What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price that seems too good to be true, while another is significantly higher. It’s confusing, and the pressure to make the right multi-thousand-dollar decision is immense.

Choosing the wrong machine, the cheap machine, can be a disaster. A breakdown during your peak harvest season could cost you more in lost produce than your entire initial savings. So, what are you really paying for with a high-quality machine, and what risks are you taking with a low-cost one?

The true difference between a high-quality and a low-price vacuum cooler lies in the parts you cannot easily see. It’s the brand of the compressor, the quality of the steel, the intelligence of the software, and the reliability of the after-sales support. It is the difference between a short-term purchase and a long-term investment.

Over my years in this industry, I’ve seen both sides of this coin. I’ve visited farms with our ALLCOLD machines running flawlessly for over a decade. I have also been called by frustrated growers who bought a cheaper alternative, only to have it fail within two years. They ask me, "Mila, what went wrong?" The answer is almost always found in the small details of the original quote—details that were overlooked in favor of a lower upfront price. Let’s pull back the curtain and look at exactly where those differences lie.

Why Do Core Components Make or Break a Machine?

You receive two quotes. Both say "50HP Refrigeration System." They seem the same, but they are not. One is hiding a critical secret: the use of cheap, unreliable core components that are the heart and soul of the machine.

This is the single biggest gamble in purchasing a low-cost cooler. While it might work perfectly for the first few months, a no-name vacuum pump or a generic compressor is a ticking time bomb. When it fails, your entire cooling operation stops dead.

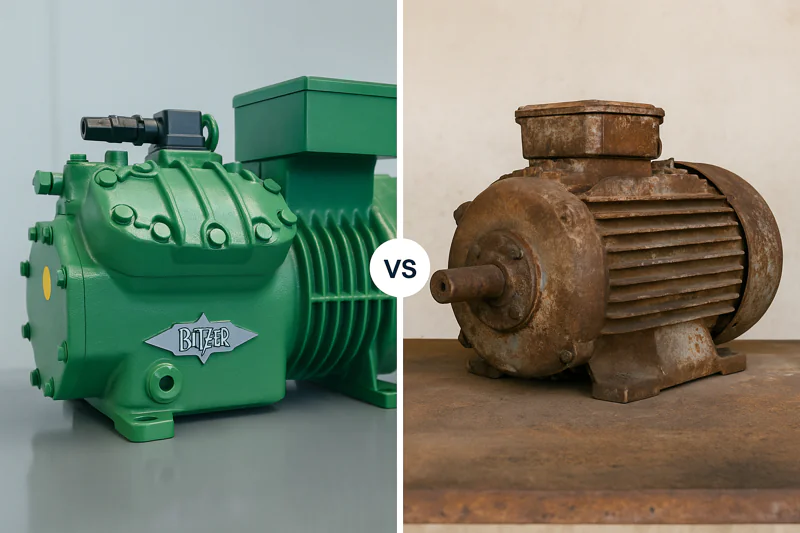

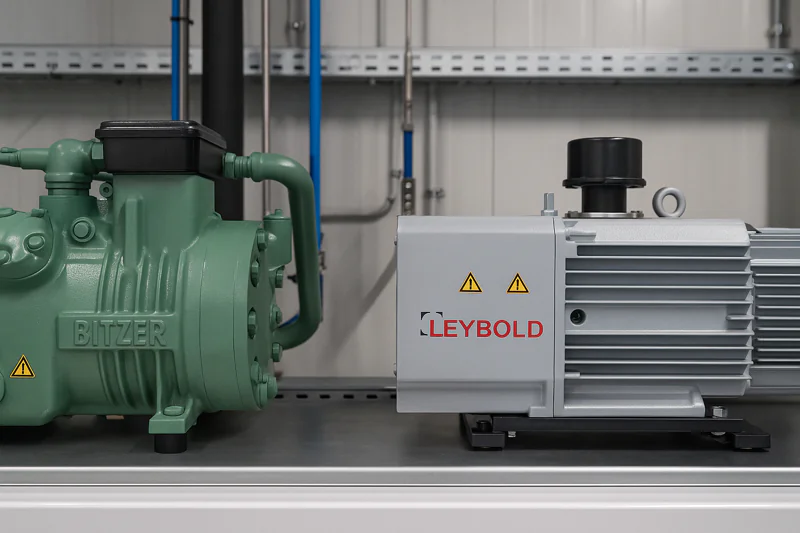

A premium vacuum cooler is built with internationally recognized components from brands like Bitzer, Copeland, and Leybold. These are more expensive upfront but offer unmatched reliability, efficiency, and a global service network. Cheaper machines use obscure or copycat brands with no proven track record, leading to frequent breakdowns.

Deconstructing the "Engine Room"

For a professional buyer like Norman, verifying the component brands is a critical step in his quality control process. He knows that a machine’s performance is only as strong as its weakest link. For a hands-on owner like Carlos, who cannot afford downtime during his peak harvest, component reliability is everything. When I design a system for a client, the first things we specify are the vacuum pump1 and the compressor. They are the two most expensive and hardest-working parts of the entire system.

Think of it like buying a car. You wouldn’t buy a car from a company that refused to tell you who made the engine. Yet, many buyers purchase vacuum coolers without asking for the brand of the compressor (the engine of the refrigeration) or the vacuum pump (the engine of the pressure reduction). Top-tier German brands like Bitzer2 (compressors) and Leybold/Busch (vacuum pumps) have a century of engineering excellence behind them. They run more efficiently, last longer, and have service centers and spare parts available worldwide. A low-cost machine cutting corners here is not saving you money; it’s transferring the risk of failure directly to you.

| Feature Comparison | Low-Price Machine | High-Quality Machine (A Better Investment) |

|---|---|---|

| Compressor Brand | Generic or No-Name Chinese Brand | Bitzer (German) or Copeland (USA) |

| Vacuum Pump Brand | Obscure or unknown supplier | Leybold (German) or Busch (German) |

| Performance Under Heat | Struggles in high ambient temps (>35°C) | Robust performance even in hot climates |

| Lifespan & Reliability | Prone to failure after 2-3 years | Designed for 10-15+ years of continuous use |

| Total Cost of Ownership | Low initial price, high repair costs | Higher initial price, very low repair costs |

Is the Chamber’s Steel Quality Just a Superficial Detail?

The vacuum chamber is the part of the machine you see and interact with every day. To a casual observer, a painted steel box looks a lot like another painted steel box. But the thickness of that steel, the quality of the paint, and the design of the door are hiding major differences in safety, durability, and hygiene.

A chamber built with thin steel can actually flex or deform under the immense, repetitive pressure of the vacuum cycles. A cheap paint job will quickly chip and rust, especially in the damp environment of a packhouse, potentially contaminating your products. This is a nightmare for any food producer.

High-quality coolers use thicker, reinforced steel (10mm or more) and a multi-layer marine-grade paint process to prevent corrosion for years. For food-focused clients, they use 304-grade stainless steel. Cheaper models use thinner steel (8mm or less) with a basic paint job that fails quickly.

More Than Just a Box

When a vacuum cooler is operating, the force on the door can be over 10 tons. It’s an incredible amount of pressure. A chamber has to be built like a submarine to withstand this force, day after day, for a decade. This is where build quality becomes a critical safety and longevity factor. I once visited a farm where the door on their cheap machine was no longer sealing properly because the chamber frame had slightly deformed over time. Their cycle times got longer and longer as the pump struggled to overcome the leak.

For a client like Sophia, who manages a central kitchen under strict HACCP rules, there is no choice: only a food-grade 304 stainless steel3 chamber is acceptable. It’s impossible to properly sanitize a rusty surface. But even for vegetable growers, the choice matters. A robust, hydraulic door mechanism, common on high-quality machines, is safer for workers and much faster than the heavy, manual sliding doors found on budget models. It’s a quality-of-life and efficiency upgrade that pays for itself. When you are assessing a quote, don’t just look at the pallet capacity; ask for the steel thickness, the paint specification, and see a video of the door in operation.

| Feature Comparison | Low-Price Machine | High-Quality Machine (A Better Investment) |

|---|---|---|

| Chamber Material | Thin Carbon Steel (8mm) | Thick Carbon Steel (10mm+) or 304 Stainless Steel |

| Coating/Paint | Basic single-layer paint | Multi-layer, sandblasted, marine-grade epoxy paint |

| Corrosion Resistance | Rust can appear within 1-2 years | Excellent resistance for 10+ years |

| Door Mechanism | Manual (heavy, slow, less safe) | Hydraulic (fast, easy, safe) |

| Hygiene Standard | Not suitable for direct food contact | Stainless models are HACCP compliant4 |

Are You Paying for Buttons or a Brain? The Critical Role of Controls.

You look at a low-cost machine and see a simple control panel with a few buttons. It seems easy. But what happens when you need to cool delicate microgreens one day and sturdy broccoli the next? That "simple" control panel becomes a massive liability.

A "one-size-fits-all" cooling cycle is a recipe for disaster. An aggressive cycle designed for lettuce can easily damage or freeze delicate, high-value products. Without precision control, you lose consistency, you risk your product, and you leave money on the table.

A premium machine has a ‘brain’: a brand-name PLC (Programmable Logic Controller) like Siemens, operated via an intuitive touch screen. This allows for saving multiple, customized cooling programs for different products, ensuring perfect, repeatable results and eliminating operator error.

The Intelligence That Drives Profit

This is a difference that separates a basic tool from a precision instrument. For a detail-oriented manager like Sophia, precision is everything. She needs to prove that her cooked rice was cooled from 90°C to 10°C in under 20 minutes for her HACCP logs. A high-end PLC logs this data automatically. A basic button box cannot. For Carlos, who grows different vegetables, having pre-set programs is a game-changer. His workers can simply select the "Sweet Corn" program on the touch screen, and the machine runs the perfect cycle. There’s no guesswork and no risk of a costly mistake.

Furthermore, a sophisticated PLC is what enables advanced features. We once had a client who grew extremely delicate organic flowers. A standard vacuum cycle would destroy them. But with our machine’s advanced PLC, we were able to program a multi-stage "soft-venting" cycle that gently lowered the pressure, cooling the flowers without causing any damage. This is impossible with a basic controller. The PLC is also the key to effective remote support. My engineers can securely log into a machine’s PLC from our office to diagnose a problem, saving days of downtime. A machine with just buttons is a black box; if something goes wrong, you’re on your own.

| Feature Comparison | Low-Price Machine ("Buttons") | High-Quality Machine ("Brain") |

|---|---|---|

| Control System | Basic relay logic or unbranded controller | Siemens PLC5 or other world-class brand |

| User Interface | Physical buttons, basic display, single language | Graphical Touch Screen (HMI), multi-language |

| Functionality | Single, fixed cooling program | Multiple customizable, pre-set programs6 |

| Product Safety | Risk of product damage or freezing | "Soft cooling" options for delicate items |

| Remote Support | Not possible | Full remote diagnostics via PLC |

Is the Supplier’s Low Price the End of the Story?

You receive a fantastic low price from a supplier you found online. But what happens after you pay? This is the question that separates a simple transaction from a long-term partnership, and it’s a major pain point for buyers like Norman who are tired of inefficient communication.

A low price often comes from a trading company or a factory with no dedicated international support team. They are great at selling you a box. They are terrible at supporting you when a sensor fails, when you need a software adjustment, or when a part needs to be replaced five years from now.

A top-tier supplier’s price includes a critical, invisible asset: a professional after-sales service and engineering team. Reliable partners like ALLCOLD offer 24/7 remote support, stock spare parts for a decade, and have a proven history of successful international installations. A cheap supplier offers a vague warranty and disappears after the sale.

The Value of a Good Partner

This is, for me, the most important difference. A machine is a complex piece of equipment. It will require service. Your operators will have questions. What is that support worth to you? Imagine it’s the middle of your broccoli harvest, and your machine stops. With a high-quality partner7, you can get an experienced engineer on a video call in an hour. They can access your machine’s PLC remotely, diagnose the problem, and guide your local technician. If a part is needed, they have it in stock and can DHL it to you immediately.

With a low-cost supplier, you send an email and wait. And wait. They may not have English-speaking technicians. They may not stock old parts. They have no experience with remote diagnostics. That low price you celebrated a year ago now seems incredibly expensive as you watch your valuable harvest lose quality by the hour. Before you choose a supplier, you must vet the company as much as you vet the machine. Ask them to show you their factory. Ask for references from your country. Ask them to explain their after-sales support8 process. Their answers will tell you everything you need to know about the true quality of their offer.

| Feature Comparison | Low-Price Supplier | High-Quality Partner (A Better Investment) |

|---|---|---|

| Company Type | Trading Company or inexperienced factory | Experienced Factory with in-house engineering |

| Communication | Slow, unresponsive, language barrier | Fast, professional, expert English-speaking engineers |

| After-Sales Support | Email-only, limited hours, no real diagnostics | 24/7 remote video support, PLC diagnostics |

| Spare Parts | Not guaranteed | Guaranteed availability for 10+ years |

| Track Record | No verifiable references or case studies | Proven track record with dozens of international references |

Conclusion

The price tag of a vacuum cooler tells only a tiny part of its story. The real value is buried in its components, its construction, its intelligence, and the team who built it. A cheaper machine isn’t a better deal; it’s a different deal—one where you accept future risks in exchange for a lower initial payment. A high-quality machine is an investment in certainty, reliability, and peace of mind for years to come.

-

Explore this link to discover top vacuum pump brands that ensure reliability and efficiency in your systems. ↩

-

Learn why Bitzer is renowned for its compressors, offering unmatched performance and longevity in refrigeration systems. ↩

-

Explore the advantages of 304 stainless steel for food safety and hygiene, crucial for any food processing operation. ↩

-

Understanding HACCP compliance is essential for maintaining food safety standards in any kitchen or food production facility. ↩

-

Explore how Siemens PLC enhances efficiency and precision in industrial settings, making it a top choice for managers. ↩

-

Learn how customizable pre-set programs can streamline operations and reduce errors in various industries. ↩

-

Discover how a high-quality partner can enhance your machinery support and ensure smooth operations. ↩

-

Learn why robust after-sales support is essential for maintaining equipment efficiency and longevity. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf

How Do You Troubleshoot Common Vacuum Cooler Problems?

Your harvest is ready, the pallets are stacking up, but your vacuum cooler suddenly stops. A red light is flashing,