How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market is filled with confusing technical specs and bold claims. Making the wrong choice can lead to years of inefficiency, lost product, and wasted capital. How do you find the right one?

To choose the best vacuum cooler, you must look beyond the price and evaluate 15 key factors across four critical areas: the core technical components, the build quality and design, the control system’s intelligence, and the long-term reliability of the supplier themselves.

I’ve spoken with hundreds of growers and processors over the years. I’ve seen them glowing with pride over a machine that transformed their business, and I’ve also heard the frustration from those who bought a machine that didn’t live up to its promise. This guide is built from those real-world experiences. It’s designed to give you the questions you need to ask to ensure you get a machine that is a long-term asset, not a short-term headache.

How Do You Evaluate the Core Technical Components?

When you look at a machine, you see a steel box. But the real heart of the system—its "engine room"—is hidden inside. These core components determine the cooler’s speed, efficiency, and lifespan. A cheap machine often uses substandard parts that will fail you when you need them most.

Evaluating the core components means asking for the specific brands and specifications of the compressor and vacuum pump. These two parts are the most expensive and the most critical to the machine’s performance and reliability.

The "Engine Room" Specifications

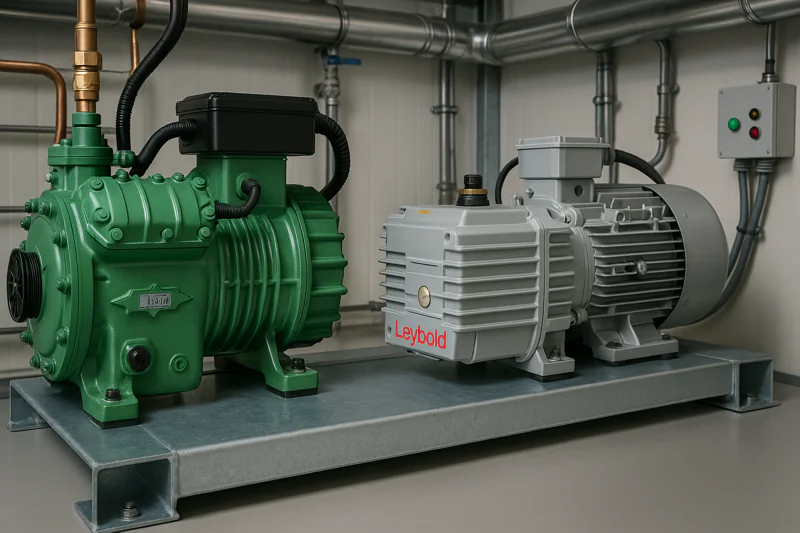

When a potential supplier sends you a quote, it might just list "50 HP Compressor." This is not enough information. It’s like buying a car and the seller only tells you the engine size, not the brand or type. As a factory owner, I know where costs can be cut, and it’s almost always on these critical, unseen parts. For a professional buyer like Norman, who is sensitive to quality, digging into these details is non-negotiable. An operator like Carlos needs a machine that runs without issues during peak season, and that reliability comes directly from these components. You need to ask specific questions about the brand names and models used. Industry-leading brands like Bitzer (Germany) for compressors or Busch/Leybold (Germany) for vacuum pumps have a global reputation for a reason: they are built to last and perform under pressure.

Here are the first set of factors to scrutinize:

- Compressor Brand & Origin1: Demand top-tier brands known for reliability.

- Vacuum Pump Brand & Type2: Oil-sealed rotary vane pumps are the standard, but the brand dictates the service life and efficiency.

- Condenser Size & Type: An undersized condenser will cause the machine to struggle and fail in hot climates.

- Refrigerant Type: Is it modern and environmentally compliant for your region?

- Quoted Cycle Time: Is the 20-30 minute cycle time a guarantee, or just a hopeful estimate?

| Feature | Standard (Low-Cost) Spec | High-Quality (What to Demand) Spec |

|---|---|---|

| Compressor | Unnamed or obscure brand | Bitzer (Germany), Copeland (USA) |

| Vacuum Pump | Generic Chinese brand | Leybold (Germany), Busch (Germany) |

| Condenser | Undersized, just meets minimum | Generously sized for high ambient temps |

| Refrigerant | Older types (e.g., R22) | Eco-friendly R404A, R448A, etc. |

| Performance Claim | "Fast cooling" | Guaranteed 20-30 min cycle to core temp |

Why Does Chamber Design and Material Quality Matter So Much?

The vacuum chamber, or vessel, is what you interact with every single day. It has to withstand immense force during every cycle and, for many applications, be easy to clean and sanitize. A poorly constructed chamber is a safety risk and a long-term maintenance problem.

A well-built chamber uses thick, properly treated steel and has a robust, easy-to-operate door. These features ensure worker safety, long-term durability against rust and metal fatigue, and ease of daily operation.

The Body and Bones of the Machine

I once visited a client who had bought a low-cost machine from another supplier. After only two years, the inside of the carbon steel chamber was covered in rust, posing a hygiene risk. The door seal was already leaking, forcing the vacuum pump to work harder and extending the cycle time. This is what happens when build quality is sacrificed for price. For a food-processing client like Sophia, who needs to meet HACCP standards3, a stainless steel chamber is the only acceptable option. But even for vegetable growers like Carlos, the chamber’s durability is key. A chamber made from thin steel can deform over time from the constant pressure changes. The door mechanism is another critical point. A heavy, manual door is slow and can cause worker injuries. A hydraulic door, while more expensive, is safer, faster, and puts less stress on the machine’s frame.

Here are the next set of factors to review on the physical build:

- Chamber Material: Is it painted carbon steel or food-grade 304 stainless steel?

- Steel Thickness: Ask for the exact thickness of the vessel walls and door.

- Weld Quality & Finish4: Are the welds smooth and clean, or are they rough and prone to corrosion?

- Door Mechanism: Is it manual, electric, or hydraulic?

- Internal Dimensions & Rail System: Is it truly customized to fit your specific pallets or trolleys for easy loading?

| Feature | Standard (Low-Cost) Build | High-Quality (What to Demand) Build |

|---|---|---|

| Chamber Material | Painted Carbon Steel | 304 Stainless Steel5 (for food/hygiene) or properly treated Carbon Steel |

| Steel Thickness | 8mm or less | 10mm or more, with reinforcement rings |

| Door Type | Manual sliding or hinged door | Smooth, fast Hydraulic Door6 |

| Internal Rails | Fixed, standard size | Customized to fit your specific pallets/trolleys |

| Finish Quality | Basic paint job, rough welds | Sandblasted, multiple coats of marine-grade paint, or polished stainless steel |

How Can Software and Controls Make or Break Your Operation?

A vacuum cooler is not just a brute-force machine; it’s a piece of precision equipment. The "brain" of the machine is its control system, which manages the complex sequence of pressure reduction and refrigeration. A poor control system can lead to inconsistent results, or worse, damaged product.

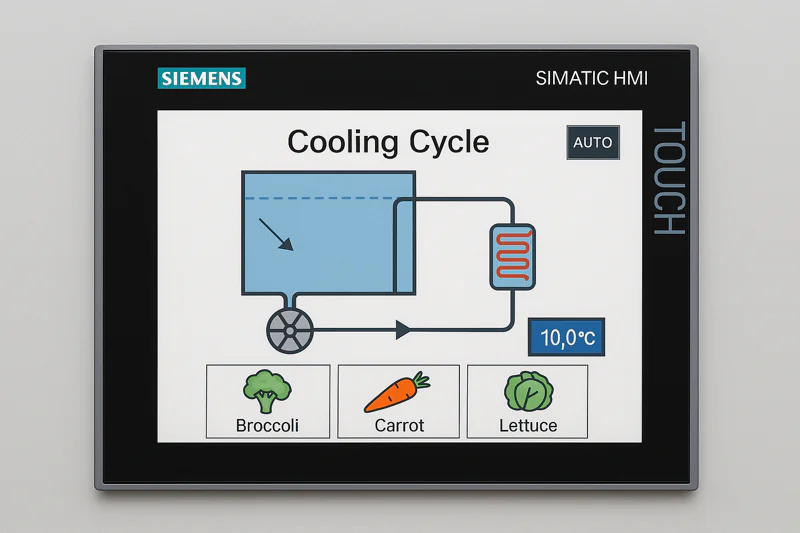

A modern, reliable vacuum cooler uses a brand-name PLC (Programmable Logic Controller) and an intuitive touch-screen interface. This allows for pre-programmed settings for different products and ensures every cooling cycle is perfect.

The Machine’s Intelligence

Imagine having a powerful machine that no one on your team can operate correctly. This is the reality for buyers who overlook the control system. For delicate products like mushrooms or some herbs, a standard, aggressive cooling cycle can cause damage. You need what we call "soft-venting" or programmable cycles, something only a good PLC can manage. My client with the organic mushroom farm was able to succeed because we could program a gentle cycle specifically for his fragile product. A simple on/off system can’t do that. For an operation like Carlos’s farm that cools different vegetables, having pre-set programs is essential. A worker can simply select "Broccoli" or "Lettuce" on the touch screen, and the machine runs the ideal cycle for that product. This eliminates human error and ensures consistency.

Here are the crucial control system factors:

- Control System (PLC) Brand: Is it a globally recognized brand like Siemens or Mitsubishi, or a cheap, unproven controller?

- User Interface (HMI)7: Is it a simple button box, or a multi-language, graphical touch screen?

- Programmable Cycles8: Can you create and save unique programs for different products?

| Feature | Standard (Low-Cost) Controls | High-Quality (What to Demand) Controls |

|---|---|---|

| PLC Brand | No-name or basic proprietary controller | Siemens, Mitsubishi, or similar top-tier PLC |

| User Interface | Basic buttons, single language | Touch Screen (HMI), multi-language, graphical |

| Functionality | Single, fixed cooling cycle | Multiple, customizable pre-set programs for different products |

Why Is Choosing the Right Supplier a Critical Decision?

You are not just buying a machine; you are entering a long-term technical partnership. When you are thousands of miles away from the factory, as many of my clients are, the supplier’s commitment to service is everything. A low price from a supplier who disappears after the sale is the most expensive mistake you can make.

A reliable supplier provides a comprehensive warranty, offers robust remote and even on-site support, and has a proven track record of successful international installations. You must vet the company as much as you vet the machine.

The Partnership Aspect

This is the most common pain point I hear about from buyers like Norman and Sophia: inefficient communication and non-existent after-sales support. A machine will inevitably have a problem, or your operators will have a question. What happens then? Will you be able to get a qualified engineer on a video call within hours? Does the supplier stock spare parts and can they ship them quickly? Do they have experience with the logistics of shipping to your country? A factory like ours, ALLCOLD, invests heavily in our service team because we know our reputation depends on our customers’ long-term success. Before you buy, you should ask for references. Ask to speak to a customer in your region. A confident supplier with nothing to hide will be happy to provide this. A supplier who cannot or will not is a major red flag.

The final, and perhaps most important, factors are:

- Warranty & After-Sales Service: What is the exact warranty period? What does it cover? How do they provide service?

- Supplier Experience & References9: How many years have they been exporting? Can they provide case studies or client references?

| Feature | Red-Flag Supplier | A Reliable Partner (What to Demand) |

|---|---|---|

| Communication | Slow replies, generic sales reps | Fast, professional replies from knowledgeable engineers |

| Warranty | Vague, 1 year with many exclusions | Clear, 2+ year warranty on key parts |

| After-Sales Support10 | Email only, slow response time | 24/7 remote video support, clear spare parts process |

| Track Record | Limited export history, no references | Proven international experience, happy to provide case studies and references |

Conclusion

Choosing the right vacuum cooler is a process of careful evaluation. By using these 15 factors as your checklist, you move from being a price-shopper to a smart investor, ensuring you acquire a machine that will be a cornerstone of your business’s quality and efficiency for many years.

-

Explore this link to understand the top compressor brands and their reliability, ensuring you make informed purchasing decisions. ↩

-

Discover the leading vacuum pump brands and types to ensure efficiency and longevity in your operations. ↩

-

Understanding HACCP standards is crucial for ensuring food safety and compliance in food processing industries. ↩

-

Discover the importance of weld quality and finish in ensuring the longevity and reliability of machinery. ↩

-

Explore the advantages of 304 stainless steel for durability and hygiene in food processing applications. ↩

-

Learn how hydraulic doors enhance safety and efficiency in machinery operations, reducing worker injuries. ↩

-

Learn about the advantages of graphical touch screens in reducing errors and improving operational efficiency. ↩

-

Explore how programmable cycles enhance efficiency and precision in machine operations, crucial for delicate products. ↩

-

This resource will highlight why supplier experience is crucial for successful long-term partnerships. ↩

-

Explore this link to understand how top companies ensure customer satisfaction through robust after-sales support. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf

How Do You Troubleshoot Common Vacuum Cooler Problems?

Your harvest is ready, the pallets are stacking up, but your vacuum cooler suddenly stops. A red light is flashing,