What is a Vacuum Cooler and How Does It Work for Fresh Vegetables?

Field heat is destroying your freshly harvested vegetables, costing you money with every passing hour. This rapid decay reduces shelf life and eats directly into your profits.

A vacuum cooler is a machine that rapidly chills fresh vegetables by lowering the air pressure in a sealed chamber. This causes water to boil off the produce surface at a low temperature, cooling it down in just 15-25 minutes and preserving its freshness.

I’ve seen many farmers and food producers face this challenge. They work hard to grow a perfect product, only to lose quality in the critical hours after harvest. The science behind vacuum cooling is simple but powerful. By changing the pressure, we can make water boil without high heat, and this is the secret to cooling produce incredibly fast. Let’s look at how it all comes together.

How does a vacuum cooler actually make vegetables cold?

Your conventional cold room takes many hours to chill produce. This slow process allows vegetables to continue to degrade, losing crispness and value before they even reach the customer.

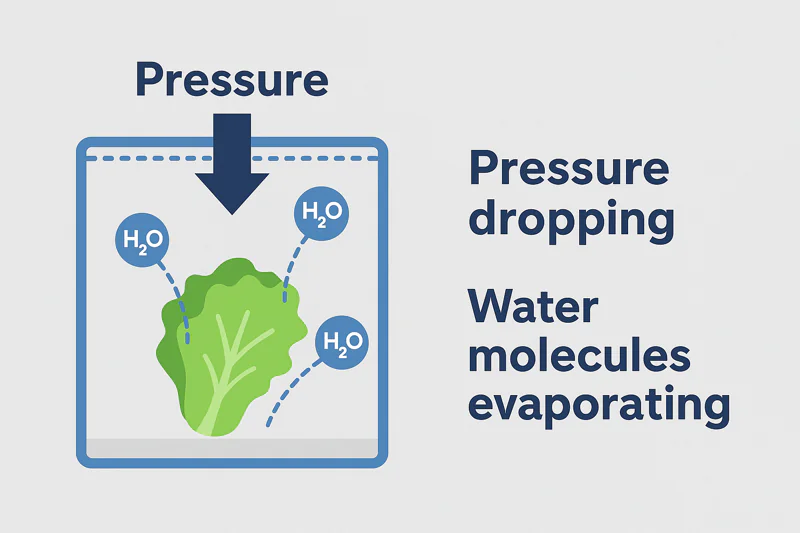

A vacuum cooler uses a powerful pump to remove air from a sealed chamber. This low pressure makes water’s boiling point drop. The moisture on the vegetables evaporates, taking heat energy with it and rapidly cooling the produce from the core.

The Science of Low-Pressure Boiling

The process is a fantastic example of physics at work. At sea level, water boils at 100°C. But if you go to a high mountain, the air pressure is lower, and water boils at a lower temperature. A vacuum cooler1 takes this to an extreme. It creates a very low-pressure environment inside a steel chamber.

The machine’s automatic cycle follows a clear sequence. First, the vacuum pump starts, and the inside pressure begins to drop quickly. During this phase, not much cooling happens. Then, once the pressure is low enough, the water on the vegetables starts to boil. This is the main cooling phase, where both the pressure and the product’s temperature drop together. In about 15 to 25 minutes, the product can go from a hot field temperature down to a cool 3°C. Once the target temperature is reached, the compressor stops, and the machine lets air back into the chamber so you can open the door.

| Cycle Stage | Inside Pressure | Product Temperature | Duration |

|---|---|---|---|

| Initial Pulldown | Decreasing ↘ | Stable → | 0-15 minutes |

| Evaporative Cooling2 | Decreasing ↘ | Decreasing ↘ | 15-25 minutes |

| Cycle Complete | Stabilizing → | Stable ↘ | After 25 minutes |

What are the key components inside a vacuum cooler?

You see a large steel box, but you are not sure what makes it work. Buying a complex machine without understanding its core parts is a big risk for any business.

The main components are a powerful vacuum pump to create the low pressure, a refrigeration system with a compressor to remove heat, and a smart PLC with a touch screen for control. We select top brands like Bitzer and Siemens for these critical parts.

The Heart of the Machine

A vacuum cooler has two main systems working together: the vacuum unit and the cooling unit. It is the quality of the parts in these systems that determines how well the machine performs. We believe in using the best to build the best.

The Vacuum Pump is the engine of the process. Its job is to remove air from the chamber quickly and efficiently. We use world-class brands like Leybold from Germany or Nash from the USA. The Refrigeration System3 is what captures the heat. As water evaporates from the vegetables, it turns into vapor. This vapor is captured and turned back into liquid on a very cold coil, which is cooled by a compressor. For this vital job, we use reliable Bitzer compressors from Germany. The Control System is the brain. A Siemens PLC and touch screen allow you to run complex cooling cycles with a simple press of a button.

| Component | Function | Brand Example | Country of Origin |

|---|---|---|---|

| Compressor | Cools the condenser to capture water vapor | Bitzer | Germany |

| Vacuum Pump4 | Removes air to lower chamber pressure | Leybold / Nash | Germany / USA |

| Touch Screen / PLC | Controls the automatic cooling cycle | Siemens | Germany |

| AC Contactor | Manages electrical power to the motors | Schneider | Germany / France |

How long does it take to cool fresh vegetables?

Your vegetables are losing quality every minute they sit waiting to be cooled. Traditional cold rooms are just too slow to handle the volume during your peak harvest season.

The cooling cycle for fresh produce is finished in around 15 to 25 minutes. The exact time can change based on the specific vegetable, how much you load, and its starting temperature. This incredible speed is what preserves peak freshness.

Speed and Efficiency

The speed of vacuum cooling5 is its biggest advantage. While one batch of lettuce is being cooled in 25 minutes, another batch can be harvested and prepared for the next cycle. Different products have different cooling times. For example, we’ve designed systems that cool baked bread from 92°C to 30°C in just 5 minutes. For steamed rice, the goal might be to go from 98°C down to 3°C, which takes about 15-25 minutes.

The entire process is automated. The operator simply loads the pallets, closes the door, and presses start on the touch screen. The machine’s PLC runs the full cycle. When the sensors detect that the product has reached the target temperature you set, the compressor will stop automatically. The system then enters a "deflation" stage to let air back into the chamber so the door can be safely opened for unloading. This efficiency allows you to process a huge amount of product in a single day.

| Product Example | Starting Temperature | Finishing Temperature | Cooling Cycle Time |

|---|---|---|---|

| Baked Bread | 92°C | 30°C | Within 5 minutes |

| Steamed Rice | 98°C | 3°C | Around 15-25 minutes |

| Fresh Vegetables | Field Temperature | Approx. 3°C | Around 15-25 minutes |

What makes a high-quality vacuum cooler?

All vacuum coolers might look like simple steel boxes from the outside. You need to know how to identify a reliable, well-built machine that will last for years.

A high-quality cooler is defined by the quality of its components and its intelligent design. It uses trusted, top-brand parts from countries like Germany, Italy, and Switzerland for maximum reliability. Advanced features like a touch screen and a troubleshooting assist system also set premium machines apart.

The Allcold Difference: Investing in Reliability

When you invest in a machine, you are investing in your business’s future. The quality of every part matters. That is why we build our coolers with components from the best manufacturers in the world. This focus on quality means our machines are more reliable, more efficient, and easier to service.

We use parts from established European and American brands known for their engineering excellence6. This includes pumps and compressors from Germany, electrical contactors from France, safety relays from Switzerland, and valves from Denmark. This commitment to quality is also reflected in the user experience7. Our machines feature easy-to-use touch screen controls and smart systems like a troubleshooting assistant to help operators solve problems quickly. These details make a big difference in the daily operation of a busy facility.

| Component | Brand Example | Country of Origin |

|---|---|---|

| Phase Protection | Carlo Gavazzi | Switzerland |

| Oil Separator | Frascold | Italy |

| Expansion Valve | Danfoss | Denmark |

| Safety Relay | Schneider | Germany / France |

Conclusion

A vacuum cooler is a powerful tool. It uses the physics of low-pressure evaporation to chill fresh vegetables faster than any other method, protecting their quality and extending their shelf life.

-

Explore this link to understand the mechanics and benefits of vacuum coolers in food preservation. ↩

-

Learn about evaporative cooling techniques and their efficiency in various industries. ↩

-

Exploring the workings of a Refrigeration System can provide insights into effective cooling technologies. ↩

-

Understanding the Vacuum Pump’s function can enhance your knowledge of efficient cooling systems. ↩

-

Explore the advantages of vacuum cooling to enhance your food processing efficiency and quality. ↩

-

Explore this link to understand how engineering excellence impacts product reliability and efficiency. ↩

-

Discover insights on user experience and its crucial role in enhancing operational efficiency and satisfaction. ↩

Mila

You May Also Like

How Do Lettuce Vacuum Coolers Actually Work: A Complete Technical Explanation?

You spend months growing the perfect lettuce, but field heat can turn your crisp harvest into wilted waste in hours.

What is the Best Lettuce Vacuum Cooler for Your Farm in 2026?

Are you watching your fresh lettuce wilt before it even reaches the supermarket shelves? You work hard to harvest, but

How Do You Handle the Peak Season Vegetable Rush?

The harvest season is here. Your fields are full of beautiful produce, but now you face the biggest challenge: a

Can You Vacuum Cool Vegetables After They Are Packaged?

You’ve just packed bags of beautiful, fresh-cut salad mix. But the product is still warm from processing and washing. This

How Do You Perfectly Cool Leafy Greens Without Damaging Them?

You’ve invested in a vacuum cooler to protect your leafy greens, but the results aren’t always perfect. Sometimes the lettuce

Will Your Vegetables Work in a Vacuum Cooler?

You’ve harvested a perfect crop, but the clock is ticking. Every minute of field heat is degrading the quality, reducing

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Are You Gambling with Your Export-Quality Vegetables?

You’ve grown a perfect crop, meeting every standard for size, color, and taste. Now comes the biggest challenge: shipping it

Is Your Cold Chain Broken Before It Even Starts?

Your company has invested millions in refrigerated trucks, state-of-the-art warehouses, and sophisticated inventory systems—a world-class cold chain. Yet, you’re still

Is Vacuum Cooling a Non-Negotiable Tool for Organic Growers?

As an organic producer, you’ve committed to a higher standard. Your customers pay a premium for vegetables that are not