and energy efficiency.

Rapid Cooling Process

Our vacuum coolers can reduce the temperature of bread from 98°C to 28°C in just 5 minutes, preserving flavor and texture while ensuring food safety.

Energy Efficient Design

Consume up to 40% less energy compared to traditional cooling methods, reducing operational costs while maintaining superior cooling performance.

Customizable Solutions

Available in various sizes and configurations to meet specific production requirements, with options for custom branding and technical specifications.

The Proven Impact of Vacuum Cooling Technology

80%

Up to 80% Faster Cooling

40%

Save 40% on Energy Costs

99%

99% Reduction in Bacterial Growth

3x

Extend Shelf Life by 3x

Key Advantages for the Food Processing Industry

Our vacuum cooling systems deliver proven benefits for bakeries, restaurants, and food manufacturers—boosting efficiency, product quality, and food safety across production lines.

For Bakeries & Pastries

- Locks in moisture to keep bread and pastries fresh longer

- Maintains crispy crusts and fluffy interiors

- Speeds up production by eliminating long cooling delays

- Ensures consistent quality across every batch

For Prepared Meals & Catering

- Prolongs shelf life naturally—no preservatives needed

- Minimizes bacterial growth during rapid cooling

- Preserves flavor, texture, and nutritional integrity

- Speeds up packaging and delivery workflows

Ready to Optimize Your Food Production?

Talk to our experts today and discover how vacuum cooling can improve your product quality, safety, and efficiency.

Technical Specifications & Versatile Applications

Our vacuum cooling systems are precision-engineered to meet the diverse demands of modern food processing. From high-volume production to delicate ingredients, we deliver consistent cooling performance tailored to your operational needs.

Technical Specifications

| Parameter | Standard Model | Industrial Model |

|---|---|---|

| Cooling Capacity | 100-300 kg/batch | 300-500 kg/batch |

| Cooling Time | 5 minutes | 5 minutes |

| Temperature Range | 98°C to 28°C | 95°C to 28°C |

| Power Consumption | 2.7 kW | 4.5 kW |

| Chamber Dimensions | 0.63m³- 1.4m³ | 2m³-3m³ |

| Control System | PLC touchscreen interface | PLC touchscreen interface |

* We offer fully customized specifications to match your unique production needs, facility space, and regulatory standards.

Ideal Applications

Bakery Products

Perfect for bread, pastries, and cakes. Rapidly reduces cooling time from hours to just minutes—preserving texture, extending shelf life, and preventing moisture loss.

Ready Meals

Quickly cool prepared meals for safe packaging and extended shelf life. Ideal for large-scale kitchens, catering services, and meal prep facilities, ensuring food safety and operational efficiency.

Pasta & Rice Products

Rapidly cool cooked pasta and rice dishes while preserving ideal texture and preventing clumping. Designed for commercial kitchens and food processing plants requiring consistent product quality.

Meat & Poultry

Quickly cool cooked meat and poultry products to below-safe temperatures, reducing bacterial growth and extending shelf life. Perfect for industrial kitchens, meat processing facilities, and large-scale food production lines.

Frequently Asked Questions

Vacuum cooling works on the principle of evaporative cooling. When a product is placed in a vacuum chamber, the pressure is reduced, causing water to evaporate at lower temperatures. This evaporation removes heat from the product, rapidly cooling it. For cooked food and bakery products, this process is particularly effective as it preserves quality while ensuring rapid temperature reduction.

Most customers experience ROI within 12-24 months, depending on production volume and operational hours. The savings come from reduced cooling time (increasing production capacity), energy efficiency (compared to conventional cooling methods), extended product shelf life, and reduced labor costs.

Vacuum cooling does cause some moisture loss (typically 2-5% by weight), but our systems are optimized to minimize this effect. For many bakery products, this slight moisture reduction actually improves texture and quality. For products where moisture retention is critical, we offer specialized solutions and process parameters to maintain optimal moisture levels.

Our vacuum coolers are designed for minimal maintenance. Routine maintenance includes regular cleaning of the chamber, inspection of seals, and periodic checks of the vacuum pump and cooling systems. We provide comprehensive maintenance guidelines and offer service packages that include preventive maintenance visits, ensuring your equipment operates at peak efficiency.

Project Gallery: Real Installations of Our Vacuum Cooling Systems

Discover how our vacuum coolers are successfully used in real food production environments—from bakeries to commercial kitchens—across the globe.

Industrial Bakery Installation

A high-efficiency vacuum cooling system installed at a commercial bakery, capable of cooling up to 200 kg of baked goods per hour. The system significantly reduces cooling time, improves product consistency, and increases overall production throughput.

Ready Meal Production Line

A custom-engineered vacuum cooling system was integrated into a ready meal production line, cutting cooling time from 2 hours to just 25 minutes. This upgrade enhanced efficiency, improved food safety, and streamlined packaging processes.

Hotel Chain Central Kitchen

A compact vacuum cooling system deployed in the central kitchen of a leading hotel chain. It enhances food safety, streamlines batch processing, and significantly extends the shelf life of prepared meals—ideal for high-volume, time-sensitive food operations.

Artisan Bread Production

A compact vacuum cooling system tailored for artisanal bakeries, preserving the delicate texture, flavor, and crust of handcrafted breads and pastries. Ideal for small-batch, high-quality baking operations.

School Catering Facility

A mid-size vacuum cooling solution supporting daily operations across school cafeterias. Designed to meet strict food safety standards while locking in nutrition and flavor, ensuring safe and healthy meals for students.

Food Export Company

A high-capacity vacuum cooling system installed for a food export company. It significantly extends product shelf life and maintains quality during long-distance shipping, ensuring freshness from factory to foreign markets.

Interested in Learning More?

Our team can provide a complete portfolio and guide you through real installation cases in a virtual tour.