How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce comes out with brown edges, or delicate spinach leaves look bruised. This is incredibly frustrating.

This inconsistency undermines the very reason you bought the machine. It creates product that is difficult to sell, damages your reputation for quality with buyers, and turns a powerful tool into an unpredictable liability in your cold chain.

You achieve perfect, damage-free cooling by precisely controlling three key parameters: the final vacuum pressure to set the exact temperature, the pump-down rate to protect delicate cell structures, and the initial moisture level of the product.

I have spent years helping growers fine-tune their vacuum cooling processes. The difference between good and great results is always in the details. It’s not about just running a cycle; it’s about running the right cycle for the specific product. Let’s dive into the three settings that will make you a master of cooling leafy greens.

What Is the Most Critical Parameter for Cooling Leafy Greens?

You run a cycle, and the final product is 4°C—too warm. You run another, and a few leaves show signs of freezing at 0°C. This lack of control is a major problem when your customers expect a consistent, high-quality product every single time.

This temperature variance happens when operators are guessing or using a generic "one-size-fits-all" setting. Inconsistent core temperatures lead directly to inconsistent shelf life. This variability is a huge red flag for professional buyers and can lead to rejected shipments and lost contracts.

The most critical parameter is the final vacuum pressure. This single setting has a direct, scientific relationship with the boiling point of water, allowing you to control the final product temperature with surgical precision, typically within a 0.5°C range.

Mastering the Pressure-Temperature Relationship1

This is the number one concept I teach every new machine owner. For a hands-on operator like Carlos, understanding this relationship turns him from a machine user into a process controller. For a procurement manager like Sophia, the data from these precise cycles is proof of a controlled, HACCP-compliant process2.

The Unbreakable Link

The science is simple: as you lower the atmospheric pressure in the chamber, the temperature at which water boils also lowers. At sea level, water boils at 100°C (212°F). Inside the vacuum cooler, we can create a pressure so low that the water on the surface of your lettuce leaves boils at just 1°C (34°F). This "cold boiling" is what evaporates moisture and pulls the heat from the product. The final pressure you set in the machine’s control system is the absolute floor for the temperature. The product cannot get colder than the boiling point of water at that final pressure. This makes it a foolproof way to prevent freezing.

Setting the Target for Different Greens

Different leafy greens have slightly different water contents and densities, so the ideal target temperature can vary. Our goal is always to get the product temperature down as low as possible without causing any ice crystals to form (freezing).

| Leafy Green Type | Ideal Final Temp Range3 (°C) | Target Vacuum Pressure4 (mbar) | Key Goal |

|---|---|---|---|

| Iceberg Lettuce | 1 – 2°C | 6.5 to 7.0 mbar | Lock in maximum crispness and density |

| Romaine Lettuce | 1 – 2.5°C | 6.5 to 7.2 mbar | Prevent wilting of outer leaves |

| Baby Leaf Spinach | 2 – 3°C | 7.0 to 7.5 mbar | Cool rapidly without causing bruising |

| Cabbage | 2 – 3°C | 7.0 to 7.5 mbar | Penetrate the dense core effectively |

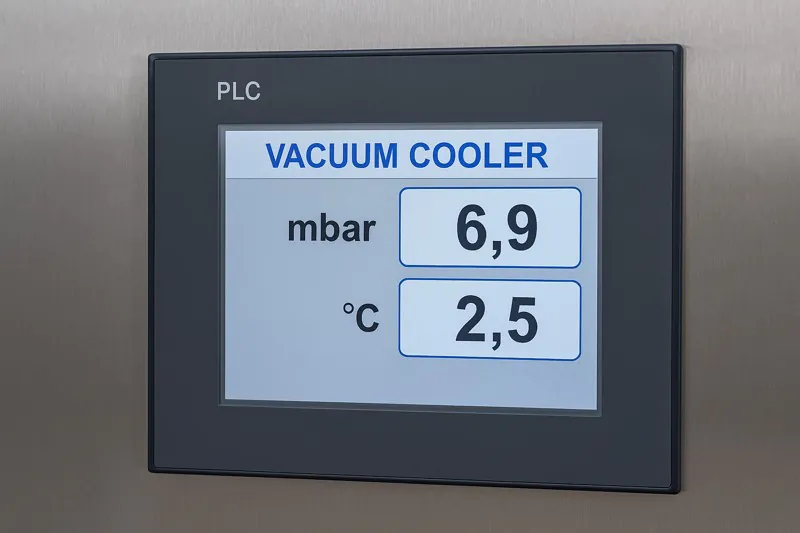

On our allcold control panels, we make this simple. You can select a "recipe" for "Iceberg Lettuce," and the system automatically targets the correct final pressure. This removes guesswork and ensures every single pallet comes out at the perfect, consistent temperature that a buyer like Norman demands.

How Does Cooling Speed Affect Delicate Leafy Greens?

Your packing house is busy, and the goal is to cool pallets as fast as possible to maximize throughput. The temptation is to set the vacuum pumps to their most powerful setting and pull the pressure down in the shortest time possible. This seems efficient, but it can be destructive.

An overly aggressive cooling speed can physically damage your most valuable and delicate greens. When the pressure drops too quickly, the water vapor inside the leaf’s structure expands explosively. This can rupture the cell walls, leading to microscopic bruising, limpness, and a drastically reduced shelf life.

The speed of cooling, or the "pump-down rate," must be adjusted based on the fragility of the green. Robust greens like iceberg can handle a fast rate, while delicate items like baby spinach require a slower, more controlled pressure drop to prevent cell damage.

Balancing Throughput with Product Quality

This is where the real artistry of vacuum cooling5 comes in, and it’s a feature that separates high-end machines from basic ones. Carlos needs to maximize the number of pallets he can cool per hour, but not at the expense of the quality Sophia expects for her restaurant chain.

The Physics of Damage

Imagine a balloon in a vacuum chamber. As you remove the air, the balloon expands. The same thing happens on a microscopic level inside every leaf. The water and air inside the plant cells expand as the external pressure drops. If this happens too fast, the cell walls stretch beyond their limit and burst. This releases enzymes that cause browning and decay. The product might look okay coming out of the cooler, but it will have a much shorter shelf life in the grocery store.

Programming "Recipes" for Different Products

The solution is to program different cooling profiles6, or "recipes," for different products. Our PLC control systems7 allow for this level of detailed customization.

- Aggressive Profile (For Robust Greens): For a hardy product like iceberg lettuce or celery, we can program the system to use all vacuum pumps from the start for the fastest possible cycle time, typically 15-20 minutes.

- Gentle Profile (For Delicate Greens): For baby spinach, microgreens, or even some tender herbs, we program a "soft cool" or two-stage cycle. The system may start with only one pump, pulling the pressure down slowly to a certain point, before engaging the second pump to finish the cycle. This gentle start allows the water vapor to escape the leaf structure in a controlled manner, preventing damage.

| Product Type | Structural Robustness | Recommended Cooling Profile | Why It’s Optimal |

|---|---|---|---|

| Iceberg Lettuce | High | Aggressive / Single-Stage | Thick cell walls can withstand rapid pressure drop |

| Romaine Lettuce | Medium | Standard / Single-Stage | Balances speed with quality |

| Baby Spinach | Low / Delicate | Gentle / Two-Stage | Prevents cell rupture8 and bruising |

| Microgreens | Extremely Low | Gentle / Two-Stage | Preserves the extremely delicate structure |

This level of control ensures you are always achieving the fastest possible cycle without ever compromising the physical quality of your most valuable products.

Should You Add Water Before Cooling Leafy Greens?

You have a pallet of romaine that was harvested on a hot, windy afternoon. It looks a little tired and dry. You know that vacuum cooling relies on moisture evaporation, so you wonder if you should spray it with water first to help the process along.

This is a common dilemma. Adding too much water can make the product soggy, increase the risk of bacterial growth, and add weight that you are just paying to remove. However, trying to cool a product that is too dry is inefficient, leading to longer cycle times and potentially not reaching the target temperature at all.

Yes, you should add a fine mist of water—a technique called "pre-wetting"—but only when the leafy greens are visibly dehydrated from field conditions. This replaces the surface moisture needed for efficient evaporative cooling without saturating the product.

A Strategic Approach to Moisture Management

This is a critical decision that directly impacts cycle efficiency9 and final product quality. It’s a key process control step that a detail-oriented manager like Sophia would want documented in her operational procedures.

The Goal of Pre-Wetting10

Remember, vacuum cooling11 removes heat by evaporating about 1.5% to 2.5% of the product’s weight in water. If the product is already dehydrated, it doesn’t have that "sacrificial" water to give up easily. The cooling process will be slow and ineffective. Pre-wetting is not about adding water; it’s about replacing the surface moisture that was lost in the field, giving the vacuum process the fuel it needs to work quickly.

The Decision-Making Process

This should be a simple Yes/No decision made by the forklift operator or supervisor before a pallet is cooled.

- When to Pre-Wet (Apply a Fine Mist):

- The harvest occurred during the hottest part of a dry, windy day.

- The product has been sitting on the loading dock for more than an hour before cooling.

- The outer leaves show any visible signs of being limp or wilted.

- When NOT to Pre-Wet:

- The product was harvested in the cool morning and is still covered in dew.

- The product was recently harvested and feels cool and moist to the touch.

- The product is destined for sealed-bag packaging where excess moisture is a major problem.

A simple table can guide this operational decision:

| Field Condition / Product State | Action Required | Rationale |

|---|---|---|

| Harvested hot & dry; looks limp | Apply a light, fine mist | Replaces lost surface moisture for an efficient cycle |

| Harvested cool & moist; looks crisp | No misting needed | Product has sufficient moisture; adding more is detrimental |

| Rainy day harvest | No misting needed | Excess water is already present |

The best method is an automated misting system12 or a spray wand with a fine nozzle that creates a fog, not a jet. The goal is to dampen the leaf surfaces, not to drench the pallet. This simple, strategic step can reduce cycle times by several minutes and ensure even the most stressed produce gets a perfect cool.

Conclusion

Optimizing vacuum cooling for leafy greens is a science of precision. By mastering the final pressure, controlling the cooling speed, and managing moisture strategically, you turn your cooler into a tool that guarantees perfect, consistent, and damage-free results every time.

-

Understanding this relationship is crucial for optimizing vacuum cooling processes and ensuring product quality. ↩

-

Exploring HACCP compliance can enhance food safety and quality assurance in your operations. ↩

-

Knowing the ideal temperature ranges helps in maintaining freshness and quality of leafy greens. ↩

-

Learning about target vacuum pressures can improve cooling efficiency and product preservation. ↩

-

Explore this link to understand the innovative process of vacuum cooling and its benefits for food preservation. ↩

-

Learn about cooling profiles to optimize your food cooling processes and maintain product quality. ↩

-

Discover how PLC control systems enhance efficiency and precision in food processing operations. ↩

-

Find out the science behind cell rupture and how to prevent it for better food quality. ↩

-

Discover key factors influencing cycle efficiency to optimize your processes and improve overall productivity. ↩

-

Understanding Pre-Wetting can enhance your vacuum cooling process, ensuring optimal product quality and efficiency. ↩

-

Explore the mechanics of vacuum cooling to improve your operational procedures and product outcomes. ↩

-

Learn how an automated misting system can streamline your moisture management and enhance product quality. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not

Can Small Farms Actually Afford a Vacuum Cooler?

You’ve poured your heart into your farm, producing the highest quality vegetables. But as soon as they’re picked, the summer