More Than a Steel Box: What Defines a Quality Vacuum Chamber?

You look at a vacuum cooler and see a big metal box with a door. It’s easy to think they are all the same. But the chamber’s design and material are where safety, durability, and hygiene are won or lost.

A quality vacuum chamber is defined by its material, structural design, door mechanism, and interior finish. Key choices include corrosion-resistant stainless steel, heavy reinforcement to withstand pressure, a door suited to your workflow, and a smooth, easy-to-clean interior.

I always tell my clients that the chamber is the foundation of the entire machine. Everything else—the pump, the refrigeration—can be perfect, but if the chamber fails, the entire investment is worthless. Let’s break down the critical design considerations that separate a mediocre box from a truly professional one.

Carbon Steel or Stainless Steel: Which Material is Right for You?

You need to make a smart investment, and a painted carbon steel chamber costs less upfront. But you worry about rust or paint chips contaminating your product. Is stainless steel worth the extra cost?

Carbon steel is a strong, budget-friendly choice for raw produce where the chamber isn’t a direct food-contact surface. Stainless steel is the superior material for all food applications, providing hygiene, corrosion resistance, and long-term value that meets food safety standards.

Building for Durability and Hygiene

Choosing between painted carbon steel and stainless steel is one of the first and most important decisions we make with a client. It comes down to balancing budget with the specific hygiene requirements of your product. For some, carbon steel is a perfectly logical choice. It is incredibly strong and less expensive, which can help with the initial project budget. We protect it with a high-performance, multi-layer industrial paint system. For a client like Carlos, who is cooling whole heads of lettuce packed in bins or on pallets, the product never directly touches the chamber walls. In this case, a well-built and well-maintained painted carbon steel1 chamber can provide years of great service. The primary vulnerability is that any deep scratch or scrape from a forklift can break the paint barrier and expose the steel, which will then begin to rust.

For a client like Sophia, managing a central kitchen under HACCP regulations2, stainless steel is the only option. We use high-quality SUS304 grade stainless steel for all our food-grade chambers. This material contains chromium, which reacts with oxygen to form a thin, invisible, and self-healing layer that prevents rust and corrosion. There is no paint to chip or flake off, which eliminates the risk of physical contamination in her food products. The surface is non-porous and easy to sanitize, making it simple to meet strict cleaning protocols. While the initial investment is higher, a buyer like Norman, who focuses on total cost of ownership3, often chooses stainless steel even for produce. He knows there is no need for future repainting, it holds its value far better, and it gives him the flexibility to handle different types of products in the future. It’s an investment in longevity and peace of mind.

| Feature | Painted Carbon Steel | SUS304 Stainless Steel |

|---|---|---|

| Initial Cost | Lower | Higher |

| Hygiene Level | Good | Superior / Food-Grade |

| Maintenance | Requires paint touch-ups | Minimal, no repainting |

| Longevity | Good, with maintenance | Excellent |

| Best For | Raw produce, non-food | All food, high-hygiene |

Round or Square: Why Does Chamber Shape Matter?

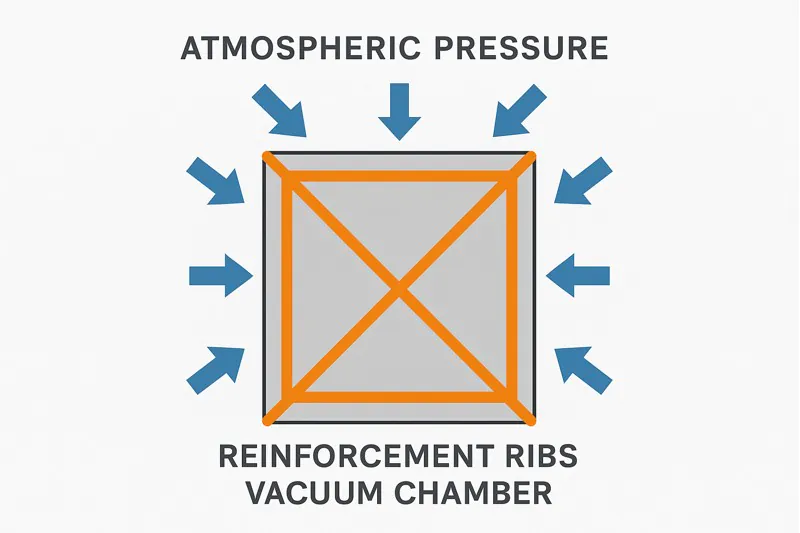

You need to cool trolleys or pallets, so a square chamber seems like the only logical choice for space. But have you thought about the immense force of the atmosphere trying to crush that chamber from the outside?

A square chamber maximizes usable floor space for pallets and trolleys, making it the practical choice for food and produce. To make it safe, it requires significant external steel reinforcement to resist the crushing force of the vacuum, a critical engineering feature.

Engineering for Strength and Practicality

The shape of the chamber is a classic battle between physics and practicality. From a pure physics standpoint, a cylinder is the strongest shape to resist external pressure. When a vacuum is pulled inside, the entire atmosphere (about 1 kilogram per square centimeter) is pressing inward on every surface. On a round chamber, this force is distributed perfectly and evenly across the structure. There are no corners or flat spots to act as weak points. This is why you see cylindrical tanks4 used for high-pressure applications. The problem is that loading square pallets or rectangular trolleys into a round chamber is incredibly inefficient. You waste a huge amount of valuable space in the corners.

For this reason, nearly all of our vacuum coolers for produce and food5 are rectangular. A client like Carlos needs to fit two 1.2-meter-wide pallets side-by-side, and Sophia needs to easily roll her rectangular bakery racks inside. A square shape is a practical necessity. The engineering challenge is that those large, flat walls desperately want to buckle inward under the vacuum load. A poorly designed chamber could literally collapse. This is where our engineering design becomes critical. We use Finite Element Analysis (FEA)6 software to model these forces and design a robust reinforcement skeleton7 for the chamber. We weld heavy-duty steel I-beams or C-channels to the exterior of the walls and door. These ribs act like the skeleton of the building, providing immense strength and rigidity to the flat panels. The size and spacing of these ribs are precisely calculated to ensure the chamber not only works but has a significant safety factor. When you see a heavily reinforced chamber, you are seeing a commitment to safety and longevity.

| Chamber Shape | Space Efficiency | Natural Strength | Reinforcement Needed |

|---|---|---|---|

| Round | Poor for pallets/trolleys | Very High | Minimal |

| Square | Excellent | Low | Extensive and critical |

Manual or Automatic: How Should Your Door Work?

An automatic door looks impressive and feels modern. But it adds cost, moving parts, and hydraulic systems. Is a simple manual door just as good, or is the convenience of an automatic door worth it?

A manual door with heavy-duty locking lugs is simple, extremely reliable, and cost-effective, making it perfect for most operations. An automatic hydraulic door is a high-efficiency option for automated production lines where reducing labor and every second of cycle time counts.

Designing a Door for Your Workflow

The chamber door is the part of the machine your team interacts with most, so its design has a direct impact on your daily workflow. We offer two main architectures, and the right choice depends entirely on your operational needs. The most common and reliable design is the manual hinged door8. This is a very heavy door mounted on robust hinges, featuring a series of strong, over-center locking lugs around the perimeter. To operate it, you swing the door shut and walk around, tightening each lock by hand. It sounds low-tech, but its simplicity is its greatest strength. There are very few moving parts to fail, and maintenance is almost zero. For an operation like Carlos’s farm, where they might run 10-15 cycles a day, the 30 seconds it takes to secure the door is a tiny part of the overall process. The unbeatable reliability during a critical, short harvest season is what matters most.

For a highly automated, high-throughput facility, those 30 seconds, multiplied over hundreds of cycles, add up. This is where we would recommend a fully automatic door9. These doors can be designed to either hinge or slide open, powered by a smooth, powerful hydraulic system10. The operator simply pushes a button, and the door unseals, opens, and closes automatically. This is essential when the vacuum cooler11 is integrated into an automated production line. Imagine a central kitchen where trolleys move from a spiral oven, into the cooler, and then onto a packaging line automatically. An automatic door is the only way to make that seamless. It reduces labor, eliminates operator fatigue from handling a heavy door, and ensures a perfect seal every time. While the initial cost and complexity are higher, the return on investment comes from increased speed and automation for large-scale producers.

| Door Type | Cost | Speed | Reliability | Maintenance |

|---|---|---|---|---|

| Manual | Lower | Slower | Extremely High | Very Low |

| Automatic | Higher | Faster | High, with maintenance | Periodic hydraulic checks |

What Lies Beneath? Why Floor Design and Interior Finish Matter.

You have the right material and a strong door. But if you look inside, are the welds rough? Does water pool on the floor after cleaning? These small interior details make a huge difference in hygiene and usability.

A well-designed chamber interior features a reinforced, sloped floor for easy drainage and polished, seamless welds. These elements are critical for preventing bacterial growth, ensuring fast and effective cleaning, and meeting strict food safety standards.

The Details That Define Quality

The quality of a vacuum chamber is truly revealed when you look at the fine details inside. These are the features that impact food safety and day-to-day use. First, let’s talk about the floor. The floor of a cooler that handles multi-ton pallets loaded by a forklift takes a beating. We design our floors with thick steel plates and weld heavy C-channel reinforcements underneath to prevent them from denting or bending over time. After cleaning, you cannot have water pooling inside the chamber, as this is a major risk for bacterial growth. That’s why we build every floor with a slight, calculated slope that directs all water to a sanitary drain, making washout fast and complete. For trolley-based systems, like those for bakeries, we weld low-profile guide rails onto the floor. This simple feature makes it effortless for an operator to roll a heavy rack in without it bumping and damaging the interior walls.

The second, and perhaps most critical detail for food safety, is the quality of the welds. On a cheaply made chamber, you will find rough, uneven welds inside with tiny cracks and pits. These imperfections are impossible to clean and quickly become breeding grounds for listeria and other bacteria. For a client like Sophia, this would be an immediate failure during a food safety audit. Our commitment to quality means that for all our stainless steel food-grade chambers, our certified welders grind every single interior weld perfectly smooth. After grinding, the welds are polished to blend seamlessly with the surrounding wall. This creates a continuous, non-porous surface that can be sanitized effectively, leaving no place for bacteria to hide. This isn’t an optional extra; it’s our standard for any food-contact machine and a core part of our design philosophy.

Conclusion

A great chamber is an engineered system. It is the thoughtful combination of the right material, a strong and safe shape, a user-friendly door, and a hygienic interior finish that creates a truly professional and lasting machine.

-

Explore the advantages of painted carbon steel for cost-effective and durable food storage solutions. ↩

-

Understand the significance of HACCP regulations in ensuring food safety and compliance. ↩

-

Discover how considering total cost of ownership can lead to smarter investment choices in equipment. ↩

-

Discover the advantages of cylindrical tanks in high-pressure scenarios, highlighting their strength and efficiency. ↩

-

Learn about vacuum coolers and their role in preserving food quality, making them essential for the food industry. ↩

-

Explore this link to understand how FEA enhances engineering designs, ensuring safety and efficiency in structures. ↩

-

Understand the importance of reinforcement skeletons in structural integrity, crucial for safe engineering practices. ↩

-

Explore the advantages of manual hinged doors, including reliability and low maintenance, ideal for various operational needs. ↩

-

Discover how fully automatic doors enhance efficiency and reduce labor in high-throughput environments. ↩

-

Learn about hydraulic systems and their importance in ensuring smooth operation of automatic doors. ↩

-

Find out how vacuum coolers work with automated systems to streamline food processing and packaging. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf