Why Must You Precool Vegetables Before Shipping Them?

Are you loading your hard-earned harvest into a refrigerated truck and just hoping for the best? This common mistake is a costly gamble that can ruin your product before it even arrives.

You must precool vegetables before shipping because refrigerated trucks are designed only to maintain a low temperature, not to remove the massive field heat from an entire load. Without precooling, your product will spoil in transit.

Shipping produce is not as simple as putting it in a cold box on wheels. The journey is one of the most dangerous parts of the supply chain. Understanding the vital role of precooling is the key to protecting your investment and delivering the quality your customers demand.

Isn’t a Refrigerated Truck Just a Cooler on Wheels?

Many people think a refrigerated truck—a "reefer"—will solve all their temperature problems during transit. But this is a fundamental misunderstanding of what the truck’s cooling unit is actually designed to do.

No, a refrigerated truck is a "maintainer," not a "remover." Its cooling system is engineered to hold a pre-set temperature against outside heat, not to pull a massive amount of field heat out of your produce.

Think about the equipment. Our allcold vacuum coolers have powerful vacuum pumps and refrigeration systems built for one purpose: to rapidly pull heat out of your product in a controlled 25-minute cycle. A truck’s reefer unit, in contrast, is much smaller. Its job is to circulate cold air and combat the heat coming through the truck’s walls from the sun and road. It simply doesn’t have the power to cool down a full load of warm produce. As a hands-on farm owner like Carlos would understand, it’s about using the right tool for the job. You wouldn’t use a small hand drill to mix a large batch of concrete, and you shouldn’t use a reefer unit to do the heavy lifting of initial cooling.

The Problem of Airflow and "Hot Spots"

Even if the reefer unit was powerful enough, there’s another major problem: airflow1. In a truck, cold air blows over the top of the pallets. If the pallets are loaded with warm produce, this cold air will just pass over them, creating a cold shell around a warm, respiring core. The produce in the center of the pallet may never cool down properly. This creates "hot spots2" where decay begins, which can then spread to the rest of the load. This is a buyer like Norman’s worst nightmare: receiving a pallet that looks good on the outside but is already rotting from the inside. Precooling with a vacuum cooler ensures every single leaf, head, and floret is uniformly chilled to its core before it’s loaded.

| Equipment | Primary Function | Cooling Power | Result on Warm Produce |

|---|---|---|---|

| Vacuum Cooler3 | Remove field heat from the product. | Very High; designed for rapid heat extraction. | Uniformly cold product in ~25 minutes. |

| Refrigerated Truck | Maintain the air temperature. | Low; designed for insulation against leaks. | Uneven cooling, "hot spots," potential for spoilage. |

What Really Happens to Warm Produce Inside a Closed Truck?

Imagine sealing a pallet of warm, living, breathing vegetables inside a dark box for several days. It’s not a pretty picture. The conditions you create can quickly turn your fresh harvest into a science experiment gone wrong.

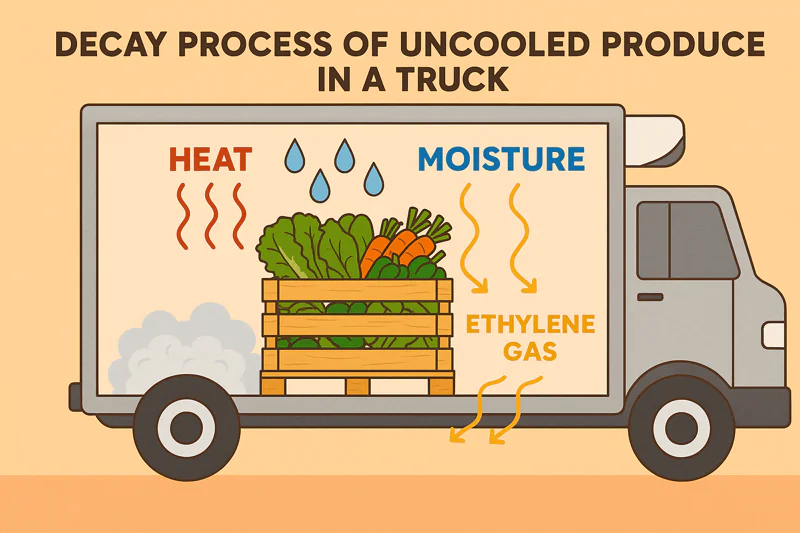

Warm produce loaded into a truck continues to respire at a high rate. It generates its own heat, moisture, and ethylene gas, creating a humid, toxic environment inside the trailer that accelerates rot and decay.

When you load warm produce, you are essentially starting a chain reaction of self-destruction. The vegetables are alive and breathing fast, consuming their own sugars and releasing heat. In a closed trailer, this heat has nowhere to go. The temperature inside the pallets can actually rise before it starts to fall. This process also releases moisture, increasing the humidity. This warm, humid environment is the perfect breeding ground for mold and bacteria. Furthermore, many types of produce release ethylene gas as they ripen and age, a process that is sped up by heat. Ethylene acts as a signal to other produce to ripen and decay faster. You’re creating a closed loop of decay that can ruin an entire shipment.

The Impact on Quality and Safety

For a procurement manager like Sophia, who is responsible for a HACCP-certified food supply chain4, this is a major red flag. The uncontrolled growth of microorganisms5 on warm, wet produce during transit is a huge food safety risk. Beyond safety, the quality plummets. The produce loses water weight, becomes wilted, and loses its crispness and flavor. By the time it arrives, it’s a vastly inferior product. When you precool the produce6, you put it into a dormant state. Respiration slows to a crawl. It generates very little heat, moisture, or ethylene. You are not just shipping vegetables; you are shipping a stable, safe, and high-quality product.

| Condition in Transit | Precooled Produce (2°C) | Unprecooled Produce (20°C) |

|---|---|---|

| Respiration Rate | Very Low | Very High |

| Heat Generation | Minimal | Significant; self-heating occurs. |

| Moisture Release | Low | High; leads to condensation ("sweating"). |

| Final Quality | Arrives fresh, crisp, and with maximum shelf life. | Arrives limp, possibly with mold, greatly reduced shelf life. |

How Does Precooling Directly Protect Your Financial Investment?

Shipping a full truckload of produce is a significant financial investment. You have costs for harvesting, labor, packaging, and freight. Precooling is not an extra cost; it’s the insurance policy that protects that entire investment.

Precooling is your primary defense against shipment rejection. A buyer receiving a warm load may refuse it on the spot, resulting in a total loss. Proper precooling guarantees you meet the quality standards your customers expect.

Let me share a story. I have a client who, before working with us, lost an entire truckload of broccoli destined for export. The reason? The buyer, just like the professional Norman we know, temped the load upon arrival. The core temperature of the pallets was over 10°C (50°F). The entire shipment was rejected. He lost the value of the product, he still had to pay the expensive freight charges, and he damaged his relationship with the buyer. This is a catastrophic, but common, story. A professional buyer’s first check is always temperature. It tells them everything they need to know about how the product was handled. Delivering a load that is perfectly chilled to 2°C is a clear signal of your professionalism and commitment to quality.

From Cost Center to Profit Protector

Many growers see a vacuum cooler7 as a cost. I encourage them to see it as a profit-protection device. By investing in proper precooling, you eliminate the single biggest reason for shipment rejections. You can confidently ship your product knowing it will arrive in the best possible condition. You can even include temperature data loggers8 in your shipments to provide undeniable proof that the product was cold from start to finish. This not only protects you from claims but also builds immense trust with your clients. They know that an order from you is a safe bet, which is the most valuable reputation you can have in this business.

| Shipping Method | Financial Risk | Client Relationship |

|---|---|---|

| Shipping Warm | High risk of rejection, total loss of product & freight. | Unreliable; damages trust and future business. |

| Shipping Precooled | Low risk; ensures product meets quality specifications. | Professional; builds a reputation for reliability. |

Can Precooling Before Shipment Build a Stronger Brand?

In today’s competitive market, you are selling more than just vegetables. You are selling quality, reliability, and peace of mind. Your post-harvest process is a direct reflection of your brand’s promise.

Yes, consistent precooling is one of the most powerful ways to build a premium brand. It transforms you from a simple commodity supplier into a trusted partner whose quality is guaranteed, shipment after shipment.

When a buyer like Norman or a farm manager like Carlos looks for suppliers, they are looking for partners who can help them succeed. A supplier who cuts corners by skipping precooling is a supplier who creates problems. Their shipments are inconsistent, their quality is unpredictable, and they require constant follow-up. A supplier who invests in technology like vacuum cooling and delivers a perfectly chilled product every time is a partner who provides solutions. Their product has a longer shelf life, leading to less waste for the retailer. It looks better, tastes better, and creates a better experience for the final consumer. This is how you move from competing on price alone to competing on quality.

The Mark of a Professional

Ultimately, your commitment to precooling becomes part of your brand identity. It says that you care about your product beyond your own farm gate. It shows you understand the needs of the entire supply chain. When your customers know that every pallet you ship has been professionally precooled to its optimal temperature, they have confidence in you. They are more likely to give you their long-term contracts, to recommend you to others, and to see you as an essential part of their business. This reputation for reliability is more valuable than any single shipment. It is the foundation of a strong, sustainable, and profitable business.

| Supplier Type | Process | Brand Perception |

|---|---|---|

| Commodity Supplier | Skips precooling to save on initial cost. | Unreliable, risky, focused on price only. |

| Premium Partner | Precools every shipment as standard practice. | Professional, reliable, focused on quality. |

Conclusion

Precooling before transport is not an optional luxury. It is a fundamental requirement for protecting your product, your investment, and your reputation. It is the critical step that ensures the quality you grew in the field arrives safely in your customer’s hands.

-

Understanding airflow management can help prevent spoilage and ensure produce stays fresh during transport. ↩

-

Learn about the impact of hot spots on produce quality and how to mitigate their effects during shipping. ↩

-

Discover how vacuum coolers enhance the freshness of produce by ensuring uniform cooling before transport. ↩

-

Understanding HACCP certification can enhance your knowledge of food safety standards and practices essential for quality control. ↩

-

Exploring this topic will provide insights into food safety risks and how to mitigate them effectively. ↩

-

Learning about the benefits of precooling can help improve your supply chain management and product quality. ↩

-

Explore how vacuum coolers can enhance shipping efficiency and protect profits, ensuring product quality and client trust. ↩

-

Learn how temperature data loggers provide proof of product quality during shipping, enhancing client confidence and reducing claims. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not