How Can Vacuum Cooling Technology Transform Your Vegetable Business?

You harvest beautiful, fresh vegetables, but by the time they reach the market, field heat has already started to degrade their quality. This loss of freshness is a direct loss of profit.

Vacuum cooling technology uses a specialized machine to run an automated cooling process. This method locks in freshness, extends shelf life, and protects the value of your freshly harvested produce by removing field heat with unmatched efficiency.

I’ve worked with growers all over the world, and they all face the same enemy: time. From the moment a vegetable is picked, its quality starts to decline. Other cooling methods can be slow, but this guide will walk you through exactly how our technology works and why it’s a game-changer for anyone serious about produce quality, reliability, and ease of use.

How does the cooling process actually work?

You are worried that a powerful machine will be complicated to operate. Your team needs a process that is simple, repeatable, and doesn’t require a specialized engineer to run every cycle.

The entire cooling process is fully automatic. An operator simply loads the produce, closes the door, and presses ‘Start’ on the touch screen. The machine handles the entire cycle, stopping automatically once the target temperature is reached.

A Simple, Automated

The system is designed for simplicity and consistency. A manager like Sophia, who runs a busy central kitchen, can’t afford complicated procedures or mismatched results. Our system ensures every batch is cooled perfectly with minimal operator input. The cycle is straightforward.

First, the operator loads the pallets into the chamber and closes the door. Then, they go to the Siemens touch screen and press the ‘Start’ button. From there, the machine takes over completely. It initiates the sequence by starting the necessary pumps and the compressor in the correct order. The system works to reach the target temperature that you have set. Once the sensors confirm the produce has reached this temperature, the compressor and condenser fans stop automatically. The machine then enters a deflation and drainage stage to prepare the chamber for opening. It’s a truly "set it and forget it1" process that delivers consistent results every time, allowing your staff to focus on other important tasks.

| Step | Action | Control Method |

|---|---|---|

| 1. Load & Secure | Operator loads pallets and closes the chamber door. | Manual |

| 2. Start Cycle | Operator presses the ‘Start’ button. | Touch Screen |

| 3. Automatic Cooling2 | Machine runs pumps and compressor in sequence. | Automatic (PLC) |

| 4. Target Reached | Compressor and fans stop automatically. | Automatic (PLC) |

| 5. Deflation & Drain | Chamber pressure is returned to normal. | Automatic (PLC) |

| 6. Unload | Operator opens the door and removes cooled produce. | Manual |

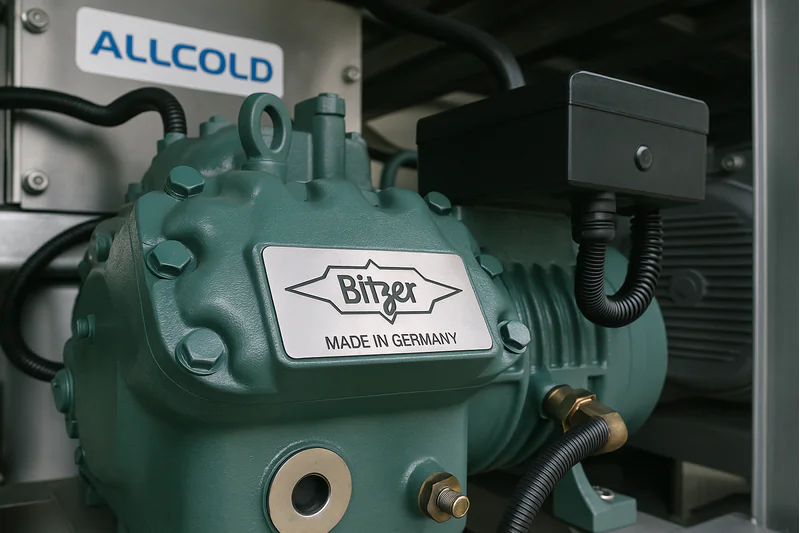

What are the key components of a reliable vacuum cooler?

Many machines look similar on the outside, and you are worried about investing in equipment that might break down. You need to know what separates a high-performance machine from a low-quality one.

A reliable vacuum cooler is built with high-quality, internationally recognized components. Key parts like the vacuum pump (Leybold), compressor (Bitzer), and control system (Siemens) ensure durability and performance.

Built with the Best

When you invest in a machine of this scale, you are investing in the future of your operation. Downtime is not an option, especially during peak season. That’s why the brand and origin of the core components are so important. After years in this industry, I know that using parts from world-class manufacturers3 is the only way to build a machine that you can truly depend on.

A professional buyer like Norman is always looking for quality. When he asks about our machines, I can confidently tell him that we build them with the best parts available. The compressor, which is the heart of the refrigeration system, is from Bitzer in Germany. The vacuum pump, the engine of the whole process, is from Leybold (Germany) or Nash (USA). The electrical systems that control everything are built with parts from Siemens and Schneider, leaders in German and French engineering. We even source components from specialists in Italy, Switzerland, and Denmark. This isn’t just about using famous names; it’s about proven engineering, reliability, and the peace of mind that comes from knowing your equipment will work day in and day out. This commitment to quality is what makes an investment in an ALLCOLD machine a smart business decision.

| Component | Brand | Country of Origin | Function |

|---|---|---|---|

| Compressor | Bitzer | Germany | Powers the refrigeration system. |

| Vacuum Pump | Leybold / Nash | Germany / USA | Creates the low-pressure environment. |

| Touch Screen / PLC | Siemens | Germany | The "brain" that controls the cycle. |

| AC Contactor | Schneider | Germany / France | Manages high-voltage electrical flow safely. |

| Phase Protection | Carlo Gavazzi | Switzerland | Protects motors from electrical faults. |

How versatile and efficient is vacuum cooling?

You’re wondering if this technology is only for one type of product, or if it is too expensive to run. You need a solution that is flexible and cost-effective for your entire operation.

Vacuum cooling is extremely versatile and suitable for a wide range of products beyond vegetables. The systems are also designed for efficiency, using smart controls and high-quality parts to ensure reliable performance.

Adaptable and Dependable

While the technology is a perfect match for post-harvest vegetable cooling, its application is much broader. The core principle of rapid cooling is valuable in many food processing sectors. For example, we designed a system for a large bakery in Hungary specifically for cooling baked bread. The speed and uniformity of the process are critical for maintaining the texture and quality of their products. This shows the adaptability of the core technology.

For a farm owner like Carlos, who might be processing different crops throughout the year, having a versatile machine is key. But versatility means nothing without efficiency and reliability. The efficiency comes from the intelligent design, using a top-tier brand like Danfoss for critical expansion valves to optimize the refrigeration cycle. Reliability is built right in. All our systems come with a 12-month guarantee from the bill of lading date, giving you a full year of security. We also offer comprehensive support, meaning if you ever have an issue, our team is ready to help you troubleshoot. This combination of adaptability, efficiency, and guaranteed support makes it a smart and secure investment for any growing food business.

| Feature | Description | Benefit |

|---|---|---|

| Versatility | Cools fresh produce, cooked foods, and baked goods. | One machine can serve multiple production lines. |

| Efficient Design | Uses premium components like Danfoss expansion valves4. | Optimizes the cooling cycle for performance. |

| User-Friendly | Simple touch-screen controls from Siemens. | Reduces training time and prevents user error. |

| Guaranteed Reliability | Backed by a full 12-month warranty5. | Provides peace of mind and protects your investment. |

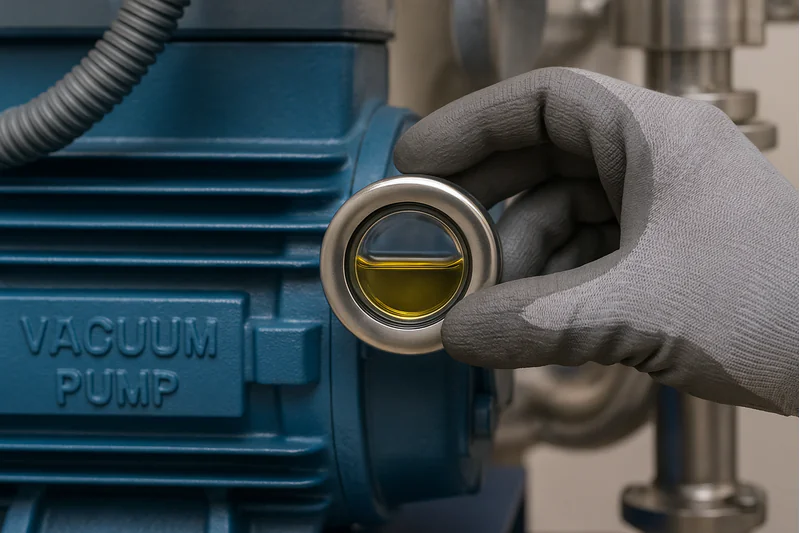

What does regular maintenance for a vacuum cooler involve?

You are concerned that such a sophisticated machine will be complicated and expensive to maintain. You need equipment that is robust and easy to care for in the long run.

Regular maintenance is simple and focuses on routine checks. This includes inspecting the vacuum pump oil monthly and performing a general hygiene cleaning every two seasons. All complex repairs, however, must be performed by qualified professionals.

Keeping Your Machine in Top Condition

A well-maintained machine is a reliable machine. While the technology inside is advanced, the routine tasks required to keep it running smoothly are quite straightforward. We provide a detailed manual with every machine, but the key checkpoints are easy to remember. Our goal is to empower owners like Carlos to handle the small things themselves while ensuring safety is always prioritized.

The most important routine check is the vacuum pump oil6, which should be inspected monthly. If you look at the sight glass and the oil appears milky, it means moisture has mixed with it, and it’s time to change it completely. It’s also good practice to perform an overall hygiene cleaning every two seasons to keep the chamber and components in good condition. For more technical tasks, safety comes first. Changing the compressor oil7, which should be done every two years, must be handled by a professional. Likewise, any checks or repairs inside the electricity cabinet should only be performed by a qualified technician after the main power has been cut off. Following this simple schedule will ensure your machine runs reliably for years to come.

| Maintenance Task | Frequency | Who Performs It |

|---|---|---|

| Check Vacuum Pump Oil | Monthly | Owner / Operator |

| Overall Hygiene Cleaning | Every Two Seasons | Owner / Operator |

| Wash Condenser | Annually | Owner / Operator |

| Change Compressor Oil | Every 2 Years | Professional Technician |

| Electrical Cabinet Service | As Needed | Professional Technician |

Conclusion

This guide shows that vacuum cooling is a powerful tool. It offers reliability through quality components and simple operation, protecting the value of your hard work from the field to the final customer.

-

Discover the benefits of a ‘set it and forget it’ approach in automation, ensuring reliability and ease of use. ↩

-

Explore this link to understand how Automatic Cooling enhances efficiency and consistency in food production. ↩

-

Exploring this resource will highlight the importance of quality components in machinery, ensuring reliability and performance. ↩

-

Explore this link to understand how Danfoss expansion valves enhance refrigeration efficiency and reliability. ↩

-

Learn why a 12-month warranty can provide peace of mind and protect your investment in food processing technology. ↩

-

Understanding the significance of vacuum pump oil maintenance can enhance your machine’s longevity and performance. ↩

-

Learn about compressor oil change frequency to ensure your machine operates efficiently and safely. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf