Direct vs. Indirect: Which Vacuum Cooling Method is Right for You?

You’ve decided on vacuum cooling, but a hidden technical choice emerges: direct or indirect cooling. This single design decision can make or break your product quality, cooling speed, and even your machine’s lifespan.

Direct cooling systems place the evaporator coils inside the vacuum chamber for the fastest cooling. Indirect systems use an external heat exchanger, offering maximum hygiene separation. For most food applications, direct cooling’s speed is the winning factor.

This seems like a minor engineering detail, but it impacts everything my clients care about. For a farm owner like Carlos, it’s about speed to preserve freshness. For a central kitchen manager like Sophia, it’s about balancing speed with hygiene. Let’s dig into why this one choice matters so much.

How does direct cooling achieve such incredible speed?

When you need to stop bacterial growth and lock in freshness, every second counts. Traditional cooling methods are simply too slow. You need a system that attacks the heat with maximum force and efficiency.

Direct cooling is incredibly fast because the super-cold evaporator coils (the "water catcher") are inside the chamber. Steam from the product instantly freezes onto these coils, causing a rapid pressure drop and accelerating the entire cooling process.

The Direct Advantage: Speed and Power

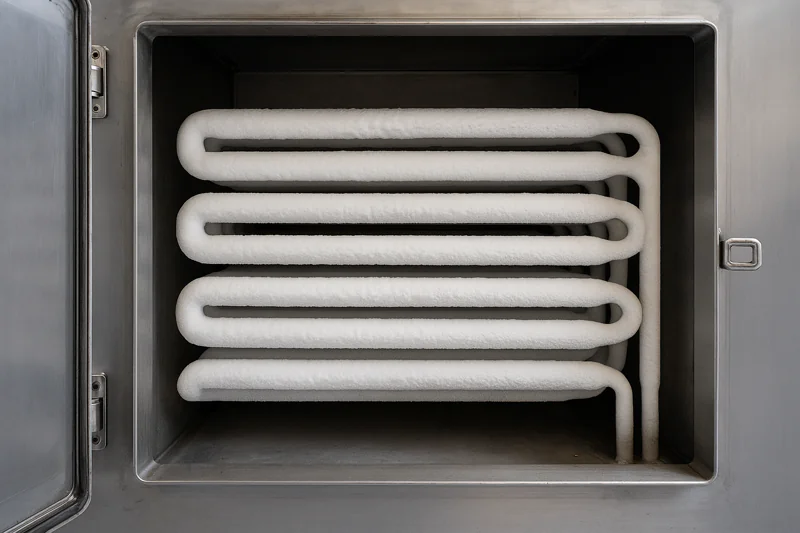

The core principle of vacuum cooling1 is removing heat by boiling water off the product. This creates a huge amount of water vapor (steam). The enemy of the vacuum pump is this very steam; the pump is designed to move air, not vapor. In a direct system, we place the solution right inside the chamber. This solution is the evaporator, a set of coils with a massive surface area that we chill to as low as -30°C (-22°F) before the cycle begins. As soon as the vacuum pump starts and the product releases steam, that vapor hits the ice-cold coils and is instantly trapped as frost. It never reaches the pump. This accomplishes two things at once: it protects the vacuum pump from damage, and more importantly, it rapidly removes vapor from the chamber. By removing the vapor, the pressure inside drops dramatically, which lowers the boiling point of the water in your product, making it cool even faster. This is the only practical way to handle the immense steam released by hot cooked foods, a problem Sophia faces daily. For producers of fresh vegetables like Carlos, this speed means getting lettuce from 30°C (86°F) down to 2°C (36°F) in under 25 minutes, adding days or even weeks to its shelf life.

| Feature | Direct Cooling System | Justification |

|---|---|---|

| Cooling Speed2 | Fastest possible | Vapor is trapped instantly at the source. |

| Pump Protection | Excellent | The coils act as a shield for the pump. |

| Product Suitability | All food (fresh & cooked) | The only method that can handle high steam loads. |

| Efficiency | Very High | Direct heat exchange is the most efficient method. |

What are the hygiene challenges of direct cooling?

Having the cooling mechanism inside the food chamber is great for speed, but it naturally raises questions about cleaning. If not designed or maintained properly, it can be a weak point in your sanitation plan.

The main challenge of direct systems is cleaning the evaporator’s densely packed fins, which can trap food particles. This requires robust cleaning protocols, like pressure washing or automated Clean-In-Place (CIP) systems, to ensure total hygiene.

Managing Hygiene in Direct Systems

Let’s be direct about this challenge. The evaporator is essentially a radiator, with hundreds of thin aluminum fins designed for maximum heat exchange surface area. When cooling products like leafy greens or flour-dusted bread, small particles can become lodged between these fins. For a quality-conscious client like Sophia, who operates under strict HACCP rules3, preventing any potential for bacterial growth is non-negotiable. This is where good engineering and clear procedures come in. Firstly, we design our systems for cleanability. This means using a specific fin spacing that is wide enough to allow for effective cleaning, not just maximum surface area. We also ensure the chamber floor and coil placement allow for complete drainage. The standard cleaning method is manual washing with a high-pressure water jet after a day’s production, a process I personally train all my clients’ teams on. For facilities requiring a higher level of automation and assurance, we offer fully integrated Clean-In-Place (CIP) systems4. These are networks of built-in nozzles that automatically spray the coils with water and sanitizer at programmed intervals, guaranteeing a perfect clean every time. This is a feature a professional buyer like Norman looks for as proof of a high-quality, auditable system.

| Challenge | Solution |

|---|---|

| Food Debris Trapping | Smart Design: Wider fin spacing, better drainage. |

| Cleaning Labor | Standardized pressure washing protocols; Optional automated CIP. |

| Hygiene Verification | Easy visual inspection; Data logging of CIP cycles. |

Why would anyone choose a slower, indirect cooling system?

If direct cooling is the champion of speed and efficiency for food, it begs the question: why does the indirect method even exist? Why add extra steps, complexity, and cost to a process if it makes it slower?

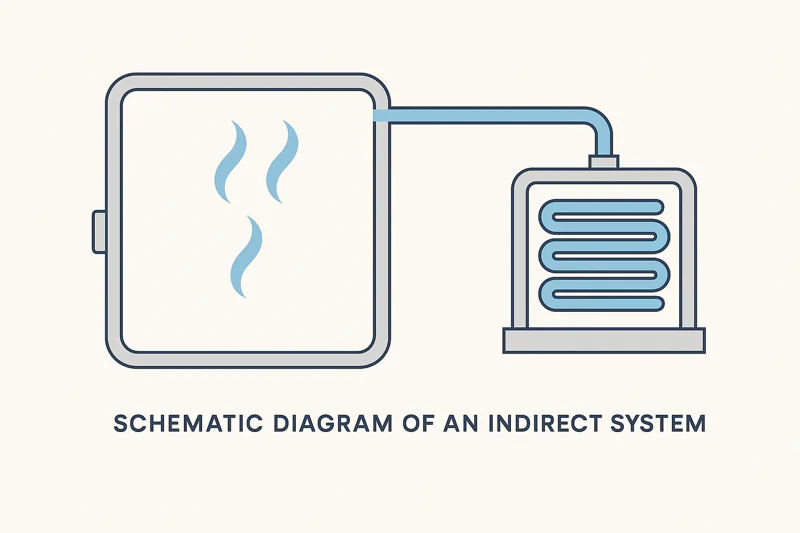

Indirect cooling is chosen for niche applications where absolute separation between the product and the refrigeration system is a regulatory must. It guarantees a perfectly empty, sterile chamber, a requirement in the pharmaceutical industry.

The Case for Indirect Cooling: Absolute Separation

In an indirect system, the vacuum chamber is simply a clean, empty, stainless steel box. There are no coils or fins inside, which makes it incredibly easy to clean and sterilize. This is its single greatest advantage. So how does it cool? The water vapor that boils off the product is sucked out of the chamber by the vacuum pump. However, before the vapor gets to the pump, it is routed through an external condenser unit. This condenser is typically a plate or shell-and-tube heat exchanger. In a separate, closed loop, a refrigeration unit chills a liquid (usually water or a glycol mix), which is then pumped through the external condenser. The hot vapor from the chamber hits the cold surfaces inside this external unit, condenses back into liquid water, and is drained away. Only the "dry" air continues to the vacuum pump. The primary reason for this complex setup is to eliminate any possibility of a refrigerant leak inside the food zone. While modern direct systems are extremely safe, in industries like pharmaceuticals, even a 0.001% risk is unacceptable. The trade-offs, however, are significant. The process is slower because the heat exchange is not happening right at the source. The system is also far more complex and expensive, with extra pumps, piping, and a large external condenser5, all of which add maintenance points.

| Aspect | Indirect Cooling System |

|---|---|

| Hygiene | Absolute physical separation of product and refrigerant. |

| Chamber Cleaning | Effortless; it’s a simple, empty vessel. |

| Complexity & Cost | Higher due to extra components (pumps, condenser). |

| Cooling Speed | Slower due to less efficient, indirect heat transfer. |

How do you choose between direct and indirect for your food?

Now that the technical differences are clear, we arrive at the final, practical question. For your lettuce, your bread, or your ready-to-eat meals, which system do you actually need to buy?

For over 99% of all food applications, direct cooling is the correct and superior choice. Its unmatched speed and efficiency are essential for food quality and safety. Indirect cooling is a specialized solution primarily for non-food industries.

The Final Decision Matrix for Food Applications

In all my years of experience, I have almost never recommended an indirect system to a food producer. The performance sacrifice is simply too great, and a well-designed direct system meets and exceeds all food safety standards. For my clients, the choice is clear. For Carlos and his fresh produce, speed is everything to maximize shelf life; direct cooling6 is the only logical choice. For Sophia and her cooked food, the massive steam load from hot rice or pasta can only be handled by the powerful "water catcher" in a direct system. An indirect system would be impractically large and slow. For a professional buyer like Norman, a direct system offers a better return on investment through higher throughput and lower capital cost, as long as we can demonstrate its effective and reliable CIP system7 for hygiene assurance. The fear of direct systems is a holdover from old, poorly designed machines. Modern direct vacuum coolers are built for hygiene and performance. Unless you are cooling sterile pharmaceutical vials, you need the speed and power of a direct cooling system.

| Product Type | Recommended System | Key Justification |

|---|---|---|

| Fresh Vegetables & Fruits | Direct | Maximum speed is critical for shelf life. |

| Bakery & Bread | Direct | Handles high moisture and is gentle on structure. |

| Cooked & Ready Meals | Direct | Only method to handle massive steam loads efficiently. |

| Pharmaceuticals | Indirect | Absolute separation is a regulatory requirement. |

Conclusion

The choice is simple. Direct cooling offers the speed and power that modern food production demands, with proven, reliable cleaning systems. Indirect cooling is a specialized tool for non-food industries with unique regulatory needs.

-

Understanding vacuum cooling can enhance your knowledge of efficient food preservation methods. ↩

-

Exploring cooling speed factors can help you optimize food storage and extend shelf life. ↩

-

Learn about HACCP rules to grasp their critical role in maintaining food safety and preventing contamination in food production. ↩

-

Explore this link to understand how CIP systems enhance hygiene and efficiency in food processing, ensuring compliance with safety standards. ↩

-

Learn about the role of external condensers in cooling systems, enhancing efficiency and safety in various applications. ↩

-

Explore this link to understand how direct cooling enhances food safety and shelf life, crucial for producers. ↩

-

Learn about the importance of CIP systems in maintaining hygiene standards, vital for food safety and quality. ↩

Mila

You May Also Like

How Do You Guarantee a Perfect Cooling Cycle Every Single Time?

You’ve invested in a state-of-the-art vacuum cooler, but its performance depends entirely on the people who use it every day.

Why Do Vacuum Cooler Energy Costs Vary So Much?

You’re calculating the return on investment for a new vacuum cooler, but there’s a huge unknown: the electricity bill. You

What Goes Into Designing a High-Quality Vacuum Cooler?

At first glance, a vacuum cooler seems simple: it is a steel box that makes vegetables cold. But this simplicity

What Are the Most Important Features in a Vacuum Cooler?

You’re comparing quotes from different suppliers, and the specification sheets all start to look the same. They all list a

Where Can You Find Reliable Vegetable Vacuum Cooler Suppliers?

You’ve made the decision to invest in a vacuum cooler, but now you face an even bigger challenge: finding a

How Much Does a Vegetable Vacuum Cooler Really Cost?

You know you need a vacuum cooler to improve your product quality, but the price is a huge question mark.

Industrial vs. Commercial Vacuum Coolers: Which Should You Choose?

Your business is growing, and you know that rapid post-harvest cooling is the key to quality and profit. But as

What's the Real Difference Between a High-Quality and a Low-Price Vacuum Cooler?

You are looking for a vacuum cooler, and you see a huge range of prices. One supplier quotes a price

How Do You Choose the Best Vegetable Vacuum Cooler in 2024?

Choosing a vacuum cooler is one of the biggest investments you’ll make in your farm or food business. The market

What Can You Learn from Farms That Mastered Vacuum Cooling?

You see the challenges in your own operation every day: the race against field heat, the constant worry about shelf