What Do You Need to Know Before Installing a Vacuum Cooler?

You are ready to upgrade your cooling process, but the thought of a complex installation is daunting. You worry about hidden requirements, unexpected costs, and lengthy downtime affecting your production schedule.

A successful vacuum cooler installation hinges on four key stages: proper site preparation, correct physical positioning, thorough pre-operation checks, and customized operational setup. Following a clear guide for these steps ensures a smooth and efficient commissioning process.

I’ve seen the relief on my clients’ faces when they realize how straightforward the installation can be. Our machines are designed to be "plug-in ready" to minimize complexity. However, being prepared is everything. A little planning goes a long way in making the setup process seamless. Let’s walk through the exact steps you need to take, from preparing the space to running your first cooling cycle.

What site preparations are necessary before delivery?

You’re concerned that your facility might not be ready for the new machine. The last thing you want is for the delivery truck to arrive, only to find the space is unsuitable.

Before the vacuum cooler arrives, you must ensure you have a stable, level foundation, the correct electrical power supply, and, if needed, a compressed air source. These elements are critical for safe and effective operation.

Building a Foundation for Success

Proper site preparation is the most important step for a trouble-free installation. Taking care of these details beforehand prevents delays and ensures your machine runs perfectly from day one. It’s about creating the ideal environment for your new investment to perform at its best.

First, the machine must be placed on stable ground and well-locked into position. An uneven or unstable floor can cause vibrations, leading to premature wear on components. Second is the power supply. You need to verify your electrical service matches the machine’s requirements. It is crucial that a professional electrician handles this connection to ensure safety. Finally, some models use a pneumatic system to close the door. For these, you must have an air compressor that can supply a steady pressure of 6-8 bars. If the machine is to be stored for a long time before use, ensure the location is protected from dampness and dust to protect sensitive components. Getting these three things right is 90% of the battle.

| Site Requirement | Specification Example | Why It’s Critical |

|---|---|---|

| Foundation | Stable, level concrete ground1 | Prevents vibration and ensures machine stability for safe operation. |

| Power Supply2 | Match machine specs (e.g., 380V/3Ph/50Hz) | Provides correct, safe power to prevent damage to electrical components. |

| Compressed Air | 6-8 bars (if required) | Ensures the pneumatic door system functions correctly and safely. |

| Environment | Protected from dampness and dust | Protects sensitive electricals and mechanical parts, especially during storage. |

How is the machine physically installed and positioned?

You’re imagining a complicated assembly process that will take days. You need the machine to be operational as quickly as possible with minimal disruption to your workflow.

Our vacuum coolers are designed to be "plug-in ready". The unit is delivered as a whole skid type, which is then moved into position, secured, and connected to power, making the physical setup fast and straightforward.

From Delivery Truck to Ready-to-Run

One of the biggest advantages of our design philosophy is the focus on easy installation3. My clients are often surprised by how quickly the machine is put in place. We deliver our vacuum coolers on a "whole skid type" basis, meaning the core components are already assembled, piped, and wired together. This is not a kit of parts; it’s a nearly complete system that arrives well piped.

The physical installation process is therefore quite simple. The skidded unit is unloaded from the truck and carefully moved, often with a forklift, to its prepared location. Once in position, the machine needs to be leveled and securely locked down to the stable ground. This prevents any movement during the powerful vacuum cycles. After it is secured, the final connections are made. This mainly involves connecting the main power supply, which must be done by a qualified technician, and hooking up the compressed air line if your model requires it. Because the machine is already configured as a plug-in-ready unit4, this entire process is much faster and less disruptive than traditional equipment installations. It minimizes on-site work and gets you operational without lengthy delays.

What initial checks should be performed before the first use?

You are anxious about starting the machine for the first time. You want to be sure everything is correct to avoid causing any damage or encountering an immediate failure.

Before the first operation, a series of checks is essential. This includes a visual inspection of all components, verifying all external connections like power and air, and ensuring fluid levels are correct.

The Pre-Flight Checklist

Starting a new machine is an important moment, and a systematic check ensures everything goes smoothly. This is a process we guide all our clients through. It’s about being methodical and confirming every part of the system is ready. Safety is the top priority, so any examination of electrical appliances should only be done by professionals.

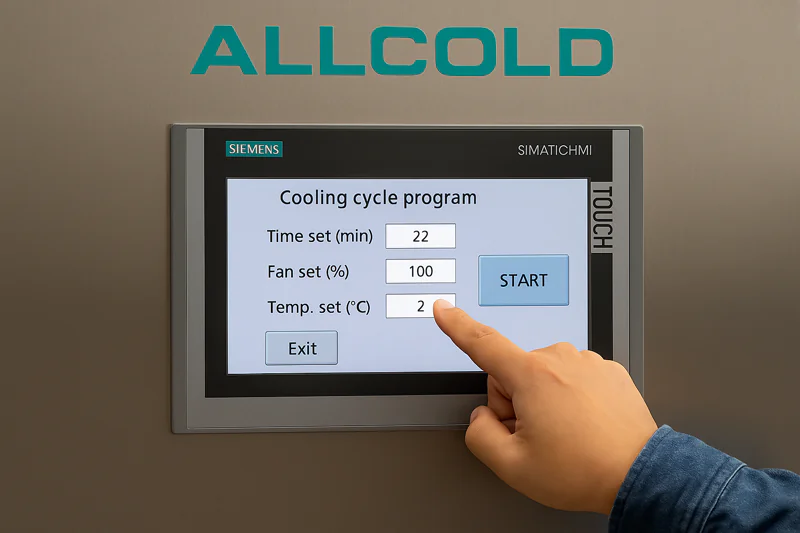

First, we do a complete visual inspection. We check that all the high-quality components, like the Bitzer compressor5 and Leybold vacuum pump6, are secure after shipping. We then check critical fluid levels. It’s important to ensure the oil level of the compressor is within the normal range of 1/3 to 2/3. Similarly, we check the observation spot on the vacuum pump to confirm its oil level is also in the normal 1/3 to 2/3 range. Next, we verify the external connections are secure. Once these pre-power checks are complete, we can turn on the main power. We then check the Siemens touch screen control panel to ensure it powers up correctly. The very first run, especially after any major work, must be started under confirmation that everything is in order.

How do you set up the machine for a specific product?

Your products have unique cooling requirements. You need to know how to program the machine to achieve the perfect cooling cycle every time, ensuring both efficiency and product quality.

Setting up the cooler is done through the simple touch screen control panel. You can program the target temperature and let the machine run its automated cooling cycle for consistent, perfect results.

Dialing in the Perfect Cool

This is where the machine’s intelligence really shines. Customizing the cooling cycle for your product is simple, thanks to the intuitive Siemens touch screen operator control7. This system gives you precise command over the cooling process to get reliable and repeatable outcomes.

The primary setting you will adjust is the target temperature8. This is the final temperature you want your product to reach at the end of the cycle, and it is important to set it above 0°C to prevent any risk of freezing. The entire cycle can then be run automatically. You simply press the ‘Start’ button on the touch screen. The machine begins the cooling process by orderly running the necessary pumps and the compressor. Once the product reaches your set target temperature8, the system will automatically stop the compressor and condenser fans. The control system handles the entire sequence, making it easy for any operator. This level of automation not only simplifies operation but also ensures that every batch is cooled to the exact same specification, guaranteeing product quality and consistency.

Conclusion

Proper installation is a straightforward process when you prepare the site, position the plug-in ready unit, perform key checks, and program the intuitive controls. This ensures your vacuum cooler is set up for success.

-

A stable foundation is essential to prevent vibrations and ensure the longevity of your machine. ↩

-

Understanding power supply requirements is crucial for safe and efficient machine operation. ↩

-

Exploring this link will reveal how easy installation can save time and reduce disruption in your operations. ↩

-

This resource will help you understand the efficiency and convenience of plug-in-ready units in modern installations. ↩

-

Explore this link to understand the Bitzer compressor’s functionality and its importance in refrigeration systems. ↩

-

Discover the various applications of Leybold vacuum pumps and how they contribute to industrial processes. ↩

-

Explore this link to understand how Siemens’ technology enhances user experience and operational efficiency. ↩

-

Learn about the importance of setting the right target temperature for optimal cooling and product quality. ↩ ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf