How Can We Fine-Tune Cooling for Cucumbers and Tomatoes?

Struggling with cucumbers losing their crunch or tomatoes turning mushy too soon? Proper cooling is vital, but getting it just right for these delicate fruit-vegetables can be tricky.

Optimizing cooling for cucumbers and tomatoes involves precise temperature control (avoiding chilling injury), selecting appropriate pre-cooling methods like gentle vacuum cooling or hydrocooling, managing cooling rates carefully, and maintaining ideal humidity levels to preserve quality and extend shelf life significantly.

Achieving that perfect balance isn’t just about dropping the temperature; it’s a science. Let’s explore the key parameters we need to tweak to get the best results for these popular items, ensuring they reach customers like Norman’s clients in peak condition.

What’s the Ideal Target Temperature Range for Fruit-Vegetables Like Cucumbers and Tomatoes?

Are your tomatoes developing off-flavors or cucumbers getting pitted after cooling? Setting the wrong target temperature can do more harm than good for these sensitive items, a concern I often discuss with growers like Carlos.

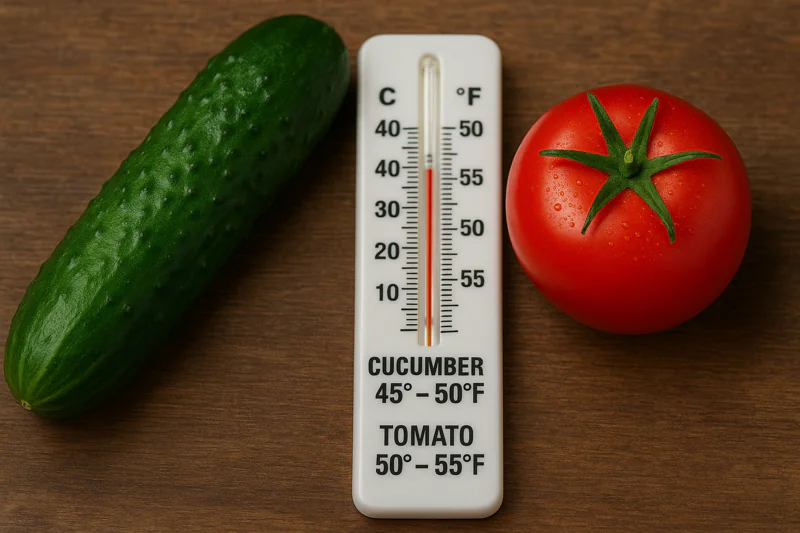

The ideal target temperature for most cucumbers is 7-10°C (45-50°F), and for tomatoes, it varies by ripeness but is generally 10-13°C (50-55°F) for ripe ones. Cooling below these specific ranges can cause chilling injury, damaging quality.

Unlike hardier vegetables, many fruit-vegetables are susceptible to chilling injury if stored too cold, even if it’s above freezing. This damage isn’t always immediately visible but can lead to significant quality loss down the line.

Understanding Chilling Injury

Chilling injury is physiological damage that occurs in some produce when exposed to low, but non-freezing, temperatures. Symptoms vary by commodity but can include:

- Surface pitting or lesions

- Water-soaked spots

- Internal discoloration or breakdown

- Failure to ripen properly (for tomatoes)

- Increased susceptibility to decay

- Development of off-flavors

Balancing Shelf Life and Quality

The goal is to cool these items enough to slow respiration and microbial growth, thus extending shelf life1, but not so cold as to induce chilling injury2. This balance is critical. For instance, Sophia, managing a central kitchen, needs tomatoes that not only last but also retain their flavor and texture for her recipes.

Here’s a general guide for common fruit-vegetables:

| Fruit-Vegetable | Recommended Storage Temperature (°C) | Recommended Storage Temperature (°F) | Common Chilling Injury Symptoms Below Range |

|---|---|---|---|

| Cucumber | 7 – 10°C | 45 – 50°F | Pitting, water-soaked spots, accelerated decay |

| Tomato (Ripe) | 10 – 13°C | 50 – 55°F | Failure to develop full color/flavor, decay, pitting |

| Tomato (Mature Green) | 13 – 21°C | 55 – 70°F | Uneven ripening, internal browning, off-flavors |

| Bell Pepper | 7 – 13°C | 45 – 55°F | Sheet pitting, calyx discoloration, decay |

| Eggplant | 10 – 12°C | 50 – 54°F | Surface scald, pitting, browning of flesh/seeds |

Always refer to specific cultivar recommendations, as sensitivities can vary. Precise temperature control is paramount.

How Does Pre-Cooling Method Affect Fruit-Vegetable Quality and Cooling Parameters?

Wondering if your current cooling method is truly the best for delicate items like cucumbers and tomatoes? The wrong choice or unoptimized parameters can damage texture and reduce market value quickly.

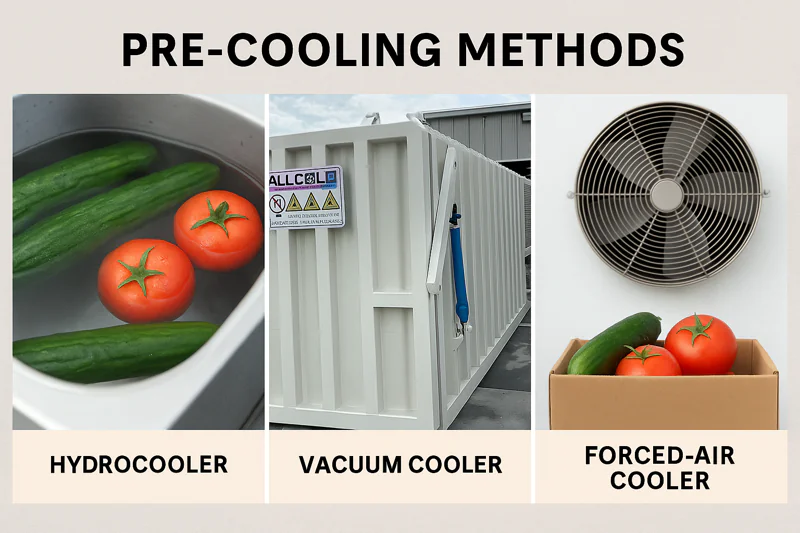

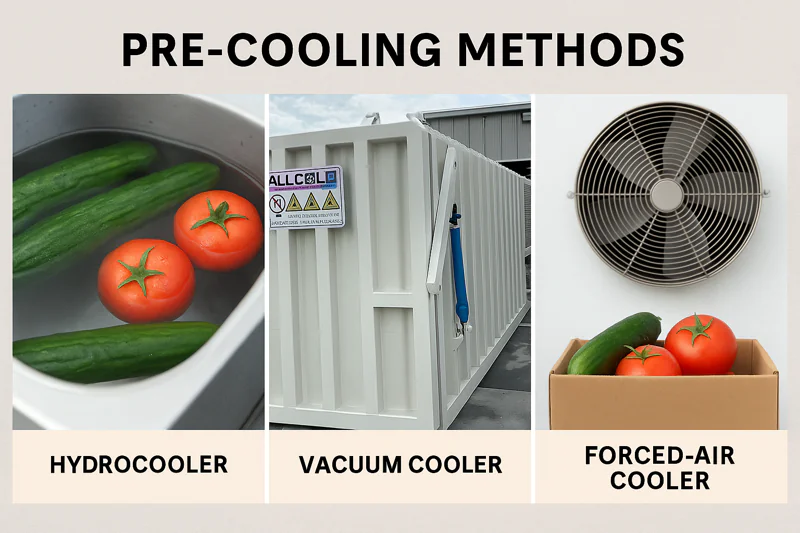

The choice of pre-cooling method—such as gentle vacuum cooling (for certain varieties), hydrocooling, or forced-air cooling—significantly impacts quality. Each method requires different parameter adjustments for speed, final temperature, and product handling to minimize stress.

The goal of pre-cooling is to rapidly remove field heat. For delicate fruit-vegetables, how this is done matters immensely. Aggressive cooling might work for robust items, but cucumbers and tomatoes need a gentler touch.

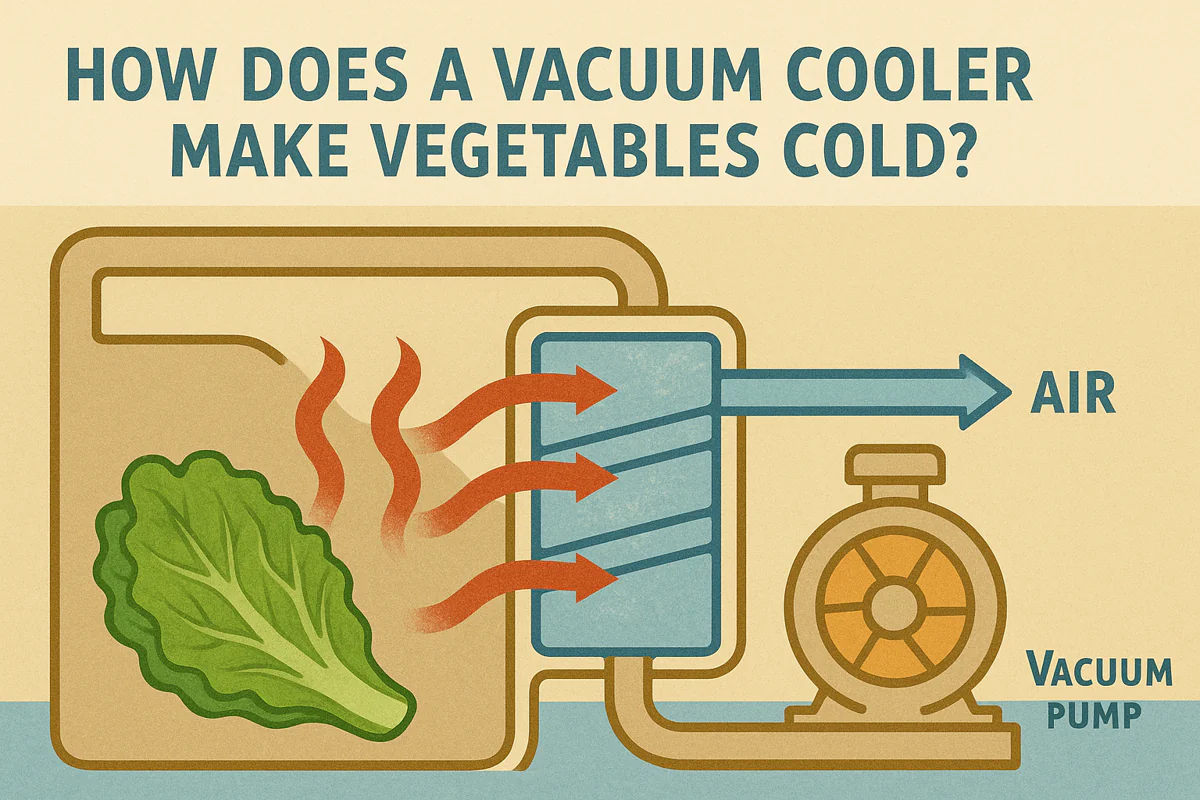

Vacuum Cooling Considerations for Fruit-Vegetables

While our allcold vacuum coolers are fantastic for leafy greens and many other items, their application for fruit-vegetables like tomatoes and cucumbers needs careful consideration.

- Suitability: Some thinner-skinned cucumber varieties might benefit, especially if a slight, controlled moisture loss is acceptable or even desirable. However, tomatoes, with their relatively impermeable skin and lower surface area-to-volume ratio, are generally less suited for pure vacuum cooling.

- Parameter Optimization: If used, the vacuum level and cycle time must be carefully controlled to prevent excessive moisture loss or cell damage. A "gentle-vac" approach might be explored. Pre-wetting could be beneficial for some cucumbers to aid evaporative cooling without drying the product too much.

Vacuum Cooling Considerations for Fruit-Vegetables

While our allcold vacuum coolers are fantastic for leafy greens and many other items, their application for fruit-vegetables like tomatoes and cucumbers needs careful consideration.

- Suitability: Some thinner-skinned cucumber varieties might benefit, especially if a slight, controlled moisture loss is acceptable or even desirable. However, tomatoes, with their relatively impermeable skin and lower surface area-to-volume ratio, are generally less suited for pure vacuum cooling.

- Parameter Optimization: If used, the vacuum level and cycle time must be carefully controlled to prevent excessive moisture loss or cell damage. A "gentle-vac" approach might be explored. Pre-wetting could be beneficial for some cucumbers to aid evaporative cooling without drying the product too much.

Hydrocooling3 and Forced-Air Cooling: Pros and Cons

These are often preferred methods for many fruit-vegetables.

- Hydrocooling: Immersing or drenching in chilled water. It’s fast and can clean the produce. Parameters to optimize include water temperature (not too cold to shock), exposure time, and water sanitation.

- Forced-Air Cooling4: Pushing cold, moist air through vented containers. It’s generally gentler than hydrocooling but can be slower. Parameters include air temperature, airflow rate, and relative humidity of the cooling air.

Here’s a comparison:

| Method | Suitability for Cucumbers/Tomatoes | Key Parameters to Optimize | Potential Issues if Not Optimized |

|---|---|---|---|

| Vacuum Cooling5 | Limited; better for some cucumbers | Vacuum level, cycle time, pre-wetting (if any) | Excessive wilting, skin damage, insufficient cooling |

| Hydrocooling | Good | Water temperature, immersion time, water quality/sanitation | Chilling injury (if water is too cold), pathogen spread |

| Forced-Air Cooling | Good | Air temperature, airflow velocity, relative humidity, stack pattern | Slow cooling, excessive dehydration, chilling injury |

Choosing the right method and fine-tuning its parameters is a crucial first step for preserving the quality of these sensitive products.

Why is Controlled Cooling Rate So Important for Delicate Fruit-Vegetables?

Is cooling your tomatoes too fast causing cracking, or too slow leading to decay? The speed of temperature drop is a critical parameter often overlooked for fruit-vegetables.

A controlled cooling rate is vital to prevent thermal shock, skin damage (like cracking in tomatoes), and excessive moisture loss in delicate fruit-vegetables. Gradual, yet efficient, cooling helps maintain cellular integrity and overall quality.

The "need for speed" in cooling must be balanced with the product’s ability to withstand rapid temperature changes. For something like a cucumber or a ripe tomato, being too aggressive can be detrimental.

The Dangers of Too-Rapid Cooling

While removing field heat quickly is generally good, if the cooling rate is too extreme for the specific commodity, several problems can arise:

- Thermal Stress/Shock6: Rapid contraction of the outer layers while the core remains warm can cause physical damage, like skin cracking in tomatoes or internal stresses in cucumbers.

- Uneven Cooling7: The surface might get too cold too quickly, potentially causing localized chilling injury before the core has adequately cooled.

- Increased Moisture Loss (in some systems): Very rapid airflow, for instance, without proper humidity, can desiccate surfaces.

Optimizing Cooling Speed in Different Systems

The ideal cooling rate varies by commodity, initial temperature, and cooling method.

- Vacuum Cooling8: For suitable products, the rate is inherently fast. Optimization involves ensuring the cycle doesn’t remove too much moisture too quickly by controlling the final pressure and duration.

- Hydrocooling: Water temperature is key. Using water that is significantly colder than the product but still above its chilling injury threshold provides rapid yet buffered cooling.

- Forced-Air Cooling: Airflow rate and temperature differentials are adjusted. Higher airflow speeds cooling but needs to be managed to prevent drying.

Here’s how cooling rate impacts quality:

| Cooling Rate Factor | Impact of Too Fast Cooling | Impact of Too Slow Cooling | Optimization Goal |

|---|---|---|---|

| Temperature Differential | Risk of surface chilling injury, thermal shock (cracking) | Prolonged exposure to warm temps, faster respiration/decay | Achieve target temp efficiently without shocking product. |

| Airflow/Water Flow | Potential for surface dehydration (air), physical damage | Inefficient heat removal, longer cooling times | Maximize contact for heat transfer without causing damage. |

| Cycle Time | (Related to overall rate) Product may not cool uniformly | Quality degradation before full cooling is achieved | Cool thoroughly to the core in a reasonable timeframe. |

Finding that "sweet spot" for cooling rate, like Carlos often experiments with on his farm for new varieties, ensures that shelf life is maximized without sacrificing the immediate quality and appearance of the fruit-vegetables.

How Can Humidity Control During and After Cooling Optimize Fruit-Vegetable Freshness?

Seeing your cucumbers shrivel or tomatoes lose their plumpness even after cooling? Humidity management is a crucial parameter for maintaining hydration and extending shelf life effectively.

Maintaining high relative humidity (around 90-95%) during forced-air cooling and subsequent storage is crucial for most fruit-vegetables. This minimizes water loss, prevents shriveling, and helps maintain turgidity and fresh appearance.

Fruit-vegetables, with their high water content, are very susceptible to moisture loss, which leads to weight loss, shriveling, and a general decline in quality. This is a major concern for buyers like Norman, as it directly impacts salability.

Impact of Low Humidity

When the surrounding air is dry (low relative humidity or RH), water evaporates from the produce surface.

- Weight Loss: Direct loss of saleable weight.

- Shriveling/Wilting: Loss of turgidity, making the product look old and unappealing.

- Reduced Shelf Life9: Dehydrated produce is often more susceptible to decay.

- Textural Changes: Cucumbers lose crispness; tomatoes can become leathery.

Strategies for Humidity Management

- During Forced-Air Cooling: If using forced-air systems, humidifiers can be integrated to ensure the cooling air doesn’t dry out the produce. The air entering the cooler should ideally be close to saturation for these products.

- During Hydrocooling: This method inherently maintains 100% RH around the product during the process.

- Vacuum Cooling: This method works by evaporating moisture, so a small amount of moisture loss (1-3%) is inherent. The key is that the cooling is so rapid that overall degradation is minimized. For products very sensitive to any moisture loss, it might be less ideal unless this small loss is acceptable.

- Post-Cooling Storage10: Store at high RH (90-95%). This can be achieved through humidification systems in cold rooms, using micro-perforated packaging, or by ensuring the cold store is well-sealed and appropriately loaded.

Maintaining optimal humidity:

| Parameter | Importance for Fruit-Vegetables | Typical Target Level | Consequences of Sub-Optimal Levels |

|---|---|---|---|

| Relative Humidity (RH) During Cooling (Forced-Air) | Prevents desiccation from moving air. | 90-95% | Shriveling, weight loss, reduced cooling efficiency. |

| Relative Humidity (RH) During Storage | Critical for maintaining hydration, turgor, and appearance. | 90-95% | Significant quality degradation, shorter shelf life. |

| Packaging | Can create a modified high-humidity micro-environment around product. | Varies | If not breathable, can lead to condensation/decay. |

For managers like Sophia, ensuring that ingredients like cucumbers and tomatoes arrive and are stored under high humidity helps maintain the fresh quality needed for her food preparations. It’s a parameter that works hand-in-hand with temperature.

Conclusion

Optimizing cooling for fruit-vegetables like cucumbers and tomatoes hinges on carefully managing target temperatures, choosing suitable methods, controlling cooling rates, and maintaining high humidity. This preserves their delicate quality and extends valuable shelf life.

-

Extending shelf life while preserving quality is essential for food management. Discover effective strategies to achieve this balance. ↩

-

Understanding chilling injury is crucial for maintaining the quality of produce. Explore this link to learn prevention methods and best practices. ↩

-

Learn about Hydrocooling techniques and their effectiveness in preserving the freshness of fruit-vegetables. ↩

-

Discover the benefits of Forced-Air Cooling and how it can be optimized for better results in fruit-vegetable preservation. ↩

-

Explore this link to understand how Vacuum Cooling can impact the quality and shelf life of fruit-vegetables. ↩

-

Understanding Thermal Stress/Shock is crucial for preventing damage to produce during cooling. Explore this link for in-depth insights. ↩

-

Uneven Cooling can lead to chilling injuries in fruits and vegetables. Learn more about its impact and prevention strategies. ↩

-

Vacuum Cooling is a fast method for preserving produce. Discover its benefits and best practices for effective use. ↩

-

Understanding how low humidity affects shelf life can help in implementing better storage practices for produce. ↩

-

Learning about post-cooling storage techniques can enhance the longevity and quality of your produce. ↩

Mila

You May Also Like

How Does a Vacuum Cooler Make Vegetables Cold?

It seems almost magical: you place warm vegetables in a steel chamber, and just 20-30 minutes later, they emerge perfectly

How Does Vacuum Cooling Forge the Strongest Link in Your Vegetable Cold Chain?

You work tirelessly to grow perfect, healthy vegetables. Yet, you know that from the moment of harvest, an invisible clock

Small-Scale vs. Large-Scale Vacuum Cooler: How Do You Choose the Right Fit?

You’re convinced that vacuum cooling is the key to elevating your product quality, but now you face a critical decision.

How Can You Master Vacuum Cooling for Leafy Greens to Maximize Quality and Profit?

You grow beautiful, vibrant leafy greens, but you know the invisible enemy is time. From the moment of harvest, the

Which Vegetables Benefit Most from Vacuum Cooling Technology?

You see the promise of rapid cooling, extended shelf life, and superior quality, but you’re unsure if this technology is

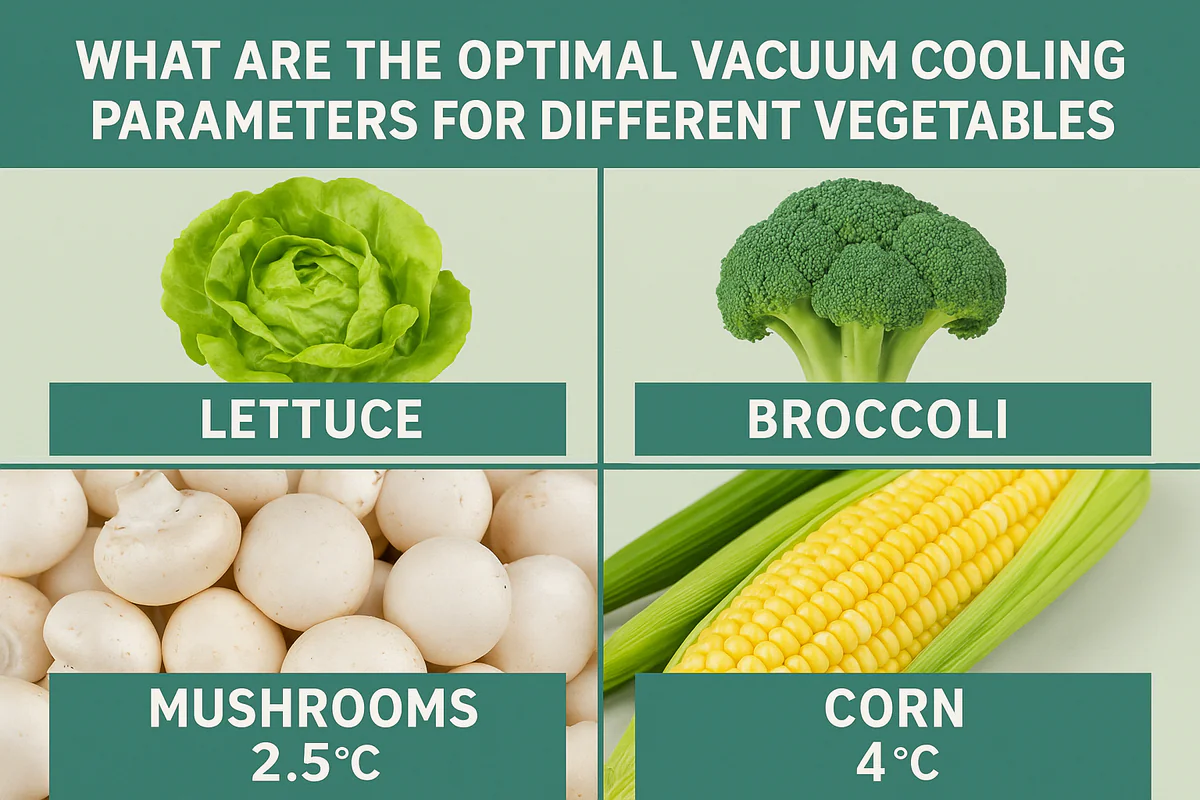

What Are the Optimal Vacuum Cooling Parameters for Different Vegetables?

You’ve harvested beautiful produce, from crisp lettuce to delicate mushrooms. But using a "one-size-fits-all" setting on your vacuum cooler feels

How Can You Reduce the Energy Costs of Your Vacuum Cooler?

Your vacuum cooler is a powerhouse of productivity, but your monthly electricity bill is climbing. You’re starting to wonder if

How Can You Keep Your Vacuum Cooler Running Flawlessly?

Your vacuum cooler is a vital asset, but you’re worried about unexpected breakdowns during peak season. Neglecting maintenance feels like

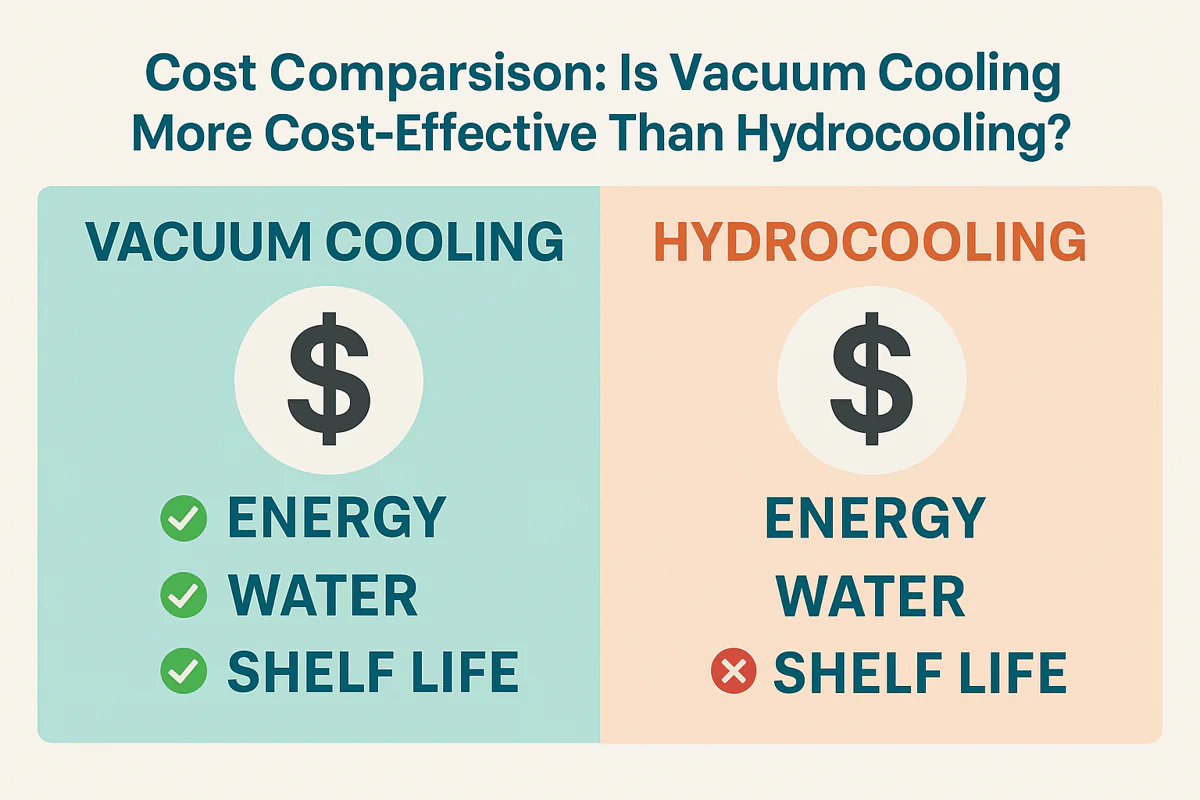

Cost Comparison: Is Vacuum Cooling More Cost-Effective Than Hydrocooling?

Choosing between cooling technologies feels like a high-stakes gamble. You need to lower your operational costs, but the wrong decision

Who Are the Top Vacuum Cooler Manufacturers for Vegetables?

Searching for a list of top vacuum cooler brands can be overwhelming. You’re not just buying a machine; you’re investing