What is a Bakery Vacuum Cooling Machine and How Does It Work?

Your ovens are running at full capacity, producing beautiful, hot bread. But then, everything grinds to a halt. Your entire production floor is clogged with cooling racks, and you have to wait for two, sometimes three, hours for the bread to cool down before you can slice and package it.

This cooling process is the biggest bottleneck in your entire operation. It wastes space, wastes time, and every minute that passes, your bread’s crust gets a little soggier and its shelf life gets a little shorter. You are losing efficiency and product quality while your bread just sits there.

A bakery vacuum cooler is a machine that cools freshly baked goods from 95°C (203°F) down to 30°C (86°F) in just 3 to 6 minutes. It works by placing the hot bread in a sealed chamber, reducing the air pressure, and causing the water inside the bread to boil at a very low temperature, rapidly removing all the heat.

This technology might sound like science fiction, but the principle behind it is simple and has been used in other industries for decades. My job is to explain how this powerful science can be applied to your bakery. It’s not magic; it’s physics. And understanding it is the first step toward revolutionizing your production process, saving you hours of time and acres of space.

How Does Vacuum Cooling Actually Work?

The idea of "boiling" your bread to cool it down sounds strange. You might worry that it will dry out the product or damage its delicate texture. It feels completely counter-intuitive, and I get this question all the time from curious bakers.

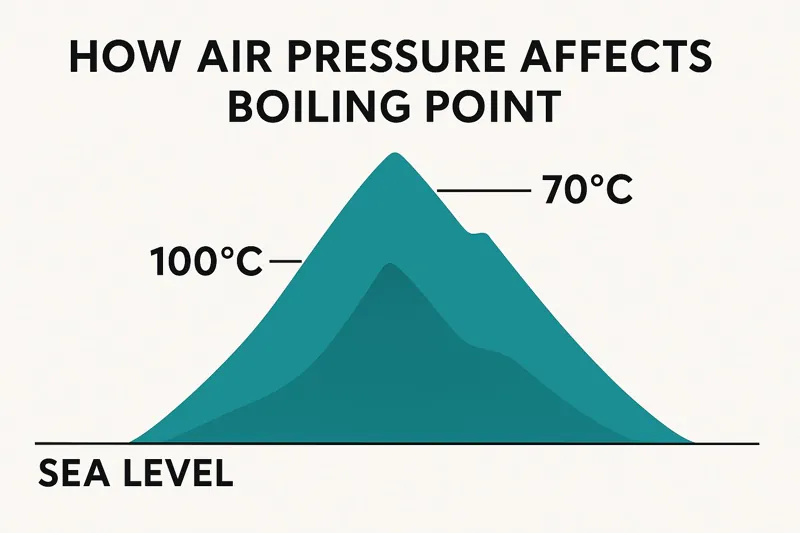

The key to understanding this is realizing that the boiling point of water is not a fixed number. It all depends on the air pressure around it. We are just taking advantage of a basic law of physics to achieve an incredible result, and the process is far more gentle than you might think.

Vacuum cooling works by creating a low-pressure environment where water evaporates (boils) at a very low temperature. This evaporation process requires a massive amount of energy, and it pulls this energy directly from the bread, cooling it from the inside out with incredible speed and efficiency.

The Simple Science of Cooling

Think about this: at sea level, water boils at 100°C (212°F). But if you were on top of Mount Everest, where the air pressure is much lower, water would boil at only about 70°C (158°F). A vacuum cooler1 is like creating an environment with even lower pressure than the top of Mount Everest, right inside a sealed, stainless steel chamber.

When we load a trolley of hot bread into our machine and start the powerful vacuum pump, we rapidly lower the pressure inside the chamber. When the pressure drops low enough, the water within the bread starts to boil, but at a temperature of only 30°C (86°F) or even lower. This is a "cold boil2." The process is called evaporation, and for water to turn from a liquid to a gas (vapor), it needs to absorb energy. This energy is called the "latent heat of vaporization3." The vacuum forces this process to happen, and the only place for the water to get that energy is from the bread itself. This rapidly pulls the heat out of the core of every loaf on the trolley.

Does it dry out the bread? No. The entire process is so fast (3-6 minutes) that only about 1-2% of the bread’s moisture is lost. This is typically moisture that would have evaporated during the long, slow, traditional cooling process anyway. But with vacuum cooling, the process is controlled. It actually strengthens the bread’s structure, a process called "gelatinization stop4," resulting in a crispier crust and a more stable crumb.

| Environment | Air Pressure (approx.) | Boiling Point of Water | Application |

|---|---|---|---|

| Sea Level | 101 kPa | 100°C / 212°F | Making tea in your kitchen. |

| Mount Everest Peak | 33 kPa | 70°C / 158°F | High-altitude cooking. |

| Vacuum Cooler | <6 kPa | <35°C / <95°F | Rapidly cooling your bread. |

What Are the Main Benefits for a Bakery?

You understand the science, but you need to know what it means for your business. How does this machine solve your real-world problems of bottlenecks, limited space, and product quality? You need to see a clear return on this investment.

The reality is that traditional cooling methods are holding your business back. You are forced to build your entire production schedule around this one slow, inefficient step. You accept product staling as a fact of life, and you design your entire facility around storing huge, space-hungry cooling racks.

The primary benefits are a massive increase in production speed, a dramatic reduction in required floor space, and a significant improvement in product quality and shelf life. This transforms your bakery’s efficiency and profitability.

Transforming Your Bakery’s Operations

Let’s break down these benefits. For a procurement manager like Sophia who is obsessed with efficiency and hygiene, or a buyer like Norman who is focused on quality and price, these points are critical.

- Massive Time Savings5: This is the most immediate benefit. A process that took 2-3 hours now takes 3-6 minutes. This means bread can be sliced and packaged just 15-20 minutes after it leaves the oven. Your production is no longer a "start and stop" process; it becomes a continuous flow. You can produce more in a single shift, reduce overtime labor costs, and respond faster to large, unexpected orders.

- Incredible Space Savings6: Think about the total floor space currently occupied by your cooling racks. A single vacuum cooler designed for two trolleys can replace the space needed for 30 or 40 trolleys in a traditional setup. For bakeries in areas with high rent, this saved space is incredibly valuable. It can be used for more production equipment, storage, or simply to create a safer, less cluttered working environment.

- Superior Quality and Shelf Life7: This is where the technology truly shines.

- Better Texture: The "gelatinization stop" I mentioned earlier locks in the bread’s internal structure. It prevents the moisture from the crumb from migrating to the crust, so you get a crispier, crunchier crust and a wonderfully soft crumb.

- Extended Shelf Life8: Baked goods are vulnerable to mold and bacteria, especially in the temperature "danger zone" between 60°C and 10°C. Traditional cooling leaves the bread in this zone for over an hour. A vacuum cooler passes through this entire zone in a matter of minutes. By preventing this early microbial growth, you can naturally extend the shelf life of your packaged bread by 3, 5, or even 7 days without adding preservatives. This reduces waste for your customers and opens up new, more distant markets for your products.

| Metric | Traditional Cooling (Racks) | Bakery Vacuum Cooling | Business Impact |

|---|---|---|---|

| Cooling Time | 2 – 3 hours | 3 – 6 minutes | 90%+ increase in production throughput. |

| Floor Space | Very High (many racks) | Very Low (one machine) | Frees up valuable floor space for other uses. |

| Product Shelf Life | Standard | Extended by 3-7 days | Reduces waste, increases sales territory. |

| Crust Quality | Becomes soft/soggy | Stays crispy and crunchy | Premium product quality that customers love. |

Which Baked Goods Can Be Cooled This Way?

You might be thinking, "This sounds great for my crusty baguettes, but I also make soft dinner rolls, delicate croissants, and rich cakes. Will this machine work for my entire product line, or is it a one-trick pony?"

This is a very important question. You are making a significant investment, and you need it to be as versatile as possible to maximize your return. You worry that the powerful vacuum might damage your more delicate products, limiting the machine’s usefulness in your bakery.

Vacuum cooling is extremely versatile and can be used for almost any baked product, including crusty bread, soft rolls, pastries, croissants, and even cakes. The key is using a machine with an advanced control system that allows you to create custom cooling "recipes" for each different item.

Custom Recipes for Every Product

A modern vacuum cooler is not a simple "on/off" device. Our machines, which use reliable Siemens PLC touch screens, allow us to program precise cooling cycles for different products. This is crucial because a dense rye loaf and a light, airy sponge cake require different treatments.

- Crusty Breads (Baguettes, Ciabatta, Sourdough): This is the ideal application. The process enhances the crust and gives the bread fantastic volume.

- Soft Breads (Dinner Rolls, Burger Buns, Tin Bread): The cooling is just as fast and effective, preserving the soft texture and extending shelf life, which is critical for food service clients.

- Laminated Doughs (Croissants, Danishes): This is a huge advantage. The rapid cooling immediately solidifies the butter or fat layers, preventing them from leaking out. This results in a flakier, lighter, and more distinct product. The layers don’t collapse, creating a beautiful and delicious pastry.

- Cakes & Muffins (Sponge Cakes, Cheesecakes): This requires more sophistication. For these delicate products, we use a feature called "vacuum delay" or a "soft cool" program. The machine reduces the pressure in two stages, allowing the cake’s structure to stabilize before applying the full vacuum. This prevents the cake from collapsing and results in a perfectly level, moist product that is ready for decorating in minutes. For a central kitchen like Sophia’s that produces high volumes of decorated cakes, this is a game-changer.

| Product Type | Traditional Cooling Challenge | How Vacuum Cooling Solves It |

|---|---|---|

| Crusty Bread | Crust becomes soggy. | Creates and maintains a perfectly crispy crust. |

| Croissants | Butter leaks out, layers collapse. | Locks in fat layers, creating a flakier texture. |

| Sponge Cake | Tends to shrink or collapse while cooling. | "Soft cool" program prevents collapse for a level cake. |

| Cooked Pies | Filling stays dangerously hot for a long time. | Cools the dense filling as fast as the crust. |

Conclusion

A bakery vacuum cooler is not just another piece of equipment. It is a fundamental shift in how you approach your entire production workflow. By replacing the slowest step with the fastest, you unlock massive potential in speed, space, and quality, leading directly to higher profitability and a better product.

-

Learn about vacuum coolers to see how they revolutionize food preservation and improve quality. ↩

-

Discover the concept of cold boil to understand its unique applications in cooking and food processing. ↩

-

Understanding latent heat of vaporization is crucial for grasping how vacuum cooling works and its efficiency. ↩

-

Exploring gelatinization stop will reveal how it enhances bread texture and quality during cooling. ↩

-

Discover how massive time savings can revolutionize your bakery’s efficiency and production flow. ↩

-

Learn about innovative space-saving solutions that can optimize your bakery’s layout and productivity. ↩

-

Explore how superior quality and extended shelf life can enhance your bakery’s reputation and customer satisfaction. ↩

-

Find out how extending shelf life can reduce waste and open new markets for your bakery’s products. ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy