What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but heat is the silent profit killer that destroys shelf life.

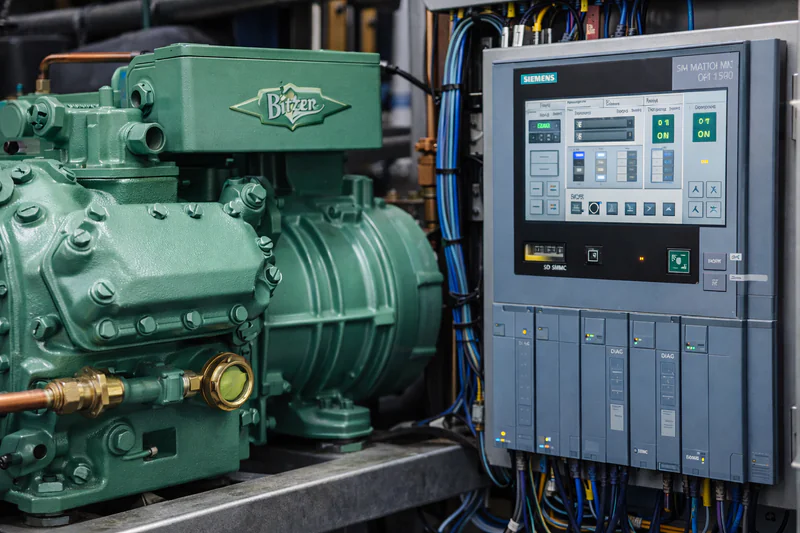

The best lettuce vacuum cooler for 2026 must cool produce to under 4°C in 20-30 minutes using reliable Bitzer compressors and Siemens PLCs. Unlike food-grade stainless steel units, cost-effective vegetable coolers (AVC Series) often feature durable painted carbon steel chambers tailored for logistics, prioritizing rapid cooling speed and massive throughput.

I have spent years at Allcold working with agricultural clients like Carlos from Mexico, who manages large-scale packing centers. I know that for you, a vacuum cooler isn’t just a machine; it is the heartbeat of your cold chain. If it stops, you lose money every minute. But with so many options on the market, how do you choose? Based on our engineering standards and the high-quality components we use across all our systems, I have compiled this buyer’s guide to help you identify what truly matters in 2026.

Does the Machine Use Top-Tier Global Components?

A machine is only as strong as its weakest part. Do you really want to trust your entire harvest to a cheap, unknown compressor brand just to save a few dollars upfront?

The most critical factor in a buyer’s guide is the "Heart" and "Brain" of the machine. You must look for globally recognized brands like Bitzer or Emerson for compressors, and Siemens or Schneider for electronics. These ensure that parts are available globally and reliability is guaranteed.

The "Heart" of the System: Compressors

When I talk to buyers like Norman from America, they often ask about the lifespan of the equipment. My answer is always about the components. At Allcold, we refuse to compromise on the core parts. The compressor is the engine that drives the entire cooling process. For lettuce, which has a large surface area and releases moisture quickly, you need a compressor that can handle high load fluctuations.

A Bitzer compressor1 (German technology) is the industry gold standard. Why? Because during the peak harvest season, your machine might run for 18 hours straight. Cheap, generic compressors often overheat or suffer from valve failures under this kind of stress. If your compressor fails in the middle of July, you are not just paying for repairs; you are paying for tons of spoiled lettuce that couldn’t be cooled. We typically use Bitzer screw compressors or piston compressors depending on the tonnage, ensuring that the refrigeration capacity matches the vacuum pump’s speed perfectly.

The "Brain": Electrical Stability

Similarly, the electrical system is where many cheaper machines fail. We use Siemens2 for our PLCs (Programmable Logic Controllers) and Touch Screens, and Schneider3 for AC contactors and thermal relays. In a farm environment, which can be dusty, damp, or suffer from unstable voltage, you need electrical components that are robust.

Imagine a simple relay burning out. If it is a generic part, you might wait weeks for a replacement from the manufacturer. With Schneider or Siemens, you can likely drive to the nearest city and buy a replacement off the shelf. This "repairability" is a hidden value that most buyers forget until it is too late. Furthermore, quality components ensure safety against hazardous voltages, protecting your workers from electric shock. We design our electrical cabinets to be spacious and well-ventilated, preventing heat buildup that often kills sensitive electronics in hot farming regions like Mexico or the Middle East.

Table: Component ROI Analysis

| Component | Premium Brand Strategy | Generic Brand Strategy | Risk Assessment |

|---|---|---|---|

| Compressor | Bitzer / Emerson | Unknown / Re-branded | High risk of burnout during peak season. |

| PLC / HMI | Siemens | Custom / Proprietary | Software crashes; hard to replace hardware. |

| Vacuum Pump | Leybold / Nash / Busch | Local generic | Slower pressure drop; longer cycle times. |

| Electrics | Schneider | No-name | Fire hazards; frequent contactor failure. |

Is the Control System Intuitive and Intelligent?

Your operators are not rocket scientists, nor should they need to be. Can your staff operate the machine easily without constantly calling for technical support?

A modern vacuum cooler must have a "Touch screen operator control" that simplifies complex physics into a single button press. Look for systems that display vacuum level, product temperature, and time elapsed clearly, and offer automated start/stop sequences to save energy.

Automation is Efficiency

In the middle of a harvest rush, nobody has time to manually adjust valves or monitor pressure gauges with a stopwatch. The best systems in 2026 feature fully automated cycles. The operator should simply push the trolley in, close the door, and press "Start." The machine should handle the rest.

Our systems use intelligent logic. The machine starts the cooling pump, then the vacuum pump, and finally the compressor in a specific sequence to reduce the electrical current surge. This "soft start" protects your farm’s power grid. We also incorporate a "Vacuum Delay Facility4." This is crucial for vegetables with higher water yield resistance. It allows the pressure to drop in stages, ensuring that the moisture evaporates evenly from the core of the lettuce to the outer leaves, preventing "freezer burn" on the surface while the center remains warm.

Precision Temperature Targeting

The most important feature for quality control is the Target Temperature Stop5. You don’t want to freeze your lettuce. Lettuce is mostly water, and if the vacuum pressure goes too low, the water inside the leaves will freeze, turning your crisp product into mush.

A smart control system uses probes inserted into the core of the lettuce. You set the target to, say, 3°C. The system monitors the temperature in real-time. Once the core temperature hits 3°C, the PLC automatically stops the vacuum pump and compressor, then initiates the "Deflation" (releasing the vacuum) and "Drainage" sequences. This precision prevents freezing injury and ensures consistent quality for every batch, whether it is a small load or a full chamber. We allow you to set the upper limit (+2°C) and lower limit (-8°C for refrigerant) to optimize the cooling curve.

Visual Data for Troubleshooting

The screen isn’t just for starting the machine; it is your dashboard. It should display the Vacuum Level, Product Temperature, and Time Elapsed. If a cycle takes 40 minutes instead of the usual 25, the operator can see immediately that something is wrong—perhaps a door seal leak or a dirty filter. This visibility allows for proactive problem-solving before the machine actually breaks down.

Key Intelligent Features to Look For:

- Auto-Stop6: Cuts off based on core temperature probes.

- Delay Start: Staggers motor starts to prevent power spikes.

- Alarm History7: Logs errors for easier troubleshooting.

- Idle Saver: Automatically shuts down if not used for a set time.

Does it Offer Flexible Installation and "Plug & Play"?

Construction costs can be a nightmare. Do you need to build a specialized room, or can the machine just arrive and start working?

The best choice for 2026 is a machine that offers a "Plug & Play" model. This minimizes installation time and cost. Look for units that are "skid mounted" or compact enough to fit into your existing warehouse layout without requiring massive civil engineering work.

The "Skid-Mounted" Advantage

I remember a client in Singapore, Sophia, who had very limited space in her central kitchen. She couldn’t afford a machine that required tearing down walls or weeks of on-site pipe welding. This is why "Compact size8" and "Plug & Play9" models are the future.

A skid-mounted design means the vacuum chamber, the vacuum pumps, the refrigeration unit, and the control panel are all built onto a single steel chassis. We pipe and wire everything in our factory. When it arrives at your farm, you simply connect the main power cable and the water supply (if it’s water-cooled). There is no need for refrigeration engineers to come and solder copper pipes at your facility. This drastically reduces installation costs and the risk of leaks caused by poor on-site installation. For our AVC vegetable coolers, even the large 6-pallet or 12-pallet systems are designed in modular sections to fit into standard shipping containers, making global logistics seamless.

Split Systems for Heat Management

However, there is one exception to the "all-in-one" rule: Heat. Vacuum coolers remove heat from the vegetables, but that heat has to go somewhere. The condenser expels it. If you put a massive machine inside a small packing room, the room will get incredibly hot.

For clients in hot climates, we often recommend a Split Design10. The vacuum chamber and controls stay inside for the operators, but the "Cooling Unit" (condenser and compressor) is placed outside or on the roof. This keeps your packing area cool and quiet. A good manufacturer will offer both options: a compact "monoblock" for large, airy warehouses, and a split system for tighter spaces. We ensure the connection pipes between the indoor and outdoor units are pre-sized and easy to connect.

Customization for Logistics11

Finally, flexibility implies sizing. Do you use standard CHEP pallets, or do you have custom stainless steel trolleys? A rigid manufacturer will force you to change your logistics. A partner will build the chamber to fit you. We define dimensions specifically based on the client’s carts. This maximizes the volume of produce per cycle, ensuring you aren’t cooling empty air. For example, if your pallet is 1.2m x 1.0m, we design the chamber width to accommodate exactly two pallets side-by-side with minimal clearance, reducing the vacuum volume and speeding up the cycle time.

Is the Chamber Material Cost-Effective for Agriculture?

Unlike pharmaceutical or cooked food processing, agricultural cooling requires a balance between durability and cost. Do you really need an expensive stainless steel chamber for boxes of lettuce?

For vegetable cooling (AVC series), the industry standard in 2026 is High-Quality Painted Carbon Steel for the main chamber structure. This significantly reduces the initial investment compared to the AVCF (food-grade) series, while still offering robust strength to withstand the massive vacuum pressure forces.

The Difference Between AVC and AVCF

It is vital to understand the distinction between our AVC (Vegetable) and AVCF (Food) series. If you are cooling cooked bread or sushi rice, as per hygiene regulations (HACCP), the entire chamber must be Stainless Steel 304 (A304) to prevent rust and bacterial growth. However, for field-harvested lettuce packed in plastic crates or cardboard boxes, the produce does not directly touch the chamber walls.

Therefore, for our AVC vegetable coolers, we utilize heavy-duty Carbon Steel reinforced with I-beams. We then apply a multi-layer industrial coating: a sandblasted base to remove impurities, followed by an anti-rust primer, and finally a durable topcoat (usually marine-grade epoxy paint). This provides excellent corrosion resistance against the moisture released by vegetables without the sky-high price tag of stainless steel.

Structural Integrity Under Pressure

Vacuum pressure is incredibly powerful—effectively 10 tons of pressure per square meter. A poorly designed square chamber can buckle or implode. We use finite element analysis (FEA) to design our carbon steel chambers with external ribbing reinforcements. This ensures the chamber remains perfectly rigid cycle after cycle, year after year.

While the main shell is painted steel, we still use stainless steel or aluminum for the internal components that matter most, such as the Evaporator Coils. These coils are constantly wet and subjected to temperature extremes. Using non-corrosive materials here ensures efficient heat transfer and prevents leaks. Furthermore, for the floor of the chamber, we often use checkered steel plate or guide rails that can withstand the heavy impact of forklifts driving in and out 100 times a day.

Maintenance of Painted Surfaces

The trade-off for the lower cost is that you must maintain the paint. Over time, forklifts might scratch the door frame. We advise our clients to touch up these scratches during the off-season to prevent rust spots. This is a small labor cost compared to the $20,000+ difference in raw material price for a full stainless steel chamber. For a savvy buyer like Norman, maximizing ROI is key, and the painted carbon steel chamber is the smartest financial choice for raw vegetable processing.

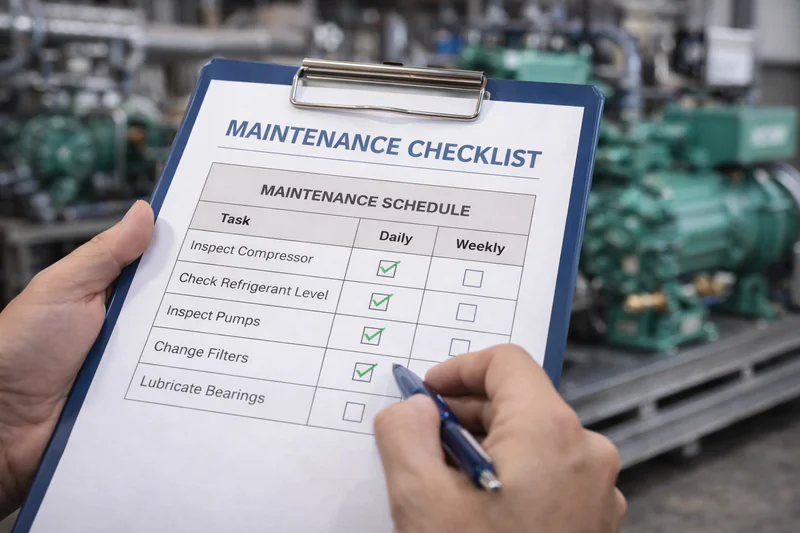

Is Maintenance Straightforward and Documented?

A broken machine during harvest season is a disaster. Does the manufacturer provide a clear roadmap for keeping the machine running?

Avoid machines that are "black boxes." The best vacuum coolers come with explicit maintenance schedules, detailing daily hygiene checks, weekly oil inspections, and seasonal overhauls. The manufacturer should also offer remote troubleshooting capabilities to assist your local team.

The Manual is Your Bible

You might be surprised how many cheap manufacturers sell a machine with a two-page leaflet. A professional machine comes with a comprehensive manual that defines limits and schedules. At Allcold, we provide detailed instruction books. Why? Because vacuum pumps are sensitive. They rely on oil to create the seal. If that oil gets contaminated with water (which happens when cooling moist vegetables), the pump loses efficiency.

We explicitly instruct operators to run the vacuum pump for 20 minutes after daily work with the suction valve closed. This process generates heat that evaporates the moisture trapped in the pump oil, preventing the oil from turning into a milky emulsion that destroys the pump. Without this knowledge, your pump will fail in six months.

Defined Checkpoints

A good buyer’s guide must emphasize specific maintenance points found in professional manuals. You need to know exactly what to check and when:

- Daily: Clean the chamber. Although it’s for raw vegetables, removing mud and leaves prevents mold growth.

- Weekly: Check the oil level in the vacuum pump and the compressor. Check the air pressure for the pneumatic doors (usually requiring 6-8 bars).

- Monthly: Inspect the condenser. If it is air-cooled, is it blocked by dust or leaves? A blocked condenser drives up electricity bills and kills compressors.

- Seasonal: A full "Hygiene Maintenance" overhaul before the season starts.

Remote Diagnostics

Finally, in 2026, you should demand a Trouble-Shooting Assist System. The PLC should be able to communicate faults. If an alarm triggers—say, "Low Pressure"—the screen should tell you. Better yet, if the machine has remote access capabilities, our engineers in China can log in, look at the data history, and tell your technician in Mexico exactly which sensor is acting up. This speed can save a shipment from spoiling.

Table: Maintenance Responsibility Matrix

| Frequency | Action Item | Who Does It? | Consequence of Neglect |

|---|---|---|---|

| Daily | Clean Debris | Operator | Bad smell; clogged drains. |

| Daily | Run Pump Warm-up | Operator | Water in oil; Pump failure. |

| Weekly | Check Oil Levels | Technician | Seized engine; Major repair cost. |

| Monthly | Clean Condenser | Technician | High energy bill; Overheating. |

| Yearly | Check Sensors | Specialist | Inaccurate cooling; Frozen produce. |

Is Safety Built-In?

We are dealing with high-pressure machinery and heavy forklifts. Ignoring safety features can lead to severe injuries that destroy your farm’s reputation.

Top-tier vacuum coolers prioritize safety interlocks. Look for machines with clear pictograms warning of entanglement or temperature hazards, and systems that prevent operation if a person is detected inside the chamber or if the door is not fully sealed.

Operator Safety Protocols

Vacuum chambers are dangerous places. They are airtight spaces. A critical safety feature is the Door Interlock. The machine must never, ever start if the door is not confirmed locked. Furthermore, there must be an emergency stop button both outside and inside the chamber (in case someone is accidentally locked in). Even though this is rare in vegetable operations where pallets are loaded by forklift, safety cannot be compromised.

Our machines come with clear safety pictograms. We warn about Entanglement Hazards (moving pumps), Extreme Temperatures (hot pipes), and Hazardous Voltage. These visual warnings are part of the standard CE compliance. We also advise that the "first running" must be done under the confirmation of electric technicians to ensure all safety loops are active.

Pressure Safety

Finally, there is the risk of residual pressure. You cannot open a vacuum door while there is negative pressure inside; the force is too great. A good system has a safety valve that ensures the chamber is fully equalized with atmospheric pressure before the door mechanism engages. This prevents "whipping or impacting injury" from a door flying open or a seal blowing out.

Additionally, for the AVC series which uses hydraulic or pneumatic sliding doors, we install safety edges. If the door encounters an obstacle (like a forklift tine or a person) while closing, it automatically reverses. This protects your expensive equipment and your staff. We also ensure that the compressed air supply is stable (6-8 bars) because a drop in air pressure could cause pneumatic cylinders to fail.

Conclusion

To secure the best lettuce vacuum cooler in 2026, you need a balance of performance and practicality. Prioritize Bitzer and Siemens components for reliability, opt for the cost-effective yet durable painted carbon steel chamber (AVC Series) for agricultural logistics, and insist on Plug & Play designs. A vacuum cooler is a long-term partnership; choose a machine that cools fast, lasts long, and keeps your harvest fresh.

-

Explore why Bitzer compressors are preferred for their reliability and efficiency, especially during peak harvest seasons. ↩

-

Learn about Siemens PLCs and their advantages in ensuring electrical stability in challenging farm environments. ↩

-

Discover how Schneider components enhance safety and repairability in agricultural electrical systems. ↩

-

Understanding the Vacuum Delay Facility can enhance your knowledge of moisture control in vegetables, ensuring quality preservation. ↩

-

Exploring the Target Temperature Stop will help you grasp how to prevent freezing injury in produce, ensuring optimal quality. ↩

-

Learning about the Auto-Stop feature can improve your operational efficiency by preventing temperature-related damage to your products. ↩

-

Discovering the significance of Alarm History can aid in proactive maintenance, reducing downtime and enhancing system reliability. ↩

-

Explore how compact size equipment can optimize space and efficiency in your kitchen. ↩

-

Learn how Plug & Play technology can save time and reduce installation costs for your operations. ↩

-

Discover the benefits of Split Design systems for maintaining a comfortable working environment. ↩

-

Understand how tailored solutions can enhance efficiency and productivity in your logistics. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer