How Does Vacuum Cooling Revolutionize Salad and Leafy Green Processing?

Your leafy greens look perfect when harvested, but wilt and decay alarmingly fast. This short window cuts into profits and leads to waste, a constant battle from the field to the supermarket shelf.

Vacuum cooling revolutionizes salad processing by rapidly removing field heat in minutes, not hours. This process drastically slows respiration and bacterial growth, locking in freshness, crispness, and extending shelf life by 7-14 days.

I’ve seen it countless times: a farmer’s hard work undone by the simple ticking of a clock. The "field heat" in freshly harvested lettuce is the enemy of shelf life. Traditional cooling methods are too slow to win this race. Let’s dive into why vacuum cooling is the game-changing technology for anyone serious about leafy greens.

Why is Rapidly Removing Field heat So Critical?

You’ve just harvested a perfect field of romaine lettuce on a warm day. But every minute that lettuce sits in the heat, you are losing valuable days of shelf life and potential profit.

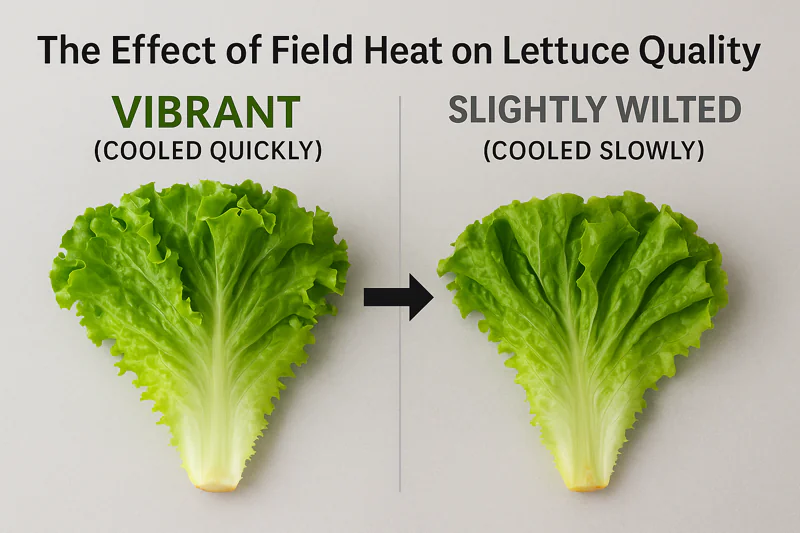

Field heat is the latent warmth from the sun and the ground absorbed by produce. It dramatically accelerates respiration and microbial growth. Rapid removal is critical because it effectively pauses this degradation, preserving quality and extending the product’s commercial life.

The Race Against the Clock

I once stood in a field in California with a large-scale grower, a client similar to Carlos. He told me, "Mila, for every hour this lettuce sits in the field after cutting, I lose a full day of shelf life1 in the supermarket." He was absolutely right. This isn’t just an expression; it’s a biological reality. Freshly cut leafy greens are still alive. They are actively "respiring"—a process where they burn stored sugars and oxygen to stay alive. Heat acts as a powerful fuel for this process. The warmer the lettuce, the faster it burns through its energy reserves, causing it to wilt, lose weight, and decay.

Furthermore, this warmth creates the perfect breeding ground for spoilage bacteria. They can double their population in as little as 20 minutes in warm, moist conditions. A traditional cold room can take 12 to 24 hours to cool the core of a dense pallet of lettuce. During all those hours, the product is in the "danger zone," actively degrading. Vacuum cooling2 is so revolutionary because it wins this race against time. It bypasses the slow process of air cooling and removes that damaging field heat from the core of every single leaf in about 20-25 minutes. By stopping respiration and bacterial growth in their tracks, you are essentially freezing the product in a state of maximum freshness.

| Cooling Method | Time to Cool Core to 2°C | Impact on Respiration |

|---|---|---|

| Cold Room | 12-24 hours | High respiration continues for hours |

| Vacuum Cooling | 20-25 minutes | Respiration halted almost instantly |

How Does Vacuum Cooling Work Without Damaging Delicate Leaves?

When you hear that vacuum cooling "boils" water off the leaves, it sounds harsh. You might worry that it will dry out or damage your delicate spinach or arugula, which would be a disaster.

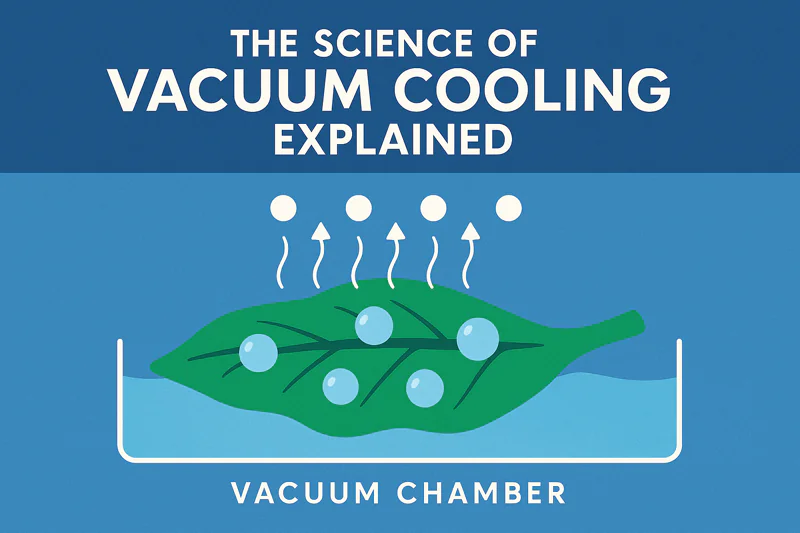

The process lowers atmospheric pressure so dramatically that water’s boiling point drops to just 2-3°C. This causes a tiny amount of surface moisture to flash-evaporate, gently and uniformly pulling heat from every leaf without causing any damage or dehydration.

The Gentle Power of Physics

Many people, including technically-minded buyers like Norman, are initially skeptical about how this process can be gentle. The key is understanding the relationship between pressure and temperature. At sea level, water boils at 100°C. But if you were on top of Mount Everest, where the air pressure is much lower, water would boil at around 71°C. A vacuum chamber3 is like creating an environment even higher than Mount Everest. Our ALLCOLD vacuum coolers create a deep vacuum, lowering the pressure to a point where water boils at just 2°C (36°F).

When a pallet of warm lettuce is placed inside and the vacuum is pulled, this "cold boil4" phenomenon begins. A very small fraction—about 1-2%—of the water on the surface of the thousands of leaves turns instantly into vapor. This phase change requires a large amount of energy, and it draws that energy in the form of heat directly from the lettuce itself. This is what causes the rapid and incredibly uniform cooling. Because this happens on every leaf surface simultaneously, from the outside of the pallet to the very center, the entire batch cools at the same rate. This is far gentler than a conventional cold room, which blows cold, dry air over the outer product for hours, potentially causing dehydration and wilting on the exposed leaves while the core remains warm. We are not "cooking" the lettuce; we are using a fundamental principle of physics to cool it with unparalleled speed and gentleness.

| Pressure Level | Water Boiling Point |

|---|---|

| Standard Atmosphere (1013 mbar) | 100°C / 212°F |

| Inside Vacuum Cooler (~6 mbar) | 2°C / 36°F |

What is the Real Impact on Shelf Life and Quality?

You’ve invested in the technology, but what are the measurable results? Your retail customers demand a consistent, high-quality product with a long shelf life. You need to know if vacuum cooling actually delivers.

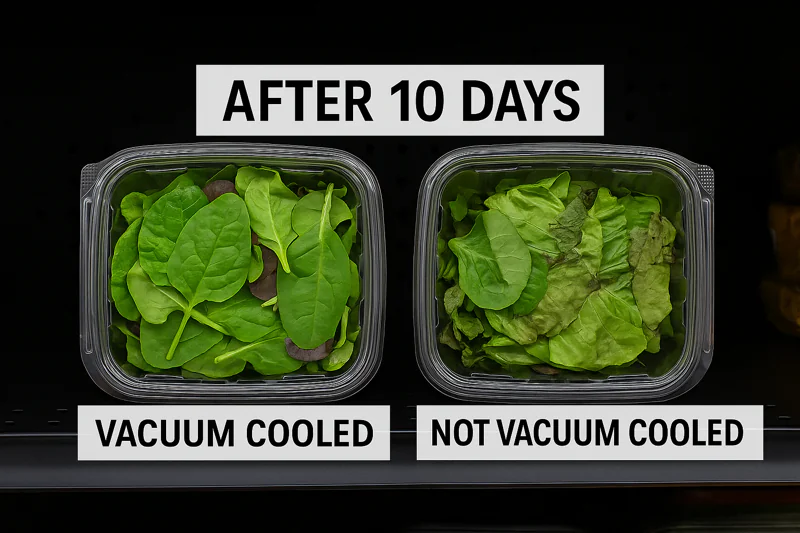

Vacuum cooling consistently adds 7 to 14 days of practical shelf life to leafy greens. Beyond longevity, it enhances quality by increasing leaf turgidity (crispness), reducing edge browning on cut salads, and improving overall food safety.

More Than Just Time: A Better Product

The primary benefit that gets everyone’s attention is the dramatic extension of shelf life5. For our clients producing bagged salads, moving from a 7-day code to a 14-day or even 21-day code is a complete game-changer. It reduces waste at the distribution center and the retail store, which is a major pain point for buyers like Norman who are judged on minimizing "shrink" or product loss. But the benefits go far beyond just a longer date code.

The quality improvement is visible. Because the cooling is so fast, the cells of the leaf don’t lose as much internal water pressure through slow dehydration. This results in a noticeably crisper, more turgid leaf. Customers can literally see and feel the difference in quality. Another critical benefit, especially for processors of cut salads, is the reduction in enzymatic browning. The cut edges of lettuce are very susceptible to turning brown. The rapid cooling immediately after cutting and washing dramatically slows down the enzyme activity that causes this browning, keeping the salad looking fresh and appealing for much longer.

Finally, there is the massive food safety6 benefit. The "danger zone" for bacterial growth is roughly 5°C to 60°C. A cold room can leave the product in this zone for many hours. A vacuum cooler moves the product through this zone in minutes. This drastically reduces the opportunity for pathogens like E. coli or Listeria to multiply, delivering a safer product to the end consumer. For any modern food processor, this reduction of risk is invaluable.

| Quality Metric | Conventional Cooling | Vacuum Cooling |

|---|---|---|

| Shelf Life | 5-7 days | 14-21 days |

| Visual Crispness | Good, but degrades | Excellent, maintained longer |

| Edge Browning | Appears quickly | Significantly delayed |

| Food Safety | Hours in "danger zone" | Minutes in "danger zone" |

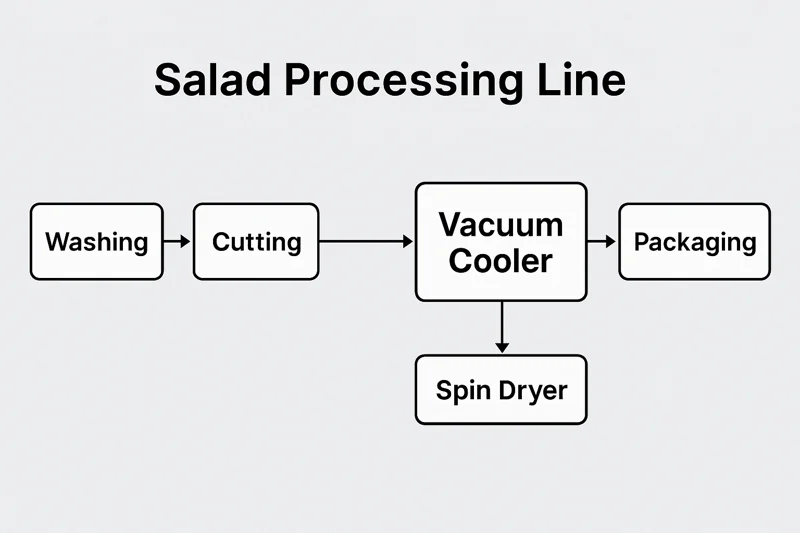

How Does Vacuum Cooling Integrate into a Modern Salad Processing Line?

You run a complex operation with washing, spin-drying, and packaging. You fear that adding a large new machine will create a bottleneck and disrupt the entire flow of your processing line.

Vacuum cooling integrates seamlessly into a salad line, typically positioned after the spin-drying stage and before packaging. It becomes a critical control point that locks in freshness just before the product is sealed, complementing the existing washing and drying process.

A Strategic Step, Not a Bottleneck

A common concern for sophisticated operators like Sophia, who manages a large-scale processing kitchen, is how this technology fits into their existing line. The integration is actually very natural and adds immense value. Here is a typical workflow for a modern salad processing plant:

- Raw Product Reception: Lettuce arrives from the field.

- Trimming & Cutting: Outer leaves are removed, and heads are cut or chopped.

- Washing & Sanitizing: The product goes through a flume or wash system.

- Spin-Drying: Excess surface water is removed in a centrifuge.

- VACUUM COOLING7: The still-cool but not ice-cold lettuce is cooled to its core, typically in its bulk bins or crates.

- Blending/Packaging: The chilled lettuce is mixed with other ingredients and packaged.

- Cold Storage & Shipping: The finished product is held for distribution.

The vacuum cooler works best at Step 5. An interesting insight is that you don’t need to spin-dry the lettuce to complete dryness. A small amount of residual clean water on the leaf surfaces is actually beneficial. This water is what will be used for the evaporative cooling process, protecting the lettuce’s own moisture. This can sometimes allow processors to be gentler in the spin-drying8 phase, which reduces mechanical damage to the delicate leaves. We design the system architecture—like our AVC-800-2 Pallets model—to match the output of the washing line. If your line produces two bins of cut lettuce every 25 minutes, we provide a two-pallet cooler with a 25-minute cycle time. It doesn’t become a bottleneck; it becomes the heartbeat of the operation, ensuring that every single bag of salad that leaves the facility is of the highest possible quality and safety.

Conclusion

For leafy greens and salads, vacuum cooling is not just an alternative; it is the superior method. It delivers unmatched speed, extends shelf life, improves quality, and enhances food safety, revolutionizing your entire processing operation.

-

Learn about the factors influencing shelf life to ensure your produce stays fresh longer. ↩

-

Explore this link to understand how vacuum cooling preserves freshness and extends shelf life for produce. ↩

-

Explore this link to understand the science behind vacuum chambers and their applications in cooling processes. ↩

-

Learn about the cold boil phenomenon and its significance in achieving rapid cooling without damaging produce. ↩

-

Exploring this link will provide insights into how extending shelf life can reduce waste and improve product quality. ↩

-

This resource will explain the critical role of vacuum cooling in minimizing bacterial growth and enhancing food safety. ↩

-

Explore this link to understand how vacuum cooling enhances food quality and safety, crucial for modern processing plants. ↩

-

Learn about the impact of spin-drying on food quality and how it can be optimized for better results in processing. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf