Vacuum Cooler Buyer's Guide: What Features Should You Consider Before Purchasing?

Making a major equipment investment is stressful. You know you need a vacuum cooler, but with so many options, choosing the wrong one could mean costly downtime and endless headaches.

The most crucial features to consider are the quality of core components, the machine’s cooling performance and energy efficiency, its long-term maintenance needs, and the reliability of the manufacturer’s after-sales support. These factors determine the true value and reliability of your investment.

I’ve guided many buyers through this process, from large-scale farm owners to central kitchen managers. They all start with the same concerns. They want to be sure they are making a smart decision that will benefit their business for years. The best way to do that is to look past the sales pitch and focus on these four fundamental areas. Let’s break them down.

What core components should you look for?

You’re worried that a lower-priced machine might use cheap parts. A breakdown during your peak harvest season is your worst nightmare, and you know a machine is only as reliable as its internal components.

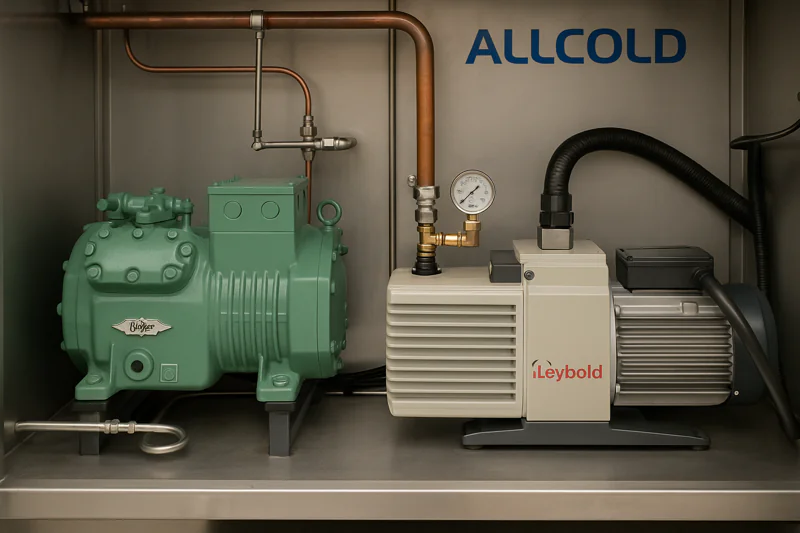

Insist on seeing a detailed parts list. A top-tier machine is built with world-class, recognizable brands like Bitzer for compressors and Leybold for vacuum pumps to ensure durability and prevent costly failures.

The Anatomy of a Reliable Machine

This is the single most important factor, and it’s something I always tell my clients to scrutinize. The brand names inside the machine are a direct reflection of the manufacturer’s commitment to quality. A reputable manufacturer will be proud to show you what’s under the hood. For our machines, we’ve built our reputation on using the best. The compressor is the heart of the system, and we use Bitzer1 from Germany. It is the industry standard for reliability. The vacuum pump, which performs the essential task of lowering the pressure, is from Leybold, another benchmark in German engineering.

This philosophy extends to every part of the system. The control system and touch screen are from Siemens2, ensuring stable and intuitive operation. The electrical system is built with Schneider contactors and relays from Germany and France, which guarantees safety and dependability. Even smaller but crucial parts like the expansion valve are from Danfoss in Denmark. When you see a parts list filled with names like these, you are not just buying a machine; you are buying peace of mind. You are investing in a lower total cost of ownership because these components are built to last, drastically reducing the risk of unexpected breakdowns and expensive repairs down the line.

| Component | Top-Tier Brand Example | Country of Origin | Why It’s a Critical Feature |

|---|---|---|---|

| Compressor | Bitzer | Germany | Industry leader for cooling power and endurance. |

| Vacuum Pump | Leybold | Germany | Ensures fast, deep, and consistent vacuum levels. |

| Control System | Siemens | Germany | Provides stable, error-free automated cycles. |

| Electricals | Schneider | Germany/France | Guarantees safe and reliable power management. |

How do you evaluate cooling performance and efficiency?

Your current cooling method is slow, creating a bottleneck that limits how much product you can ship each day. At the same time, you are concerned that a more powerful machine will lead to higher electricity bills.

Look for a balance of speed and intelligence. A great cooler offers rapid, automated cooling cycles while also incorporating energy-saving features like automatic shutdown during idle periods to reduce operational costs.

Speed That Pays, Efficiency That Saves

Performance is not just about raw power; it’s about smart power. For a food production client, we designed a system to cool baked bread from 92°C to 30°C in under 5 minutes. This kind of speed transforms an operation’s throughput. It means more batches, larger orders, and higher revenue. This is achieved through a fully automatic cooling facility where the operator initiates the cycle, and the machine handles the rest. This level of automation ensures consistency and maximizes the number of cycles you can run in a day.

However, speed must be paired with efficiency to be truly profitable. That’s why we build our machines with high-efficiency evaporators3 and air-cooled condensers, which are specifically designed to minimize the energy rating of the compressor used. This intelligent design reduces your power consumption during every single cycle. We also know that in a real-world setting, there are often delays between loading and unloading. To account for this, our machines have an automatic shutdown feature4. If the cooler is left idle for a period, it powers down completely to save electricity. A single press of the start button brings it back online, ready for the next load. This combination of rapid cooling and smart energy management is what you should demand from any machine you consider.

What does a practical maintenance schedule look like?

You’re not a refrigeration expert, and you don’t have one on staff. You need a machine that is easy to maintain without requiring constant attention or expensive specialist visits, which add to your operational costs.

A well-designed vacuum cooler should have a simple, practical maintenance plan. This means infrequent major services and routine checks that your own team can perform, such as a monthly visual check of the pump oil.

Designed for Uptime, Not Downtime

Maintenance is a hidden cost of ownership, and a good manufacturer designs their equipment to minimize it. The goal should be to keep your machine running and productive, not to create a constant service schedule. We build our machines with this in mind. The most frequent task we recommend is a simple one: once a month, your operator should visually check the vacuum pump oil5 to see if it is emulsified. If the oil looks milky, it needs to be changed; otherwise, you’re good to go. This is a task that takes minutes and requires no special tools or skills.

More intensive maintenance is scheduled for very long intervals to minimize disruption. For example, changing the lubrication oil for the Bitzer compressor6 is a task for a professional, but it only needs to be done every two years. We also recommend an overall hygiene maintenance check every two seasons to ensure the chamber is clean and the unit is running at peak efficiency. When you are not using the equipment for a long period, you should cut off the main power and protect it from dust and humidity. This straightforward, predictable maintenance schedule means your operational costs are lower and more predictable, a crucial feature for any smart buyer.

How important is warranty and after-sales support?

You understand that even the best machines can have problems. Your biggest fear is investing a large sum of money only to be left without support when an issue arises, especially during a critical time.

*It is absolutely essential. Look for a manufacturer that provides a clear warranty, like a 12-month guarantee, and offers direct, accessible technical help, such as 724 hours phone assistance.**

A Partner for the Long Haul

The quality of a manufacturer’s support system tells you everything you need to know about their confidence in their own product. A machine is a long-term asset, and you are entering a long-term relationship with the company that built it. We formalize this partnership right from the start. Every ALLCOLD system comes with a 12-month guarantee7 that begins after the installation date. This provides a safety net for your investment and ensures that we stand behind our workmanship.

But a guarantee is only useful if you can actually reach someone when you need help. That’s why we provide 7*24 hours phone assistance8 for technical support. If an issue occurs, we have a clear procedure. You are asked to send a detailed written description of the failure, along with relevant pictures, to our team. Our engineering and after-sales service team will then check the information, form a diagnosis, and guide you to a solution immediately. This transparent and responsive process is designed to get you back up and running as fast as possible. This level of support is not a bonus feature; it is a fundamental requirement you should look for in any manufacturer

Conclusion

Choosing the right vacuum cooler comes down to these four pillars: robust components, efficient performance, simple maintenance, and reliable support. Prioritizing these features will ensure you acquire a valuable asset, not a liability.

-

Explore this link to understand why Bitzer is synonymous with quality and reliability in the compressor industry. ↩

-

Discover how Siemens technology ensures stable and intuitive operation in machinery, enhancing overall performance. ↩

-

Explore this link to understand how high-efficiency evaporators can significantly reduce energy costs and improve system performance. ↩

-

Learn about the advantages of automatic shutdown features in machines to enhance energy savings and operational efficiency. ↩

-

Understanding the significance of vacuum pump oil maintenance can enhance equipment longevity and efficiency. ↩

-

Learn about the maintenance needs of Bitzer compressors to ensure optimal performance and reduce downtime. ↩

-

Understanding a 12-month guarantee can help you assess product reliability and manufacturer confidence. ↩

-

Exploring 7*24 hours phone assistance can reveal how manufacturers prioritize customer service and support. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf