Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You see the motor power ratings on the quote, but they don’t tell the whole story. How much will this machine actually cost to run every day, every month, every year?

This uncertainty is a major financial risk. A machine with a low purchase price but poor energy efficiency can end up costing you tens of thousands of dollars more over its lifespan. You could unknowingly be buying a "cheap" machine that is incredibly expensive to own.

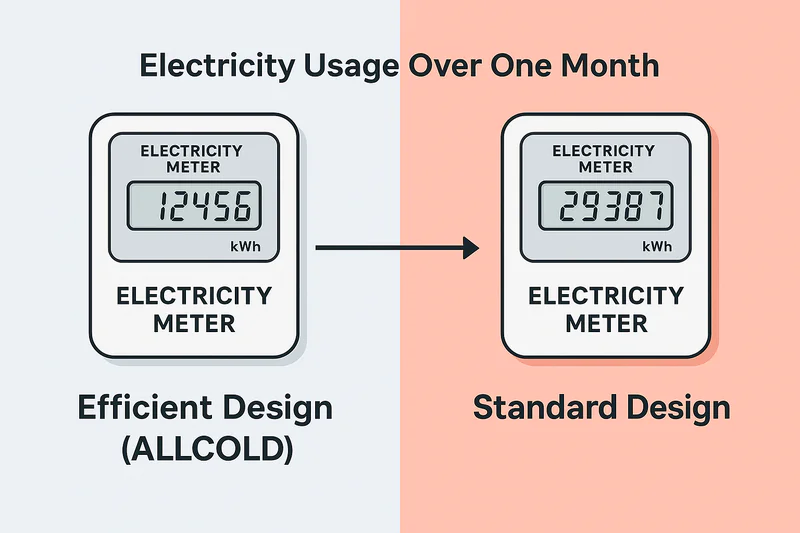

The energy consumption of a vacuum cooler depends heavily on the efficiency of its core components, primarily the refrigeration compressor and the vacuum pump. A well-designed model with premium, high-efficiency components and smart system design can use 20-40% less energy than a poorly designed counterpart with the same cooling capacity.

I’ve talked to many clients who were shocked by the high power bills from their old, inefficient machines. They were sold on a low price, not on a low total cost. In this analysis, I will break down exactly where the electricity goes and show you how different design choices impact your bottom line. This is the information you need to make a financially sound investment.

How Much Does the Compressor Brand Affect Your Power Bill?

The refrigeration compressor is the single largest consumer of electricity in a vacuum cooler. You might see two machines with similar cooling capacities, but one uses a generic compressor while the other features a premium brand like Bitzer and costs more. Is that extra upfront cost really justified?

Ignoring the compressor’s efficiency is like buying a car without checking its fuel economy. A cheap, inefficient compressor is a power-hungry beast. It will run longer and draw more current to achieve the same amount of cooling, inflating your electricity bills every single day you operate it. This hidden cost adds up fast.

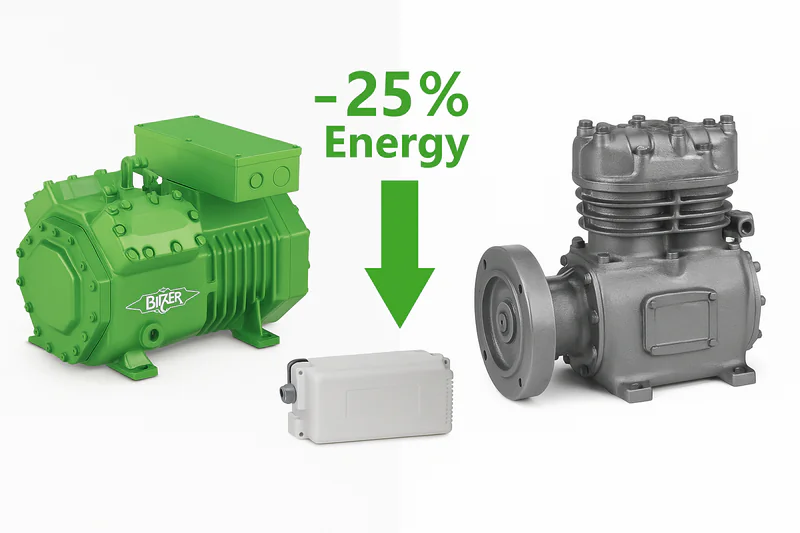

Yes, the compressor brand has a massive impact. A premium, high-efficiency screw compressor from a manufacturer like Germany’s Bitzer is engineered to produce more cooling output per kilowatt of electricity. This superior efficiency can directly reduce your machine’s energy consumption by 15-30% compared to a standard or generic compressor.

The Engine of Efficiency

For a professional buyer like Norman, who analyzes every aspect of Total Cost of Ownership1, the compressor’s efficiency is a non-negotiable point. It’s the difference between a profitable investment and a long-term financial drain.

Measuring Efficiency: The Coefficient of Performance2 (COP)

In refrigeration, efficiency is measured by the Coefficient of Performance, or COP. In simple terms, this is the ratio of cooling power produced to the electrical power consumed. A higher COP means better efficiency. Premium brands like Bitzer invest heavily in research and development to maximize this number. They use advanced screw rotor profiles, high-quality motors, and precise manufacturing tolerances to squeeze every bit of performance out of the electricity they use. A generic compressor might have a COP of 2.5, while a high-end Bitzer model in the same application could have a COP of 3.5 or higher. That’s a huge difference in real-world energy use.

The Financial Impact

Let’s look at a practical example. Imagine two 10-pallet vacuum coolers, each running 10 cycles a day, 200 days a year.

- Machine A (Generic Compressor): Uses 50 kWh per cycle.

- Machine B (High-Efficiency Bitzer): Uses 38 kWh per cycle (a 24% saving).

The annual energy consumption3 would be:

- Machine A: 50 kWh/cycle 10 cycles/day 200 days/year = 100,000 kWh

- Machine B: 38 kWh/cycle 10 cycles/day 200 days/year = 76,000 kWh

At an average electricity cost of $0.15/kWh, the annual savings from choosing the efficient Bitzer compressor would be $3,600. Over a 10-year period, that’s $36,000 in savings, which often far exceeds the initial price difference.

| Feature | High-Efficiency Model (e.g., Bitzer) | Standard / Generic Model |

|---|---|---|

| Coefficient of Performance (COP) | High (e.g., >3.5) | Low (e.g., <2.8) |

| Energy per Cycle (Example) | ~38 kWh | ~50 kWh |

| Estimated Annual Cost | $11,400 | $15,000 |

| Long-Term Financial Impact | Lower Total Cost of Ownership | Higher operational costs |

Can the Vacuum Pump Choice Waste Energy?

The vacuum pump is the second major energy consumer. A quote will list the motor’s power rating in kilowatts (kW), and you might assume a more powerful motor means a better, faster pump. But is that always true?

A poorly selected or inefficiently integrated vacuum pump wastes energy in two ways: it runs longer than necessary, and it draws more power while doing so. If the pump is a cheap brand, or if it’s connected with inefficient piping, you’ll be paying for wasted electricity on every single cycle, extending your processing times and hurting your throughput.

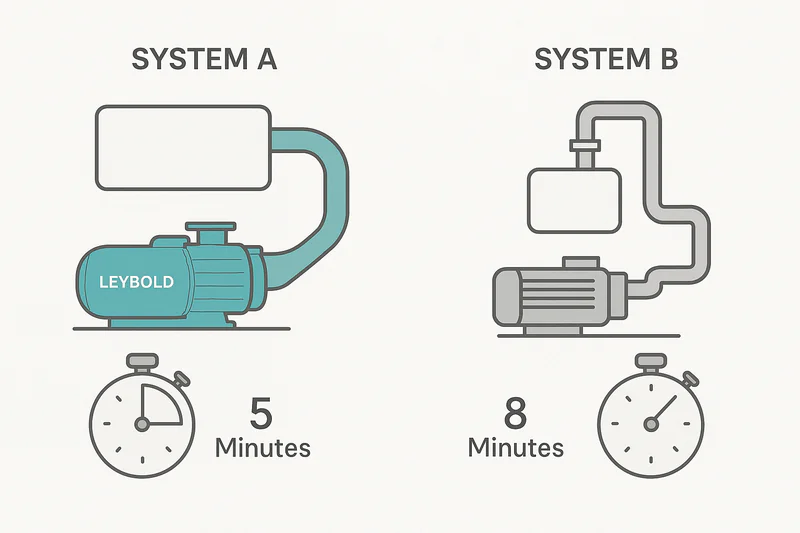

Yes, the pump system design is critical to energy efficiency. A correctly sized, premium pump (like Leybold) combined with large-diameter, unrestricted piping allows the system to reach the target vacuum pressure faster. This shorter run time directly translates to lower kilowatt-hour consumption per cycle.

It’s Not Just the Pump, It’s the System

For a hands-on farm owner like Carlos, time is money. He needs fast cycles to get his produce cooled and shipped. A system that achieves this speed efficient4ly is the ultimate goal, as it maximizes both throughput and profitability.

The Airflow Bottleneck5

The most common flaw in cheap vacuum cooler designs is restrictive piping. Manufacturers use smaller-diameter pipes with sharp, 90-degree bends to save space and cost. This creates massive air friction and chokes the vacuum pump. The pump has to work much harder and longer to pull the air out of the chamber. At ALLCOLD, we use large-diameter stainless steel pipes with long, sweeping bends. This creates a super-highway for the air, allowing our high-quality Leybold pumps to evacuate the chamber at their maximum rated speed. The result is a much shorter pump-down time.

Run Time is Key

Energy consumption is power multiplied by time (kWh = kW * hours). Even if two pumps have the same power rating (kW), the one that completes the job in less time will use less total energy.

- Inefficient System: A 30 kW pump runs for 8 minutes (0.133 hours) = 4 kWh.

- Efficient ALLCOLD System: The same 30 kW pump, thanks to better piping, runs for only 5 minutes (0.083 hours) = 2.5 kWh.

That’s a saving of 1.5 kWh on every single cycle, purely from smart design. Over a year, this adds up to significant savings. We don’t just sell you a good pump; we design a complete system that allows the pump to perform at its peak efficiency.

| System Design | Efficient (ALLCOLD Philosophy) | Inefficient (Common Flaw) |

|---|---|---|

| Pump Quality6 | Premium, reliable (e.g., Leybold) | Generic, unknown brand |

| Piping Design | Large diameter, smooth, sweeping bends | Narrow diameter, sharp 90-degree bends |

| Pump-down Time (Example) | ~5 minutes | ~8 minutes |

| Energy per Cycle7 (Pump) | ~2.5 kWh | ~4.0 kWh |

How Does "Balanced" System Design Save Electricity?

This is a factor that almost never appears on a technical specification sheet, but it has a profound impact on energy use: the size of the evaporator and condenser coils. You see the compressor’s power, but not whether it’s paired with the right supporting components.

An "unbalanced" system, where a powerful compressor is paired with undersized evaporator and condenser coils, is incredibly inefficient. It’s like forcing a large engine to breathe through a tiny straw and exhale through a clogged exhaust. The compressor is constantly under high strain, working much harder and drawing more power than it should.

A balanced system, with deliberately oversized evaporator ("cold trap") and condenser coils, allows the entire refrigeration loop to operate at lower pressures and temperatures. This massively reduces the workload on the compressor, resulting in significant energy savings, especially in warm ambient conditions.

The Hidden Efficiency Multiplier

This is where true engineering expertise comes into play. It’s a design choice that adds to our manufacturing cost, but we do it because it provides immense long-term value to our customers. This commitment to superior design is something that resonates with detail-oriented managers like Sophia, who need equipment that performs reliably to the highest standards.

Reducing Compressor Strain

The evaporator is where heat is absorbed, and the condenser is where it’s released. If these coils are too small, the pressure difference across the compressor (known as the "pressure ratio8") increases dramatically. The compressor motor has to work exponentially harder to overcome this higher pressure ratio. By investing in oversized coils9 with a greater surface area, we lower this operating pressure. The compressor can then move the refrigerant easily, doing the same amount of cooling with far less effort and electricity.

Performance on Hot Days

This is where a balanced design truly shines. On a hot day, an unbalanced system with a small condenser will struggle to release heat. Its operating pressure will skyrocket, and its efficiency will plummet. It may even trip on a high-pressure safety switch, shutting down your operation. Our balanced systems10, with their large condensers, can efficiently release heat even in high ambient temperatures, maintaining their high efficiency and reliable performance when you need it most. Our customers in Mexico, the Middle East, and South Asia depend on this robust performance.

| System Balance | Balanced (ALLCOLD Design) | Unbalanced (Common Cost-Cutting) |

|---|---|---|

| Evaporator/Condenser Size | Oversized for high efficiency | Undersized to save initial cost |

| Compressor Workload | Low strain, operates coolly | High strain, runs hot |

| Efficiency in Hot Weather | Maintains high efficiency | Performance drops dramatically |

| Long-Term Energy Savings | Significant (5-15% of total draw) | Negligible, high running costs |

Conclusion

Energy efficiency isn’t a single feature you can buy; it’s the result of a holistic design philosophy. It comes from choosing premium components, designing intelligent systems, and prioritizing the total cost of ownership over a low initial price. Look beyond the price tag to see the full picture.

-

Exploring TCO helps buyers assess long-term financial impacts beyond initial costs. ↩

-

Understanding COP is crucial for evaluating compressor efficiency and making informed purchasing decisions. ↩

-

Learn about energy consumption factors to optimize efficiency and reduce operational costs. ↩

-

Explore how an efficient cooling system can save time and money for farm owners. ↩

-

Understanding airflow bottlenecks can help improve system design and efficiency. ↩

-

Learn why investing in high-quality pumps is crucial for optimal cooling system performance. ↩

-

Discover strategies to minimize energy consumption and enhance efficiency in cooling operations. ↩

-

Understanding pressure ratio is crucial for optimizing HVAC efficiency and performance. ↩

-

Explore how oversized coils can enhance cooling efficiency and reduce energy costs. ↩

-

Learn why balanced systems outperform unbalanced ones, especially in extreme temperatures. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf

How Do You Troubleshoot Common Vacuum Cooler Problems?

Your harvest is ready, the pallets are stacking up, but your vacuum cooler suddenly stops. A red light is flashing,