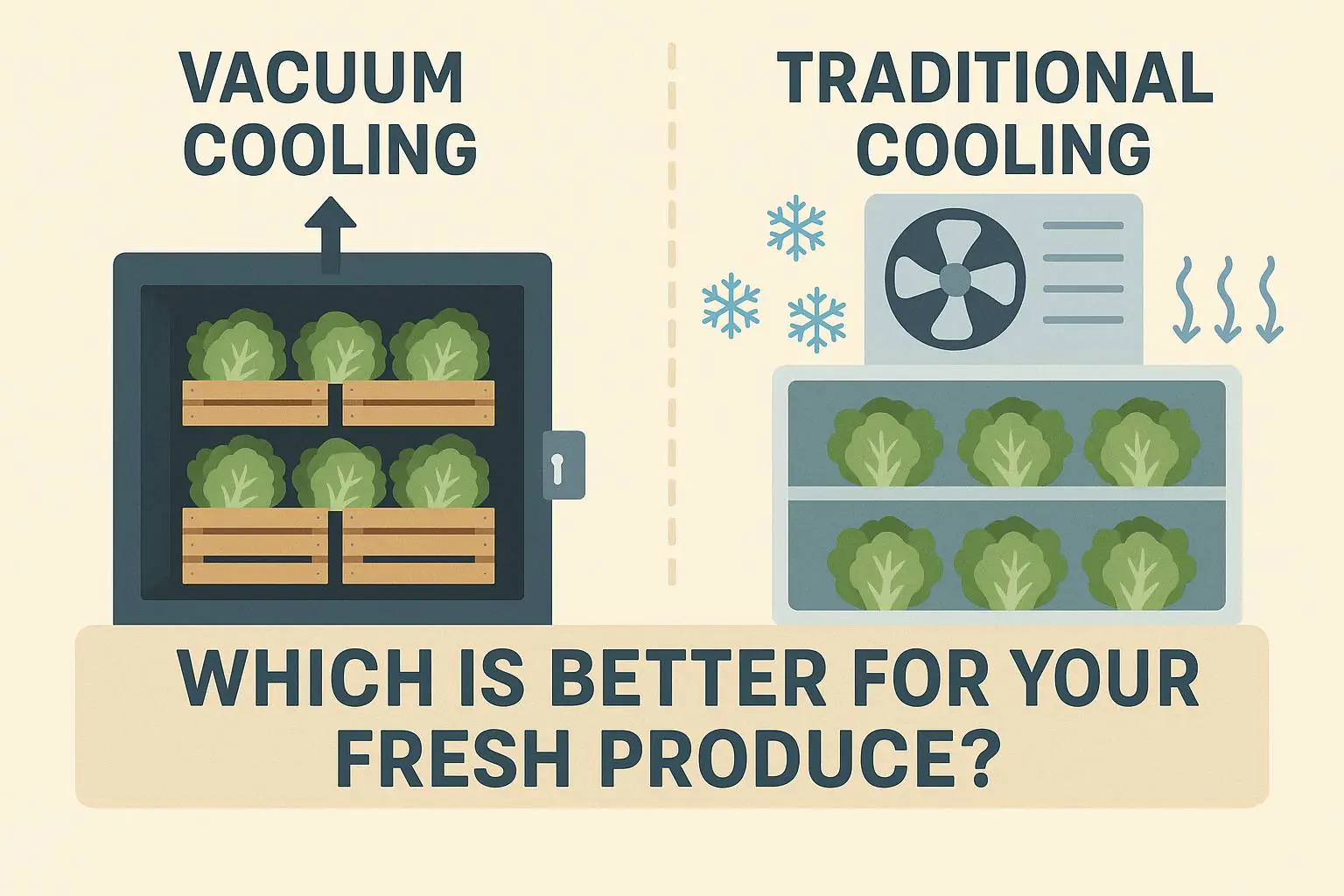

Vacuum Cooling vs. Traditional Cooling: Which is Better for Your Fresh Produce?

Your traditional cold room is slow. It takes hours to cool your fresh produce, and with every passing minute, field heat is degrading quality, reducing shelf life, and costing you money.

Vacuum cooling is superior for its speed and efficiency. It cools produce in just 15-25 minutes, compared to many hours for traditional methods. This rapid process locks in freshness, extends shelf life, and preserves the quality of your harvest in a way slow cooling cannot.

I’ve seen the difference firsthand. A farmer like Carlos in Mexico invests everything into growing the perfect crop. But if the cooling process is too slow, a big part of that value is lost before it even leaves the packing center. Traditional cooling is a waiting game that you often lose. This article will break down exactly why vacuum cooling is a faster, more effective, and more profitable choice.

How does cooling speed impact produce profits?

Your traditional cold room takes hours to remove field heat. During this long wait, your vegetables continue to respire, lose moisture, and degrade, directly cutting into your profits.

Vacuum cooling completes its cycle in around 15-25 minutes. This incredible speed stops degradation almost instantly, preserving the weight and quality of your produce, which translates directly to higher profits.

Time is Money in the Produce Business

The fundamental difference between these two methods comes down to physics. Traditional cooling1 relies on forcing cold air over the surface of the produce. The heat must slowly transfer from the core to the outside, which is an incredibly slow process, especially for densely packed pallets. Vacuum cooling2 is completely different. By lowering the pressure in a sealed chamber, it causes a small amount of water in the vegetables to boil at a very low temperature (around 3°C). This evaporation pulls heat from the very core of the product outwards, resulting in extremely fast and uniform cooling.

For my clients, this speed is a game-changer. We even designed a machine for a bakery in Hungary that cools fresh bread from 92°C to 30°C in under 5 minutes. For a farm owner, this means you can harvest, cool, and ship produce on the same day. There is no bottleneck at the cold room. Your products get to market faster, fresher, and with more sellable weight, which is exactly what a buyer like Norman is looking for. Slow cooling is a liability; rapid cooling is a competitive advantage.

| Feature | Vacuum Cooling | Traditional Cooling (Forced Air) |

|---|---|---|

| Cooling Time | 15-25 minutes | 6-12+ hours |

| Cooling Method | Evaporation from the core | Convection on the surface |

| Throughput | High; multiple cycles per day | Low; one or two cycles per day |

| Impact on Business | Gets product to market faster, maximizes freshness | Creates bottlenecks, risks quality loss |

Which method truly protects the quality and shelf life?

Your produce looks fantastic right after harvesting, but after hours in a conventional cooler, it can lose its crispness and vibrant color. This decline in quality leads to rejected shipments and lost revenue.

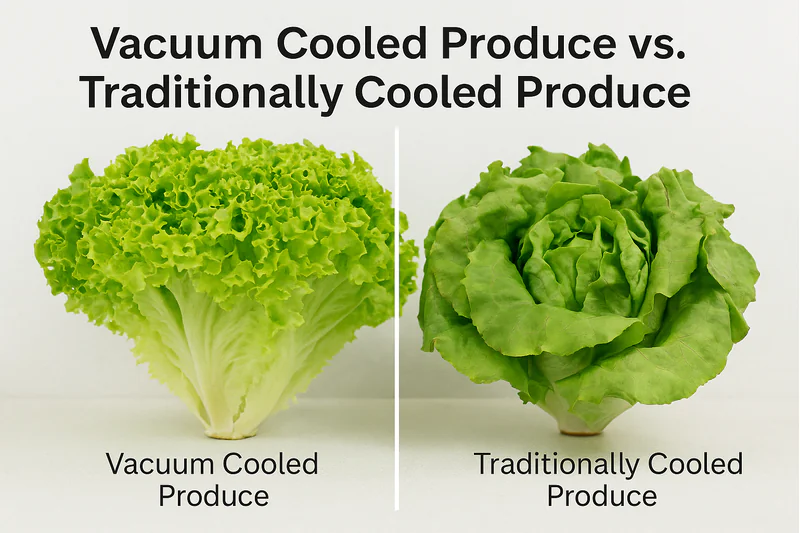

Vacuum cooling better protects quality by stopping the aging process almost instantly. The rapid, even cooling preserves moisture, texture, and nutrients, leading to a significantly longer shelf life and a more appealing product.

Locking in the Freshness from the Field

From the moment a vegetable is picked, it begins to die. It respires, consumes its own sugars, and loses water to the air. The goal of any cooling method is to slow this process down as quickly as possible. Because traditional cooling is so slow, the produce continues to degrade for hours, losing valuable moisture and crispness. Vacuum cooling3, by contrast, brings the core temperature down in minutes, putting the product into a state of preservation almost immediately.

Furthermore, it ensures the cooling is uniform. For produce with high water resistance, we include a "vacuum delay facility" to guarantee that the entire load, from the outside to the very center, is cooled evenly. This prevents the outer layers from getting too cold while the core remains warm. For a supermarket supplier like Carlos, this means his broccoli stays greener and his lettuce stays crisper for days longer. This extended shelf life reduces waste for the retailer and builds a reputation for high-quality, reliable produce. Traditional methods simply cannot offer this level of quality control.

| Quality Factor | Vacuum Cooling | Traditional Cooling |

|---|---|---|

| Moisture Loss | Minimal | Significant |

| Uniformity | Excellent, from core to surface | Poor, outside cools faster than inside |

| Shelf Life | Significantly extended | Standard or reduced |

| Final Appearance | Vibrant, crisp, fresh | Can be dull, limp, or dehydrated |

What about the energy costs and efficiency?

You see a powerful, fast machine and assume it must have a high energy cost. With electricity prices always rising, you are worried about the long-term operational expense of new technology.

Modern vacuum coolers are built for high efficiency. They use premium components and smart energy-saving features, such as an automatic shutdown mode, to minimize electricity consumption and reduce overall operating costs.

Designed to be Smart and Efficient

While vacuum coolers are powerful, they are engineered to be efficient. A key benefit of the speed is that the main components, like the large compressor and pumps, only run for short periods—just 15-25 minutes per cycle. A traditional cold room, on the other hand, must run its refrigeration system for many consecutive hours to achieve the same result. This extended runtime adds up to significant energy consumption.

Our machines are built with this in mind. We use high-efficiency evaporators4 and air-cooled condensers specifically to minimize the energy rating (KW) of the compressors used. I always point out to clients that the system includes smart power-saving features5. For instance, the machine will automatically start motors in a delayed sequence to avoid a massive power draw all at once. Even more importantly, if the cooler is left idle for a period of time, it will automatically shut down completely to save electricity. To start it again, a simple press of the start button is all that’s needed. This intelligent design ensures that you are only using power when you are actively cooling, making it a much more cost-effective solution in the long run compared to a constantly running cold room.

| Feature | Vacuum Cooling | Traditional Cooling |

|---|---|---|

| Compressor Run Time | 15-25 minutes per cycle | Many hours per cycle |

| Smart Features | Automatic shutdown, delayed start | Typically runs continuously |

| Component Design | High-efficiency evaporators | Standard components |

| Overall Energy Use | Lower per ton of cooled product | Higher per ton of cooled product |

Which system is more reliable and easier to maintain?

You are worried about investing in advanced machinery. You need to know that your equipment will be dependable day after day and that support is available if you need it.

High-quality vacuum coolers are built for reliability using world-class components from brands like Bitzer and Siemens. They require simple routine maintenance and are backed by a full warranty and 24/7 technical support.

Engineered for Uptime and Peace of Mind

Reliability starts with the parts you use. When a professional buyer like Norman asks about our machines, I am proud to show him the component list. The compressor is from Bitzer in Germany, the vacuum pump from Leybold, and the entire control system is built around Siemens technology. We use trusted brands from Germany, Italy, Switzerland, and Denmark. This isn’t about marketing; it’s about building a machine that can withstand the demands of a busy packinghouse season after season.

Maintenance is also designed to be straightforward for the operator. The most common tasks are simple visual checks. You need to check the vacuum pump oil monthly to see if it looks milky, which would mean it needs changing. A general hygiene cleaning every two seasons is also recommended. For safety, more complex tasks like changing the compressor oil or any electrical repairs must be done by a qualified professional. To give you complete peace of mind, every ALLCOLD system comes with a 12-month guarantee and access to our 7*24 hour phone assistance for any technical support you might need. This combination of superior build quality and dedicated support makes it a more reliable long-term investment.

| Factor | Vacuum Cooling | Traditional Cooling |

|---|---|---|

| Core Components | Premium brands (Bitzer, Siemens, Leybold)6 | Varies widely, often generic |

| Routine Maintenance | Simple checks (oil, cleaning) | Can require defrost cycles, fan checks |

| Professional Service | Required for major electrical/compressor work | Required for refrigerant leaks, system repairs |

| Manufacturer Support | 12-month guarantee, 24/7 support7 | Varies by supplier, often limited |

Conclusion

Vacuum cooling is the clear winner for speed, quality preservation, and efficiency. It is a strategic investment that protects the value of your produce far better than slow, traditional methods.

-

Learn about the limitations of traditional cooling methods and how they can impact your business’s competitiveness and product quality. ↩

-

Explore the advantages of vacuum cooling to understand how it can enhance efficiency and freshness in your produce operations. ↩

-

Explore the advantages of vacuum cooling to understand how it enhances freshness and shelf life of produce. ↩

-

Explore how high-efficiency evaporators can significantly reduce energy consumption and improve cooling performance. ↩

-

Learn about innovative smart power-saving features that enhance energy efficiency and reduce operational costs. ↩

-

Explore how premium brands enhance reliability and performance in machinery, ensuring long-term investment. ↩

-

Learn why comprehensive support and guarantees are crucial for peace of mind and operational efficiency. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not