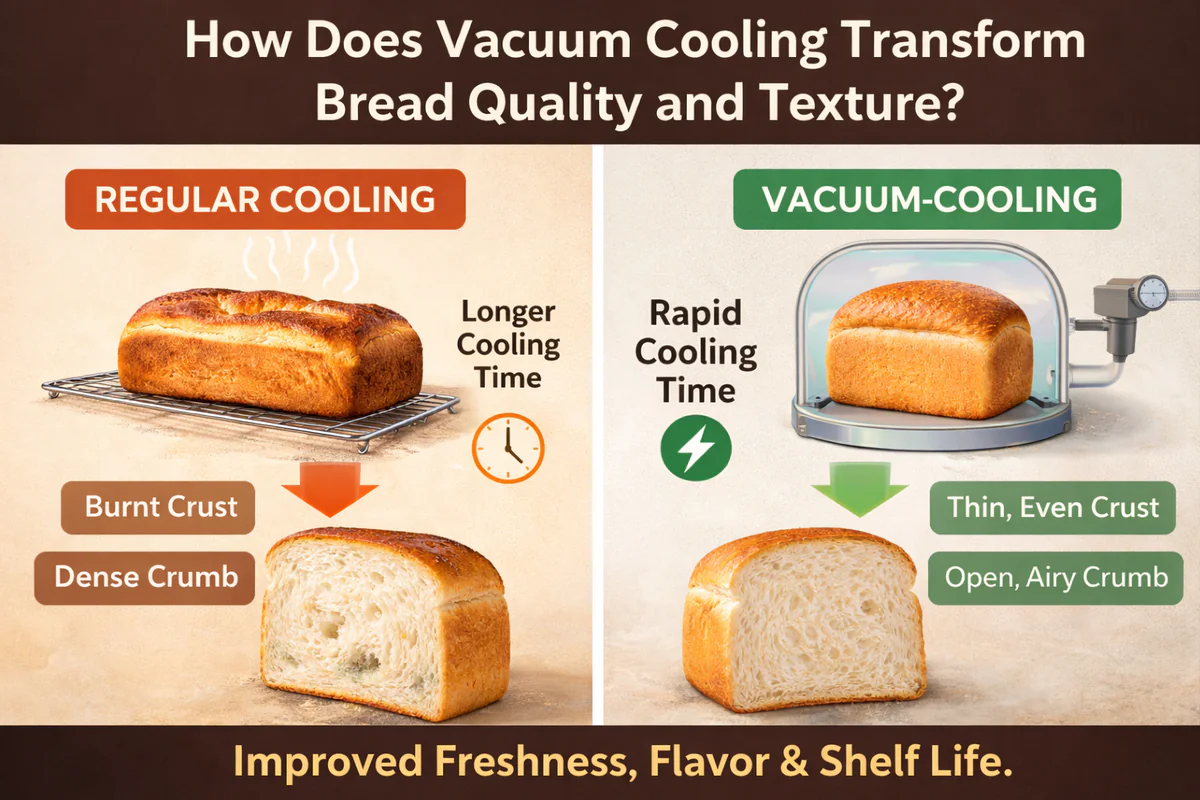

How Does Vacuum Cooling Transform Bread Quality and Texture?

You spend hours perfecting your dough recipe, only to watch the crust go soft and the loaf shrink while it cools on the rack. The weather changes, humidity rises, and suddenly your premium bread feels like a supermarket sponge.

Vacuum cooling improves bread quality by flash-boiling moisture from within the loaf, which instantly sets the crumb structure and creates a crispy, shattered crust. This process locks in aroma, maximizes volume, and extends shelf life by minimizing exposure to mold spores.

At Allcold, I have spent years arguing with bakers who believe "slow natural cooling" is the only way. They are wrong. Natural cooling is uncontrolled cooling. In a bakery, "uncontrolled" means inconsistent. I tell my clients: you control the mixing, you control the proofing, and you control the baking. Why do you let the weather control the cooling?

Vacuum cooling is not just about speed; it is about "fixing" the quality you worked so hard to create in the oven. It is the difference between a baguette that stays crispy for 6 hours and one that gets chewy in 60 minutes. It is the difference between a loaf that stands tall and one that collapses at the "waist." Below, I will explain exactly how this technology changes the physics of your bread for the better.

Why Does Vacuum Cooling Create a Superior, Crispier Crust?

You bake a perfect baguette, but by the time it reaches the customer, the crust is leathery and tough. This happens because moisture from the center migrates slowly to the surface, making the crust soggy.

Vacuum cooling creates a lasting crispiness by evaporating surface moisture instantly before it can soften the crust. The rapid pressure drop causes the moisture to "flash off," leaving the crust dry, shattered, and crunchy for much longer than traditional cooling methods.

The Physics of the "Singing" Crust

When you take bread out of the oven, it is full of steam. In traditional cooling, this steam tries to escape. It moves from the hot center (98°C) to the cooler surface. It sits there, on the crust, slowly evaporating into the room. If your bakery is humid—like Carlos’s factory in Mexico—that moisture does not evaporate. It soaks into the crust. Your crispy baguette becomes a chewy stick.

With vacuum cooling1, we change the rules. We put the bread in the chamber and drop the pressure.

Water boils at 100°C at sea level. But inside my machine, at a vacuum of 30 millibars, water boils at roughly 24°C.

Because the bread is hot (95°C), the water inside turns to steam instantly. It does not slowly migrate; it explodes outward. This is called "Flash Evaporation2."

The "Shattered" Effect:

This rapid burst of steam does something magical to the crust. It creates micro-fractures. We call this a "shattered crust3."

- Traditional Crust: Smooth, thick, and eventually leathery.

- Vacuum Crust: Thin, egg-shell like, and incredibly crunchy.

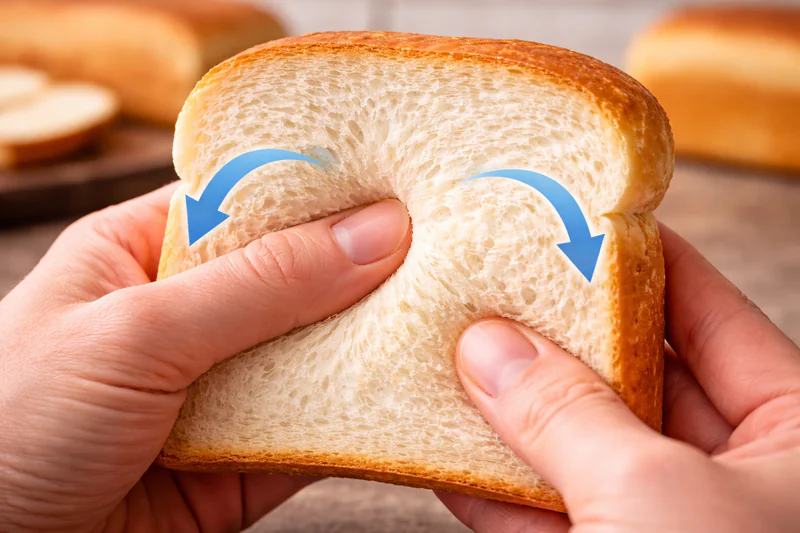

When you squeeze a vacuum-cooled roll, it crackles. It "sings."

The Humidity Battle:

I visited a client in South Korea during the rainy season. His croissants were going soft in 20 minutes. We installed a vacuum cooler. The machine sucked the moisture out so fast that the ambient humidity didn’t matter. The croissants stayed crispy for 8 hours.

This is critical for B2B bakers. If you deliver bread to a supermarket, it sits in a plastic bag. If the crust has any excess moisture, that bag becomes a steam room. Vacuum cooling dries the crust perfectly, so when you bag it, it stays crispy.

The Maillard Reaction4:

Some bakers worry we suck out the flavor. Actually, we lock it in. The "Maillard Reaction4" creates those toasted flavors in the crust. Because we cool the bread in 3 minutes instead of 2 hours, we stop the cooking process immediately. The crust doesn’t get overcooked or burnt while waiting to cool. The contrast between the dark, tasty crust and the white crumb is preserved perfectly.

| Feature | Traditional Cooling | Vacuum Cooling | Result for Customer |

|---|---|---|---|

| Moisture Migration | Slow, outward to surface | Instant, explosive removal | No soggy crusts. |

| Crust Texture | Becomes chewy/leathery | Becomes shattered/crunchy | Premium mouthfeel. |

| Cooling Environment | Dependent on room humidity | Independent (Closed chamber) | Consistency every day. |

| Bagging Time | Must wait 1-2 hours | Can bag immediately | Fresher product delivery. |

How Does It Maximize Volume and Prevent Collapsing?

You hate seeing your beautiful, high-domed loaves shrink and wrinkle as they cool. This "waistline" effect creates an ugly product that looks small on the shelf and upsets your customers.

Vacuum cooling stabilizes the starch structure immediately, "freezing" the loaf’s volume at its peak. This prevents the structure from collapsing under its own weight, ensuring your bread retains its full oven-spring size and uniform shape.

Locking in the "Oven Spring"

We need to talk about starch. Specifically, "Gelatinization5."

When bread is in the oven, the starch granules absorb water and swell up. This, combined with the gluten network, holds the bread up. It is like an inflated balloon.

However, when the bread comes out of the oven, the structure is still soft. It is unstable.

In traditional cooling, the bread sits hot for a long time. The gluten is soft. Gravity works on the loaf. The weight of the crust pushes down. The sides suck in. We call this "shrinking" or the "waistline effect." You might lose 10% to 15% of the volume.

The Vacuum Solution: Structural Stabilization

When we turn on the vacuum cooler, we drop the temperature from 95°C to 30°C in about 3 to 5 minutes.

Starch "retrogrades" (hardens) as it cools.

By cooling it in minutes, we force the starch to harden instantly while the loaf is still fully inflated.

It is like pouring concrete. Traditional cooling is like slow-drying cement; it might shift. Vacuum cooling is like "quick-set" cement. It freezes the shape perfectly.

The Uniform Crumb:

It is not just about the outside shape; it is about the inside.

Cut open a traditionally cooled sandwich loaf. You often see dense spots near the bottom or large, uneven holes near the top. This is because heat rises and moisture settles.

In a vacuum cooler, the cooling happens everywhere at once. The pressure drop affects the center and the crust simultaneously.

- Result: A perfectly uniform crumb structure.

- Benefit: For industrial slicers (like Norman uses in the US), this is a dream. The bread is firm and uniform. The slicer blades don’t tear the bread. You get fewer crumbs and less waste.

The Sponge Cake Example:

This is even more dramatic with sponge cakes or panettone.

Traditionally, you have to hang panettone upside down so it doesn’t collapse.

With vacuum cooling, you don’t need to flip it. You stabilize the structure so fast that it supports its own weight. This saves massive amounts of labor and space. I have a client who saved 200 square meters of factory space just by removing his cooling racks and spiral conveyors.

Troubleshooting the "Explosion":

I must be honest. If you pull the vacuum too fast on a weak dough, you can actually expand the loaf too much and break it. It can look like a balloon that popped.

This is why our Allcold machines have adjustable "recipes." We control the speed of the pressure drop. For a delicate brioche, we go slower. For a dense rye bread, we go faster.

| Aspect | Traditional Cooling | Vacuum Cooling | Business Impact |

|---|---|---|---|

| Final Volume | Shrinks by 10-15% | Retains 98-100% volume | Bigger looking product. |

| Crumb Density | Uneven (dense bottom) | Uniform throughout | Better for slicing. |

| Stability | Collapses easily | Sets instantly | Stacks better/No deformation. |

| Handling | Fragile when warm | Firm immediately | Less damage by robots/staff. |

How Does Vacuum Cooling Keep Bread Softer for Longer?

You assume that because vacuum cooling boils off water, it dries out the bread. This is the biggest myth in the industry, and believing it prevents you from achieving a shelf life that is days longer than your competition.

Vacuum cooling actually retains more moisture than slow cooling because the process is so fast. While it removes some water to cool, it stops the prolonged evaporation that happens during hours of natural cooling, keeping the crumb moist and soft.

The Moisture Paradox

When I meet new clients at exhibitions, they always ask: "Mila, if you boil the water, won’t my bread be dry?"

I understand the logic. But the math proves otherwise.

The Math of Evaporation:

- Scenario A (Traditional): Your bread sits on a rack for 2 hours. It is hot. It steams. The air conditioning blows on it. It loses moisture from the crust and the crumb. Over 120 minutes, you might lose 4% to 6% of the total weight in water evaporation.

- Scenario B (Vacuum): My machine forces evaporation. Yes, we boil the water. To cool bread from 95°C to 30°C, physics says we must evaporate about 3% to 4% of the water weight.

- The Difference: The vacuum process takes 4 minutes. Once it hits 30°C, the machine stops. The evaporation stops. We seal the moisture in.

- The Result: Often, vacuum-cooled bread retains more total moisture than bread left to dry out for hours in a drafty room.

The Distribution of Moisture:

In traditional cooling, the crust is dry, but the area under the crust is often soggy, while the center is okay. It is uneven.

Vacuum cooling pulls moisture from the core to the surface.

This means the moisture is evenly distributed throughout the crumb.

High moisture content = Softness.

Softness = Perception of Freshness.

The "Staling" Process:

Staling is not just drying out; it is the crystallization of starch.

Because vacuum cooling1 locks more water into the starch structure (gelatinization), the starch stays flexible for longer.

Sophia, my client in Singapore, supplies sandwiches to convenience stores. She found that traditional bread felt "stale" after 2 days. With vacuum cooling1, her sandwiches feel soft for 5 days. She didn’t add any chemicals. She didn’t add preservatives. She just changed the cooling method.

Recipe Adjustment:

If you find the bread is slightly drier (which can happen with very small rolls), the solution is simple.

Add 2% more water to your dough.

In a traditional oven, adding 2% more water might make the dough unmanageable or the inside raw.

But because vacuum cooling6 is so good at removing moisture, you can afford to bake with higher hydration.

- Benefit: Water is free. Flour is expensive. If you sell bread by weight, selling more water is pure profit. Vacuum cooling allows you to sell "High Water Content" bread that is fully baked and safe.

| Factor | Traditional Cooling | Vacuum Cooling | Advantage |

|---|---|---|---|

| Evaporation Time | 90 – 150 Minutes | 3 – 8 Minutes | Stops drying out process. |

| Water Loss | Uncontrolled (3-6%) | Controlled (3-4%) | Predictable yields. |

| Crumb Softness | Hardens after 24 hrs | Soft for 3-5 days | Longer shelf life. |

| Hydration Limit | Limited by baking time | Can increase by 2-5% | Higher yield/profit. |

How Does This Technology Prevent Mold and Extend Shelf Life?

You fight a constant battle against mold, especially in summer, leading to returned products and lost revenue. You might be adding expensive preservatives that your customers hate, just to keep the bread safe.

Vacuum cooling extends shelf life by passing through the bacterial "danger zone" (30°C-60C) in seconds rather than hours, and by cooling in a sterile, HEPA-filtered environment that prevents mold spores from landing on the product.

The Hygiene Revolution

Food safety is the number one priority for industrial bakers.

Mold and bacteria need three things to grow: Food (bread), Moisture (water), and Warmth.

The temperature range between 20°C and 60°C is the "Danger Zone." This is where bacteria multiply the fastest.

1. The Speed Factor:

- Traditional: Your bread sits in the "Danger Zone" for maybe 90 minutes as it slowly cools from 95°C down to room temperature. This is a party for bacteria. Bacillus cereus (which causes "rope" in bread) loves this warm temperature.

- Vacuum: We crash cool. We drop from 95°C to 25°C in 4 minutes. The bread spends almost zero time in the Danger Zone. The bacteria simply do not have time to multiply.

2. The Sterile Environment:

Think about your cooling room. Is it perfectly clean?

Probably not. There is flour dust in the air. There are wild yeast spores. People are walking past.

When bread cools naturally, it acts like a sponge for the air. It sucks in the room air as it contracts. If the room air has mold spores, your bread now has mold spores.

- The Vacuum Advantage: The cooling happens inside a stainless steel chamber. It is sealed.

- The Air Filter: When we break the vacuum (let air back in), we force that air through a HEPA filter7 (and optionally UV light).

- The Result: The air touching your bread is cleaner than the air in a hospital operating room. You are packaging "sterile" bread.

3. No Condensation in the Bag:

This is the killer for shelf life.

If you bag bread when it is 35°C (which often happens when you are in a rush), condensation forms inside the plastic bag. Water droplets + Bread = Mold in 2 days.

Vacuum cooling8 guarantees the core temperature is exactly what you set (e.g., 25°C).

You can bag it immediately. There is no residual heat. There is no condensation.

The Economic Impact:

I have a client, Norman, who supplies burger buns. He used to accept a 5% return rate due to mold.

After installing our machine, his return rate dropped to 0.5%.

Also, he reduced his use of calcium propionate (a mold inhibitor).

- Marketing Win: He can now put "No Preservatives9" on his label. His customers love it.

- Financial Win: He saves money on chemicals and waste.

| Variable | Traditional Cooling Room | Vacuum Chamber | Safety Benefit |

|---|---|---|---|

| Time in Danger Zone | 60 – 120 Minutes | < 5 Minutes | minimal bacterial growth. |

| Air Quality | Open warehouse air | HEPA Filtered Air | No spore contamination. |

| Slicing Temp | Variable (often too warm) | Precise (e.g. 25°C) | No gumming up slicers. |

| Packaging | Risk of condensation | Bone dry surface | No moisture for mold. |

Conclusion

Vacuum cooling is not just a faster way to cool bread; it is a better way to bake. By controlling the physics of evaporation, you achieve a crispier crust, a uniform volume, a softer crumb, and a longer, chemical-free shelf life. It turns the most unpredictable part of your production—cooling—into a precise, science-based advantage that your customers can taste and your bottom line will notice.

-

Learn about vacuum cooling and how it revolutionizes bread quality and shelf life. ↩ ↩ ↩

-

Understanding Flash Evaporation can enhance your knowledge of how vacuum cooling transforms bread texture. ↩

-

Discover the unique characteristics of a shattered crust and why it’s preferred in modern baking. ↩

-

Explore the Maillard Reaction to learn how it enhances the flavor and color of baked goods. ↩ ↩

-

Understanding gelatinization is crucial for mastering bread texture and structure. ↩

-

Explore how vacuum cooling enhances bread freshness and shelf life, revolutionizing baking methods. ↩

-

HEPA filters are essential in maintaining sterile environments, ensuring food safety and quality in production. ↩

-

Vacuum cooling significantly reduces mold growth and improves bread quality, making it a game-changer for bakers. ↩

-

Labeling products as No Preservatives can attract health-conscious consumers and boost sales.

ce | No moisture for mold. | ↩

Mila

You May Also Like

When Should You NOT Use Vacuum Cooling for Your Bakery?

Are you tired of waiting hours for your bread to cool down while your profits evaporate? You might think vacuum

Is Your Cooling Strategy Burning Your Profits? A Cost-Benefit Analysis of Vacuum vs. Conventional Cooling

As a bakery owner, you look at your balance sheet every month. You see the cost of ingredients, labor, and

Hybrid Cooling Solutions: Can Combining Vacuum and Traditional Methods Save Your Bakery?

Are you torn between the speed of new technology and the reliability of traditional freezing? Many bakery owners feel they

Blast Freezers vs Vacuum Coolers: Which Is the Right Choice for Your Bakery?

Are you tired of watching your freshly baked bread sit on racks for hours, taking up valuable space while you

Bakery Vacuum Cooling vs Spiral Cooling Systems: Which Is Better for Your Business?

Are you struggling with slow production lines because your bread takes forever to cool down? You are not alone. Cooling

Is a Vacuum Cooler the Missing Ingredient in Your Hotel or Restaurant Bakery?

Imagine your kitchen is in full swing, and the freshly baked bread is finally out of the oven, but it

Can One Cooling System Handle Your Entire Bakery Menu?

You juggle sourdough, delicate pastries, and frozen dough lines daily. Yet, one cooling mistake ruins the texture of your artisan

Is Your Frozen Dough Production Losing Quality Before It Hits the Freezer?

You watch your energy bills climb month after month while your blast freezers work overtime. You see production bottlenecks form

How Can Organic Bakeries Extend Shelf Life Without Preservatives?

You pour your heart into sourcing the finest organic flours and perfecting natural fermentation, only to watch your hard work

Can Vacuum Cooling Finally Fix the "Gummy" Texture in Gluten-Free Bread?

You watch your perfectly risen gluten-free loaves come out of the oven, only to see them sink or turn gummy