What Innovations Truly Changed the Vacuum Cooling Game?

You see a modern, stainless steel vacuum cooler operating flawlessly and it looks simple. But behind that easy operation are decades of engineering and a few game-changing inventions that completely transformed the technology from a niche science into an industrial powerhouse.

The most important innovations in vacuum cooling history are the development of oil-free pumps, the integration of smart PLC automation, the creation of high-efficiency water catchers for hot foods, and the shift to flexible, modular machine designs.

These weren’t just small improvements; they were fundamental breakthroughs. Each one solved a major problem that was holding the technology back. For my clients, whether it’s a hygiene-focused manager like Sophia or a maintenance-conscious owner like Carlos, these innovations are the reason they can trust our machines today. Let’s look at what really moved the needle.

How did we get rid of the dirtiest part of the machine?

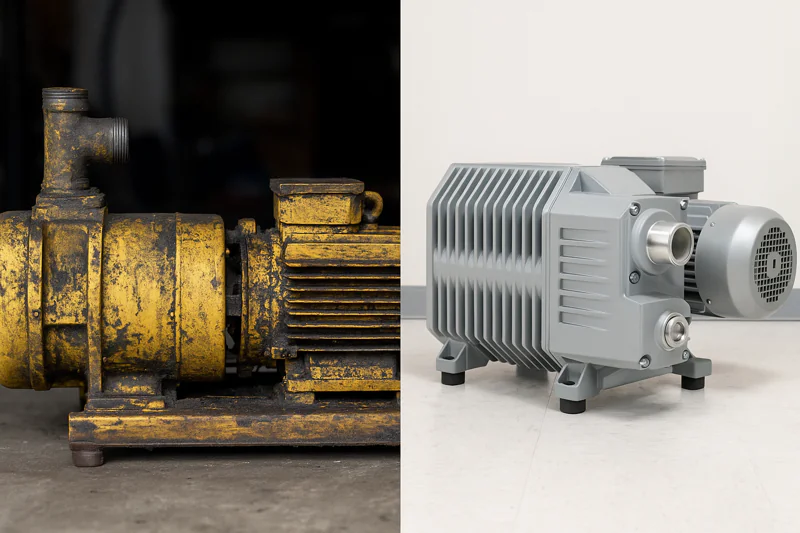

For years, the heart of any vacuum system was the oil-sealed rotary vane pump. It was a workhorse, but a messy one. It required constant oil changes, produced a fine oil mist, and always carried the risk of oil contamination in the vacuum chamber. This was a huge headache for operators.

The invention of the oil-free, or dry screw, vacuum pump was a monumental leap forward. It eliminated the risk of oil contamination, drastically reduced maintenance, and provided cleaner, more stable performance, which is essential for modern food applications.

Oil-Sealed vs. Oil-Free: A Clear Winner

This innovation completely changed the maintenance and hygiene conversation. I remember dealing with clients’ complaints about the old oil pumps. They were noisy, they smelled, and the cost of buying and disposing of specialized vacuum oil added up. For a food processing client like Sophia, who lives by HACCP rules, the tiny possibility of oil vapor getting into her product was a non-starter. The dry screw pump solved all these problems at once. Inside the pump, two precisely engineered screws spin without touching each other, moving the air out of the chamber without needing any oil as a sealant. The direct benefits are massive. First, there is zero risk of oil contamination1, which is a critical point during any food safety audit. Secondly, maintenance drops from frequent, messy oil changes to a simple annual gearbox oil check, reducing downtime and labor costs. The working environment also improves dramatically; the continuous oil mist from older pumps, which could settle on floors and other equipment, is completely gone. This move to oil-free technology2 was a crucial step in making vacuum coolers truly clean, low-maintenance, and perfect for the stringent demands of the modern food industry.

| Feature | Old Oil-Sealed Pump | Modern Oil-Free Pump |

|---|---|---|

| Food Safety | Risk of oil contamination | Zero risk of contamination |

| Maintenance | Frequent, messy oil changes | Minimal (e.g., annual gear oil) |

| Running Cost | Constant need for oil & filters | No oil consumption |

| Environmental | Waste oil disposal issues | Clean operation, no waste oil |

| Performance | Degrades as oil gets dirty | Stable and consistent |

What made the machines smart enough to run themselves?

Imagine driving a car with no dashboard, just a few levers and your best guess. That’s what operating early vacuum coolers was like. It relied entirely on the skill of the operator to watch analog gauges and manually control valves. This led to inconsistent cooling and was highly prone to human error.

The innovation that brought intelligence and consistency was the integration of a Programmable Logic Controller (PLC) with a Human-Machine Interface (HMI) touch screen. This automated the entire process, making perfect results repeatable by any operator.

From Manual Guesswork to Digital Precision

This was the shift from brawn to brains. Instead of a complex panel of wires and relays, we now use a Siemens PLC3 as the machine’s central nervous system. It’s a rugged industrial computer that we can program with perfect "cooling recipes4." For example, a bakery manager like Sophia can have a specific program for her croissants that cools them gently, and a different one for dense bread that requires a more aggressive cycle. The operator simply selects the program on the visual touch screen and presses start. The PLC handles the rest, perfectly controlling the vacuum pumps and refrigeration system to follow the ideal cooling curve every time. This automation is critical for buyers like Norman who need documented proof of quality. The system can log data from every cycle, providing a complete record of time, temperature, and pressure. Crucially, it also makes support incredibly efficient. We build in troubleshooting guides and can even access the system remotely for diagnostics. This means I can help a client in Mexico solve a problem from my office in China, saving them from costly downtime. This leap to smart automation made the machines reliable, user-friendly, and accountable.

How did we master cooling steamy, hot foods without wrecking the pump?

Vacuum cooling works by boiling water at a low temperature. Now, imagine doing that with freshly cooked rice or bread straight from a 95°C oven. This process releases a truly massive amount of hot steam. Early vacuum systems simply couldn’t handle it; the water vapor would overwhelm the vacuum pump, causing damage and stopping the cooling process.

The crucial innovation for cooked foods was the development of an oversized, high-efficiency evaporator, which we call a "water catcher." This super-cold refrigeration coil is designed to instantly trap all the water vapor as ice, protecting the pump.

The Power of the Ice Trap

This was a pure physics problem that required a brute-force engineering solution. A vacuum pump is designed to move air, not a flood of water vapor. To solve this, we innovated the water catcher5. It’s a specialized heat exchanger inside the vacuum chamber, packed with a huge surface area of copper pipes and aluminum fins. Its size isn’t random; we calculate the required surface area based on the client’s product, its initial temperature, and its water content. Before the main vacuum stage, the refrigeration system chills these coils down to an extremely low temperature, often -30°C. As soon as the vacuum starts and the hot food releases steam, that vapor hits the frigid coils and instantly freezes solid. It never gets close to the vacuum pump. After the cycle, the machine runs an automatic defrost cycle, warming the coils to melt the ice, which is then drained away. This innovation is the single most important reason we can now cool cooked foods6. It’s the key technology that allows a central kitchen manager to cool products safely through the bacterial "danger zone" in minutes, a task that is impossible without this specialized component.

| System Type | Without Water Catcher | With High-Efficiency Water Catcher |

|---|---|---|

| Pump Safety | High risk of vapor damage | Pump is fully protected |

| Cooling Speed | Very Slow (stalls at high pressure) | Very Fast (reaches low pressure quickly) |

| Application | Only suitable for low-moisture products | Essential for hot, steamy, cooked food |

| Final Temperature | Fails to reach target temperature | Easily reaches target (e.g., <10°C) |

How did machines go from "one size fits all" to a "perfect fit"?

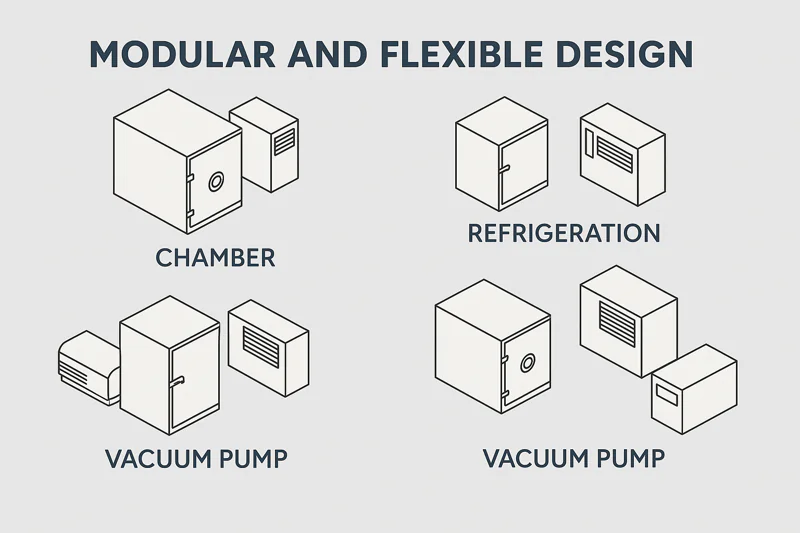

In the early days, a vacuum cooler was a single, massive, welded unit. You bought the standard model, and it was your problem to find space for it in your facility. If the doors weren’t big enough, you had to knock down a wall. This rigid, monolithic design was hugely inefficient and frustrating for customers.

The innovation of modular design fundamentally changed how machines are built and installed. By creating separate, pre-engineered modules for the chamber, refrigeration, and vacuum systems, we can now create custom-fit solutions for any space.

Adaptable by Design: Solving Space and Logistics Puzzles

This was an innovation in manufacturing philosophy. Instead of one giant, inflexible machine, we started designing the core components as independent skids. This means we have the vacuum chamber module, the refrigeration module, and the vacuum pump module as separate, pre-engineered blocks. This is a huge advantage for my clients. For a professional buyer like Norman sourcing for different facilities, this is a dream. The modules are designed to fit perfectly into standard shipping containers, drastically reducing international freight costs7 and complexity. On-site, we can arrange them to solve real-world facility challenges. We can create an L-shape to fit a corner, or even place the noisy refrigeration skid outside the building to improve the work environment. It also radically simplifies installation, as we can bring the separate, smaller modules through standard doorways and assemble them in place. This approach also allows for future upgrades. A business can start with a smaller refrigeration module and easily swap it for a larger one as their production grows, without replacing the entire vacuum cooler. This move to modularity8 was the final step in making the technology truly adaptable.

Conclusion

These four innovations—oil-free pumps, smart controls, high-efficiency water catchers, and modular design—are the pillars of modern vacuum cooling. They transformed a cumbersome technology into the clean, intelligent, and flexible solution that businesses rely on today.

-

Understanding oil contamination risks is vital for food safety, ensuring compliance with health regulations. ↩

-

Exploring oil-free technology can reveal innovative solutions that enhance efficiency and hygiene in food processing. ↩

-

Explore this link to understand the capabilities of Siemens PLCs and how they revolutionize industrial automation. ↩

-

Learn about cooling recipes and their importance in achieving consistent quality in baked goods. ↩

-

Explore this link to understand how a water catcher enhances vacuum systems and improves food safety. ↩

-

Discover effective methods for cooling cooked foods to ensure safety and quality in food preparation. ↩

-

This link will offer strategies and tips for minimizing international freight costs, crucial for businesses looking to optimize logistics. ↩

-

Exploring this resource will provide insights into how modularity enhances flexibility and efficiency in manufacturing processes. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf