Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This trapped heat inside the sealed bag is a ticking time bomb, accelerating decay and ruining the product before it even reaches the store.

You are stuck with a difficult choice. Opening the bags to cool them would introduce contaminants and ruin the retail-ready packaging. But using a slow, conventional cold room will cause condensation inside the bags, making the greens soggy and unappealing.

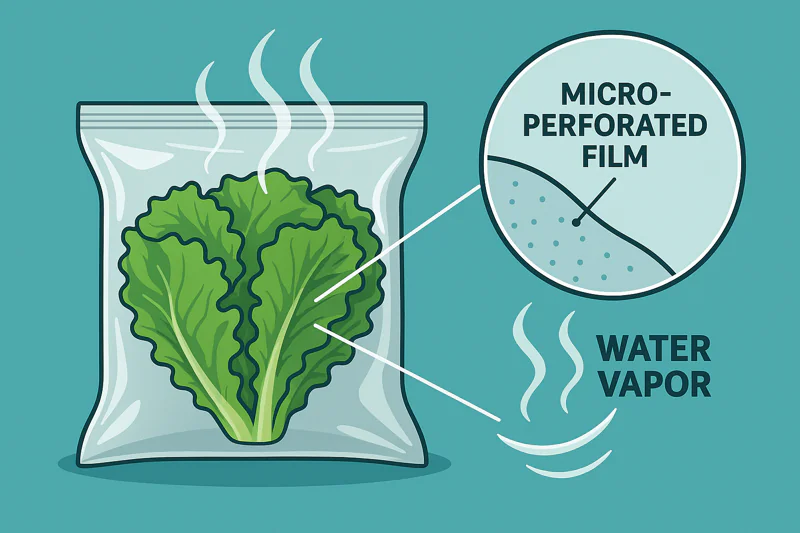

Yes, you can absolutely vacuum cool fresh-cut vegetables after they are packaged, provided you use special micro-perforated packaging. This film allows water vapor to escape during the cooling cycle, enabling rapid, in-pack cooling that extends shelf life and improves safety.

This is a game-changing strategy for any business producing retail-ready or food-service-ready packaged vegetables. By cooling the product in its final packaging, you create a closed, hygienic cold chain from the moment of sealing. It’s the ultimate way to guarantee quality and safety for your customers, and it’s a process I have helped many of my clients perfect.

Why Would You Want to Cool Produce After Packaging?

At first, it might seem backward. Why add another layer—the bag—for the cooling process to work through? Wouldn’t it be faster to cool the loose product? While cooling loose product is effective, it misses out on a huge opportunity to enhance food safety.

Every time you handle produce after it has been cooled, you risk re-contamination. Moving cooled lettuce from bulk bins into a bagging machine exposes it to the ambient air, the equipment surfaces, and human contact. This is a critical risk point in any HACCP plan.

Cooling after packaging creates a "final kill step" for heat and microbial activity within the sealed environment. This minimizes post-cooling handling and contamination risks, delivering a safer, more stable product to the end customer.

The Food Safety Advantage

For a procurement manager like Sophia, who is responsible for the safety of food served in a fast-food chain, a "pack-then-cool" process is a massive selling point. It demonstrates a supplier’s commitment to the highest hygiene standards.

The "Closed Cold Chain1" Concept

The biggest benefit is the creation of a closed cold chain. From the moment your bagging machine seals the package, the product is protected.

- No Post-Cooling Contamination2: The product is never again exposed to the open environment of the packing facility. Any airborne yeasts, molds, or bacteria cannot get in.

- Reduced Human Handling: By moving directly from the bagger to the cooler to the shipping case, you dramatically reduce the number of times the product is touched or transferred between containers.

- HACCP Compliance3: This workflow provides a clear and robust Critical Control Point (CCP). The vacuum cooling step becomes a verifiable process that brings the sealed product to a safe temperature, and it’s all done without breaking the package’s seal.

Let’s compare the two workflows from a food safety and handling perspective.

| Factor | Cool-then-Pack Workflow | Pack-then-Cool Workflow4 | Advantage |

|---|---|---|---|

| Contamination Risk | High. Product is exposed after cooling. | Extremely Low. Product is sealed before cooling. | Safer final product. |

| Product Handling | High. Transfer from cooler to packing machine. | Low. Transfer from packing machine to cooler. | Fewer opportunities for damage and contamination. |

| Final Product State | Product is packed warm and cools slowly in the cold chain. | Product is packed cold and stable. | Better quality and longer shelf life upon arrival. |

| Suitability for Retail | Good, but requires excellent cold chain management. | Excellent. Ideal for retail-ready products needing long shelf life. | Higher confidence for retailers and food service customers like Sophia. |

By adopting a pack-then-cool methodology, you aren’t just selling fresh-cut vegetables; you are selling confidence.

What is the Secret to Cooling Through a Sealed Bag?

So, if cooling inside the bag is so great, why doesn’t everyone do it? Many have tried. They put their standard, solid plastic bags of salad into a vacuum cooler, start the cycle, and watch in horror as the bags inflate like balloons and sometimes even pop.

If the bags don’t pop, they open the door after 20 minutes to find the product inside is still warm. It’s a complete failure. This happens because standard plastic film is a perfect vapor barrier. It’s designed to keep moisture in.

The secret is using specially engineered micro-perforated film for your bags. This film contains thousands of tiny, invisible holes that are large enough for water vapor molecules to escape, but small enough to prevent bacteria and contaminants from getting in.

The Science of Perforated Film

This is the technical key that unlocks the entire process, and understanding it is crucial for a hands-on owner like Carlos who needs to source the right materials for his production line.

How a Vacuum Cooler Works (Quick Recap)

Vacuum cooling works by lowering the atmospheric pressure, which lowers the boiling point of water. The water on the surface of the vegetables then boils at a very low temperature (e.g., 2°C). This "boiling" is the evaporation that rapidly pulls heat from the product.

Why Standard Bags Fail

A standard, non-perforated bag (like a Ziploc bag) is a sealed system. When the pressure outside the bag drops, the higher-pressure air and water vapor trapped inside cause it to inflate. Furthermore, no water vapor can escape from the product to the outside, so no evaporation can occur. No evaporation means no cooling. It’s that simple.

The Magic of Micro-perforations

Micro-perforated film5 is a highly engineered product. The perforations are created with lasers or hot needles to precise specifications.

- Vapor Escape6: The tiny holes allow the water vapor being released by the vegetables during the vacuum cycle to escape the bag. This allows the cooling process to work almost as if the bag wasn’t there.

- Pressure Equalization7: The holes also allow the pressure inside and outside the bag to equalize, preventing the bag from inflating and bursting.

- Modified Atmosphere Packaging (MAP)8: After cooling, these same perforations allow the product to "breathe" in a controlled way. This is essential for fresh-cut produce, which continues to respire (consume O2 and produce CO2) even at low temperatures. The perforations help create a balanced Modified Atmosphere Packaging environment inside the bag, which is critical for extending shelf life and preventing anaerobic spoilage.

| Film Type | Vacuum Compatibility | Cooling Effect | Shelf Life Potential | Best Use Case |

|---|---|---|---|---|

| Standard Plastic Film | None. Bags inflate and pop. | Zero. Traps vapor and heat. | Poor for fresh-cut. | Storing dry goods, or for cool-then-pack methods. |

| Micro-Perforated Film | Excellent. Allows pressure to equalize. | Excellent. Allows water vapor to escape. | Excellent. Creates a breathable, stable environment. | The required material for any "pack-then-cool" operation. |

When you speak to your packaging supplier, you must specifically ask for micro-perforated film suitable for vacuum cooling fresh produce.

What is the Optimal Workflow for the "Pack-then-Cool" Method?

You’re convinced that cooling in the bag is the best method for your retail salad mix. You’ve sourced the right micro-perforated bags. Now, how do you arrange your production line to make this work smoothly and efficiently?

Getting the workflow wrong can create bottlenecks or compromise the final product quality. For example, if the product is too wet when it goes into the bag, the excess water will be trapped, leading to a soggy salad even if it’s cooled correctly.

The optimal workflow is: Process -> Wash -> Thoroughly De-water -> Pack in Micro-Perforated Bags -> Vacuum Cool. The de-watering step becomes the most critical setup point to ensure a high-quality, crisp final product.

A Step-by-Step Guide

Let’s refine our previous workflow for this specific technique. This is the exact process I would help a client like Carlos implement in his facility.

- Process: Vegetables are cut, sliced, or shredded as required. No change here.

- Wash/Treat: The cut product is washed in chilled, treated water to clean it and reduce microbial load. No change here.

- Thoroughly De-water: This step is now more important than ever. Because the product is going into its final bag, you must remove as much surface water as possible. A high-efficiency centrifugal spinner is the best tool for this job. The goal is a product that feels cool and damp to the touch, but leaves no visible water on your glove. Excess water trapped in the bag leads to anaerobic conditions and bacterial growth.

- Pack in Micro-Perforated Bags: The de-watered product is immediately transferred to a bagging station. It is weighed and sealed in the special micro-perforated bags. The bags are then placed into crates or onto pallets.

- Vacuum Cool: The pallet of sealed bags is loaded into the vacuum cooler. You’ll use a specific recipe on the control panel for this process. The cycle might be slightly longer (e.g., 25-30 minutes instead of 20) to account for the slight resistance of the film. The machine will bring the product temperature down to 2°C, right through the bags.

- Box and Ship: Once the cycle is complete, the crates of cold, sealed bags are taken directly to be placed in their final shipping boxes. The cold chain is never broken, and the product is never touched again.

| Step | Action | Key Objective | Why It’s Critical in This Workflow |

|---|---|---|---|

| 1. Process | Cut the vegetables. | Create the product. | Standard first step. |

| 2. Wash | Clean and treat the cut product. | Hygiene. | Standard second step. |

| 3. De-water | Use a centrifuge to spin-dry thoroughly. | Remove surface water. | Prevents sogginess and spoilage inside the final sealed bag. |

| 4. Pack | Seal in micro-perforated bags. | Create the final retail unit. | This step now happens before cooling. |

| 5. Vacuum Cool | Cool the pallet of sealed bags to 2°C. | Halt degradation inside the final package. | The final, critical step to lock in quality and safety. |

| 6. Box | Place cold bags into shipping cases. | Prepare for shipment. | The product is never exposed again. |

Conclusion

Cooling fresh-cut vegetables after they are packaged is not only possible, it is the superior method for producing safe, high-quality, retail-ready products. It is the key to a truly modern and hygienic processing line.

-

Understanding the Closed Cold Chain concept can enhance your knowledge of food safety and hygiene standards. ↩

-

Learning about post-cooling contamination risks can help you implement better food safety practices. ↩

-

Exploring HACCP Compliance will provide insights into critical control points that ensure food safety in the supply chain. ↩

-

Discovering the Pack-then-Cool Workflow benefits can improve your understanding of safe food handling and quality. ↩

-

Explore the advantages of micro-perforated film for packaging, especially in preserving fresh produce. ↩

-

Understand the importance of vapor escape in the cooling process and its impact on product quality. ↩

-

Discover how pressure equalization prevents packaging issues and enhances cooling efficiency. ↩

-

Learn about MAP and its role in extending the shelf life of fresh-cut produce. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer