What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity is deceptive. The wrong design choices in materials, components, or system integration can lead to a machine that is unsafe, inefficient, unreliable, and a nightmare to operate.

Choosing a machine based on a low price without understanding its design is a huge gamble. You risk buying a system with an undersized refrigeration unit that can’t hit the target temperature, a weak vacuum chamber that could be a safety hazard, or a control system that gives you inconsistent results.

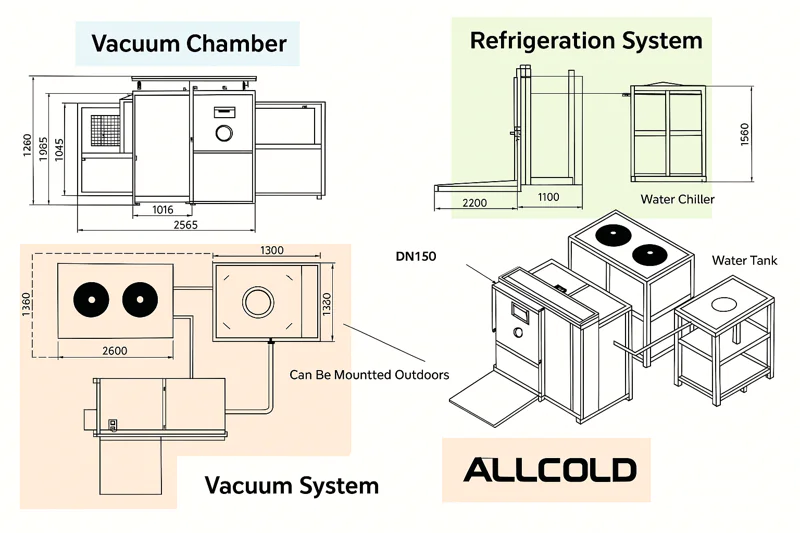

A high-quality vacuum cooler design is a carefully integrated system of four key sub-systems: a robust and hygienic vacuum chamber, a powerful vacuum pump system, an efficient refrigeration system, and a smart PLC control system. The technical requirements for each must be perfectly matched to ensure safety, performance, and reliability.

As an engineer, this is what I am most passionate about. A great machine isn’t just about using good parts; it’s about a smart design philosophy that prioritizes long-term performance and value for the owner. In this article, I will pull back the curtain and show you the technical requirements and design details that we build into every ALLCOLD machine.

How is a Vacuum Chamber Designed for Safety and Hygiene?

The vacuum chamber is the most visible part of the machine, but its most important design features are the ones you can’t easily see. You might be told it’s made of "stainless steel," but this tells you nothing about its strength, safety, or suitability for a food environment.

A poorly designed chamber is a massive liability. Under the immense pressure of a vacuum, a weak or poorly welded chamber can buckle or deform, creating a serious safety risk. If it’s made from the wrong materials or has rough internal surfaces, it can become a breeding ground for bacteria, making it impossible to meet food safety standards.

A vacuum chamber must be designed as a pressure vessel, using thick, food-grade SUS304 stainless steel with internal reinforcements to withstand atmospheric pressure safely. All internal welds must be ground smooth and polished to a sanitary finish to prevent microbial growth and ensure easy cleaning.

The Engineering of the Chamber

For a food processing manager like Sophia, whose entire operation is built around HACCP compliance1, the design of the chamber is a make-or-break issue. It is the foundation of the entire machine’s safety and hygiene.

Structural Integrity and Safety

When we create a near-perfect vacuum inside the chamber, the outside atmosphere exerts a crushing force on every surface. The total force on the door alone can be over 20 tons. Our design process starts with a structural analysis2 to ensure the chamber can handle this force with a massive safety margin. We use heavy-gauge SUS304 steel plates for the walls, floor, and ceiling. Then, we weld thick steel reinforcement ribs to the exterior of the chamber. This creates a rigid structure that will not bend, flex, or deform, even after decades of daily cycles. We take safety very seriously.

Material Science for Food Safety

The choice of material is critical. We use SUS304 stainless steel3 exclusively for all surfaces that come into contact with the product. This grade of steel has excellent corrosion resistance, so it will not rust or pit when exposed to water and the natural acids from vegetables. Cheaper machines might use a lower grade like SUS201, which looks similar at first but can begin to rust over time, compromising food safety. All internal welds are meticulously performed by certified welders and then ground down and polished to a smooth, sanitary finish. This eliminates the microscopic cracks and crevices where bacteria can hide, a detail that is absolutely essential for our clients in the food processing industry.

| Design Requirement | ALLCOLD Engineering Solution | Why It Matters to You |

|---|---|---|

| Structural Safety | Heavy-gauge steel plates with external rib reinforcement | Prevents catastrophic failure and ensures operator safety. |

| Material Choice | Certified Food-Grade SUS304 Stainless Steel | Guarantees corrosion resistance and long lifespan. |

| Hygiene | Smooth, polished internal welds and surfaces | Prevents bacterial growth4, allows for easy cleaning. |

| Door Seal | High-quality, durable silicone gasket | Ensures a perfect seal for fast vacuum pull-down. |

What Goes into Designing a Powerful and Reliable Vacuum System?

The vacuum system is the engine of the cooler. You see a motor and a pump, but the design of the entire system—including the pump, the piping, the valves, and the layout—determines its performance and reliability.

A poorly designed vacuum system is incredibly frustrating. It will be slow, struggling to pull the chamber down to the required pressure, which extends your cycle times and reduces your throughput. It might be loud, inefficient, and prone to leaks, requiring constant maintenance and causing unexpected downtime right when you need it most.

A reliable vacuum system is designed around a correctly-sized, world-class vacuum pump from a brand like Leybold or Nash. The system requires large-diameter piping to maximize airflow and high-quality valves to ensure a perfect, leak-free seal every cycle.

Optimizing for Speed and Airflow

For a large-scale farmer like Carlos, speed is everything. Every minute saved on a cooling cycle is a minute gained in packing and shipping his produce. The design of the vacuum system is directly responsible for that speed.

The Heart of the System: The Pump

The process begins with selecting the right vacuum pump5. We need to match the pump’s capacity (measured in cubic meters per hour) to the volume of the chamber. An undersized pump will work too hard and take too long. This is why we partner with the best brands in the world, like Germany’s Leybold and USA’s Nash. These pumps are industrial workhorses, designed for efficiency and incredible longevity. They provide the raw power needed to evacuate the chamber quickly.

The Lungs of the System: Piping and Valves

Having a powerful pump is useless if the air can’t get to it. This is a common design flaw in cheaper machines. They use narrow pipes with sharp bends, which restricts airflow6 and chokes the pump, much like trying to breathe through a thin straw. At ALLCOLD, we use large-diameter, stainless steel pipes with smooth, sweeping bends to create an unrestricted pathway for the air to escape. This allows the pump to work at its maximum efficiency, dramatically reducing the time it takes to pull the vacuum. We use high-quality pneumatic valves7 that seal perfectly, preventing leaks that would make the pump run longer and waste energy.

| Design Requirement | ALLCOLD Engineering Solution | Why It Matters to You |

|---|---|---|

| Pumping Power | Premium pumps from Leybold or Nash | Provides the speed and reliability for short cycle times. |

| System Efficiency | Large-diameter pipes with minimal, smooth bends. | Maximizes airflow for the fastest possible pump-down. |

| Reliability | High-quality, leak-proof valves and connections. | Prevents energy waste and reduces maintenance needs. |

| Serviceability | Components are laid out for easy access to oil fills. | Makes routine maintenance quick and simple for your team. |

Why is the Refrigeration System Design So Critical for Performance?

The refrigeration system, or "cold trap," is where the magic of cooling actually happens. It’s a complex system of a compressor, condenser, and evaporator. A spec sheet might list the power of the compressor, but this doesn’t tell you if the system is properly designed and balanced.

An undersized or poorly designed refrigeration system is the leading cause of poor cooling performance. The machine will struggle to reach your target temperature, especially on hot days. It will run inefficiently, driving up your electricity bills. In the worst cases, it can lead to compressor burnout, the single most expensive component to replace.

The refrigeration system must be designed as a balanced loop, where a high-efficiency Bitzer compressor is matched with an oversized evaporator (cold trap) and condenser. This ensures it can capture all the water vapor from the produce and cool it down rapidly and efficiently.

The Science of Heat Removal

When water evaporates from the vegetables inside the vacuum, it turns into a massive volume of water vapor. The job of the refrigeration system is to capture this vapor and turn it back into ice on a freezing-cold surface. For a professional buyer like Norman, who focuses on Total Cost of Ownership8, the efficiency of this system is paramount.

The Compressor: The Powerhouse

We start with the best compressor on the market: Germany’s Bitzer. Bitzer compressors9 are known for two things: incredible reliability and high energy efficiency. They provide the maximum amount of cooling power for every kilowatt of electricity they consume. This choice directly translates to lower daily operating costs for our customers.

The Evaporator: The Key to Speed

This is the most critical design secret. The evaporator, or "cold trap," is the radiator-like coil inside the system that gets intensely cold. To cool quickly, you need a huge amount of cold surface area to capture the water vapor instantly. Many manufacturers use undersized evaporators to save money. This creates a bottleneck; the vapor can’t be trapped fast enough, so the cooling cycle takes longer. We design our machines with deliberately oversized evaporators10. This extra surface area costs us more to build, but it gives our machines the ability to cool faster and reach lower temperatures than the competition, especially when the ambient temperature is high.

The Condenser: Balance is Everything

The condenser’s job is to release the heat that has been captured from the product. We match the condenser size to the compressor and evaporator to create a balanced system11 that isn’t under stress. This smart, balanced design means the components run cooler, use less energy, and last much longer.

| Design Requirement | ALLCOLD Engineering Solution | Why It Matters to You |

|---|---|---|

| Cooling Power | Premium, high-efficiency Bitzer compressors | Delivers reliable cooling power with lower energy consumption. |

| Cooling Speed | Oversized evaporator coils with large surface area | Captures vapor faster for shorter cycle times. |

| System Efficiency | A balanced system where all components are correctly sized. | Reduces component stress, lowers energy bills, and extends lifespan. |

| Smart Controls | Automatic shutdown when idle to save electricity. | Prevents wasted energy between cooling cycles. |

Conclusion

A vacuum cooler is more than a list of parts; it’s a fully integrated system where every design choice matters. By focusing on robust materials, top-tier components, and smart, balanced engineering, we build machines that are not just effective, but safe, reliable, and efficient for years to come.

-

Understanding HACCP compliance is crucial for ensuring food safety and quality in processing operations. ↩

-

Learn how structural analysis ensures safety and integrity in engineering designs, especially in food processing. ↩

-

Explore the benefits of SUS304 stainless steel for food safety and durability in processing equipment. ↩

-

Discover effective strategies to prevent bacterial growth, ensuring hygiene and safety in food processing. ↩

-

Explore this link to discover top-rated vacuum pumps that enhance efficiency and speed in industrial applications. ↩

-

Understanding airflow’s impact on vacuum pump efficiency can help optimize your system for better performance. ↩

-

Learn about the advantages of using high-quality pneumatic valves to improve system reliability and reduce energy waste. ↩

-

Understanding TCO helps buyers make informed decisions on long-term savings and efficiency. ↩

-

Explore how Bitzer compressors enhance reliability and energy efficiency in cooling systems. ↩

-

Learn how oversized evaporators improve cooling speed and efficiency, crucial for optimal performance. ↩

-

Discover the significance of a balanced system for energy savings and component longevity. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf

How Do You Troubleshoot Common Vacuum Cooler Problems?

Your harvest is ready, the pallets are stacking up, but your vacuum cooler suddenly stops. A red light is flashing,