What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a vacuum pump, a compressor, and a steel chamber. It’s almost impossible to tell which features are genuinely important and which are just marketing noise.

This confusion is risky. If you focus only on the lowest price, you might unknowingly be buying a machine with low-quality core components. A cheap machine that breaks down during your peak harvest season isn’t a bargain; it’s a catastrophe waiting to happen.

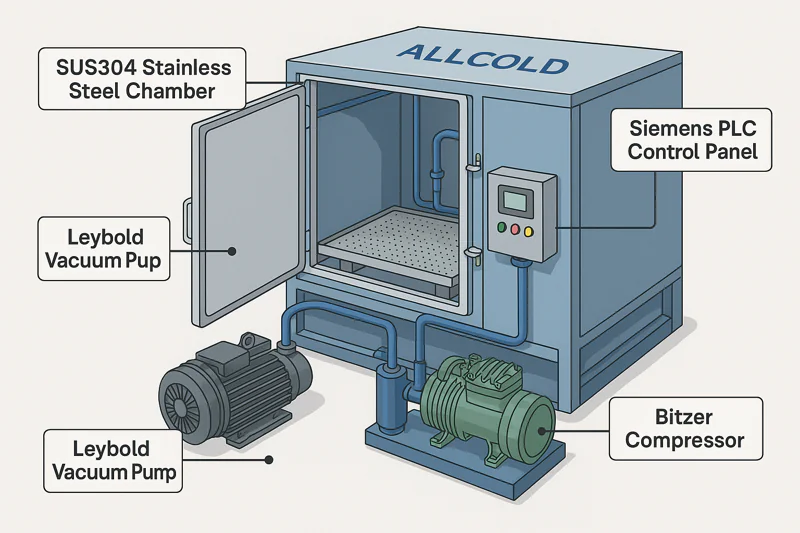

The most important features are the core components that determine reliability and performance: the brand of the vacuum pump and refrigeration compressor, the quality of the vacuum chamber construction, and the sophistication of the PLC control system. Investing in quality in these four areas is non-negotiable.

I’ve been designing and building these machines for years. I know what separates a cooler that lasts for 15+ years from one that fails in three. In this article, I will walk you through the four features you absolutely must scrutinize. This is the insider knowledge you need to choose a machine that will be a reliable workhorse for your business.

Is the Vacuum Pump Brand Really That Important?

The vacuum pump is the engine of the entire system, but most quotes just list a power rating. You might see a machine with an unknown pump brand that is cheaper than one with a famous German brand, and you wonder if the extra cost is justified.

The temptation to save money here is strong, but a low-quality vacuum pump is the single most common point of failure in a poorly made machine. It will struggle to pull a deep vacuum, extending your cycle times. And when it breaks down, getting spare parts can be a nightmare, leaving your very expensive machine idle.

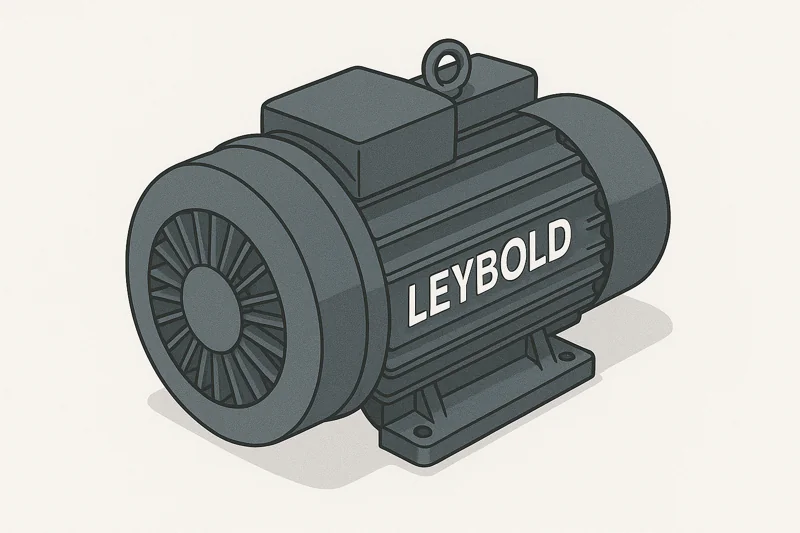

Yes, the brand is critical. A world-class vacuum pump from a manufacturer like Germany’s Leybold is your single best guarantee of reliability, performance, and long-term parts availability. A cheap pump is a false economy that will cost you far more in downtime and slow performance.

The Engine of Your Cooler

The vacuum pump’s job is to remove a massive volume of air from the chamber to lower the boiling point of water. This is heavy, demanding work, cycle after cycle. For a hands-on owner like Carlos, who runs his equipment hard during harvest season, pump failure is not an option.

Performance Under Pressure

A top-tier pump from Leybold is engineered with extremely high tolerances. This means it can create a deeper vacuum faster and more efficiently than a generic pump. What does this mean for you?

- Faster Cycle Times1: A better pump reaches the target pressure quicker, shaving minutes off every cycle. Over a full day, this adds up to more pallets cooled.

- Deeper Cooling2: For some products, achieving the lowest possible core temperature requires a very deep vacuum. A high-quality pump can hit these levels consistently.

Reliability and Longevity3

This is where the investment truly pays off. Leybold pumps are designed to run for thousands of hours with only routine maintenance. Their bearings, seals, and motors are built for industrial duty. Cheaper pumps often use lower-grade materials that wear out quickly under the heat and stress of daily operation. When a professional buyer like Norman is evaluating a machine, he knows that the cost of replacing a cheap pump in year three completely erases any initial savings. Furthermore, global brands like Leybold have a worldwide network for service and spare parts, a critical consideration for our clients from North America to the Middle East.

| Feature | Top-Tier Brand (e.g., Leybold) | Generic / Cheap Brand |

|---|---|---|

| Reliability | Extremely High; designed for 24/7 operation | Prone to overheating and premature failure |

| Performance | Fast pump-down, achieves deep vacuum | Slower cycles, struggles to reach target pressure |

| Global Support | Excellent; parts and service are available | Very poor; finding spare parts can be impossible |

| Total Cost of Ownership4 | Lower over the long term | Higher due to downtime, repairs, and replacement |

Why Does the Refrigeration Compressor Matter So Much?

The compressor is the heart of the refrigeration system, yet on a spec sheet, it’s often just a model number. You might not see the brand listed, or it might be a name you don’t recognize. Is it worth paying more for a machine with a premium compressor brand?

This single component is the biggest consumer of electricity in the entire system. A cheap, inefficient compressor will not only struggle to cool your produce effectively, but it will also inflate your energy bills every single day. A failure in this component is also one of the most expensive repairs.

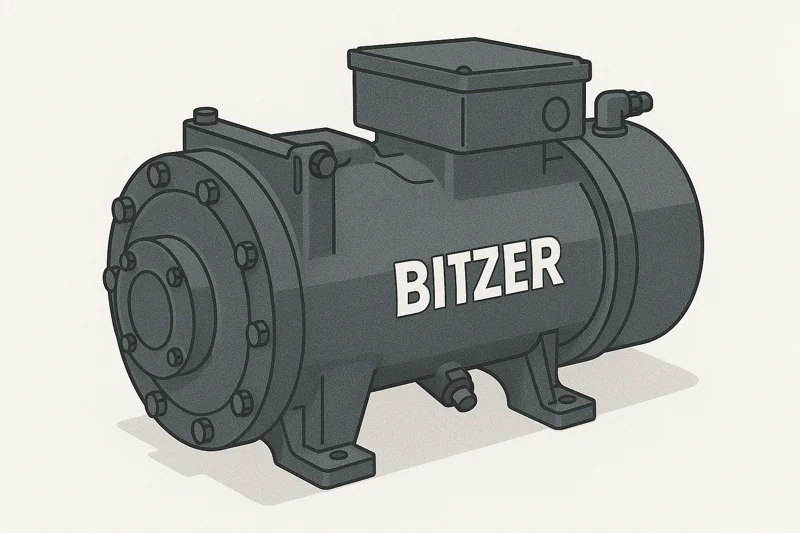

The compressor brand is a critical indicator of energy efficiency and cooling performance. A world-class compressor, such as from Germany’s Bitzer, ensures stable and rapid cooling while using the minimum amount of electricity, directly impacting your daily operational costs and long-term reliability.

The Powerhouse of Cooling

During vacuum cooling, water evaporates from the produce. This water vapor must be captured and frozen onto a super-cold surface called an evaporator (or "cold trap"). The compressor’s job is to keep that evaporator freezing cold, even when it’s being hit with a massive amount of water vapor.

Energy Efficiency is Key

A high-quality compressor from a brand like Bitzer is designed for maximum efficiency. This means it provides more cooling power for every kilowatt of electricity it consumes. At ALLCOLD, we pair these efficient compressors with oversized condensers and evaporators5. This smart design reduces the strain on the compressor, allowing it to run cooler and use less energy. For a cost-conscious buyer, the monthly electricity savings from a Bitzer compressor can add up to thousands of dollars over the life of the machine. Our systems also feature smart shutdown logic, turning the machine off automatically after a period of inactivity to save even more power.

Reliability Under Load

The refrigeration system is a closed loop operating under high pressure. A failure here is not a simple fix. Bitzer compressors6 are legendary in the commercial refrigeration world for their durability. They are built to handle the continuous cycling and heavy loads required in a production environment without faltering. We choose Bitzer because our customers in demanding climates, from the heat of Mexico to the humidity of Southeast Asia, need a machine that performs flawlessly on the hottest day of the year.

| Feature | Top-Tier Brand (e.g., Bitzer) | Generic / Cheap Brand |

|---|---|---|

| Energy Efficiency | Very High (Lower electricity bills) | Poor (Higher operational costs) |

| Reliability | Excellent; built for continuous industrial use | High risk of burnout and costly failure |

| Cooling Power | Stable and powerful, even in high ambient temps | Performance drops off when it’s needed most |

| Lifespan | 15-20 years with proper maintenance | 3-5 years is common |

What Kind of Control System Do I Actually Need?

You see options for "manual controls" or a "PLC system," and the PLC option is always more expensive. You might think, "I just need to turn it on and off. Why do I need a complicated computer?"

This thinking is a trap. A basic control system with simple buttons and relays gives you no precision and no feedback. You can’t adjust the cooling curve for different vegetables, and if there’s a problem, the machine can’t tell you what’s wrong. You will get inconsistent cooling results and face longer downtime when issues arise.

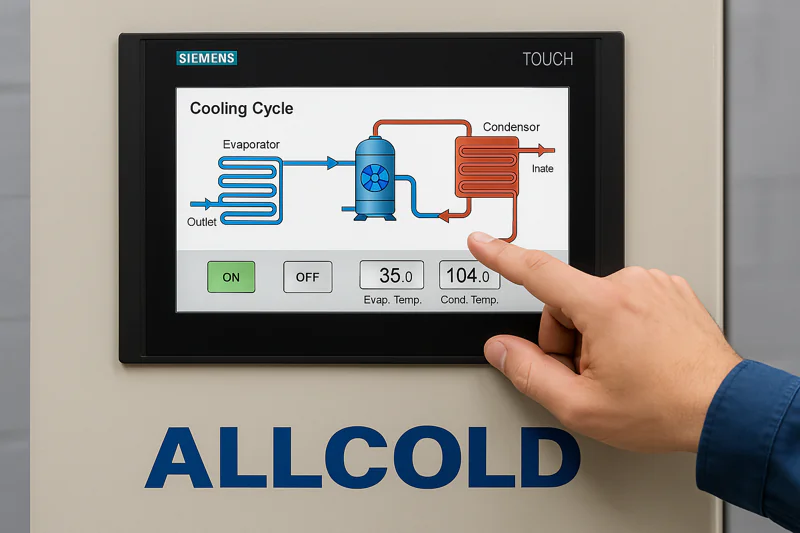

You must have a modern PLC (Programmable Logic Controller) with a touch screen interface. A reliable PLC from a global brand like Siemens gives you the precision to get consistent results, the flexibility to cool different products, and the diagnostic tools needed for rapid troubleshooting.

The Brains of the Operation

A modern vacuum cooler is a sophisticated piece of equipment. Controlling the interaction between the vacuum pump and the refrigeration system is key to getting perfect results. This is a job for a computer, not a simple switch. For a manager like Sophia, who needs to guarantee food safety and quality for a fast-food chain, the precision of a PLC is not a luxury; it’s a requirement.

Precision and Consistency

With a Siemens PLC7, we can program specific cooling "recipes" for different products. For example, delicate herbs might need a slower pressure drop than sturdy broccoli. The PLC controls the valves and motors with millisecond precision to follow this recipe perfectly every time. This means every batch comes out at the exact same target temperature, with no risk of freezing or under-cooling. Our systems even include a "vacuum delay" function, which allows the PLC to hold the vacuum at a specific level to ensure the core of a dense product cools uniformly.

Smart BDiagnostic and User-Friendly Operation

The touch screen makes operation simple. The operator can see the chamber pressure, product temperature, and cycle time all on one clear display. More importantly, the PLC is constantly monitoring dozens of sensors. If a problem occurs, like an electrical phase imbalance, the PLC will display an alert and shut down the machine safely. We can even install a remote access module, allowing our engineers in China to log in to your machine’s PLC to diagnose problems and guide your local technician. This feature has saved my clients countless hours of downtime.

| Feature | Modern PLC System (e.g., Siemens) | Basic Relay / Manual Controls |

|---|---|---|

| Control Precision | Extremely high; custom cycles for products | Very low; a crude on/off process |

| Consistency | Guarantees identical results every batch | Inconsistent, depends heavily on operator |

| Diagnostics | Self-diagnostics and remote access capable | None; troubleshooting is pure guesswork |

| Ease of Use | Intuitive touch screen interface | Confusing array of buttons and switches |

What Should the Vacuum Chamber Be Made Of?

Every supplier will tell you their chamber is made of "stainless steel." But this is a vague term. You don’t know the specific grade of the steel, how thick it is, or how well it has been welded and reinforced.

Choosing a machine with a poorly constructed chamber is dangerous and costly. The immense force of the vacuum can cause a weak chamber to buckle or even collapse. A chamber made from a low grade of stainless steel will rust, creating a serious food safety hazard and failing any hygiene audit.

The vacuum chamber must be constructed from heavy-gauge, food-grade SUS304 stainless steel. This ensures it has the structural integrity to be safe under vacuum and the corrosion resistance to be hygienically cleaned, meeting global food safety standards.

The Foundation of Safety and Hygiene

The vacuum chamber isn’t just a box; it’s a pressure vessel operating in reverse. When we pull a near-perfect vacuum, the atmosphere is pushing on every square meter of the chamber’s surface with over 10,000 kg of force. Strength is not optional.

Material Grade and Thickness

We use SUS304 stainless steel8 for all our chambers. This is the industry-standard material for food processing equipment for two reasons. First, it is very strong. Second, it is highly resistant to corrosion from water and the organic acids found in vegetables. Some manufacturers may use a cheaper grade like SUS201 to save cost, but this material will eventually rust in a wet environment. We also use thick steel plates and add internal steel reinforcement ribs to ensure the chamber never flexes or buckles under pressure.

The Importance of Welding

This is a detail that separates high-quality manufacturers9 from the rest. The quality of the welding is critical for both strength and hygiene. As a procurement manager for a fast-food chain, Sophia knows that a poor weld creates microscopic cracks and crevices where bacteria can hide, making it impossible to clean properly and creating a major HACCP violation risk10. Our certified welders are craftsmen who create smooth, continuous, and fully-penetrated welds. We then grind and polish these welds to a sanitary finish, leaving no place for bacteria to grow. This commitment to construction quality is why our machines are trusted in food processing facilities around the world.

| Feature | High-Quality SUS304 Construction | Poor-Quality Construction |

|---|---|---|

| Material | Certified food-grade SUS304 stainless steel | Carbon steel or low Dgrade SUS201 stainless |

| Safety | Thick plates with internal reinforcement | Thin walls that can buckle or deform |

| Hygiene & Food Safety | Smooth, polished welds, easy to clean | Rough welds with pits that harbor bacteria |

| Lifespan | Will last for decades without corrosion | Can show signs of rust within a few years |

Conclusion

When you look at a quote, don’t just look at the price. Look deeper. Look for the brands that mean reliability—Leybold, Bitzer, Siemens. Ask about the materials and the quality of construction. These are the features that define a machine that will be a profitable, long-term asset for your business.

-

Understanding faster cycle times can help you optimize your cooling processes and improve efficiency. ↩

-

Exploring deeper cooling benefits can enhance your knowledge of product preservation and quality control. ↩

-

Learn why investing in reliable pumps can save you money and reduce downtime in your operations. ↩

-

Understanding total cost of ownership helps in making informed purchasing decisions for long-term savings. ↩

-

Discover how oversized components enhance cooling efficiency and reduce strain on compressors, leading to better performance. ↩

-

Explore the advantages of Bitzer compressors, known for their efficiency and reliability in commercial refrigeration systems. ↩

-

Explore how Siemens PLC enhances food safety and quality through precision control. ↩

-

Explore the advantages of SUS304 stainless steel, known for its strength and corrosion resistance, essential for food safety. ↩

-

Discover tips on identifying high-quality manufacturers, crucial for ensuring safety and hygiene in food equipment. ↩

-

Learn about HACCP violation risks and how to prevent them, ensuring compliance in food processing environments. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf

How Do You Troubleshoot Common Vacuum Cooler Problems?

Your harvest is ready, the pallets are stacking up, but your vacuum cooler suddenly stops. A red light is flashing,