Batch or Continuous: Which Vacuum Cooling System is Right For You?

Choosing a major piece of equipment can be daunting. You know you need vacuum cooling, but then you see terms like "batch" and "continuous." This decision can completely change your production flow and efficiency.

Batch systems cool products in separate, distinct loads, offering flexibility. Continuous systems cool products on a moving conveyor, offering maximum throughput for single-product lines. The right choice depends entirely on your production volume and product variety.

This isn’t just a technical detail; it’s a strategic business decision. For a farm owner like Carlos with different crops, or a central kitchen manager like Sophia with various menu items, flexibility is key. But for a massive food factory, non-stop production is the only goal. Understanding the core difference is the first step to choosing the right system for your business.

What is a batch vacuum cooling system and who needs one?

Imagine your factory handles different products every day. Croissants in the morning, then cooked rice for lunch service, then steamed vegetables. A single, inflexible machine would be a disaster. You need a system that can adapt.

A batch system is like a high-tech oven, but for cooling. You load a trolley or pallet of product, seal the door, run a specific cooling cycle, and then unload it. It’s perfect for businesses that need flexibility.

The Flexibility of One Batch at a Time

The batch vacuum cooler1 is the most common type of system for a reason: it’s incredibly versatile. The process is simple and mimics other familiar processes in a food production environment. You load your product, select the correct pre-programmed "recipe" on the PLC touch screen, and press start. The machine does the rest. Once the cycle finishes in a few minutes, you unload the cooled product and can immediately load the next, completely different batch. This adaptability is essential for someone like Sophia, who manages a central kitchen. Her production schedule is diverse. A batch system allows her to cool pans of rice, then switch to cooling cooked chicken portions just by selecting a different program. For a farmer like Carlos, he can cool a full pallet of freshly harvested lettuce, and in the next cycle, cool a batch of more delicate broccoli with a gentler cooling curve. This system decouples the cooling process from the rest of the production line, providing a buffer and preventing bottlenecks if one part of the line stops. While it requires labor for loading and unloading each cycle, its lower initial cost and ability to handle nearly any product make it the go-to choice for most small to medium-sized enterprises.

| Aspect | Description | Best Suited For |

|---|---|---|

| Process Flow | Load -> Seal -> Cool -> Unload | Production with varied products or schedules |

| Flexibility | Extremely high; can change product each cycle | Bakeries, central kitchens, mixed-produce farms |

| Labor | Requires manual loading and unloading per cycle | Facilities where labor is available for this task |

| Footprint | Relatively compact, self-contained unit | Spaces that cannot fit a long, continuous line |

What about continuous vacuum cooling systems—how do they work?

Now, let’s consider a completely different scale. Think of a massive factory that makes only one thing, like packaged salads, and it runs 24/7. Stopping to load and unload individual trolleys would be impossibly slow and inefficient. They need a system that never stops.

A continuous system is a long tunnel that a conveyor belt runs through. Your product enters one end, gets cooled as it travels through the vacuum, and comes out the other side, ready for packaging, with no breaks.

The Power of Non-Stop Production

Continuous vacuum coolers2 are the titans of the industry. They are designed for one purpose: maximum, uninterrupted throughput. These systems are highly complex pieces of engineering. The product moves on a conveyor belt through a long chamber, or sometimes a series of interconnected chambers. Special airlocks at the entrance and exit allow the product to enter and leave while maintaining the deep vacuum inside the main tunnel. This is a true inline process, meaning it integrates seamlessly into a fully automated production line3. For example, a bag of salad mix can come directly from the washing and bagging machine, enter the continuous cooler, and exit at the perfect temperature to go straight into a refrigerated truck. The main advantage is the incredibly low labor cost per unit; the system essentially runs itself once it’s set up. However, this power comes with trade-offs. The initial investment is enormous compared to a batch system. And they are extremely inflexible. A continuous cooler is custom-engineered for a specific product’s size, weight, and cooling characteristics. You cannot use it to cool anything else. This makes it suitable only for the largest food manufacturers with a dedicated, high-volume, single-product line.

| Feature | Batch System | Continuous System |

|---|---|---|

| Throughput | Moderate, limited by cycle/labor time | Extremely high and constant |

| Integration | Stand-alone unit | Fully integrated into an automated line |

| Product Handling | Single, static load (e.g., pallet) | Moving on a conveyor belt |

| Flexibility | High (any product) | Very Low (one specific product) |

How do you compare the costs, from initial price to daily operation?

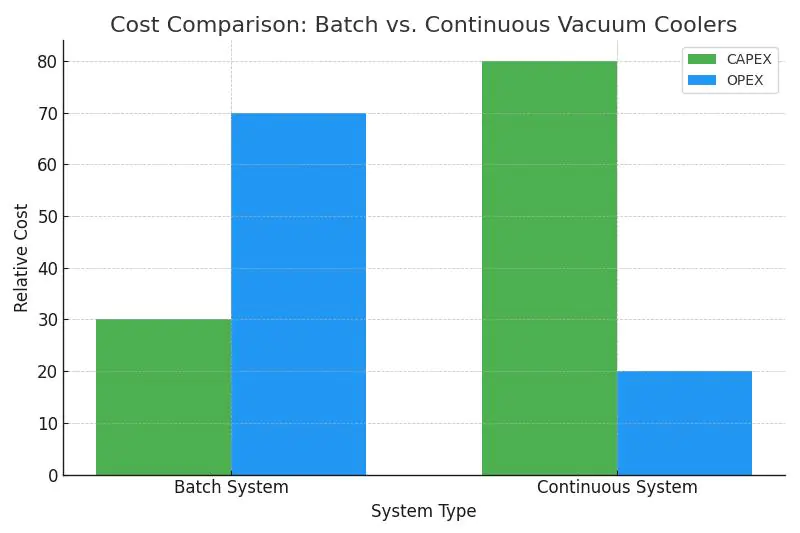

When a professional buyer like Norman is evaluating equipment, the sticker price is only the beginning of the story. He needs to understand the total cost of ownership (TCO) because a machine that’s cheap to buy might be expensive to run.

Batch systems have a much lower initial purchase price (CAPEX). Continuous systems have a very high initial cost but can offer a lower operational cost (OPEX) per unit, but only at extremely high, continuous production volumes.

Unpacking the True Cost of Ownership

Let’s break down the lifetime costs. The Capital Expenditure (CAPEX)4, or the initial purchase price, is the most obvious difference. A standard batch system is a relatively straightforward piece of equipment to manufacture. A continuous system is a massive, custom-engineered project involving complex airlocks and conveyor systems, making its initial cost several times higher. The Operational Expenditure (OPEX)5 is where the calculation gets more complex. For labor, a batch system requires at least one person to load and unload trolleys. A continuous system, once running, requires almost no direct labor for product handling. For energy, a continuous system running at full capacity can be more efficient because it maintains a stable vacuum. A batch system cycles on and off, which can consume more energy per cycle, but it uses zero energy when it’s not running. This makes batch systems more efficient for non-continuous production schedules. Finally, maintenance on a batch system is simpler—fewer moving parts. A continuous system has conveyors, motors, and complex airlock seals that require more specialized maintenance. For most businesses, the math clearly favors a batch system; the enormous CAPEX of a continuous system can only be justified by massive, 24/7 production volumes where the labor savings eventually pay back the initial investment.

| Cost Factor | Batch System | Continuous System |

|---|---|---|

| Initial Price (CAPEX) | Low to Moderate | Very High |

| Labor Cost (OPEX) | Higher per unit (manual handling) | Very low per unit (automated) |

| Energy Cost (OPEX) | Efficient for intermittent work | More efficient only at full capacity |

| Maintenance Cost (OPEX) | Lower (simpler mechanics) | Higher (more moving parts, complex) |

How does the system choice impact product handling and quality?

You can have the most efficient machine in the world, but if it damages your product, it’s worthless. The way a system handles your food is just as important as how fast it cools it. The choice between batch and continuous has a major impact here.

Batch systems are gentler on products as they are cooled while stationary on a pallet or trolley. Continuous systems involve movement on a conveyor, which requires a uniform product and carries a higher risk of damaging delicate items.

From Machine to Shelf: The Impact on Your Product

The physical handling within each system is fundamentally different. In a batch system, products are carefully arranged on trolleys or pallets before being loaded. During the entire vacuum cooling process, the product remains perfectly still. This is ideal for delicate items like leafy greens, soft baked goods, or carefully plated ready-to-eat meals. You have complete control over how the product is placed, ensuring it doesn’t get bruised, broken, or dislodged. This guarantees the highest possible quality and visual appeal. A continuous system, by contrast, requires the product to travel on a conveyor belt. While these are designed to be smooth, there is inherent movement, vibration, and the potential for friction or tumbling, especially at the entry and exit points of the airlocks. This means continuous system6s are best suited for robust, uniform products, such as granular products like rice, durable vegetables, or securely packaged items. They are not suitable for delicate or irregularly shaped products. This difference is critical. For Sophia’s kitchen, where presentation of a ready-meal is part of the product’s value, the gentle, static nature of a batch system7 is a requirement, not just a preference. The choice of system directly influences the final quality that your customer receives.

Conclusion

Choose a batch system for flexibility with varied products. Choose a continuous system for massive, non-stop throughput of a single product. Understand your production needs first.

-

Explore this link to understand the mechanics and benefits of batch vacuum coolers in food production. ↩

-

Explore this link to understand how Continuous vacuum coolers enhance efficiency and reduce labor costs in food manufacturing. ↩

-

Discover insights on automated production lines and their role in maximizing throughput and minimizing costs. ↩

-

Understanding CAPEX is crucial for making informed investment decisions in equipment and systems. ↩

-

Exploring OPEX helps businesses manage ongoing costs effectively and optimize their financial strategies. ↩

-

Learn about continuous systems and their efficiency in handling robust products, which can optimize your production process. ↩

-

Explore this link to understand how batch systems enhance product quality and presentation, crucial for delicate items. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf