How Can You Lock in the Freshness of Your Harvested Herbs?

Your fields of fragrant basil, mint, and cilantro look and smell perfect at harvest. Yet, within hours, they begin to wilt and their precious aroma fades, turning a premium crop into a discounted product.

You can lock in freshness by using a vacuum cooler. This technology removes field heat in under 30 minutes, instantly halting the wilting process and, crucially, preserving the volatile essential oils that give herbs their distinct aroma and value.

I’ve walked through herb farms where the air is thick with incredible scents. The farmers work hard to cultivate herbs with the perfect aromatic profile. But they all share the same frustration: that amazing aroma literally evaporates after harvest. It’s a race against time that they often lose. Our job is to give them the technology to win that race, preserving the quality they worked so hard to create.

Why Do Fresh Herbs Lose Their Flavor and Aroma So Fast?

A fresh bunch of parsley smells amazing in the field but smells like plain grass just a day later. This rapid loss of character is not your imagination; it’s a real and costly biological process.

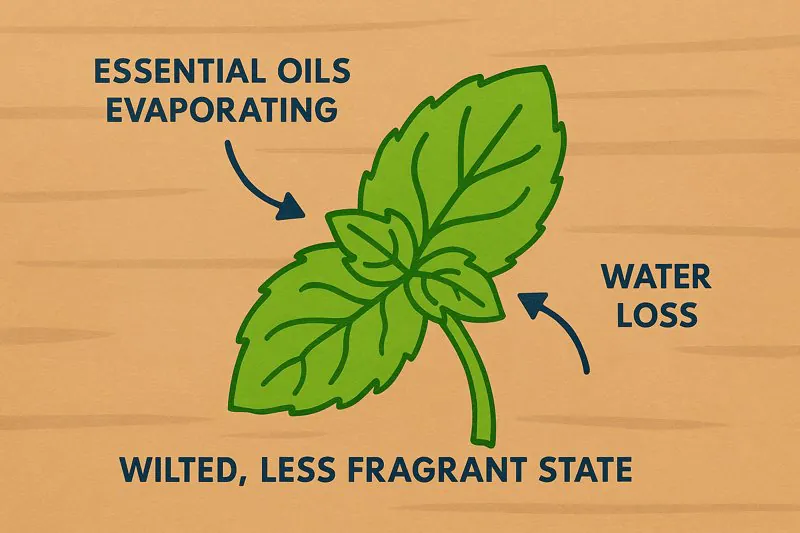

Herbs lose their aroma quickly because their valuable essential oils are highly volatile and evaporate when warm. This, combined with a high respiration rate that causes wilting, rapidly degrades the herb’s quality after it’s been cut.

The Twin Thieves: Heat and Air

After you cut an herb, it faces two immediate enemies that steal its value. The first is its own metabolism. The herb is still alive and "breathing," a process called respiration. This consumes its energy and releases heat, causing the delicate leaves to lose water and wilt. The second, and more unique, challenge for herbs is the nature of their aroma. The wonderful scents and flavors of mint, basil, or rosemary come from compounds called volatile essential oils1. As the name "volatile" suggests, they easily turn from a liquid into a gas and escape into the air. Heat is the main trigger for this process.

The "field heat2" that an herb holds from the sun acts as a powerful accelerator for both of these problems. A grower like Carlos, with acres of cilantro, knows this pain well. Every hour the herbs sit in the sun or in a warm packing shed, more of their essential oils—the very essence of their market value—are lost forever. At the same time, the leaves are losing turgidity and beginning to droop. Simply moving them to a cold room is not a fast enough solution. The herbs on the inside of a crate can stay warm for hours, continuing to wilt and lose their precious aroma.

| Degradation Factor | At Ambient Temperature | In a Standard Cold Room |

|---|---|---|

| Respiration Rate | Very High | High, slowly decreasing |

| Essential Oil Loss | Very High | Continues during slow cooling |

| Wilting (Water Loss) | Rapid | Slows over many hours |

| Overall Quality Loss | Immediate and Severe | Significant before core cools |

How Does Vacuum Cooling Lock In the Aroma And Color of Herbs?

You can’t sell the memory of a great aroma; the customer needs to experience it. Traditional cooling methods let the best part of your herbs disappear into thin air before they can be sold.

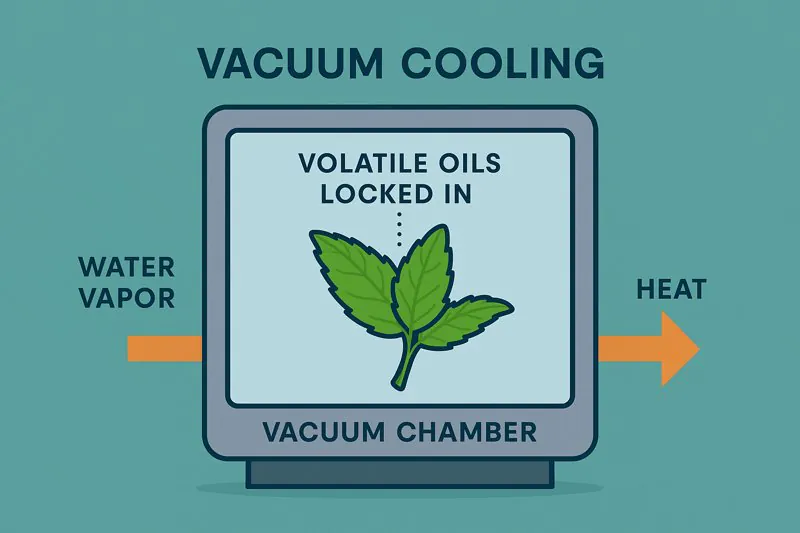

Vacuum cooling uses low pressure to trigger rapid evaporative cooling. This process instantly drops the herb’s core temperature, which drastically reduces the volatility of essential oils, locking them into the leaves and preserving their natural color.

Using Physics to Beat Biology

The technology behind vacuum cooling is simple but powerful. When we place crates of freshly cut herbs into our sealed chamber and lower the air pressure, we change the laws of physics. At a deep vacuum, water boils at a very low temperature, around 2-3°C (35-37°F). A tiny amount of moisture on the vast surface area of the herb leaves begins to evaporate, or "boil away," without heat. This phase change from liquid to gas requires a lot of energy. The energy is pulled directly from the herbs themselves in the form of heat. The result is an incredibly fast and uniform temperature drop across the entire load, typically in less than 30 minutes.

This rapid chilling has two critical effects on herbs. First, it immediately stops the high respiration rate, halting the wilting process and preserving the herb’s physical structure and weight. Second, and most importantly, it dramatically lowers the volatility of the essential oils. Cold temperatures make these oils much more stable and less likely to evaporate. By cooling the herb from 30°C to 3°C in minutes, we effectively "lock" the aroma and flavor inside the leaves. It also deactivates the enzymes that cause browning and discoloration, preserving the vibrant green appearance customers associate with freshness.

| Preservation Aspect | Slow Cooling in Cold Room | ALLCOLD Vacuum Cooling3 |

|---|---|---|

| Cooling Principle | Slow Convective Cooling | Rapid Evaporative Cooling |

| Aroma Preservation | Poor (oils evaporate) | Excellent (oils locked in) |

| Color Preservation | Fair (browning enzymes active) | Excellent (enzymes deactivated) |

| Time to Target Temp | 8 – 12 hours | 15 – 30 minutes |

How Does Rapid Pre-Cooling Improve Herb Quality and Shelf Life?

Your supply chain is a race against the clock. Herbs that leave your farm looking great can arrive at the distributor wilted and spoiled, leading to rejected shipments and lost revenue.

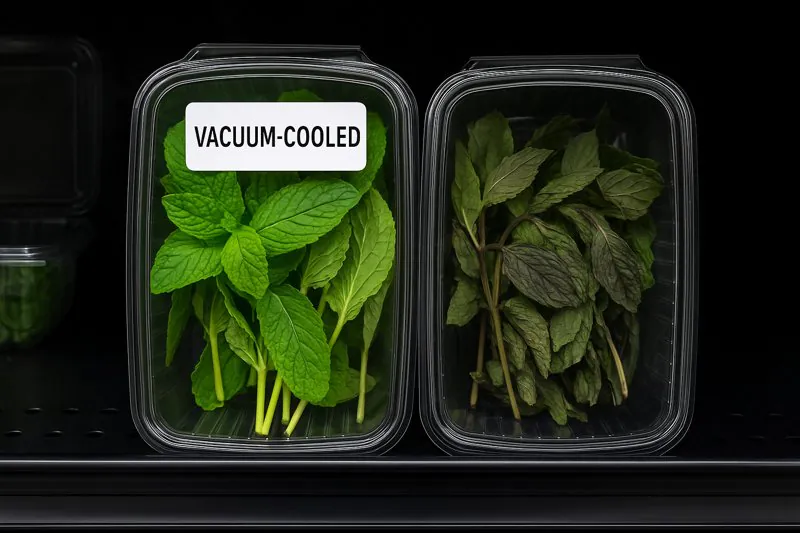

Rapid pre-cooling significantly extends shelf life by putting the herb into a state of metabolic hibernation. This allows it to withstand the stresses of transport, arriving at the retailer with several extra days of peak freshness.

A Stronger Link in the Cold Chain

For a professional buyer like Norman, consistency is everything. He needs to know that the herbs he orders will arrive in excellent condition and will last on the supermarket shelf. The biggest point of failure in the herb supply chain is the transition from the farm to the refrigerated truck. Loading warm herbs into a cold truck is a classic mistake. The truck’s refrigeration unit cannot remove the field heat fast enough, so the herbs continue to degrade for hours during transit.

Vacuum cooling4 solves this problem at the source. By pre-cooling your herbs before they are loaded, you are placing a stable, hibernating product into the cold chain. The refrigerated truck only has to maintain the cold, a task it can do easily and efficiently. This has huge benefits. First, the herbs arrive in much better physical condition. Because they retain their water and turgidity, they are more resilient and less prone to bruising during handling. Second, the shelf life5 is dramatically extended. An herb that has been properly pre-cooled can last for many days longer than one that was cooled slowly. This gives retailers a wider sales window, reduces waste, and ultimately allows growers to build a reputation for premium quality that commands a better price.

| Impact Area | Without Pre-Cooling | With ALLCOLD Vacuum Cooling |

|---|---|---|

| Condition on Arrival | Often wilted, aroma loss | Fresh, turgid, aromatic |

| Retail Shelf Life | Short, rapid decline | Extended by several days |

| Rejection Rate | High risk | Very Low |

| Market Reputation | Inconsistent | Premium and Reliable |

Can Pre-Cooling Improve the Efficiency of Herb Drying?

Drying is a common way to preserve herbs, but the process can destroy their color and flavor. You end up with a brown, tasteless product that has lost most of the value you grew into it.

Yes, vacuum pre-cooling herbs immediately after harvest is a critical first step for high-quality drying. It preserves the color and essential oils before the drying process begins, resulting in a finished dried product with superior aroma and appearance.

A Better Start for a Superior Finish

For a food processor or a central kitchen manager like Sophia, the quality of ingredients is non-negotiable. She needs dried herbs that meet strict quality and hygiene standards. The final quality of a dried herb is determined long before it enters the dryer. The most significant damage—loss of color and volatile oils—happens in the hours immediately following harvest, while the herbs are waiting to be processed.

By integrating vacuum cooling6 as the very first step, you fundamentally change the outcome. You harvest the herbs and, within an hour, cool them down to 3°C. This instantly stops the degradation. The herbs are now in a stable state. When these cold, stable herbs enter the dryer, they are starting from a much higher quality baseline. More of their essential oils are still locked in the leaves. Their color is still a vibrant green because the browning enzymes were never activated. The result is a far superior dried product. It retains more of its natural color, more of its aromatic profile, and more of its flavor. This also has hygiene benefits. The rapid cooling minimizes the time that herbs spend in the temperature "danger zone" where bacteria and mold can grow, leading to a cleaner, safer final product that meets strict HACCP standards7.

| Attribute of Final Dried Herb | Dried Without Pre-Cooling | Dried After Pre-Cooling |

|---|---|---|

| Color | Often brown or faded yellow | Vibrant green, more natural |

| Aroma | Weak, grassy scent | Strong, true-to-type aroma |

| Flavor Profile | Dull, diminished flavor | Richer, more complex flavor |

| Overall Quality & Value | Low / Commodity Grade | High / Premium Grade |

Conclusion

Vacuum cooling is an essential tool for any serious herb grower or processor. It directly protects the most valuable assets of your crop—its aroma and color—extending shelf life and ensuring premium quality.

-

Understanding volatile essential oils can enhance your knowledge of herb preservation and flavor. ↩

-

Exploring the impact of field heat can help growers optimize their post-harvest processes. ↩

-

Explore this link to understand the science behind vacuum cooling and its benefits for preserving freshness. ↩

-

Explore this link to understand how vacuum cooling enhances product quality and extends shelf life in the supply chain. ↩

-

Discover insights on how pre-cooling can significantly improve the shelf life of herbs, benefiting both retailers and consumers. ↩

-

Explore how vacuum cooling enhances food quality and safety, ensuring superior flavor and aroma in dried herbs. ↩

-

Learn about HACCP standards to understand their critical role in maintaining food safety and hygiene in food processing. ↩

Mila

You May Also Like

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer