Who Are the Top Vacuum Cooler Manufacturers for Vegetables?

Searching for a list of top vacuum cooler brands can be overwhelming. You’re not just buying a machine; you’re investing in your farm’s future, and you need a partner you can trust.

The top vacuum cooler manufacturers are not just names on a list, but companies defined by their use of high-quality components, proven performance, comprehensive after-sales support, and designs that prioritize low operational costs. This combination ensures long-term value and reliability for your farm’s operations.

As someone who works with farmers every day, I know the anxiety that comes with a major equipment purchase. Instead of just giving you a list of names, I think it’s more helpful to show you what to look for. Let’s break down the essential qualities that separate a truly top-tier manufacturer from the rest. These are the benchmarks you should use to measure any company you consider.

What components define a top-tier manufacturer?

You’ve heard horror stories about equipment failing during peak season. A machine is only as strong as its weakest part, and a cheap component can lead to a catastrophic breakdown and lost revenue.

A top manufacturer never compromises on core components. They build their systems using world-renowned brands like Bitzer for compressors and Leybold for vacuum pumps to ensure maximum reliability and a long service life.

The Foundation of Reliability

When you look inside a machine, the brand names on the parts tell you a story about the manufacturer’s philosophy. We believe that building a durable machine starts with choosing the best components from the very beginning. It’s a non-negotiable part of our process. The heart of the cooling system, the compressor, comes from Bitzer1 in Germany, a brand synonymous with performance and endurance. The vacuum system relies on a Leybold pump, another pillar of German engineering known for its powerful and consistent operation.

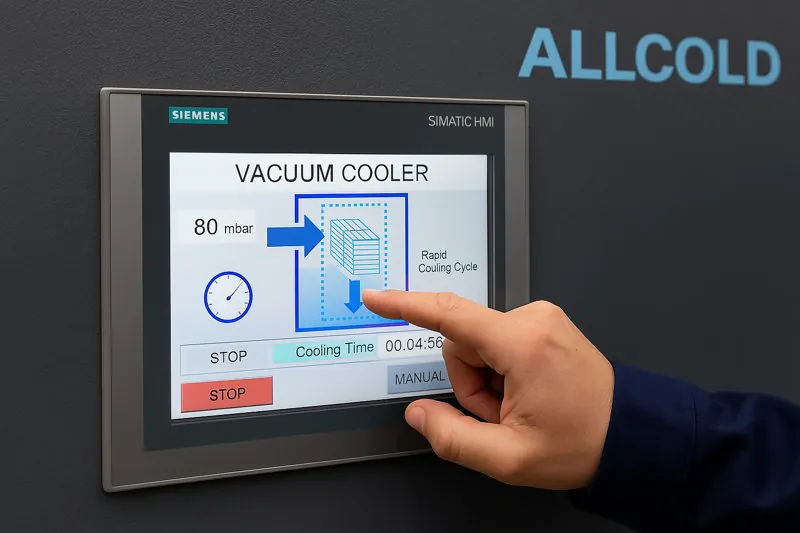

This commitment to quality extends throughout the entire electrical system. We use Siemens2 for touch screens and control systems because they offer intuitive and flawless operation. The contactors and safety relays are from Schneider, another industry leader. While using these premium parts increases the upfront cost slightly, it dramatically reduces the total cost of ownership. It’s an investment in preventing downtime, minimizing repair bills, and giving you peace of mind that your machine will work when you need it most. Any manufacturer you consider a "top" choice should be transparent about their component list.

| Component | Industry-Leading Brand We Use | Why It Matters for a Top-Tier Machine |

|---|---|---|

| Compressor | Bitzer (Germany) | Provides unmatched reliability and cooling efficiency. |

| Vacuum Pump | Leybold (Germany) | Ensures fast, effective, and consistent cooling cycles. |

| Control System | Siemens (Germany) | Offers stable, user-friendly, and precise operation. |

| Electricals | Schneider (Germany) | Guarantees safe and dependable power management. |

How does performance and efficiency separate the best brands?

Your cooling process can be a major bottleneck, limiting daily output. A slow machine costs you money, while an inefficient one drives up your electricity bills, eating into your profits.

Leading manufacturers deliver both speed and efficiency. Their machines achieve rapid cooling cycles, often around 15-25 minutes, and include smart features like automatic shutdown to save electricity when idle.

More Than Just Cooling

Performance in a vacuum cooler has two dimensions: speed and intelligence. Speed is about throughput. The ability to cool produce from field temperature down to 3°C in around 15 to 25 minutes completely changes your operational capacity. It means you can process more pallets per day, meet tighter deadlines, and take on larger clients. We achieve this with a powerful combination of a robust vacuum pump and a high-capacity refrigeration system. The entire cycle runs automatically; the operator simply uses the touch screen control to start the process.

But speed is worthless if it’s not efficient. A top-tier machine must also be smart about energy consumption. We design our systems with high-efficiency evaporators3 and air-cooled condensers specifically to minimize the energy draw of the compressor. Furthermore, we recognized that there are often delays between loads. Our machines address this with an automatic shutdown feature4; if the cooler is left idle for a period, it powers down to save electricity. The next cycle starts with a simple press of the start button. This combination of raw speed and smart efficiency is a hallmark of a leading manufacturer.

Is after-sales support a mark of a leading company?

A great machine is only part of the equation. When you have a problem during a critical harvest, being unable to get expert help immediately can be devastating for your business.

*Absolutely. A top manufacturer stands behind their product with a comprehensive guarantee and accessible, expert support. This includes a 12-month guarantee and 724 hours phone assistance for technical issues.**

A Partnership, Not Just a Purchase

The relationship with your equipment manufacturer shouldn’t end once the machine is delivered. A truly great company acts as a long-term partner, committed to your success. We formalize this commitment in two critical ways. First, every ALLCOLD system comes with a 12-month guarantee5 that starts from the date of installation. This protects your initial investment and gives you confidence as you integrate the new equipment into your workflow.

Second, and perhaps more importantly, we provide ongoing, accessible support. Problems don’t keep business hours. That’s why we offer 7*24 hours phone assistance6 for technical support. If you encounter an issue, you are encouraged to send a detailed description and pictures to our engineering team. They will check the information, form a diagnosis, and guide you toward a solution immediately. This level of responsiveness is a key differentiator. It minimizes downtime, protects your product, and ensures your operation keeps running smoothly. When you evaluate manufacturers, ask them to detail their failure claim procedures; it will tell you a lot about their commitment to their customers.

Why is a focus on low maintenance a key quality factor?

Complex and frequent maintenance is a hidden cost. It requires skilled labor, causes downtime, and adds unpredictability to your operational budget, draining resources that could be used elsewhere.

A top-tier manufacturer designs equipment for easy and infrequent maintenance. This includes simple monthly checks your own staff can perform and long intervals between major services, like changing compressor oil only every 2 years.

Designed for the Real World

A vacuum cooler should be a workhorse, not a constant source of maintenance headaches. A top manufacturer understands this and engineers their machines for reliability and straightforward upkeep. The goal is to maximize uptime and keep your operational costs predictable. We design our maintenance schedule to be as non-intrusive as possible. For example, a key routine check is simply looking at the vacuum pump oil7 once a month to see if it has emulsified (looks milky). This is a simple visual task that anyone on your team can do in minutes.

More significant tasks are intentionally infrequent. The lubrication oil for the high-performance Bitzer compressor8 only needs to be changed by a professional every two years. Other tasks include a general hygiene maintenance cleaning every two seasons to ensure optimal performance and food safety. This practical, real-world approach to maintenance means you spend less time and money servicing your equipment and more time using it to generate revenue. It’s a critical, though often overlooked, quality of a leading manufacturer.

| Maintenance Task | Recommended Frequency | Impact on Operations |

|---|---|---|

| Check Vacuum Pump Oil | Monthly | Simple, visual check by your staff. Minimal downtime. |

| Change Compressor Oil | Every 2 years | Long service interval reduces major service costs. |

| Hygiene Maintenance | Every two seasons | Ensures food safety and long-term performance. |

Conclusion

The best manufacturer is one that delivers quality, performance, and support. By focusing on these key criteria—premium components, efficiency, robust support, and low maintenance—you can find a partner that delivers real, long-term value.

-

Explore this link to understand why Bitzer is synonymous with performance and endurance in cooling technology. ↩

-

Discover how Siemens’ intuitive control systems contribute to stable and precise operations in industrial applications. ↩

-

Explore this link to understand how high-efficiency evaporators can enhance energy savings and performance in cooling systems. ↩

-

Learn about the benefits of automatic shutdown features in cooling systems to improve energy efficiency and reduce costs. ↩

-

Understanding the significance of a 12-month guarantee can help you make informed decisions about your equipment investments. ↩

-

Exploring the benefits of 7*24 hours phone assistance can reveal how crucial timely support is for your business operations. ↩

-

Understanding the significance of vacuum pump oil checks can enhance equipment reliability and reduce maintenance costs. ↩

-

Exploring Bitzer compressor maintenance can help ensure optimal performance and longevity of your cooling systems. ↩

Mila

You May Also Like

How Does Vacuum Cooling Forge the Strongest Link in Your Vegetable Cold Chain?

You work tirelessly to grow perfect, healthy vegetables. Yet, you know that from the moment of harvest, an invisible clock

Small-Scale vs. Large-Scale Vacuum Cooler: How Do You Choose the Right Fit?

You’re convinced that vacuum cooling is the key to elevating your product quality, but now you face a critical decision.

How Can You Master Vacuum Cooling for Leafy Greens to Maximize Quality and Profit?

You grow beautiful, vibrant leafy greens, but you know the invisible enemy is time. From the moment of harvest, the

Which Vegetables Benefit Most from Vacuum Cooling Technology?

You see the promise of rapid cooling, extended shelf life, and superior quality, but you’re unsure if this technology is

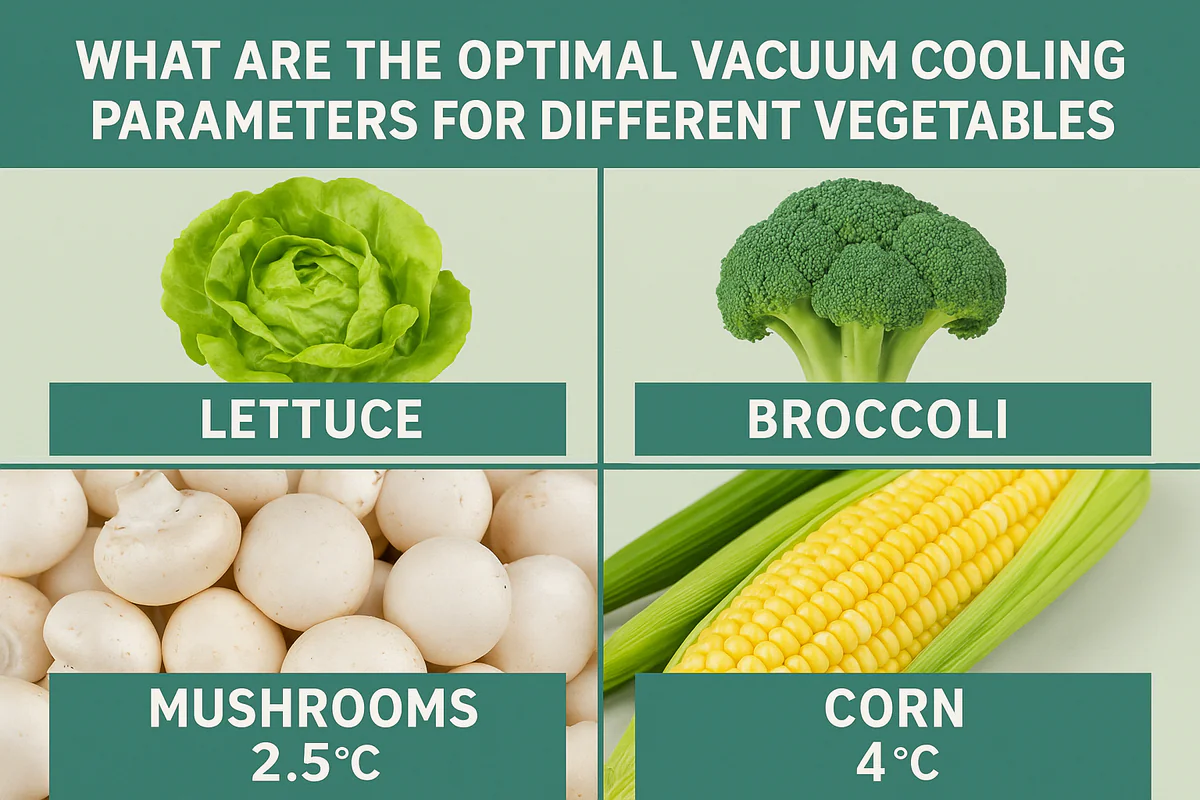

What Are the Optimal Vacuum Cooling Parameters for Different Vegetables?

You’ve harvested beautiful produce, from crisp lettuce to delicate mushrooms. But using a "one-size-fits-all" setting on your vacuum cooler feels

How Can You Reduce the Energy Costs of Your Vacuum Cooler?

Your vacuum cooler is a powerhouse of productivity, but your monthly electricity bill is climbing. You’re starting to wonder if

How Can You Keep Your Vacuum Cooler Running Flawlessly?

Your vacuum cooler is a vital asset, but you’re worried about unexpected breakdowns during peak season. Neglecting maintenance feels like

Cost Comparison: Is Vacuum Cooling More Cost-Effective Than Hydrocooling?

Choosing between cooling technologies feels like a high-stakes gamble. You need to lower your operational costs, but the wrong decision

ROI Analysis: Is a Vacuum Cooler Worth the Investment for Your Farm?

You see the high upfront cost of a vacuum cooler and hesitate. But slow cooling methods and post-harvest losses are

What Defines the Best Commercial Vacuum Cooler for Your Vegetable Processing Facility?

Choosing the right equipment is a huge decision. A slow or unreliable cooler can ruin your harvest’s quality, hurt your